Introduction to Senhui: Suzhou Senhui Semiconductor, supported by a strong research and technology team, focuses on providing comprehensive process solutions and wafer processing services for global compound semiconductor customers. The team members have years of experience in the semiconductor industry, possessing decades of rich capabilities in photolithography, thin film processes, epitaxy, bonding processes, as well as etching, wet processing, and polishing development and manufacturing capabilities, with mature technology and extensive process experience.

The 104% composite tariff (including a 34% base rate and punitive clauses) imposed by the U.S. on the semiconductor sector is accelerating the restructuring of the global third-generation semiconductor industry chain. As the core force in silicon carbide wafer processing services, domestic chip companies are facing the dual challenges of short-term pain and long-term transformation.

1. Triple Challenges Under High Tariff Pressure

-

Soaring Equipment Procurement Costs Force Technological Breakthroughs U.S. equipment giants (Applied Materials / Lam Research) hold nearly 40% of the global semiconductor equipment market share, and tariffs have caused the import premium for key equipment in silicon carbide chip mass production processes to exceed 50%. To address supply risks for core equipment such as photolithography and etching machines, leading silicon carbide wafer processing technology companies have initiated domestic substitution plans, such as Zhongwei Semiconductor achieving an etching machine yield rate exceeding 85%.

-

Global Supply Chain Restructuring Creates Market Changes

-

Increased U.S. market access costs: In addition to the existing 20%-70% tariffs, the price advantage of silicon carbide MOSFET wafer processing products for export to the U.S. has weakened, leading some overseas customers to turn to Japanese and Korean suppliers.

-

Upgraded technology licensing barriers: The U.S. has restricted the export of equipment for processes below 14nm to China, forcing third-generation semiconductor wafer processing technology companies to accelerate independent IP development, with the number of domestic patents for silicon carbide power devices surging by 63% year-on-year in 2024.

Capital Market Volatility Highlights Industry Resilience Tariff policies have triggered fluctuations in the global semiconductor sector (TSMC fell 9% in one day / SMIC Hong Kong stock fell 16%), but silicon carbide wafer manufacturers have achieved counter-cyclical expansion through diversified financing. For example, Tianyue Advanced received a strategic investment of 3 billion yuan specifically for the development of 8-inch silicon carbide substrates.

2. Industry Opportunities Amid Structural Changes

-

Domestic Substitution Creates a Window of Technological Dividend The obstruction of high-end AI chip imports has driven a surge in demand for silicon carbide wafer processing services, with leading manufacturers achieving a capacity utilization rate of 92%. For instance, Taiko Tianrun’s 6-inch silicon carbide production line has surpassed the industry average yield, and the delivery cycle for automotive-grade chips has been shortened to 45 days.

-

Third-Generation Semiconductor Materials Overtaking The penetration rate of silicon carbide devices in the fields of new energy vehicles and photovoltaics has increased to 27%, with SiC power device wafer processing becoming a focal point for technological breakthroughs. BYD Semiconductor has adopted independent wafer processing technology to achieve mass production of 1200V silicon carbide modules, reducing costs by 40% compared to imported solutions.

-

Regional Supply Chain Builds a New Ecosystem The Yangtze River Delta / Guangdong-Hong Kong-Macao Greater Bay Area has formed a silicon carbide wafer processing technology cluster, reducing operational costs through equipment sharing and joint R&D. For example, Hefei Jinghe Integrated and Sanan Optoelectronics have jointly established a silicon carbide laboratory, shortening the R&D cycle by 30%.

3. Strategies for Breakthroughs by Silicon Carbide Wafer Manufacturers

-

Cost Reduction through Technology: Developing 8-inch silicon carbide substrate slicing technology, reducing single crystal preparation costs by 25%

-

Market Shift: Expanding into the European new energy vehicle supply chain, with local silicon carbide MOSFET wafer processing companies obtaining certifications from Volkswagen / Bosch

-

Ecological Co-construction: Collaborating with SMIC, Huahong Grace, and others to create a third-generation semiconductor wafer processing technology alliance, sharing a patent pool covering 92% of core processes

