PI/SiO2@ZIF-8 Nanofiber Membrane for High-Temperature Exhaust Gas Filtration and Efficient Formaldehyde Adsorption

The authors studied a novel composite nanofiber membrane (PI/SiO2@ZIF-8) that exhibits excellent high-temperature exhaust gas filtration performance and efficient formaldehyde adsorption capacity. By introducing silica (SiO2) nanospheres and metal-organic frameworks (ZIF-8) into polyimide (PI), the resulting nanofiber membrane demonstrates high filtration efficiency, low resistance, and good thermal stability and mechanical properties in high-temperature environments. The study found that the addition of SiO2 nanospheres can reduce fiber packing density and air filtration resistance, while the introduction of ZIF-8 significantly enhances the material’s formaldehyde adsorption performance. The PI/SiO2@ZIF-8 nanofiber membrane shows a weight loss rate of only 4% at temperatures above 300°C, demonstrating outstanding thermal stability. Additionally, its formaldehyde adsorption capacity reaches 41.58 mg/g within 4 hours, which is more than 12 times that of the PI/SiO2 nanofiber membrane without ZIF-8.

Research Background

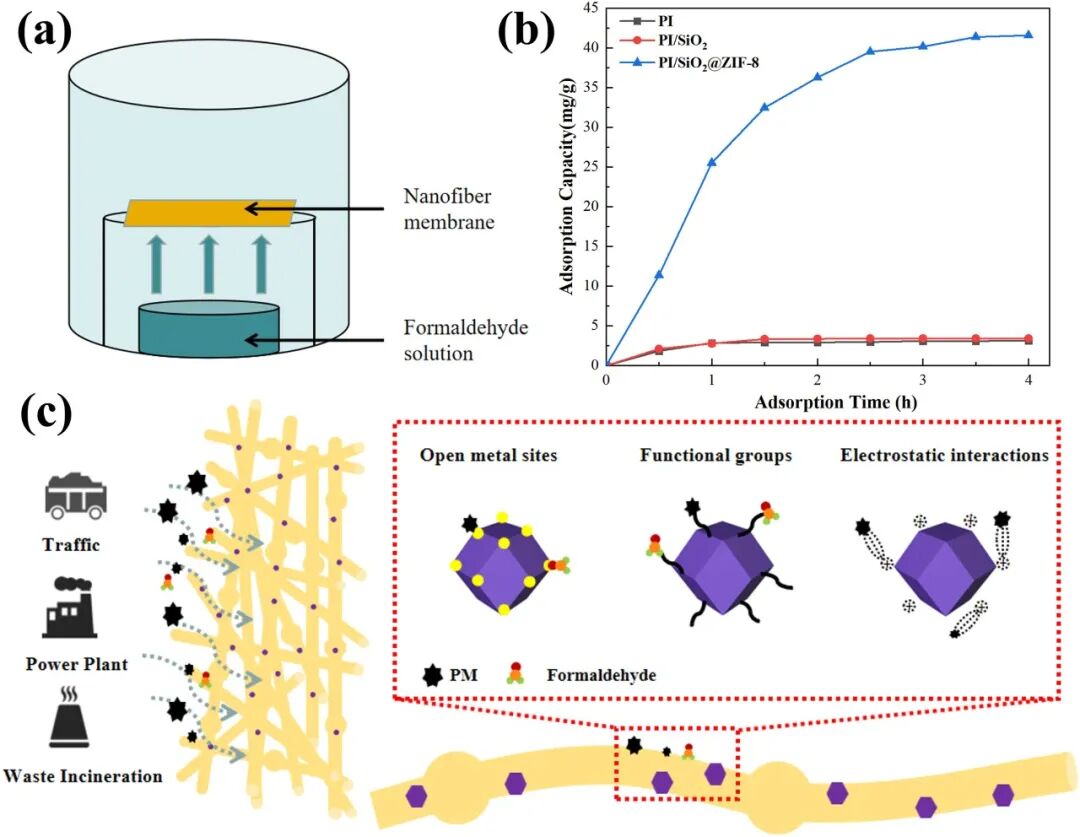

With the rapid development of modern industry and transportation, a large amount of inadequately treated high-temperature exhaust gas is released into the atmosphere. These exhaust gases contain complex pollutants such as solid particles and toxic gases (e.g., formaldehyde, HCl, and SOx), which pose serious threats to the ecological environment and human health. Traditional filtration materials are prone to oxidation and have poor wear resistance in high-temperature environments, making it difficult to effectively filter harmful substances like formaldehyde from high-temperature exhaust gases. Therefore, developing multifunctional filtration materials that can effectively filter particulates and adsorb toxic gases at high temperatures is of great significance. The PI/SiO2@ZIF-8 nanofiber membrane developed in this study not only effectively filters particulates from high-temperature exhaust gases but also efficiently adsorbs harmful gases like formaldehyde, providing a new solution for the purification of high-temperature exhaust gases, helping to reduce air pollution and protect the ecological environment and human health.

