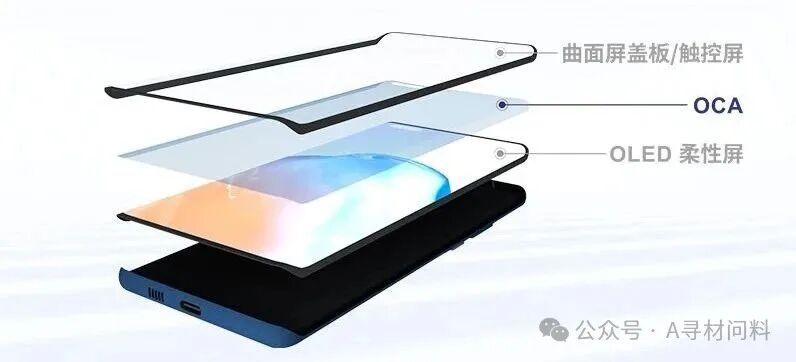

OCA optical adhesive is the “invisible link” in the electronic display industry, ensuring the thinness, high brightness, and reliability of modern screens through exceptional optical performance and stable adhesion. With the popularity of foldable screens and large in-car displays, the technology is upgrading towards flexibility and ultra-thinness. The domestic substitution process (such as Zhongjiu Guofeng and Sidike) will further reduce the cost of the industrial chain. Many companies have broken the monopoly of the US, Japan, and South Korea, with product performance comparable to imported brands, and are applied in the supply chains of Huawei, Xiaomi, and other automotive and display screens, showcasing their strong R&D and production capabilities, as well as their determination on the path of domestic independence.Here are some domestic manufacturers producing OCA optical adhesive without substrates:Jinghua New Materials

With the popularity of foldable screens and large in-car displays, the technology is upgrading towards flexibility and ultra-thinness. The domestic substitution process (such as Zhongjiu Guofeng and Sidike) will further reduce the cost of the industrial chain. Many companies have broken the monopoly of the US, Japan, and South Korea, with product performance comparable to imported brands, and are applied in the supply chains of Huawei, Xiaomi, and other automotive and display screens, showcasing their strong R&D and production capabilities, as well as their determination on the path of domestic independence.Here are some domestic manufacturers producing OCA optical adhesive without substrates:Jinghua New Materials  Founded in 2006, it has achieved various polymerization technologies in OCA products, making technological breakthroughs in full lamination OCA, blind hole OCA, OLED 3D OCA, foldable OCA, and automotive OCA. Foldable OCA products are used by leading domestic mobile phone companies in the latest foldable phones, successfully achieving domestic substitution. Jiangsu Jinghua has 3 OCA optical adhesive coating lines with a designed capacity of 12 million square meters per year; Anhui Jinghua has a designed annual production capacity of 26 million square meters for OCA optical film adhesive tape, 21 million square meters for silicone protective film, and 40 million square meters for release film.Rijiu Optoelectronics Founded in 2010, its products include ITO conductive films, optical hardening films, and protective films. OCA optical adhesive has a good reputation among clients, with increasing shipment volume and market share. Zhejiang Rijiu New Materials is its wholly-owned subsidiary, with main products including ITO conductive films, OCA optical adhesives, optical release films, and high-temperature protective films. As of 2019, Rijiu New Materials has 2 imported OCA optical adhesive coating lines, planning an OCA thin adhesive production capacity of 11 million square meters per year and a full lamination OCA optical adhesive production capacity of 10 million square meters per year.

Founded in 2006, it has achieved various polymerization technologies in OCA products, making technological breakthroughs in full lamination OCA, blind hole OCA, OLED 3D OCA, foldable OCA, and automotive OCA. Foldable OCA products are used by leading domestic mobile phone companies in the latest foldable phones, successfully achieving domestic substitution. Jiangsu Jinghua has 3 OCA optical adhesive coating lines with a designed capacity of 12 million square meters per year; Anhui Jinghua has a designed annual production capacity of 26 million square meters for OCA optical film adhesive tape, 21 million square meters for silicone protective film, and 40 million square meters for release film.Rijiu Optoelectronics Founded in 2010, its products include ITO conductive films, optical hardening films, and protective films. OCA optical adhesive has a good reputation among clients, with increasing shipment volume and market share. Zhejiang Rijiu New Materials is its wholly-owned subsidiary, with main products including ITO conductive films, OCA optical adhesives, optical release films, and high-temperature protective films. As of 2019, Rijiu New Materials has 2 imported OCA optical adhesive coating lines, planning an OCA thin adhesive production capacity of 11 million square meters per year and a full lamination OCA optical adhesive production capacity of 10 million square meters per year. Saiwu Technology Its innovative engineering strategy covers multiple stages, from demand identification to pre-marketing control. It has certain technical and market accumulation in the R&D and production of OCA optical adhesives, with products applied in various fields.Sidike Founded in 2006, its main products include functional film materials, electronic-grade adhesive materials, and more, applied in consumer electronics and new display fields. Its OCA products can be used in mobile terminals, wearable devices, commercial display screens, televisions, and automotive displays, with long-term stable cooperation with internationally renowned companies such as Foxconn and Tesla.

