Industrial software refers to software specifically designed for or primarily used in the industrial sector, aimed at improving the R&D, manufacturing, production management levels, and performance of industrial equipment. Industrial software is a programmatic encapsulation and reuse of industrial technology and knowledge, representing the pinnacle of industrialization. In practical industrial scenarios, such as metallurgy, petrochemicals, automotive manufacturing, and shipbuilding, people have acquired skills, techniques, and experiences, which have been encapsulated into industrial software through programmatic, algorithmic, and modeling methods. Industrial software can be used to control production equipment, optimize manufacturing and management processes, and improve productivity, serving as the “soul” of modern industry.

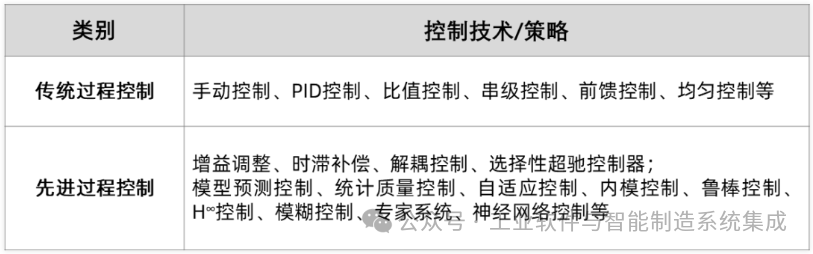

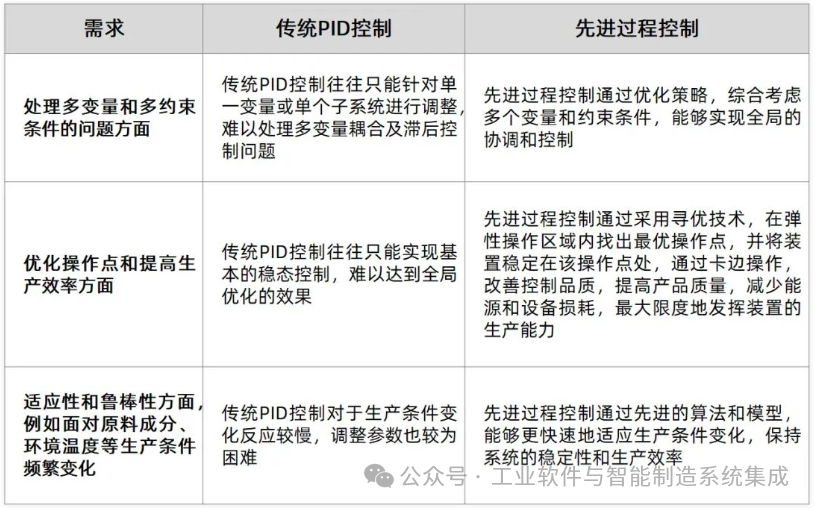

As industrial production processes become larger and more complex, the requirements for product quality, yield, safety, and environmental impact are becoming increasingly stringent. In particular, conventional PID control strategies are inadequate for key process control systems in process industries characterized by complexity, multivariable interactions, time-variance, and MIMO features. Therefore, advanced process control (APC) has garnered widespread attention. The APC system refers to a collection of artificial intelligence control strategies that offer better control quality than conventional PID control. Advanced process control systems are used to address complex industrial process control problems where conventional control methods are ineffective or even impossible. Artificial intelligence, as a cutting-edge technology, extends and enhances human intelligence through bionic algorithms. After decades of development and accumulation, artificial intelligence is transitioning from proprietary AI to general AI, driven by the interdependent and collaborative development of distributed network technologies such as data, intelligent algorithms, and perceptual computing, expanding into “ubiquitous intelligence” applications. Engineering practices have shown that AI systems can creatively and effectively solve complex problems. The high-end industrial process control system engineering platform (DEP-APCEW2.0) is a value-driven technology and system that integrates various AI algorithms and subsystems, relying on a complete industrial data chain, modular intelligent components, an open process system development architecture, and general modules for conventional system integration. This allows users to focus resources on their core business to efficiently build differentiated intelligent process control systems with deep perception, intelligent optimization, and precise control, while effectively transforming cutting-edge R&D achievements into productivity through high-end intelligent measurement and control systems, fostering new sustainable economic growth points for enterprises.

The six mainstream development directions of industrial control systems

Industrial control automation technology is a comprehensive technology that applies control theory, instrumentation, computers, and other information technologies to achieve detection, control, optimization, scheduling, management, and decision-making in industrial production processes, aiming to increase output, improve quality, reduce consumption, and ensure safety. It mainly includes three parts: industrial automation software, hardware, and systems. As one of the most important technologies in modern manufacturing since the 20th century, industrial control automation technology primarily addresses issues of production efficiency and consistency. Although automation systems do not directly create benefits, they significantly enhance the production processes of enterprises.

1. Low-cost industrial control automation based on industrial PCs will become mainstream

Since the 1960s, Western countries have relied on technological advancements (i.e., new equipment, new processes, and computer applications) to transform traditional industries, leading to rapid industrial development. The most significant change at the end of the 20th century was the formation of a global market. The global market has led to unprecedented competition, prompting enterprises to accelerate time-to-market for new products, improve quality, reduce costs, and enhance service systems, which is referred to as T.Q.C.S. for enterprises. Although computer-integrated manufacturing systems (CIMS) combine information integration and system integration to pursue a more complete T.Q.C.S., enabling enterprises to “deliver the right information to the right people at the right time in the right way to make the right decisions,” this automation requires substantial investment, representing a high-investment, high-benefit, and high-risk development model that is difficult for most small and medium-sized enterprises to adopt. In China, small and medium-sized enterprises and quasi-large enterprises are still following the path of low-cost industrial control automation.