Research Overview

Research Methods

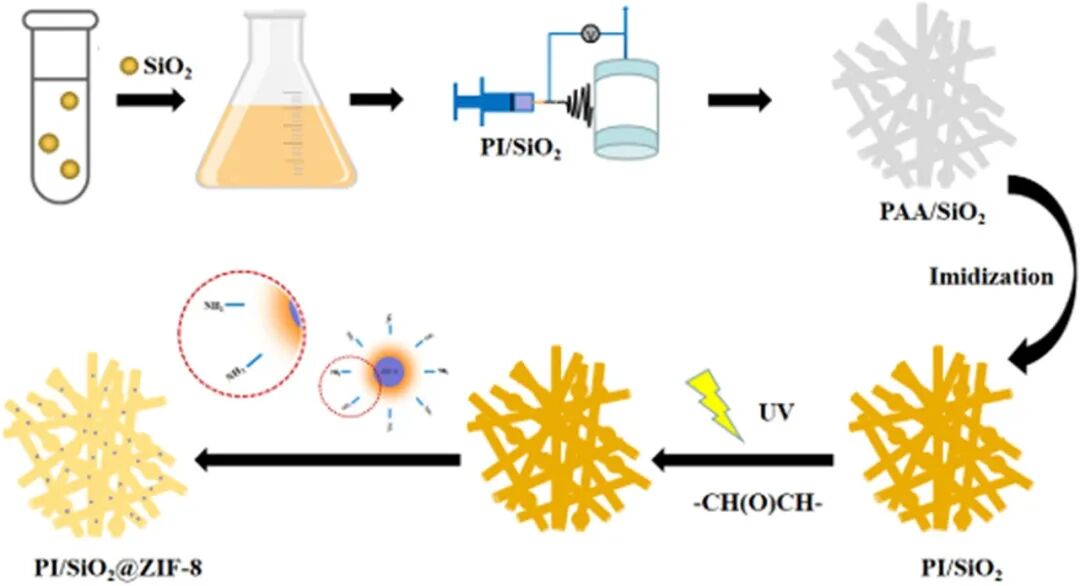

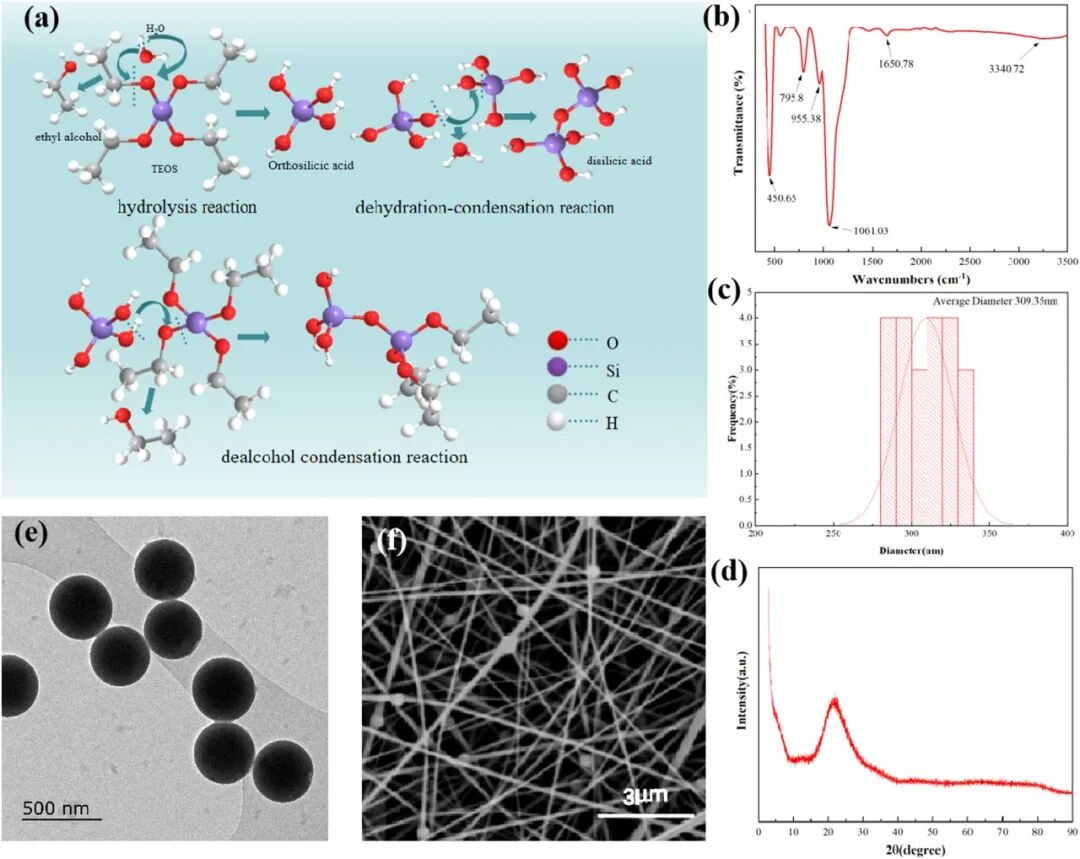

Preparation of SiO₂ nanospheres: SiO₂ nanospheres with a diameter of approximately 309.35 nm were prepared through the hydrolysis and condensation of TEOS under alkaline conditions.

