The Industrial Internet is an important engine for empowering industrial enterprises and promoting high-quality industrial development. The 2022 “Government Work Report” once again emphasized accelerating the development of the industrial internet. Based on the analysis of domestic and foreign industrial internet models, this paper innovatively proposes an industrial internet ecosystem model composed of a “three-dimensional, four flows, and six layers” spatial structure.

This paper will deeply analyze the operational mechanism of the industrial internet ecosystem model, namely the operational mechanisms of entity flow, resource flow, data intelligence flow, and dynamic value flow. Among them, the data intelligence flow demonstrates the value of data as a new type of production factor flowing through different levels and dimensions of the model, explaining the basic logic of improving the intelligence level of enterprise production systems and delivered products, while also clarifying the basic path of digital transformation.

1. Existing Industrial Internet Reference Models at Home and Abroad and Comparative Analysis

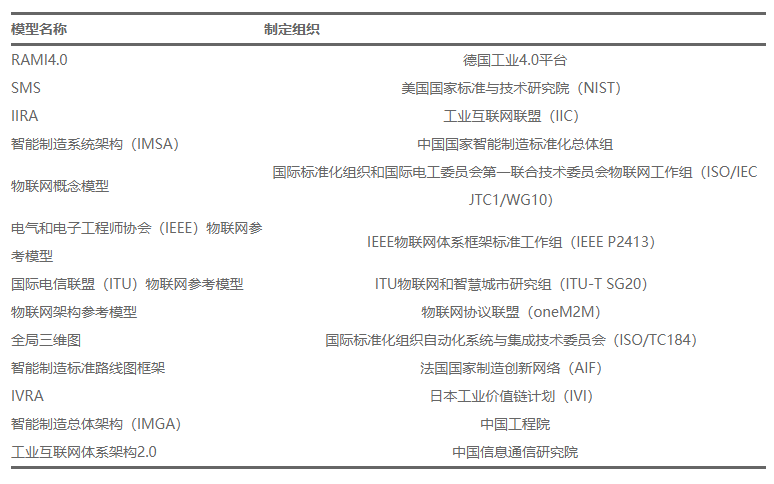

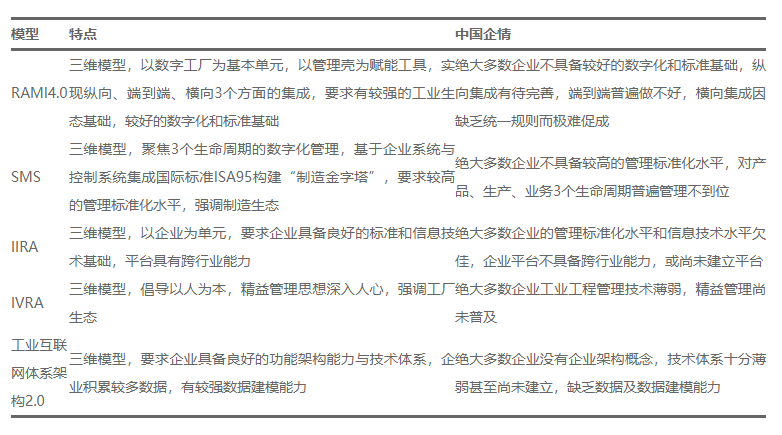

Due to different national conditions, development stages, and goals, the definitions and implementations of industrial internet models vary from country to country, depending on the industrial foundation conditions. The International Organization for Standardization classifies intelligent manufacturing and industrial internet as similar entities, usually comparing Germany’s Industry 4.0 Reference Architecture Model (RAMI4.0), the United States’ Smart Manufacturing Ecosystem (SMS), Industrial Internet Reference Architecture (IIRA), and Japan’s Industrial Value Chain Reference Architecture (IVRA) for research. There are 13 common industrial internet-related models at home and abroad (see Table 1).

Table 1 Overview of Industrial Internet Related Reference Models at Home and Abroad

Among the existing industrial internet models at home and abroad, the construction ideas and standard constraint technical paths of Germany, the United States, and Japan are particularly worth learning and referencing. Table 2 lists the comparative analysis of five typical industrial internet reference models.

