First, NPT is American thread, BSPT is British thread, and PT is also British thread, with PT being the Japanese JIS standard. In fact, BSPT and PT are the same.

BSPT/NPT

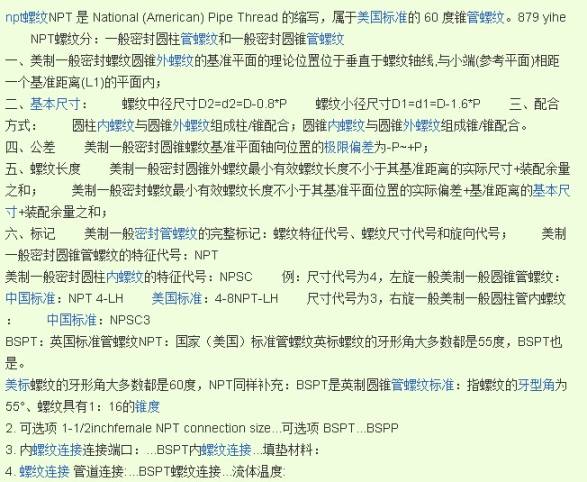

BSPT is the British standard for tapered pipe threads: it refers to a thread angle of 55° with a taper of 1:16.

1. BSP is the British pipe thread, but there are distinctions like BSP.Tr., BSP.PI., and BSP.F.

BSP.Tr. is tapered pipe thread used for sealing connections. BSP.PI. is parallel pipe thread used for sealing connections, having only internal threads that fit with the external threads of BSP.Tr.

BSP.F. is parallel pipe thread used for general connections.

Just knowing BSP is not enough; it’s best to confirm details. Otherwise, if there’s an oil or gas leak, it could be a big problem.

2. The G thread is the same as the BSPP thread, both are British cylindrical pipe thread codes with a thread angle of 55 degrees.

3. How many types of British threads are there? What are the characteristics and notation of BSP threads? There are two types: BSPP (pipe thread) and BSPT (55-degree tapered pipe thread, which is incompatible with the American 60-degree tapered pipe thread NPT).

4. Comparing G threads and Rp threads, what are the similarities and differences, and are they interchangeable in use?

Both G threads and Rp threads are 55° cylindrical pipe threads. They differ only by country (organization) which results in different codes. G is the code for China, France, the former Soviet Union, and Japan;

PF is the code for Japan; BSP and BSPP are the codes for the UK; R and K are the codes for Germany (R is for internal threads, K is for external threads); TPYБ is the code for the former Soviet Union; Rp is the ISO code.

—————————

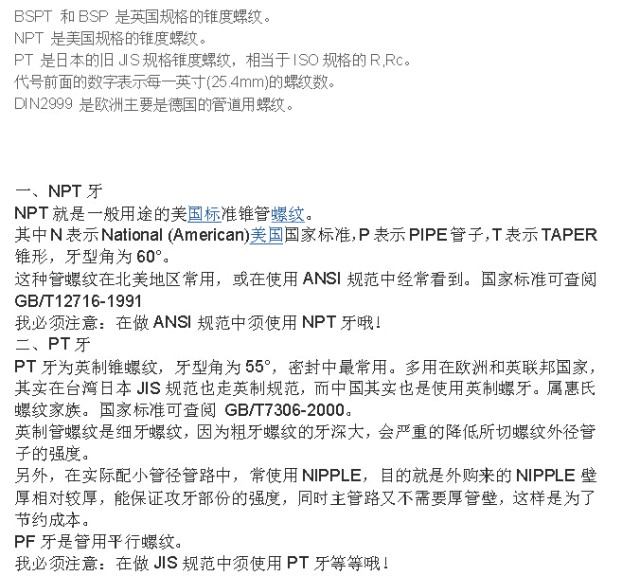

BSPT and BSP are British specifications for tapered threads. NPT is the American specification for tapered threads. PT is the old JIS specification for tapered threads in Japan, equivalent to ISO specifications R and Rc.