Saiwu Technology Its innovative engineering strategy covers multiple stages, from demand identification to pre-marketing control. It has certain technical and market accumulation in the R&D and production of OCA optical adhesives, with products applied in various fields.Sidike Founded in 2006, its main products include functional film materials, electronic-grade adhesive materials, and more, applied in consumer electronics and new display fields. Its OCA products can be used in mobile terminals, wearable devices, commercial display screens, televisions, and automotive displays, with long-term stable cooperation with internationally renowned companies such as Foxconn and Tesla. Xinglun Technology Strategically focused on the new materials sector, OCA products are highly cost-effective. Under the trend of domestic substitution, it has entered the supply chains of BOE, Tianma, Huaxing, and Visionox, supplying in bulk. Changzhou Xinglun has 1 imported OCA optical adhesive coating line, planning a production capacity of 6 million square meters per year, and also has 3 hundred-level coating lines, 2 thousand-level coating lines, 6 ten-thousand-level coating lines, and 5 blown film lines, with a production capacity of 10 million square meters per month.Lushan New Materials

Xinglun Technology Strategically focused on the new materials sector, OCA products are highly cost-effective. Under the trend of domestic substitution, it has entered the supply chains of BOE, Tianma, Huaxing, and Visionox, supplying in bulk. Changzhou Xinglun has 1 imported OCA optical adhesive coating line, planning a production capacity of 6 million square meters per year, and also has 3 hundred-level coating lines, 2 thousand-level coating lines, 6 ten-thousand-level coating lines, and 5 blown film lines, with a production capacity of 10 million square meters per month.Lushan New Materials

TP OCA optical adhesive is mainly used for bonding cover plates and touch screens, suitable for G+F/G+F+F/P+G structures.

Product Features:Suitable for bonding various substrates, stable bonding strength; high transparency, low haze; good durability, no yellowing; excellent ink filling performance.

OCA optical adhesive for LCD full lamination

LCDOCA optical adhesive for full lamination,is mainly applied in the full lamination (post-UV curing) of liquid crystal display modules, suitable for G+F+F or In-cell and On-cell structures.

Product Features:Stable bonding strength, high lamination yield; excellent cold rework and hot rework properties; high reliability, no Mura; excellent ink filling performance.

Low dielectric LCD full lamination optical adhesive, mainly applied in the full lamination (post-UV curing) of touch display modules with low dielectric constant, suitable for G+F+F or In-cell and On-cell structures.

Product Features:Low dielectric constant; stable bonding strength, high reliability; high transparency, low haze; excellent ink filling performance.

OCA optical adhesive for OLED full lamination

3D curved OLED full lamination optical adhesive, mainly applied in the full lamination applications (post-UV curing) of curved AMOLED display modules, suitable for bonding between CG, TP, CPOL (circular polarizer), and OLED display modules.

Product Features:Suitable for bonding various substrates, stable bonding strength; high transparency, low haze; high reliability, no Mura; excellent ink filling performance.

Flexible foldable OLED full lamination optical adhesive, mainly applied in the full lamination of flexible foldable optical devices, suitable for bonding between CG, TP, CPOL (circular polarizer), and OLED display modules.

Product Features:Low modulus over a wide temperature range; strong bonding to flexible optical devices and functional films; can withstand up to 200,000 folds; good optical transparency, low haze; good durability, no yellowing.

LCDOCA optical adhesive for full lamination,is mainly applied in the full lamination (post-UV curing) of liquid crystal display modules, suitable for G+F+F or In-cell and On-cell structures.

Product Features:Stable bonding strength, high lamination yield; excellent cold rework and hot rework properties; high reliability, no Mura; excellent ink filling performance.

Low dielectric LCD full lamination optical adhesive, mainly applied in the full lamination (post-UV curing) of touch display modules with low dielectric constant, suitable for G+F+F or In-cell and On-cell structures.