Table 2 Comparison of Typical Industrial Internet Reference Models

(1) Germany’s RAMI4.0 is centered around digital factories, with a rigorous hierarchical management structure, starting from a strong industrial ecological foundation, a digitalization level around Industry 3.0, and numerous standards (about 700 items). For Chinese enterprises that have not yet completed industrialization, with uneven digitalization levels and generally weak quality awareness, most enterprises, especially the vast majority of small and medium-sized enterprises, do not have the conditions to apply this model.

(2) The SMS model launched by the U.S. National Institute of Standards and Technology (NIST) considers the product lifecycle, factory lifecycle, and order lifecycle as three dimensions, with the intersection point on the “manufacturing pyramid”, emphasizing the establishment of an “intelligent manufacturing ecosystem” based on standards. This model is suitable for large enterprises with relatively complete standards, requiring a good foundation of lifecycle management industrial software. Many Chinese enterprises, especially small and medium-sized enterprises, lack relevant standards or do not follow relevant standards, and have weak information technology foundations, making it difficult to adopt this model.

(3) The IIRA model is an industrial internet reference architecture model proposed by the Industrial Internet Consortium (IIC) in the United States, which was previously benchmarked against RAMI 4.0. IIRA emphasizes architecture and is suitable for IIC members and industrial IoT community architects to operate. The implementation requires enterprises to have good standards and information technology foundations, which is also not suitable for the vast majority of domestic enterprises.

(4) Japan’s IVRA model is the only model that includes people as a special resource in the asset dimension and incorporates the management philosophy of Plan-Do-Check-Act (PDCA). This is due to Japan’s long-standing employment culture centered on people, a deep understanding of the human-machine relationship, and the pervasive lean thinking in enterprises. Chinese enterprises generally have certain management shortcomings and extensive management practices, making it impossible to apply this model directly.

(5) The industrial internet system architecture 2.0 proposed by China provides a functional framework, technical system, and implementation framework for the industrial internet, deconstructing the industrial internet system architecture from a technical perspective. However, this architecture is somewhat complex, making it not easy for large enterprises to understand, and for small and micro enterprises, the lack of architectural concepts makes it even more difficult to comprehend.

The model serves as a map for enterprises implementing the industrial internet. An industrial internet model that is suitable for China’s national and enterprise conditions can help enterprises clarify direction and quickly find implementation entry points and paths. Therefore, learning from and referencing the excellent top-level design ideas of advanced industrial internet models from around the world, such as those from Germany, the United States, and Japan, extracting their technical essence and common elements (three-dimensional models, emphasis on ecology, etc.), and eliminating inapplicable parts, is the starting point and foothold for constructing China’s independent industrial internet model.

In addition to drawing on the design advantages of existing industrial internet models from Germany, the United States, Japan, etc., we also need to identify and clarify several cognitive misunderstandings about the industrial internet when constructing a model suitable for China.

2. Analysis of Misunderstandings about the Industrial Internet

1. The industrial internet is not just an information infrastructure

The industrial internet is not only the technical connection of the industrial end such as “product ‒ person ‒ machine ‒ material ‒ method ‒ environment ‒ measurement”, nor is it merely a mapping of its operational mechanisms. It also includes the mapping of management relationships, process relationships, production organization, upstream and downstream entity supply chains, and other relationship networks of these industrial ends. Industrial site data has always been closely and frequently interacting with the industrial ends it depends on, mapping more complex industrial site relationship networks with complex data types. Data is transmitted, penetrated, and loaded according to the mapped industrial site relationship network, calculated, analyzed, and reasoned based on given industrial mechanism models and algorithms, and ultimately makes business decisions/predictions to solve practical problems on industrial sites.

From the industrial attributes of the industrial internet, it cannot be viewed merely as a new type of “information infrastructure” similar to big data, artificial intelligence (AI), fifth-generation mobile communication (5G), and other new generation information and communication technologies (ICT), but should also be regarded as a new type of “industrial infrastructure”.