The number preceding the code indicates the number of threads per inch (25.4mm).

DIN2999 is the European standard, mainly German, for pipe threads.

1. NPT Thread

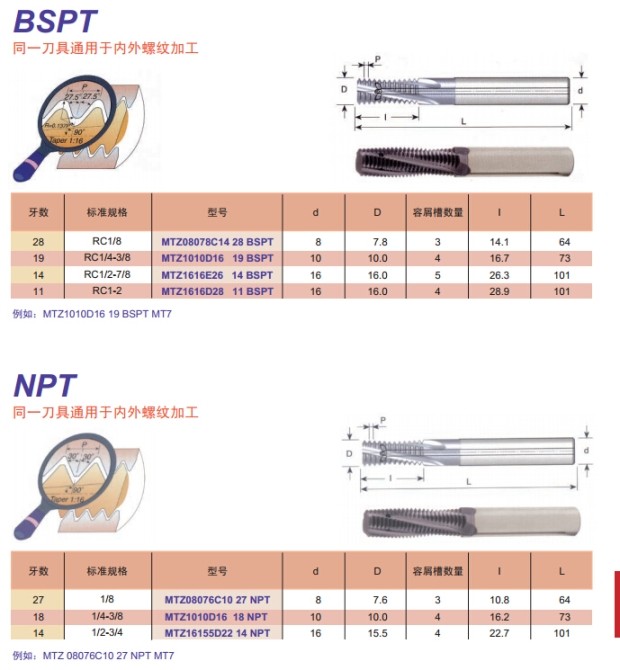

NPT is the general-purpose American standard tapered pipe thread.

Here, N stands for National (American) Standard, P stands for PIPE, and T stands for TAPER, with a thread angle of 60°.

This type of pipe thread is commonly used in North America or is often seen in ANSI standards. The national standard can be referenced in GB/T12716-1991.

I must note: when working with ANSI standards, NPT threads must be used! 2. PT Thread PT thread is a British tapered thread, with a thread angle of 55°, commonly used for sealing. It is widely used in Europe and Commonwealth countries. In fact, in Taiwan, the Japanese JIS standard also follows British specifications, and China also uses British thread.

2. PT Thread PT thread is a British tapered thread, with a thread angle of 55°, commonly used for sealing. It is widely used in Europe and Commonwealth countries. In fact, in Taiwan, the Japanese JIS standard also follows British specifications, and China also uses British thread.

British pipe threads are finer threads because coarse threads have a greater thread depth, which can significantly reduce the strength of the pipe with external threads.

Additionally, in practical applications with small diameter pipelines, nipples are often used. The purpose is that the purchased nipple has a relatively thick wall, ensuring the strength of the threaded part, while the main pipeline does not require a thick wall to save costs. PF thread is a parallel thread for pipes.

I must note: when working with JIS standards, PT threads must be used, etc.!

3. Others

G is a 55-degree non-thread sealing pipe thread, part of the Whitworth thread family. Marked as G represents cylindrical threads. The national standard can be referenced in GB/T7307-2001. G is the general term for pipe threads, and the division into 55 and 60 degrees is functional, commonly referred to as cylindrical pipe threads. ZG is commonly referred to as tapered pipe threads, indicating that the thread is machined from a conical surface. Most common water pipe fittings are like this, with the old national standard marked as Rc for metric threads, while British and American threads are indicated by the number of threads per inch. This is their biggest difference; metric threads use 60-degree equilateral thread profiles, while British threads use isosceles 55-degree profiles, and American threads use 60 degrees.

Metric threads use metric units, while British and American threads use imperial units. Pipe threads are primarily used for connecting pipes, with tight fits between internal and external threads, with straight and tapered pipe threads. The nominal diameter refers to the diameter of the connected pipe, and evidently, the major diameter of the thread is larger than the nominal diameter. 1/4, 1/2, 1/8 are the nominal diameters of British threads, measured in inches.