Industrial control automation mainly consists of three levels: basic automation, process automation, and management automation, with the core being basic automation and process automation.Traditional automation systems have been largely monopolized by PLCs and DCSs in the basic automation part, while the process automation and management automation parts are mainly composed of various process computers or minicomputers, whose high prices for hardware, system software, and application software deter many enterprises.Since the 1990s, with the development of PC-based industrial computers (referred to as industrial PCs), PC-based automation systems composed of industrial PCs, I/O devices, monitoring devices, and control networks have rapidly gained popularity, becoming an important means to achieve low-cost industrial automation. Many steel companies have upgraded their equipment by removing original DCS or single-loop digital controllers and replacing them with industrial PCs to form control systems, employing fuzzy control algorithms to achieve good results.Since PC-based controllers have proven to be as reliable as PLCs and are accepted by operators and maintenance personnel, PC-based control systems are easy to install and use, have advanced diagnostic functions, and provide system integrators with more flexible options. From a long-term perspective, the maintenance costs of PC control systems are low.In recent years, industrial PCs have developed exceptionally rapidly in China. Globally, industrial PCs mainly include two types: IPC industrial computers and CompactPCI industrial computers, along with their variants, such as AT96 bus industrial computers. Due to the high stability, hot-swappability, and redundancy requirements of basic automation and process automation for industrial PCs, existing IPCs can no longer fully meet these requirements and will gradually exit this field, to be replaced by CompactPCI-based industrial computers, while IPCs will occupy the management automation layer.

2. PLCs are developing towards miniaturization, networking, PC-based systems, and openness

For a long time, PLCs have been the main battlefield in the field of industrial control automation, providing very reliable control solutions for various automation control devices, forming a tripartite balance with DCS and industrial PCs. At the same time, PLCs are also facing challenges from other technological products, especially from industrial PCs.

Currently, there are about 200 PLC manufacturers worldwide, producing over 300 types of products. The domestic PLC market is still dominated by foreign products, such as Siemens, Modicon, A-B, OMRON, Mitsubishi, and GE. After years of development, domestic PLC manufacturers have also applied their products in various industries.

Miniaturization, networking, PC-based systems, and openness are the main directions for the future development of PLCs/PACs.

Currently, one of the biggest trends in the field of process control is the expansion of Ethernet technology, and PLCs are no exception. More and more PLC suppliers are beginning to offer Ethernet interfaces. It is believed that PLCs will continue to shift towards open control systems, especially those based on industrial PCs. The distributed control system (DCS) was introduced in 1975, with manufacturers mainly concentrated in the US, Japan, and Germany. In China, DCS was first introduced in the late 1970s through large imported equipment sets, with the first batch including projects in synthetic fibers, ethylene, and fertilizers. At that time, DCS in major industries in China (such as power, petrochemicals, building materials, and metallurgy) was almost entirely imported. Initially, while introducing, digesting, and absorbing foreign technology, efforts began to develop domestic DCS technology.

According to survey data published by the China Instrument and Control Society, the current state of the DCS market in China is as follows:Miniaturization, diversification, PC-based systems, and openness are the main directions for the future development of DCS. Currently, the market share of small DCS has gradually begun to overlap with PLCs, industrial PCs, and FCSs. In the future, small DCS may first integrate with these three systems, and “soft DCS” technology will first develop in small DCS. PC-based control will be more widely applied in small to medium-scale process control, and various DCS manufacturers will successively launch small DCS systems based on industrial PCs. Open DCS systems will extend both upwards and downwards, allowing field data from production processes to flow freely within the enterprise, achieving seamless integration of information technology and control technology, and moving towards integrated measurement and control management.

3. Control systems are developing towards Fieldbus Control Systems (FCS)

Due to the development of 3C technology, process control systems will evolve from DCS to FCS.FCS can completely decentralize PID control to field devices (Field Devices). Fieldbus-based FCS represents a new generation of production process automation systems that are fully decentralized, fully digital, fully open, and interoperable, which will revolutionize the traditional industrial automation control system architecture that relies on one-to-one 4(20mA analog signal lines.According to IEC61158, a fieldbus is a digital, bidirectional transmission, multi-branch structure communication network installed between field devices in the manufacturing or process area and automatic control devices in the control room. Fieldbus enables measurement and control devices to possess digital computing and digital communication capabilities, improving the accuracy of signal measurement, transmission, and control, as well as enhancing the functionality and performance of systems and devices.

Currently, in the competition among various fieldbus technologies, Ethernet-based COTS (Commercial-Off-The-Shelf) communication technology is becoming a new highlight in the development of fieldbus. The focus is mainly on two aspects:

(1) Whether a unified global fieldbus standard can emerge;

(2) Whether fieldbus systems can completely replace the currently popular DCS systems.

Using fieldbus technology to construct low-cost fieldbus control systems promotes the intelligence of field instruments, decentralization of control functions, and openness of control systems, aligning with the technological development trends of industrial control systems. The development of computer control systems has evolved through base pneumatic instrument control systems, electric unit modular analog instrument control systems, centralized digital control systems, and distributed control systems (DCS), and will now move towards fieldbus control systems (FCS). Although FCS based on fieldbus is developing rapidly, there is still much work to be done, such as unifying standards and instrument intelligence. Additionally, the maintenance and modification of traditional control systems still require DCS, so FCS will take a long time to completely replace traditional DCS, while DCS itself is also continuously developing and improving. It is certain that FCS, combined with new technologies such as DCS, industrial Ethernet, and advanced control, will possess strong vitality. Industrial Ethernet and fieldbus technology, as flexible, convenient, and reliable data transmission methods, are increasingly being applied in industrial sites and will occupy a more important position in the control field.