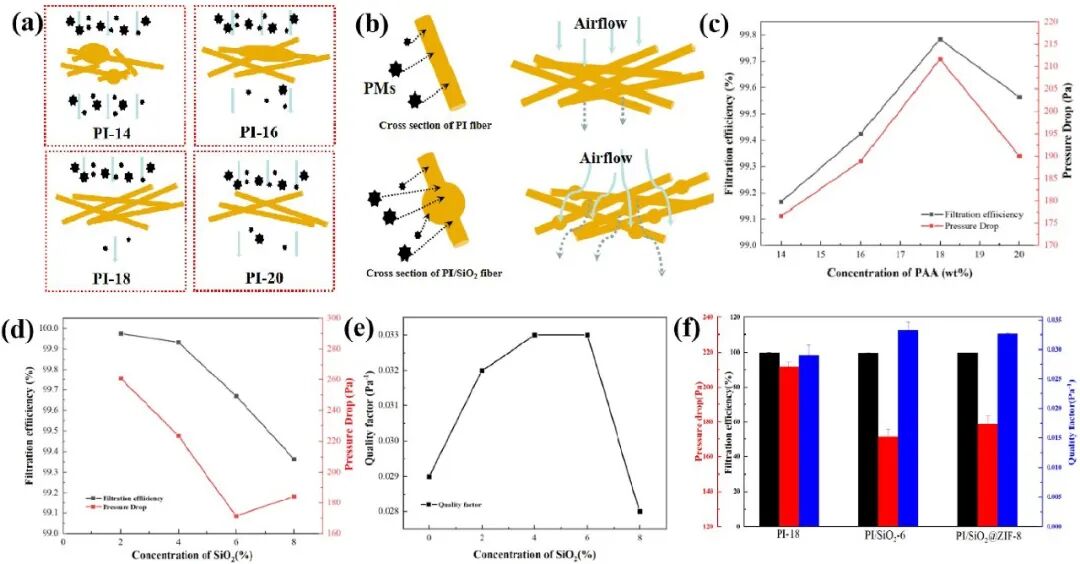

Preparation of PI/SiO₂ nanofiber membrane: SiO₂ nanospheres were mixed with polyamic acid (PAA) solution, and the PI/SiO₂ nanofiber membrane was prepared using electrospinning technology. The specific steps include mixing the PAA solution with varying proportions of SiO₂ nanospheres, electrospinning, and thermal imidization.

Grafting of ZIF-8: NH₂-ZIF-8 powder was first synthesized, and then grafted onto the surface of the PI/SiO₂ nanofiber membrane using a UV initiator, forming the PI/SiO₂@ZIF-8 composite nanofiber membrane.

A series of performance tests were conducted on the prepared nanofiber membrane, including X-ray diffraction (XRD), scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), thermogravimetric analysis (TGA), pore size analysis, and single fiber strength testing to characterize its structure and performance. Additionally, an automatic filter material testing device was used to evaluate air filtration performance, and a self-made experimental setup was used to test formaldehyde adsorption performance.

Key Results

Filtration performance: The filtration efficiency of the PI/SiO₂@ZIF-8 nanofiber membrane reaches 99.703%, with a pressure drop of 178.7 Pa and a quality factor (QF) of 0.0326 Pa⁻¹, demonstrating excellent filtration performance.

Thermal stability: At 250°C, the weight loss rate of the PI/SiO₂@ZIF-8 nanofiber membrane is only 4%, significantly lower than that of traditional materials, indicating good thermal stability.

Mechanical properties: After grafting ZIF-8 using UV light, the tensile strength and elongation at break of the nanofiber membrane increased to 6.44 MPa and 19.5%, respectively, showing good mechanical properties.

Formaldehyde adsorption performance: The PI/SiO₂@ZIF-8 nanofiber membrane achieves a saturated adsorption capacity of 41.58 mg/g for formaldehyde within 4 hours, which is more than 12 times that of the PI/SiO₂ nanofiber membrane without grafted ZIF-8.

Research Conclusion