4. Just to throw in some more, let’s stuff it all in!

1. Recognition of Unified Thread in Inches

Unified threads in inches are widely adopted in inch-based countries. This type of thread is divided into three series: coarse thread series UNC, fine thread series UNF, and extra fine thread series UNFF, plus a fixed pitch series UN. Marking method: thread diameter—number of threads per inch series code—accuracy grade. Example: coarse thread series 3/8—16 UNC—2A

Fine thread series 3/8—24 UNF—2A

Extra fine thread series 3/8—32 UNFF—2A

Fixed pitch series 3/8—20 UN—2A

The first number 3/8 indicates the thread outer diameter, measured in inches. To convert to metric units in mm, multiply by 25.4, i.e., 3/8×25.4=9.525mm; the second and third numbers 16, 24, 32, 20 are the number of threads per inch (the number of threads in 25.4mm length); the text code UNC, UNF, UNFF, UN is the series code, and the last two digits 2A indicate the accuracy grade.

2. Conversion of 55° cylindrical pipe threads

55° cylindrical pipe threads originate from the inch series but are widely adopted in both metric and inch-based countries, used for connecting pipe joints and pipes that transport liquids, gases, and electrical wires. However, the codes differ by country, and should be converted according to the table (comparison table) below, listing the 55° cylindrical pipe thread codes from various countries.

Country Code

China G

Japan G, PF

UK BSP, BSPP

France G

Germany R (internal thread), K (external thread)

Former Soviet Union G, TPУБ

ISO Rp

3. Conversion of 55° tapered pipe threads

55° tapered pipe threads refer to threads with a thread angle of 55° and a taper of 1:16. This series of threads is widely used worldwide, but their codes differ by country. The following table lists the foreign codes that should be converted to our national codes.

Country Code

China ZG, R (external thread)

UK BSPT, R (external thread), Rc (internal thread)

France G (external thread), R (external thread)

Germany R (external thread)

Japan PT, R

ISO R (external thread), Rc (internal thread)

4. Conversion of 60° tapered pipe threads

60° tapered pipe threads refer to threads with a thread angle of 60° and a taper of 1:16. This series of threads is used in the machine tool industry in China, the US, and the former Soviet Union. The code was previously designated as K in China, later designated as Z, and now changed to NPT. The thread code comparison table is as follows.

Country Code

China Z (old) NPT (new)

USA NPT

Soviet Union B

5. Conversion of 55° trapezoidal threads

Trapezoidal threads refer to threads with a thread angle of 30° in the metric system. This series of threads has a relatively unified code internationally. The thread codes are listed in the following table.

Country Code

China T (old) Tr (new)

ISO Tr

Germany Tr

Former Soviet Union Tr

5. Let’s collect some more thread types, it may overlap with the above, but let’s gather it all first!

By thread application, they can be divided into:

1. International Metric Thread System:

This is the thread adopted by our national standard CNS. The thread crest is flat for easy machining, and the thread root is rounded to increase thread strength. The thread angle is 60 degrees, and specifications are denoted by M. Metric threads can be divided into coarse and fine threads. Notation like M8x1.25. (M: code, 8: nominal diameter, 1.25: pitch).

2. American Standard Thread:

Threads with flat tops and roots, providing better strength. The thread angle is also 60 degrees, and specifications are indicated by the number of threads per inch. This type of thread can be divided into coarse (NC), fine (NF), and extra fine (NEF) levels. Notation like 1/2-10NC. (1/2: outer diameter; 10: threads per inch; NC code).

3. Unified Thread:

Developed collaboratively by the USA, UK, and Canada, it is the commonly used imperial thread today.

The thread angle is also 60 degrees, and specifications are indicated by the number of threads per inch. This type of thread can be divided into coarse (UNC), fine (UNF), and extra fine (UNEF). Notation like 1/2-10UNC. (1/2: outer diameter; 10: threads per inch; UNC code).

4. V-shaped threads:

With pointed tops and roots, they have weaker strength and are not commonly used. The thread angle is 60 degrees.

5. Whitworth threads:

Threads adopted by British national standards. The thread angle is 55 degrees, represented by the symbol “W”.