Product Features:Low dielectric constant; stable bonding strength, high reliability; high transparency, low haze; excellent ink filling performance.

Crown New Materials Founded in the early 1990s, the founding team entered the adhesive new materials industry and established Crown Company in 2000. It has four major production bases: Zhongshan Crown, Jiangsu Crown, Guangdong Crown, and Zhejiang Crown. The under-construction Zhejiang Crown is expected to reach an annual production scale of 10 million square meters of optical OCA adhesive tape upon completion. Its OCA product line includes full lamination OCA, automotive OCA, UV barrier OCA, and silicone-based OCS, meeting the needs of various fields such as consumer electronics and automotive displays.Fuyin Group

Founded in the early 1990s, the founding team entered the adhesive new materials industry and established Crown Company in 2000. It has four major production bases: Zhongshan Crown, Jiangsu Crown, Guangdong Crown, and Zhejiang Crown. The under-construction Zhejiang Crown is expected to reach an annual production scale of 10 million square meters of optical OCA adhesive tape upon completion. Its OCA product line includes full lamination OCA, automotive OCA, UV barrier OCA, and silicone-based OCS, meeting the needs of various fields such as consumer electronics and automotive displays.Fuyin Group  Founded in 2006, it is one of the earliest companies to enter the OCA optical adhesive field in China. It began producing OCA optical adhesive at the end of 2013 and was the first company in China to introduce foam adhesive tape production lines and acrylic adhesive tape production lines. Its products cover OCA optical adhesives, acrylic adhesive tapes, and more than 1,000 product models across 9 major series, with four major production bases and three R&D departments. Dongguan Fuyin has 11 production lines, with an annual output of 43 million square meters of electronic-grade adhesive materials; Anhui Fuyin started production in 2019 and has put into use 16 automated production lines for OCA optical adhesives, with an annual output of 50 million square meters of electronic-grade adhesive materials, 80 million square meters of functional film materials, and 9 million square meters of functional foam materials.Gaoren New MaterialsFounded in 2014, it has 6 fully automated high-end coating equipment and complete R&D testing facilities. Its products include OCA optical adhesives, SCA optical adhesives, EVA adhesive films, etc. In 2022, the sales volume of optical adhesives reached over 2 million square meters, and in 2023, a new optical adhesive project is expected to produce 1,300 tons of EVA adhesive films, 300 tons of SCA optical adhesives, and 3,750 tons of OCA optical adhesives.

Founded in 2006, it is one of the earliest companies to enter the OCA optical adhesive field in China. It began producing OCA optical adhesive at the end of 2013 and was the first company in China to introduce foam adhesive tape production lines and acrylic adhesive tape production lines. Its products cover OCA optical adhesives, acrylic adhesive tapes, and more than 1,000 product models across 9 major series, with four major production bases and three R&D departments. Dongguan Fuyin has 11 production lines, with an annual output of 43 million square meters of electronic-grade adhesive materials; Anhui Fuyin started production in 2019 and has put into use 16 automated production lines for OCA optical adhesives, with an annual output of 50 million square meters of electronic-grade adhesive materials, 80 million square meters of functional film materials, and 9 million square meters of functional foam materials.Gaoren New MaterialsFounded in 2014, it has 6 fully automated high-end coating equipment and complete R&D testing facilities. Its products include OCA optical adhesives, SCA optical adhesives, EVA adhesive films, etc. In 2022, the sales volume of optical adhesives reached over 2 million square meters, and in 2023, a new optical adhesive project is expected to produce 1,300 tons of EVA adhesive films, 300 tons of SCA optical adhesives, and 3,750 tons of OCA optical adhesives. Shuangxing New Materials Although it started late in OCA R&D, it has emerged in the optical materials market due to its strong technical accumulation in optical films and its ability to respond quickly to customer needs. In 2025, it will increase investment in OCA R&D, establish a professional R&D team, and conduct industry-university-research cooperation with universities, achieving significant progress in the basic formula research of OCA optical adhesives, with the potential for substantial breakthroughs in R&D and production.

Shuangxing New Materials Although it started late in OCA R&D, it has emerged in the optical materials market due to its strong technical accumulation in optical films and its ability to respond quickly to customer needs. In 2025, it will increase investment in OCA R&D, establish a professional R&D team, and conduct industry-university-research cooperation with universities, achieving significant progress in the basic formula research of OCA optical adhesives, with the potential for substantial breakthroughs in R&D and production.