2. The industrial internet is not just the Internet of Things (IoT)

Since the beginning of the 21st century, the IoT industry has flourished, with physical entities increasingly achieving interconnectivity over a larger range. The industrial internet is an industrial-native interconnection network established based on industrial Ethernet/control networks and industrial IoT. “Industrial site + industrial end” is both the ontology and soil for generating problems, as well as the resources and leverage for solving problems. Industrial IoT focuses on the industrial field, using the industrial ends such as “product ‒ person ‒ machine ‒ material ‒ method ‒ environment ‒ measurement” as basic resources and connection/enabling objects, possessing strong industrial attributes; while IoT has a broader connection range, mainly connecting physical ends that do not possess industrial attributes, thus the two are significantly different.

3. The industrial internet is not just a technical network

The native interconnection network is an objective existence that transcends technology in nature, such as the gravitational network between planets, the ecological network between organisms, the relational network between individuals, and the collaborative network between enterprises. These networks were not established after the development of technical networks, but rather, the technical networks have continuously learned from and mimicked the objectively existing native interconnection networks, integrating with them, which has led to today’s technological heights. An analysis of industry data from recent years shows that when the enterprise entity relationship network in the industry is well-developed, the level of industrial internet application is also high (e.g., the power and light industry with highly developed operational networks ranks first nationally). Therefore, studying the industrial internet model cannot solely focus on the technical network; the entity relationship networks such as regional collaborative networks, family relationship networks, and local cooperation networks that small and medium-sized enterprises possess should also be a research focus. However, in existing industrial internet models at home and abroad, there has been no research content on enterprise entity relationship networks.

4. The industrial internet is not just the territory of large enterprises

Currently, the development path of the industrial internet in China mainly involves large enterprises building platforms while small and medium-sized enterprises move to the cloud. Large enterprises have advantages in capital, talent, and enterprise operational networks, but it is not only large enterprises that can build the industrial internet; small and micro enterprises can also build an industrial internet suitable for their needs, leveraging their unique enterprise entity collaborative relationship networks to implement the industrial internet in niche areas.

In summary, China urgently needs to explore an independent industrial internet model that reflects both advanced industrial thinking at home and abroad and aligns with national and enterprise conditions, forming an ecological system framework that guides the development, integration, and operation of the industrial internet, accommodating large, medium, small, and micro enterprises, allowing them to build the industrial internet according to their respective needs.