Suitable for manufacturing by rolling method. Notation like W1/2-10. (1/2: outer diameter; 10: threads per inch; W code).

6. Knuckle threads:

Standard threads set by DIN in Germany. Suitable for connecting light bulbs and rubber hoses. Represented by the symbol “Rd”.

7. Pipe threads:

Threads used to prevent leakage, often used for connecting gas or liquid fittings. The thread angle is 55 degrees, which can be divided into straight pipe threads denoted as “P.S., N.P.S.” and tapered pipe threads denoted as “N.P.T.”, with a taper of 1:16, meaning 3/4 inch per foot.

8. Square threads:

Providing high transmission efficiency, second only to ball threads, but cannot be adjusted with nuts after wear, which is a disadvantage. Commonly used in the screw of a vise and threaded rods of cranes.

9. Trapezoidal threads:

Also known as Acme threads. They have slightly lower transmission efficiency than square threads, but can be adjusted with nuts after wear. The metric thread angle is 30 degrees, while the imperial thread angle is 29 degrees. Commonly used in lathe lead screws. Represented by the symbol “Tr”.

10. Buttress threads:

Also known as inclined threads, suitable only for unidirectional transmission, such as screw jacks and presses. Represented by the symbol “Bu”.

11. Ball screw threads:

These are the most efficient threads, but they are difficult to manufacture and have extremely high costs, used in precision machinery, such as CNC machine lead screws.

Notation for imperial bolts:

LH 2N 5/8 × 3 – 13 UNC-2A

(1) LH indicates left-hand thread (RH indicates right-hand thread, which can be omitted).

(2) 2N indicates double-threaded.

(3) 5/8 indicates imperial thread, with an outer diameter of 5/8 ”.

(4) 3 indicates bolt length of 3”.

(5) 13 indicates 13 threads per inch.

(6) UNC indicates unified standard coarse thread.

(7) 2 indicates fit grade for external threads (3: tight fit; 2: medium fit; 1: loose fit) A: external threads (can be omitted) B: internal threads.

Imperial threads: The size of imperial threads is usually indicated by the number of threads per inch of length, referred to as “threads per inch”, which is equal to the reciprocal of the pitch. For example, a thread with 8 teeth per inch has a pitch of 1/8 inch.

1. British Standard Thread (Thread pitch shape angle 55°)

BSW----British Standard Whitworth Thread (Coarse) B.S.F.----British Standard Whitworth Thread (Fine) G----Straight pipe thread (external thread divided into A, B two levels, taps divided into G, G-D) R----Tapered external pipe thread (old code ZG; KG) RC----Tapered internal pipe thread (old code ZG; KG)

2. American Standard Thread (Thread pitch shape angle 60°)

Thread of American standard (Thread pitch shape angle 60° UNC----Unified coarse pitch thread (Instead of NC) UNF----Unified fine pitch thread (Instead of NF) UNEF----Unified superfine pitch thread UN-----Unified fixed pitch thread UNS----Unified special thread NPT----General purpose tapered pipe thread (old code Z; K) NPSC----Straight pipe internal thread for connection NPSM----Straight pipe thread for general purpose NPTF----Dryseal tapered pipe thread NPSF----Dryseal straight pipe internal thread for fuel

3. Metric Thread ZM-----Metric tapered pipe thread

4. Other Threads SM----Thread for sewing machine PZ----Special thread for gas cylinder 5V1-20V1-Tyre valve thread

Explanation of thread code example:

1/4-20UNC

1/4-Nominal diameter 1/4″ nominal dia. 1/4″

20-Twenty teeth per inch

UNC-Unified standard coarse thread

——————————

Classification of thread applications

1. British Standard Thread (Thread pitch shape angle 55°)

BSW―――― British Standard Whitworth Thread (Coarse)

BSF ――― British Standard Whitworth Thread (Fine)

BA ――― British Association Thread

G――――― Straight pipe thread (external thread divided into A.B two levels; taps divided into G. G-D)