4. Data communication systems are developing towards openness, network narrowband, and polymorphism

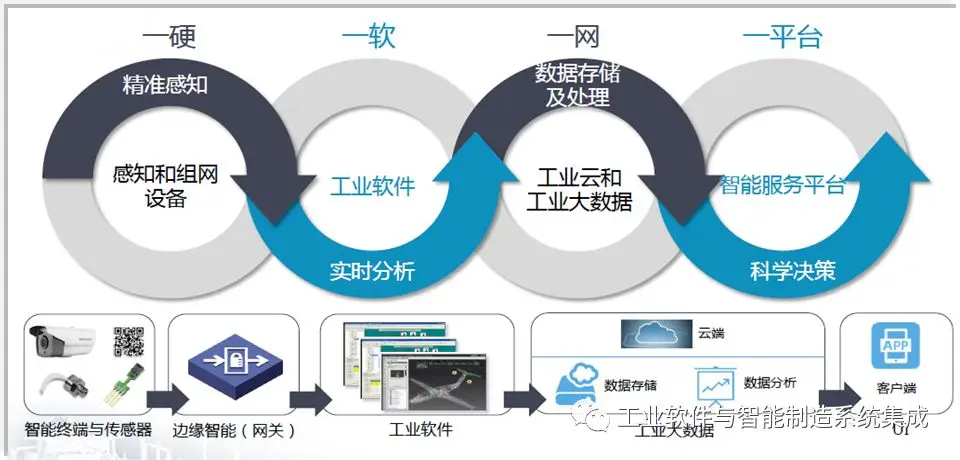

High-end manufacturing relies on data. Data is an emerging resource and production factor across various industries. For manufacturing, data is as essential as water, electricity, and roads, and its application is limited only by imagination. With the development and integration of information technology, the Internet, the Internet of Things, and advanced manufacturing technologies, the world is nurturing a new industrial revolution. Although there are different interpretations and phases, the trend towards digitization and intelligence is consistent. In modern manufacturing, research systems, aerospace, military measurement and control communication, urban life, and many other fields, data is converging to present characteristics of “NVDIA”: Networked (Network), massive data volume (Volume), polymorphism (Variety), rapidity (Velocity), value (Value), distributed (Distributed), address configuration (IP address configuration), and accurate time-base signals (Accurate time-base-signal). This imposes extremely stringent data communication quality requirements on manufacturing enterprises and process system integration. How to achieve unified system digitization of polymorphic data from different types of sensors, anti-interference, precise timing, multi-level system precision synchronization, narrowband high-speed transmission, and perceptual computing; constructing a high-end data communication system compatible with the next generation of “data not falling to the ground” distributed real-time network perception measurement and control systems has become a key common foundational issue that must be addressed for the deep transformation and upgrading of manufacturing, making it a compulsory course rather than an elective one!

High-end precision autonomous controllable data communication systems are the “C4ISR” systems of manufacturing, providing foundational data communication services for the entire manufacturing process. The complete autonomous distributed, digital, modular, and networked general distributed high-end industrial data acquisition and network communication software system DADCS (Distributed Digital Advanced Data Communication System) and secure high-speed industrial basic networks and computer hardware systems together form the neural center of manufacturing,realizing command, control, communication, computer, information, monitoring, and reconnaissance in a unified manufacturing enterprise multi-modal perception and distributed network duplex high-speed data communication.“Industrial General Distributed Network Duplex Precision Time-Frequency Polymorphic Data Integration Communication System” serves as a general data chain system for manufacturing enterprises to construct distributed, networked, intelligent, flexible, and collaborative production systems, with specific functions as follows::

Interconnected perception:A single network cable carries different types of polymorphic data, tightly connecting devices, production lines, factories, suppliers, products, and customers..

Data-driven:Data becomes the production resource of enterprises. Products, equipment, R&D, industrial chains, operations, management, sales, and consumers are all driven by data..

System integration:Integrating distributed sensors, embedded terminal systems, intelligent control systems, and communication facilities through industrial ICT software and secure networks forms an intelligent perception system. This enables full interconnectivity between people, machines, and services, achieving high levels of horizontal, vertical, and end-to-end integration..

Digital manufacturing:High-quality industrial data flows support complex process modeling, production process network collaboration, and manufacturing forms that balance large-scale production with networked collaborative manufacturing, making production processes more flexible, personalized, and customized.

5. Industrial control networks will evolve into digital factories combining wired and wireless technologies

Since the first civilian network system ARCnet was put into operation in 1977, wired local area networks have achieved success and rapid development due to their wide applicability and technological cost advantages. However, in industrial sites, some environments prohibit or restrict the use of cables or make it difficult to use cables, making it challenging for wired local area networks to function effectively. As a result, wireless local area network technology has developed and been applied. With the continuous advancement of microelectronics technology, wireless local area network technology will play an increasingly significant role in industrial control networks.

Wireless LAN technology can conveniently connect network devices wirelessly, allowing people to access network resources anytime and anywhere. It is an important direction for the development of modern data communication systems. Wireless LAN can provide Ethernet interconnectivity without using network cables. While promoting the development of network technology, wireless LAN is also changing people’s lifestyles. Wireless communication protocols typically use IEEE802.3 and 802.11. 802.3 is used for point-to-point connections, while 802.11 is used for point-to-multipoint connections. Wireless LAN can be implemented on ordinary local area networks through wireless hubs, wireless access points (APs), wireless bridges, wireless modems, and wireless network cards, with wireless network cards being the most common. The future research directions for wireless LAN mainly focus on security, mobility, network management, and the relationship with other mobile communication systems such as 5G.

In the field of industrial automation, there are thousands of devices such as sensors, detectors, computers, PLCs, and card readers that need to be interconnected to form a control network. Typically, the communication interfaces provided by these devices are RS-232 or RS-485. Wireless LAN devices use isolated signal converters to convert the RS-232 serial signals of industrial devices into wireless LAN and Ethernet signals, complying with the IEEE802.11b wireless LAN and IEEE802.3 Ethernet standards, supporting standard TCP/IP network communication protocols, effectively expanding the networking communication capabilities of industrial devices.

The combination of computer network technology, wireless technology, and intelligent sensor technology has given rise to the new concept of “networked intelligent sensors based on wireless technology.” This type of networked intelligent sensor based on wireless technology allows data from the industrial site to be transmitted, published, and shared directly over the network via wireless links. Wireless LAN technology can provide high-bandwidth wireless data links and flexible network topologies for various intelligent field devices, mobile robots, and automation equipment in factory environments, effectively compensating for the shortcomings of wired networks in certain special environments, further enhancing the communication performance of industrial control networks.

6. Industrial control software is developing towards advanced control

Since its inception in the early 1980s, industrial control software has undergone 20 years of development. As an application software, industrial control software has continuously evolved alongside the rise of PCs. Industrial control software mainly includes human-machine interface software (HMI), PC-based control software, and production management software. Currently, China has developed a batch of real-time monitoring software platforms, advanced control software, process optimization control software, and other complete application software with independent intellectual property rights, achieving certain breakthroughs in engineering and productization, breaking the monopoly of similar application software abroad. Through applications in hundreds of enterprises (installations) in industries such as chemicals, petrochemicals, and papermaking, it has promoted technological transformation in enterprises, improved production process control levels and product quality, and created significant economic benefits for enterprises.

The Importance of High-End Industrial Process Control Systems for Manufacturing

The large-scale and complex nature of modern industrial production processes has led to increasingly stringent requirements for product quality, yield, safety, and environmental impact. Many complex, multivariable, time-varying key variable controls cannot be adequately addressed by conventional PID strategies, leading to widespread attention on advanced process control. The advanced process control (APC) measurement and control system refers to a collection of control strategies that differ from conventional algorithms and offer better control effects than conventional PID control. Advanced control systems are used to address complex industrial process control problems where conventional control methods are ineffective.