1. Industrial Internet Ecosystem

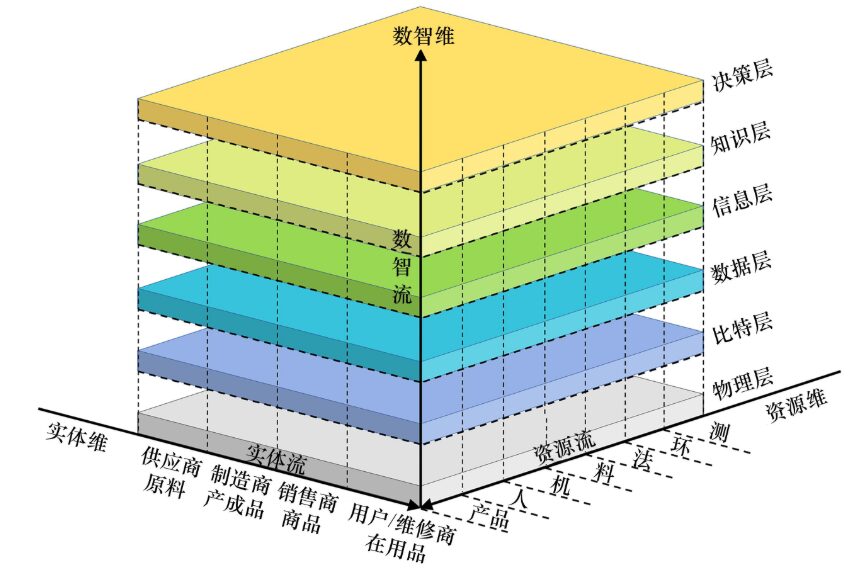

The industrial internet ecosystem refers to the new industrial network formed by the interaction of all industrial elements (industrial entities, resources, data, knowledge, etc.) related to the industrial field and the many stakeholders on its value chain, based on intelligent technology and following the principles of integration, symbiosis, and win-win cooperation, forming a dynamic organic whole. This paper extracts the common characteristics of “three-dimensional + ecology” by comparing and analyzing multiple industrial internet reference models, and for the first time proposes the concept of the Industrial Internet Ecosystem Model (IIEM), creating a universally applicable industrial internet model driven by “data + knowledge” (see Figure 1). By identifying the good effects of the industrial internet overlaying the enterprise entity relationship network, the model connects “entity + resource” as connecting elements, eliminating the common data and information “islands” that enterprises face.

Figure 1 IIEM Structure Diagram

2. Components of the Industrial Internet Ecosystem Model

1. Industrial Entities

Industrial entities consist of enterprise entities and product entities and are the first core elements of the industrial internet ecosystem. Industrial entities exist as independent enterprise entities within the enterprise entity network system operating in the market economy, reflecting enterprise value through the timely delivery of high-quality product entities. The intangible and rigid demand for product manufacturing is driven by orders and links upstream and downstream enterprise entities, forming entity flow, which is described by the entity dimension.

2. Resources

Resources are the second core element that cannot be missing in the industrial internet ecosystem. “Product ‒ person ‒ machine ‒ material ‒ method ‒ environment ‒ measurement” constitutes the resource network system of enterprises. The efficient completion of high-quality products is a process of resource aggregation, process realization, continuous enhancement of product value, and even enterprise value enhancement. During this process, orders drive resources to flow dynamically, constantly changing the attributes of resources, forming resource flow, which is described by the resource dimension.

3. Data

Data is the third core element constituting the industrial internet ecosystem. As a value carrier, the value-added process of products interacts with the enterprise entity network and resource network in the form of data, mapping industrial entities, integrating product value flow under resource loading, accurately mapping, circulating, and applying at different lifecycle stages and levels, forming a data network system, described by the data dimension.

4. Knowledge

Knowledge is the fourth core element constituting the industrial internet ecosystem. Building mechanism models and data models with knowledge supports human and machine decision-making, solving specific problems, which is the basic logic and method of interaction between people and the objective world. Knowledge is the product of data and information after reconstruction and dimensional elevation, where digital knowledge coexists with data flow. The data flow that carries digital knowledge is the data intelligence flow.

3. Structure of the Industrial Internet Ecosystem Model

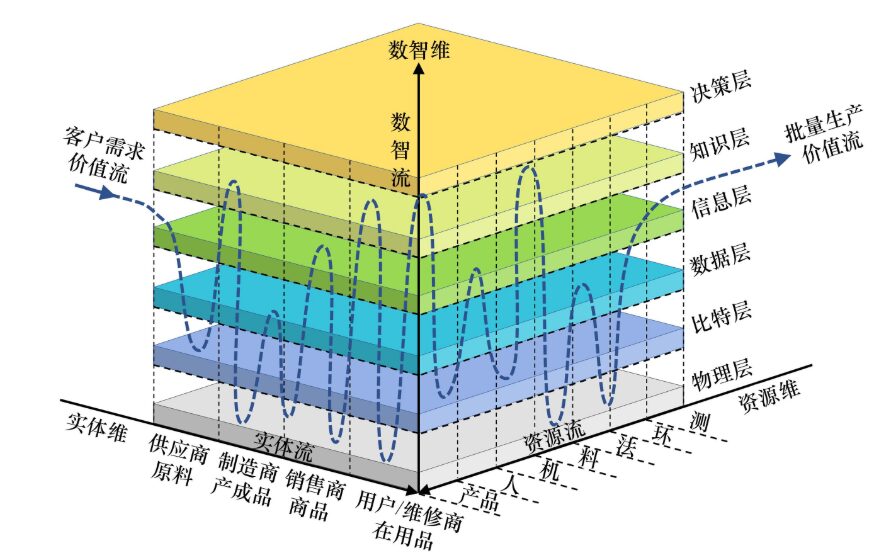

The IIEM is structured as “three dimensions, four flows, and six layers”, emphasizing planning, establishing, and operating the industrial internet ecosystem centered on industrial entities, as shown in Figure 1.