This study successfully developed a novel PI/SiO2@ZIF-8 composite nanofiber membrane that not only exhibits excellent high-temperature exhaust gas filtration performance but also possesses efficient formaldehyde adsorption capacity. By introducing SiO2 nanospheres and ZIF-8 into PI, the material’s thermal stability, mechanical properties, and filtration efficiency were significantly improved while reducing air filtration resistance. This material provides a new solution for the efficient purification of high-temperature exhaust gases. Future research can further optimize the preparation process of the material, reduce costs, and enhance its stability and durability in complex environments. Additionally, exploring the incorporation of other functional materials into the membrane could enable the adsorption and purification of a wider variety of harmful gases, expanding its application range.

Discussion and Outlook: Further optimization of the preparation process for the PI/SiO2@ZIF-8 nanofiber membrane is needed to reduce costs and improve production efficiency, making it easier for large-scale production and application. Testing in actual industrial waste gas treatment scenarios is necessary to verify the long-term stability and purification effectiveness of the material, providing data support for practical applications.

Full text link:

https://doi.org/10.1016/j.polymer.2024.127974

References:

PI/SiO2@ZIF-8 nanofiber membrane with excellent high temperature exhaust gas filtration performance and efficiently formaldehyde adsorption capacity,

Polymer, Volume 319, 2025, 127974.

END

The information contained in this public account is for learning and communication purposes only, and the views expressed are neutral, without any express or implied guarantee of accuracy, reliability, or completeness. Copyright belongs to the original author or institution. If there are any copyright issues, please contact us in a timely manner, and we will correct or delete it as soon as possible.