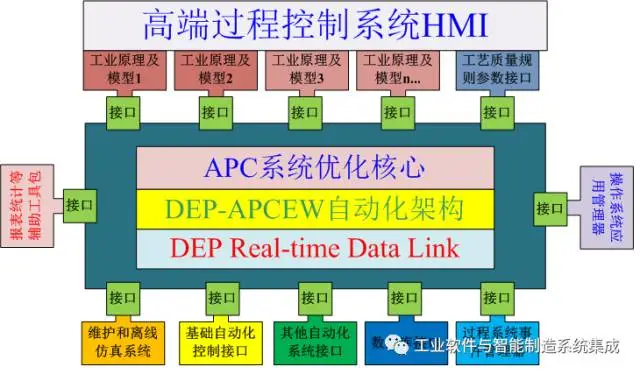

The high-end process control system engineering platform applies mature and stable industrial general ICT systems at the bottom layer, based on a networked DEP-CPS architecture, compatible with third-party systems, and seamlessly integrates into existing automation and information systems. It completes real-time duplex data communication between the APC model system and PLC/PAC/L1 system sensors and enterprise information systems; fully revitalizes the existing automation equipment and information automation system resources of enterprises; and minimizes the cost and time pressure of enterprise production line transformation and upgrading.

Value advantages of the APC system platform:

1. The industrial process control engineering platform provides convenient application development interfaces and maintenance debugging tools, effectively shortening project development cycles, reducing resource investment and technical costs, and lowering system implementation and maintenance costs.

2. The compatibility of the industrial process control engineering platform with heterogeneous systems can enhance the portability of process control application systems, improve system scalability, facilitate user upgrades and modifications to process control application systems, and reduce subsequent maintenance development costs.

3. The technical framework and general services provided by the industrial process control engineering platform can improve the stability of process control systems, reduce delivery costs, and enhance end-user satisfaction.

4. The industrial process control engineering platform adopts a standard Client/Server structure, complete industrial data chain, and open process system development architecture, allowing users to focus resources on their core business. It drives traditional automation systems to evolve into intelligent systems.

The high-end process control system platform based on computer control and simulation technology serves as a carrier and engineering implementation platform for industrial intelligence.

Figure 2: High-end process control system engineering platform for smart factories

Figure 2: High-end process control system engineering platform for smart factories

Industrial process control system software serves as the intelligent control core of industrial manufacturing systems, controlling the core process of manufacturing to a certain extent. It determines the level of intelligence in manufacturing processes. With the development and transformation needs of the manufacturing industry itself, industrial process control system software is evolving from human-machine interfaces and basic strategy configurations towards advanced process control. Advanced process control (APC) refers to control algorithms based on mathematical models that must be implemented using computers, collectively referred to as advanced process control strategies, such as adaptive control, predictive control, robust control, and intelligent control (expert systems, fuzzy control, neural networks). Currently, dozens of companies worldwide have launched hundreds of advanced process control system products, forming a strong industrial process application software industry globally. The APC system consists of advanced process control models and high-end communication systems (real-time data communication systems), with strict monopolization of real-time communication data chains and industry APC models abroad. Therefore, having industry-specific advanced process control models and supporting high-end integrated basic data communication with independent intellectual property rights is of great significance for enhancing the independent innovation capabilities of the industrial sector, improving the intelligence level of the industry, stabilizing the high-quality product ratio, and cultivating the core market competitiveness of enterprises.

The high-end industrial process control system engineering platform is a complex general industrial process control system engineering platform that deeply integrates electronics, control engineering, relevant industrial process principles, and computer measurement and control technology. It integrates relevant industrial process technologies, modern measurement and control technologies, and industrial process-related hardware, developing into a highly integrated industrial application system through mathematical methods and programming techniques. The open architecture of APCEW enables dynamic intelligent control of different industrial process technologies under industrial production conditions. It lays a solid engineering foundation for researchers in different industrial process technologies to study process improvements and new product development.

1. Industries applying APC measurement and control systems

Currently, APC has been successfully applied in multiple process industries in China, covering dozens of typical process production installations in refining, petrochemicals, chemicals, raw pharmaceuticals, metallurgy, and thermal power.

Refining industry: Atmospheric and vacuum distillation units, catalytic cracking units, continuous reforming units, hydrocracking units, hydrofining units, delayed coking units, gas fractionation units.

Petrochemical industry: Ethylene units, aromatics complex units, aromatics extraction units, alkylbenzene units, molecular sieve dewaxing, styrene units, PTA units, polypropylene units, polyethylene units.

Chemical industry: Soda ash units, caustic soda units, ammonia synthesis units, fluorochemical units, calcium carbide furnace units, organosilicon units, polysilicon units, methanol units, sulfuric/phosphoric acid units.

Other industries: Boilers, air separation units, hard alloy reaction processes, gas mixing processes, etc.