The three dimensions are the entity dimension, resource dimension, and data intelligence dimension, which analyze the ecosystem formed by the superposition of the industrial internet’s entity network system, resource network system, and data network system from three dimensions. Among them, the entity dimension is a comprehensive dimension composed of enterprise entities and product entities, reflecting the actual situation of production operations within enterprises and business cooperation outside enterprises, as well as the attribute changes of products at different stages and different enterprises, such as the terminal products of upstream enterprises being raw materials or components for downstream enterprises. The establishment of the entity dimension transcends the conventional practice of only considering internal interconnectivity and directly guides enterprises to focus on interconnectivity between enterprise entities.

The four flows are entity flow, resource flow, data intelligence flow, and dynamic value flow. Each of the three dimensions has flows expressing the business characteristics of that dimension, and the three flows together constitute the dynamic value flow. The flows of the four dimensions reflect the value flow mechanism under multiple dimensions. The composition of the resource flow consists of the most common elements on industrial sites, such as “product ‒ person ‒ machine ‒ material ‒ method ‒ environment ‒ measurement”, suitable for the context of Chinese enterprises and commonly seen connection elements in the industrial internet. According to the basic logic of manufacturing, as indicated by the arrow directions of the entity dimension and resource dimension in Figure 1, entity flow and resource flow flow towards the final product, aggregating and adding value.

The six layers are the physical layer, bit layer, data layer, information layer, knowledge layer, and decision layer. The six layers analyze the value forms of the data intelligence flow at different levels, digitalizing the physical layer through bits, revealing the essence and path of enterprise digital transformation through a method of reconstruction and dimensional elevation and deconstruction.

4. Operational Mechanism of the Industrial Internet Ecosystem Model

1. Operational Mechanism of Entity Flow Linked by Market Demand

The industrial internet is not only built and applied within the scope of the enterprise itself; the cooperative relationships between enterprise entities are particularly important, which is key to forming an ecosystem. The intangible and rigid demand is linked through orders in the supply chain, highlighting the close cooperation between an enterprise entity and external entities, forming the digital economic relationship between entities.

The term entity has two meanings: one refers to enterprise entities, and the other refers to product entities in the supply chain. From the perspective of enterprise entities, different representatives such as suppliers, manufacturers, sellers, and users/maintenance personnel form a rich and diverse cooperative ecosystem supported by intelligent technology, constituting an integrated and symbiotic “supply chain network” system. From the perspective of product entities, different forms of product entities, such as raw materials, finished products, goods, and consumables, express the phased results at different stages of the product lifecycle, factory lifecycle, and order lifecycle.

Whether it is different representatives of enterprise entities or different forms of product entities, these four types of enterprise representatives and four forms of product entities run through the product lifecycle, factory lifecycle, and order lifecycle, which are essential basic production processes and the value-added process of product entities for all enterprise entities.

In the entity dimension, the future core competitiveness of enterprise entities includes the accurate connection of supply and demand relationships between different enterprise entities, the value-added changes and smooth flow of product entity forms, and the control capabilities of enterprise entities over the “supply chain network”. Previous industrial internet research has focused more on the connections of “machine ‒ material ‒ method ‒ environment ‒ measurement”, lacking consideration of human connections, including how to connect human operational skills, management states, and the collaborative relationships formed by people.

2. Operational Mechanism of Resource Flow in the Product Value Loading Process

The resource dimension describes the attribute changes and flow states of the “product ‒ person ‒ machine ‒ material ‒ method ‒ environment ‒ measurement” resources required for enterprise research and development, production, operation, and management. Product entities, regardless of whether they are in the stages of raw materials, research products, work-in-progress, finished products, goods, or consumables, all require their owners (suppliers, manufacturers, sellers, users/maintenance personnel) to configure various resources to support the R&D, production, sales, use, and maintenance of that product.