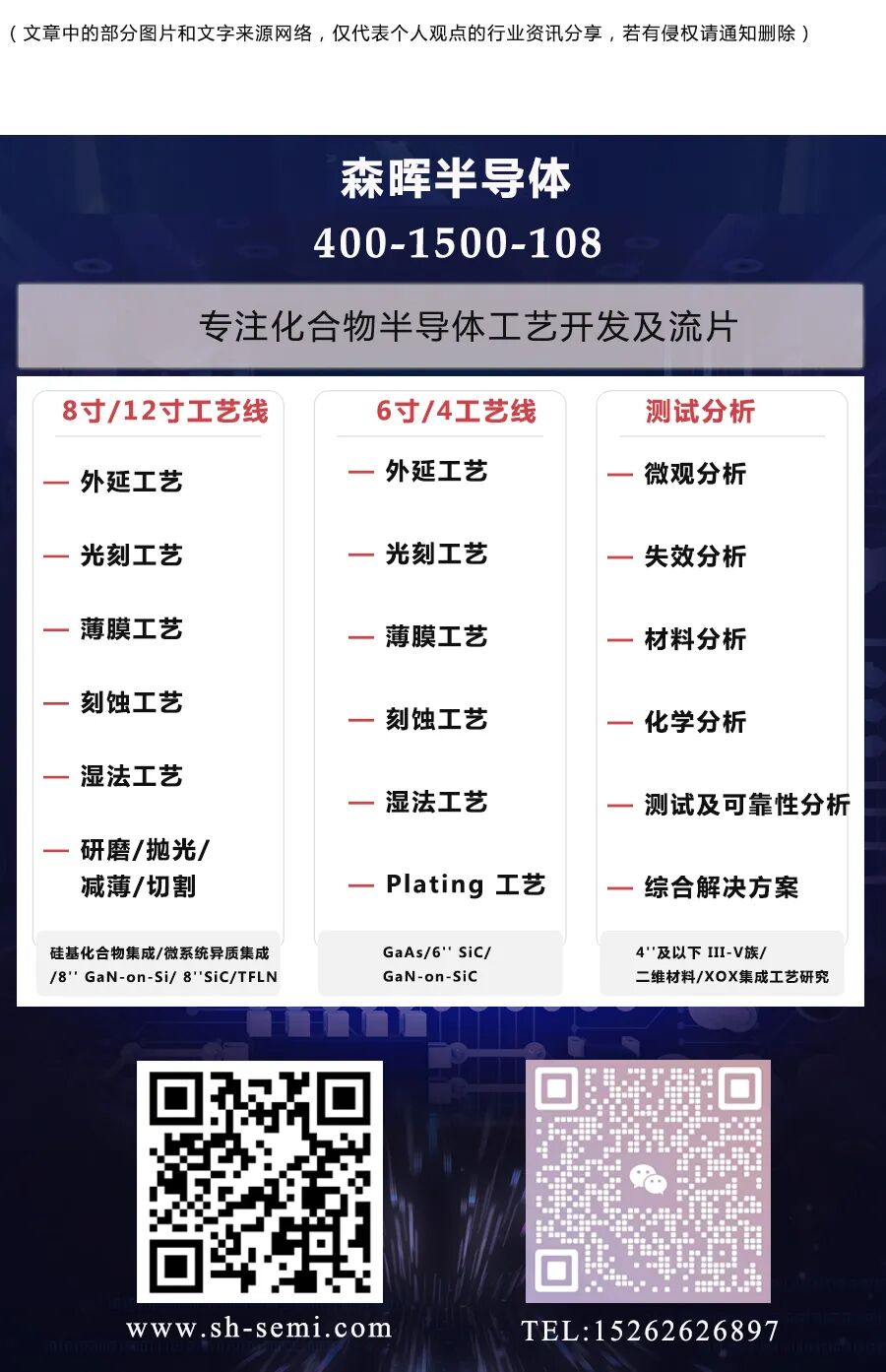

For more information about gallium arsenide wafer processing, silicon carbide wafer processing, gallium nitride wafer processing, 4-inch wafer processing, 6-inch wafer processing, 8-inch wafer processing, and 12-inch wafer processing, please contact 15262626897 for detailed communication.