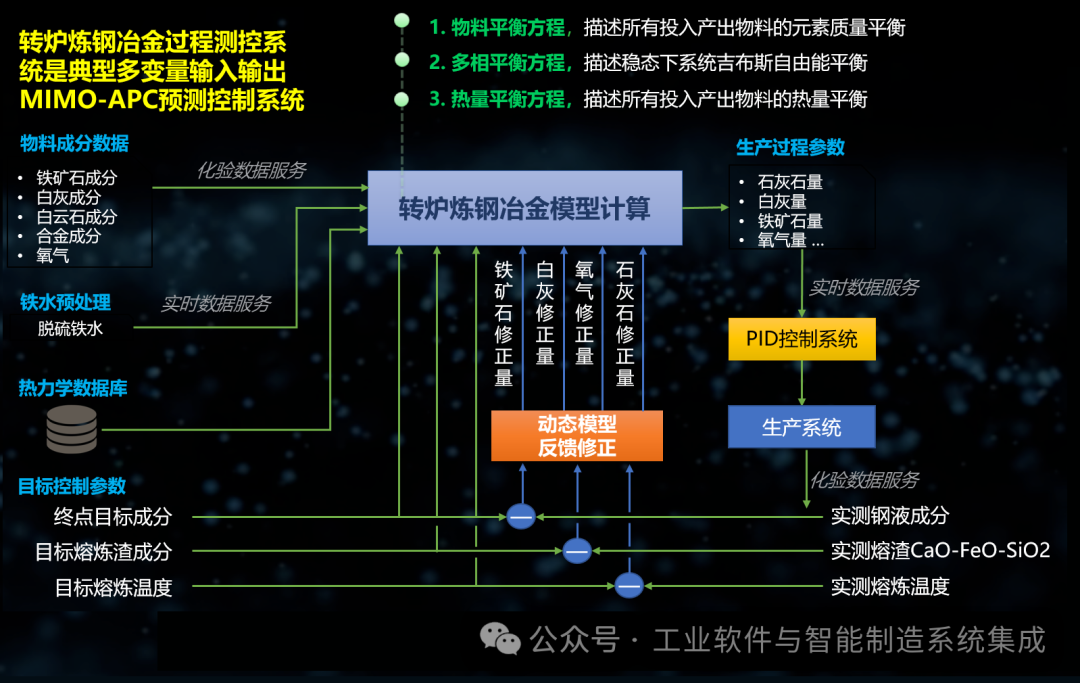

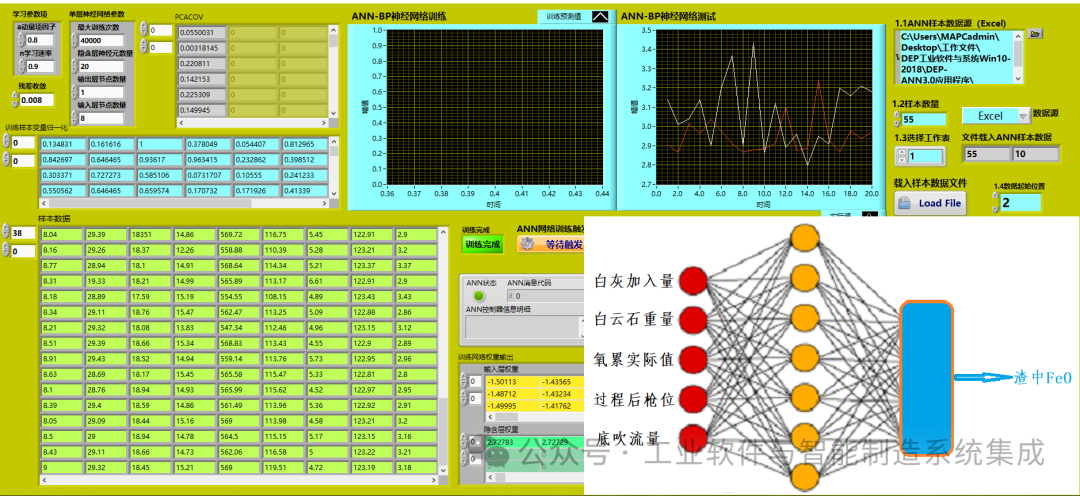

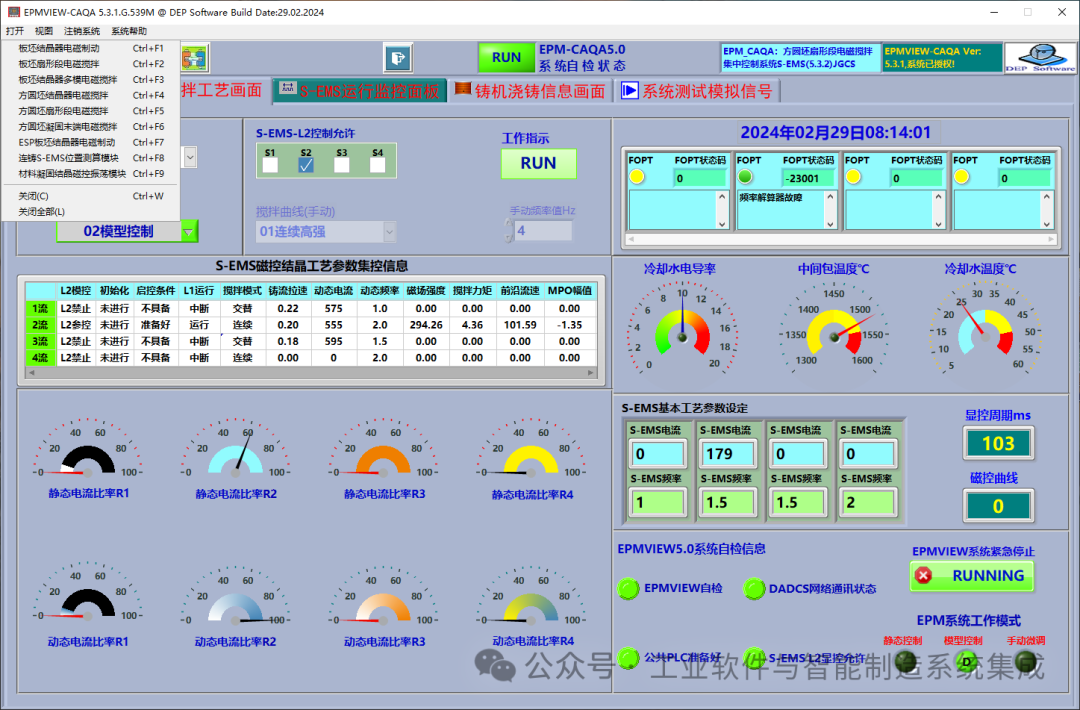

2. Case studies of APC measurement and control systems in various industriesThe application of advanced control systems can improve the performance of dynamic process control, reduce the fluctuation range of process variables, enabling them to approach their optimized target values and push production installations to operate closer to their constraint boundary conditions,ultimately enhancing the stability and safety of installations, ensuring the uniformity of product quality, improving target product yield, increasing processing capacity, reducing operating costs, and minimizing environmental pollution.In the petrochemical industry, China Petroleum & Chemical Corporation’s Zhenhai Refining & Chemical Company developed cracking furnace depth control and real-time optimization software (APC+RTO). RTO automatically calculates optimization values based on changes in raw material quality, cracking furnace operating cycles, and pricing systems, while APC automatically executes adjustments, saving over 7,190 tons of standard coal annually without changing the total feed load of the installation; China National Petroleum Corporation’s Dushanzi Petrochemical Company developed an APC advanced control and RTO real-time optimization system for ethylene units,resulting in more timely and accurate cracking depth adjustments, with ethylene and propylene yields increasing by 0.2% and 0.1%, respectively.In the coal chemical industry, Shenhua Baotou Coal Chemical Company introduced the APC system in polyethylene and polypropylene units, applying it to reactor automatic control, circulating gas component control, product performance calculation, and yield control in key production units, significantly improving the automation level of process production control,and achieving improvements in polymerization reaction conversion rates, product quality, and yield.In the metallurgy industry, Ansteel Bayuquan Company applied an automated steelmaking process control system in three converters, achieving automation of oxygen lance process control, charging automation, sub-lance automation, and “one-click” steelmaking, realizing precise perception of initial conditions for converter smelting, stabilizing the smelting process control, and achieving a carbon temperature hit rate of 90.4%,stably controlling and minimizing the final steel liquid oxygen content, thereby improving the initial steel liquid quality.In the thermal power industry,Zhejiang Juhua Thermal Power Co., Ltd. optimized the boiler control of its #8 unit.After the APC transformation was put into operation, the fan automatically adjusted, reducing the electrical consumption of the boiler fan, while the main steam pressure and temperature of the boiler became more stable, with significantly reduced fluctuation ranges, improving the safety and economic operation level of the boiler, and increasing boiler efficiency by 0.3 percentage points.