3. BDIKW Model Supporting the Operation Mechanism of Data Intelligence Flow

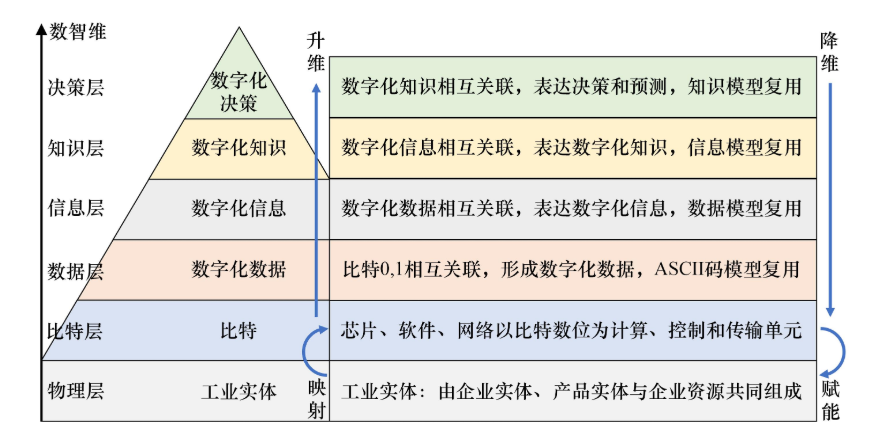

The Data-Information-Knowledge-Wisdom (DIKW) model is divided into four levels: data (D), information (I), knowledge (K), and wisdom (W). Based on the DIKW model, this paper proposes a digital BDIKW model. Based on ASCII code, the bit layer (B) serves as the “digital foundation” to deconstruct and reconstruct the traditional DIKW model, forming the methodology that “everything originates from bits” and “everything that can be digitized is digitized”. The BDIKW model consists of the bit (B) layer, digital data (D) layer, digital information (I) layer, digital knowledge (K) layer, and digital decision (W) layer. Among them, the digital decision layer is where human-like machine intelligence makes decisions/predictions, or humans and machines jointly make decisions/predictions. The physical layer consists of the entity dimension and resource dimension, representing industrial entities. Industrial entities are mapped to the BDIKW model, where elements such as big data, AI, 5G, and industrial software in the BDIKW model empower industrial entities (see Figure 2).

Figure 2 BDIKW Model on the Data Intelligence Dimension

4. Operational Mechanism of Dynamic Value Flow Combining Three Flows

The business interactions, demand transmission, order-driven, and supply chain interactions between enterprise entities form entity flow, which flows along the entity dimension; the products carrying market demand accumulate through orders, driving the “product ‒ person ‒ machine ‒ material ‒ method ‒ environment ‒ measurement” resource flow, which flows along the resource dimension; the digital data/information/knowledge that penetrates enterprise entity barriers converges into data intelligence flow, which flows along the data intelligence dimension, continuously digitalizing, deconstructing, and optimizing the physical layer; the combination of the three flows forms a dynamic value flow, reflecting the operational logic of entity relationship networks, resource networks, and data networks (see Figure 3).

Figure 3 Operational Mechanism of Dynamic Value Flow in IIEM

The intrinsic mechanism of the industrial internet ecosystem is the co-construction of ecological enterprises, demand orders driving resources, resource aggregation for intelligent decision-making, data empowering value flow, and the mutual elevation of product enterprises’ value.

The industrial internet, combined with the existing entity relationship networks of enterprises, will effectively improve the success rate of applications. Small and medium-sized enterprises can fully utilize their regional collaborative networks, family relationship networks, and local cooperative networks under the guidance of IIEM, taking advantage of rapid decision-making, short links, and easy deployment, based on “productized industrial internet” solutions to build their own industrial internet ecosystems. The IIEM has a certain universality, meeting the needs of enterprises to choose personalized industrial internet implementation paths based on their enterprise conditions.

In the future, IIEM can be directly integrated into industrial internet platforms, achieving the ideal goal that large, medium, small, and micro enterprises can “use the model invisibly”, allowing China’s industrial internet construction to truly form an ecosystem that benefits billions of enterprises. In the future, we look forward to the promotion and verification of the IIEM model in more enterprises and industries, providing references for the construction of China’s industrial internet.

–THE END–