R――――― Tapered external pipe thread (old code ZG; KG)

RC―――― Tapered internal pipe thread (old code ZG; KG)

RP―――― Straight internal pipe thread (connected with tapered external thread R)

2. American Standard Thread (Thread pitch shape angle 60°)

UNC――――― Unified coarse pitch thread (replacing NC)

UNF――――― Unified fine pitch thread (replacing NF)

UNEF―――― Unified superfine pitch thread

UN――――― Unified fixed pitch thread

UNS―――― Unified special thread

NBUTT―――― Buttress thread

NPT――――― General purpose tapered pipe thread (old code Z; K)

NPSC―――― Straight internal pipe thread for connection

NPTR―――― Tapered pipe thread for connecting lead rods

NPSM―――― Straight pipe thread for general purpose

NPSL――――― Straight pipe thread with locking nut for loose fit mechanical connection

NPSH――――― Hose connection thread

NH―――――― Fire hose connection thread

NPTF――――― Dryseal tapered pipe thread

NPSF――――― Dryseal straight pipe internal thread for fuel

NPSI――――― Dryseal general straight pipe internal thread

ANPT――――― Aviation American tapered pipe thread

F-PTF Dryseal (fine thread) tapered pipe thread

PTF-SAE SHORT――Dryseal SAE short tapered pipe thread

NGO――――― Gas cylinder outlet thread

NGT――――― Tapered thread for gas cylinders

NGS――――― Straight thread for gas cylinders

SGT――――― Special tapered thread for gas cylinders

0.650-19UNS Safety device thread

ACME――――― Trapezoidal thread (thread pitch shape angle 29°)

G――――――― General purpose trapezoidal thread

C――――――― Centering trapezoidal thread

STUB ACME――Standard short pitch trapezoidal thread

3. Metric Thread

M――――――― Metric thread

ZM―――――― Metric tapered pipe thread

Tr――――――― Trapezoidal tapered thread (old code T)

4. Other Threads

SM――――――― Sewing machine thread

PZ――――――― Gas cylinder tapered thread

PG――――――― Gas cylinder straight thread

TBG―――――― Oil pipe thread

5V1 to 20V1――― Valve core thread

PF――――――― Japanese cylindrical pipe thread

PT――――――― Japanese tapered pipe thread

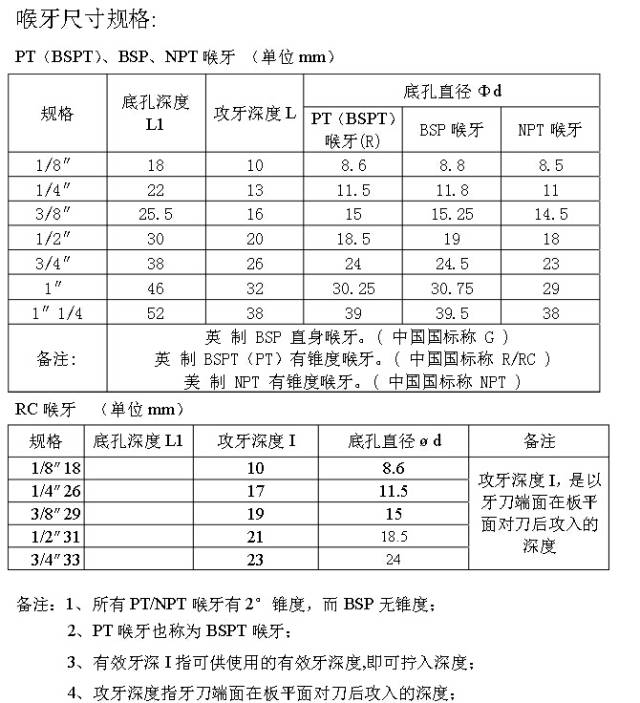

NPT is a type of American National Standard Taper Pipe Thread, belonging to the American standard 60-degree tapered pipe thread. The abbreviation N=National (American) Standard, P=Pipe, T=Taper, and the national standard can be referenced in GB/T12716-1991.