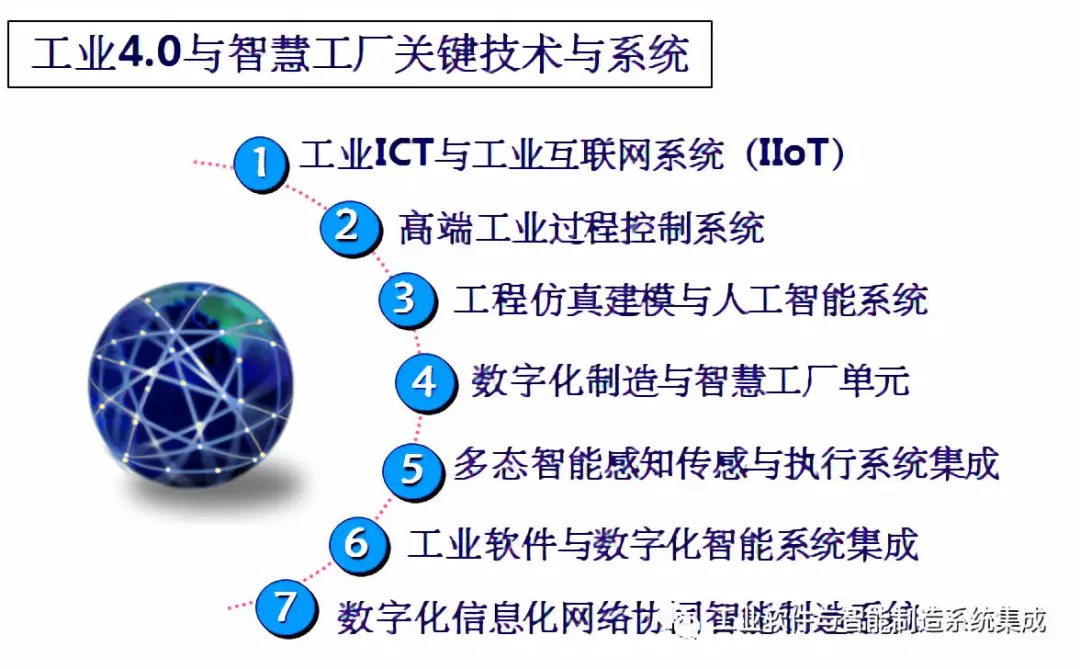

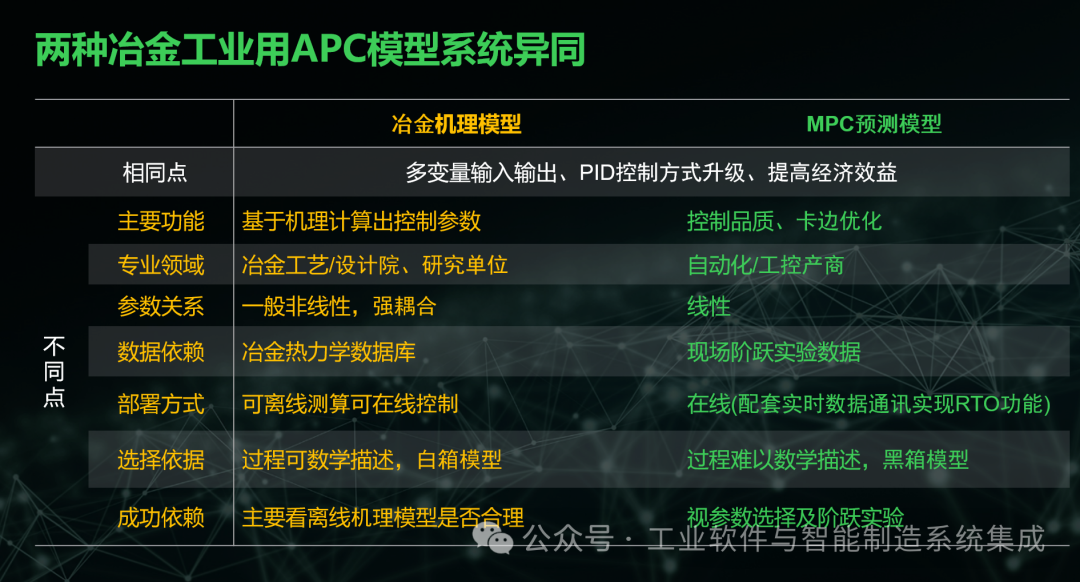

3. Challenges in deploying APC measurement and control systemsCompared to traditional PID control, advanced process control indeed has significant advantages and can create immense value, making it worthy of promotion and application. However,it is also important to note that the application difficulty of APC is considerable. First, in the typical ERP/MES/PCS three-layer structure, APC is classified as part of the PCS layer along with DCS/PLC, regarded as a system at the production control level, which will conduct real-time data communication with lower-level control systems such as DCS/PLC, primarily facing the challenge of real-time duplex measurement and control communication; secondly, the APC system also involves in-depth industry process principles, mechanism modeling, testing simulation, and program encapsulation, requiring a deep understanding of the physical and chemical principles of industrial processes and the relationships between various operating variables, which demands high levels of professional knowledge and practical experience from personnel. Moreover, the effective operation of APC heavily relies on models, but industrial processes often exhibit numerous uncertainties, non-linearities, multivariable couplings, and significant lags, making it very challenging to establish accurate and reliable dynamic models.Additionally, the performance of controller models may change due to environmental variations, equipment performance degradation, and other factors, necessitating continuous adjustments and refinements of model parameters. Considering all these factors, the application and maintenance of APC face significant challenges.Currently, China’s manufacturing industry needs to further address issues such as high energy consumption, large resource consumption, low product added value, and serious environmental pollution during its development. The goal and role of APC are to optimize the stability and accuracy of process control systems, improve product quality and production efficiency, reduce energy consumption and costs,and significantly empower enterprises to achieve efficient and green manufacturing processes.Looking to the future, for future industrial manufacturing, a wide range of process workers will form an inseparable bond with APC systems, fully utilizing industry-specific APC systems to create immense value for enterprises. Now is an opportune time for process industry workers in metallurgy, petrochemicals, and cement to correctly recognize the importance of process control systems for self-initiated work, and enterprises with conditions can even develop their own industry-specific APC process control systems with independent intellectual property rights.Taking the steel industry as an example: the steel industry is an important foundational industry for the national economy,and steel products are a crucial material support for building a modern strong country.Enhancing the physical quality and stability of conventional steel grades, developing and mass-producing high-end steel grades, and continuously optimizing the research and development of metallurgical processes and materials are fundamental. Metallurgical process models and industrial software systems are their carriers. Excellent metallurgical processes cannot remain confined to laboratories; achieving deep integration of metallurgical process digitization and modeling is essential; applying excellent metallurgical process principles to steel material production to achieve online metallurgical process narrow window and product quality stability control; realizing real-time optimization of process and product quality from the root to avoid many product defects is the pinnacle of metallurgical processes, a watershed for product grades and levels, and a gathering place for high-end composite talents in steel intelligent manufacturing. Metallurgical process models and their industrial software systems are the high ground of steel intelligent manufacturing, but they remain a blind spot for many steel enterprises. Building their own metallurgical model systems can not only cultivate and unleash new quality productivity for their units but also have far-reaching significance.Future visions of “adaptive autonomous control systems” and “process automation similar to autonomous driving” can be anticipated. It is expected that industrial process control systems will become more intelligent, capable of addressing increasingly complex and variable process control challenges, and through the integration of emerging technologies such as artificial intelligence, they will possess stronger autonomous learning and adaptive capabilities, achieving higher levels of intelligent decision-making and adaptive operation in process control.4. Development directions of APCVigorously developing industrial automation and high-end industrial process intelligent control systems is an effective means to accelerate the transformation and upgrading of traditional industries, improve the overall quality of enterprises, enhance the overall national strength, adjust industrial structures, and rapidly invigorate large and medium-sized enterprises. The state will continue to implement a series of high-tech industrialization projects for industrial process automation, using information technology to drive industrialization, promote further development of industrial automation technology, strengthen technological innovation, achieve industrialization, and address the deep-seated issues facing national economic development,achieving innovative development and further improving the overall quality and comprehensive strength of the national economy. Advanced process control (APC) is a class of advanced control strategies and technologies based on mathematical models, involving the collection and analysis of operational data, identification and establishment of industrial operation models, and optimization of control strategies and algorithms. From a technical perspective, the integration and development trend of APC with new generation information technologies such as artificial intelligence and industrial big data is becoming increasingly significant, and the introduction of new technologies also provides new ideas and methods for the development of APC technology. For example, AI can be used to identify complex behaviors of systems, assist in discovering hidden patterns and correlations in production processes, and design and optimize controllers; reinforcement learning can be applied to optimize parameters of control systems, enhancing the performance of intelligent control algorithms. Leveraging industrial big data technology can provide rich historical and real-time data, using data analysis to assist knowledge mining, helping APC more accurately describe the dynamic characteristics and constraints of systems, thereby designing more effective controllers. The high-end industrial process control system engineering platform (DEP-APCEW) is the carrier for the deployment of the next generation of industrial intelligent models and control software applications. The platform integrates advanced sensors, controllers, simulation modeling, and polymorphic real-time communication technologies into industrial intelligent manufacturing systems; rich advanced mathematical function modules are used to construct numerous high-end complex key control models for different industries, integrating into high-end industrial process control systems through the DEP-APCEW2.0 architecture platform; the platform’s openness allows experts, scholars, and engineering technicians from different industries and fields to work in parallel on the same platform, fully leveraging their significant advantages. It transforms digital and intelligent manufacturing technologies, new principles, and new processes from laboratory principles and theoretical R&D results into high-end intelligent control systems for online application deployment in industrial manufacturing processes and production lines. The basic generalized platform + user application system’s efficient modular system integration model will transform digital and intelligent manufacturing technologies, new principles, and new processes from laboratory principles and theoretical R&D results into high-end intelligent control systems for online application deployment in industrial manufacturing processes and production lines.

Enterprises adopting intelligent new technology systems based on the DEP-APCEW platform to transform and upgrade traditional production line automation systems will deeply integrate excellent production process R&D achievements and measurement and control systems to improve production efficiency, reduce energy consumption, and stabilize high-quality product ratios, with R&D achievements directly transforming into enterprise productivity; applying intelligent control model design and upgrading onboard controller systems based on the DEP-APCEW platform will endow onboard control systems with highly intelligent “brains,” significantly improving response speed, measurement and control system accuracy, and control quality. Supporting industrial software and equipment to lead and drive future industrial development, assisting enterprises in occupying advantageous positions in increasingly fierce market competition. Steadily helping the manufacturing level of the respective application industries move towards mid-to-high-end.

Currently, the development of intelligent manufacturing characterized by deep self-perception, intelligent optimization self-decision-making, and precise control self-execution poses new and higher requirements for the integration of process control systems. Intelligent manufacturing in process industries urgently needs a generalized and standardized process control system engineering platform that deeply integrates various artificial intelligence algorithms and subsystems, with multi-disciplinary cross-functional interfaces. The DEP-APCEW2.0 high-end industrial process control system engineering platform is a complex system engineering that deeply integrates electronics, control engineering, complex artificial intelligence algorithms and subsystems, relevant industrial process principles, and computer measurement and control technology, integrating relevant industrial process technologies, modern measurement and control technologies, and industrial process-related hardware, developing into a highly integrated industrial application system that achieves dynamic intelligent control of process technologies under industrial production conditions. It bridges the gap between process industry equipment and production process personnel, macro parameters of processes and micro boundary conditions, providing a platform for process workers to validate new principles and ideas; develop new technologies and processes; and improve product performance and high-end product preparation. It lays a solid engineering foundation for researchers in different industrial process technologies to study process improvements and new product development. The high-end process control system engineering platform APC model achieves real-time duplex data communication with PLC/PAC/L1 system sensors and enterprise information systems through a networked, distributed real-time Ethernet unified system polymorphic industrial general data chain; adopting a standard Client/Server structure, compatible with third-party systems, seamlessly integrating into existing automation and information systems, fully revitalizing the existing automation equipment and information automation system resources of enterprises; facilitating online application deployment and system integration, minimizing the cost and time pressure of enterprise production line transformation and upgrading.

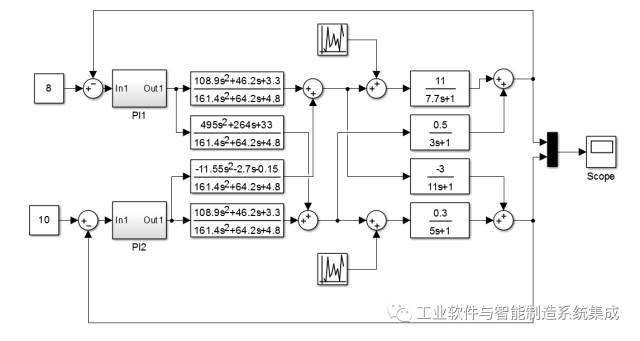

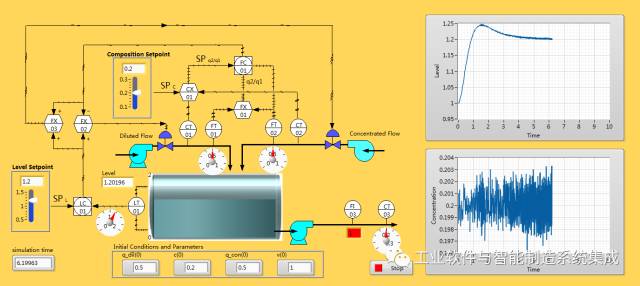

The industry APC system, equipped with knowledge models related to process industries, is an extremely important carrier and implementation pathway for the intelligentization of process industries. Due to the high risks and long R&D testing cycles involved in the development and integration of industry APC systems, an offline simulation system for engineering control systems is particularly necessary. Engineering control system simulation, also known as computer control simulation technology, has penetrated various fields. Heavy precision equipment control requires complex model control technology, necessitating pre-simulation before trial assembly; high value-added products require simulation modeling technology; modern process industry APC process measurement and control systems and high-end equipment’s complex control systems require advanced simulation and control technology. Relying on computer systems and software, specific engineering principles are established through corresponding mathematical transformations to create relevant engineering mechanism models, feeding digital signals to excite, detect, and verify output results to achieve offline simulation research and continuous improvement of engineering and physical problems, as well as various natural problems. The complex engineering principles and artificial intelligence joint simulation modeling engineering platform (hereinafter referred to as DEP-ETSEW) is mainly applied to the core algorithm design, verification, and engineering simulation of intelligent control systems, allowing intelligent control systems to be fully validated in digital space from design to system integration and product finalization, reducing uncertainties from design to production manufacturing, compressing and advancing the manufacturing process in digital space, allowing the manufacturing process to be tested in digital space, thereby improving the success rate and reliability of systems and shortening the time from design to product conversion.

The DEP-ETSEW platform integrates rich advanced mathematical function modules and artificial intelligence subsystems, including tools for modeling, simulating, analyzing, and designing linear time-invariant (LTI) continuous or discrete systems, capable of creating dynamic models of LTI systems (including state-space models, transfer function models, zero-pole-gain models), model transformation functions, model reduction functions, system model connection functions, time-domain response (impulse response, step response) analysis functions, frequency-domain analysis (Bode plots, Nyquist plots, stability margins, Nichols plots) functions, discrete systems, machine vision, mathematical statistics analysis, fuzzy control functions and toolkits, system identification, model predictive control, and many other high-end complex control models for different industries to construct high-end industrial process control systems.

The DEP-ETSEW platform allows experts, scholars, and engineering technicians from different industries and fields to work in parallel on the same platform, fully leveraging their significant advantages. The built-in simulation signal generator can simulate hundreds of waveforms of different frequencies and phases, supporting custom formula waveforms for the simulation and functional testing of engineering principle system prototypes. Through rigorous and comprehensive functional testing, the engineering simulation system can be seamlessly integrated with the high-end industrial process control system platform (DEP-APCEW2.0) for direct use in online control systems, significantly shortening the cycle from R&D to deployment of high-end industrial process control system products.

Typical process industry applications include energy power, petroleum, chemicals, metallurgy, mining, aerospace, gas turbine power, and rail transportation. Process industry enterprises jointly apply intelligent new technology systems based on the DEP-ETSEW2.0 & DEP-APCEW2.0 engineering platform to transform and upgrade traditional production line automation systems, deeply integrating excellent production process R&D achievements and measurement and control systems to improve production efficiency, reduce energy consumption, and stabilize high-quality product ratios, achieving online dynamic real-time optimization and closed-loop control characterized by edge control and narrow window process parameter control, with cutting-edge industrial R&D achievements directly transforming into online enterprise productivity; typical discrete industrial applications include the joint deployment of distributed real-time measurement and control communication systems DADCS, DEP-ETSEW2.0 & DEP-APCEW2.0 engineering platform’s intelligent control model design and upgrading onboard controller systems, endowing onboard control systems with highly intelligent “brains,” significantly improving response speed, measurement and control system accuracy, and control quality. Supporting industrial software and equipment to lead and drive future industrial development, assisting enterprises in occupying advantageous positions in increasingly fierce market competition. Steadily helping the manufacturing level of the respective application industries move towards mid-to-high-end.

Some actual cases of APC systems in the metallurgy industry:

Conclusion

Industrial intelligence refers to the process of collecting, transmitting, processing, and comprehensively utilizing information through information infrastructure during industrial production, management, and operations. The national focus on using information technology to drive industrialization has three main aspects: first, focusing on the application of electronic information technology to improve the automation of production processes, the intelligence of control, and the informatization of management in traditional industries; second, focusing on the application of advanced manufacturing technologies to promote high-quality and efficient production in the manufacturing sector, revitalizing the equipment manufacturing industry; third, upgrading the key technologies, common technologies, and related supporting technology levels, processes, and equipment levels of key industries. The main goals of the national implementation of high-tech industrialization are twofold: first, to develop high technology, form emerging industries, and cultivate new growth points; second, to utilize advanced technologies to transform and optimize traditional industries, cultivating new quality productivity to improve the quality of economic growth.