With the rapid development of the PCB industry, PCBs are gradually moving towards high-precision fine lines, small apertures, and high aspect ratios (6:1-10:1). The copper requirement for holes is 20-25μm, and for boards with DF line spacing ≤ 4 mil, most PCB manufacturers face plating adhesion issues. Adhesion can cause direct short circuits, affecting the first pass yield during AOI inspection, and severe adhesion or multiple points that cannot be repaired can lead to scrapping.

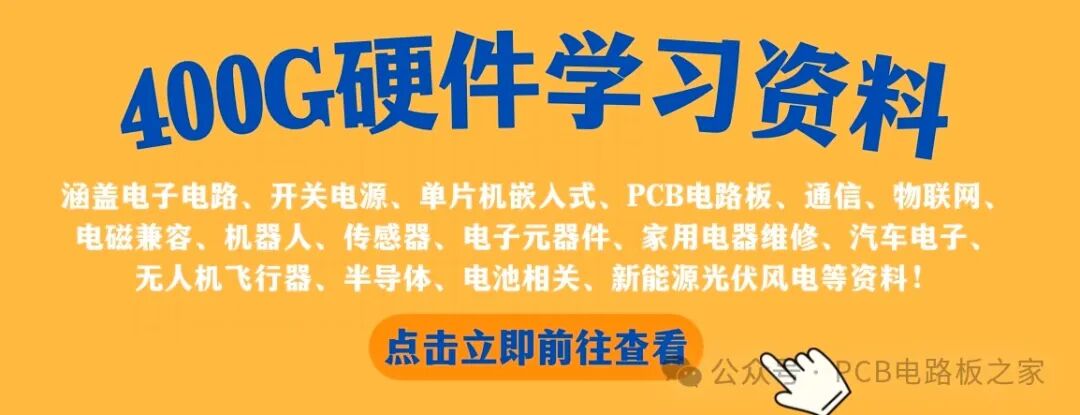

Illustration of Plating Adhesion Issues: Analysis of PCB Plating Adhesion Principles① If the copper thickness of the patterned electroplating line exceeds the dry film thickness, it will cause adhesion. (Generally, the dry film thickness used by PCB factories is 1.4 mil)② If the copper thickness of the patterned electroplating line plus the tin thickness exceeds the dry film thickness, it may cause adhesion.Analysis of Causes of PCB Plating Adhesion

Analysis of PCB Plating Adhesion Principles① If the copper thickness of the patterned electroplating line exceeds the dry film thickness, it will cause adhesion. (Generally, the dry film thickness used by PCB factories is 1.4 mil)② If the copper thickness of the patterned electroplating line plus the tin thickness exceeds the dry film thickness, it may cause adhesion.Analysis of Causes of PCB Plating Adhesion

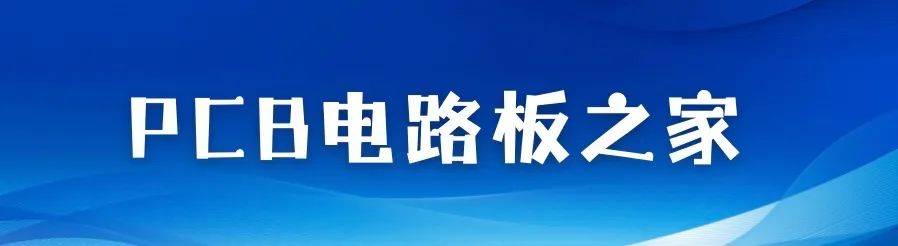

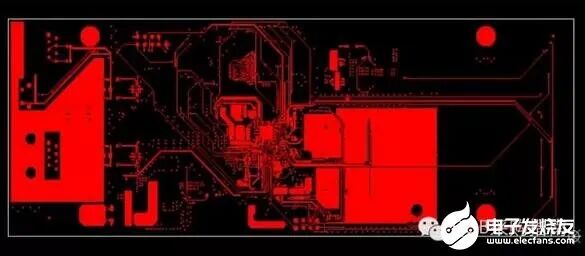

1. Images and Photos of Boards Prone to Adhesion

From the photos of the actual boards in Figures 3 and 4, it can be seen that the lines are relatively dense, and the aspect ratio of the engineering design layout differs significantly, which is not conducive to current distribution. The minimum D/F line gap is 2.8 mil (0.070 mm), the minimum hole is 0.25 mm, board thickness: 2.0 mm, aspect ratio 8:1, and hole copper requirement > 20μm. This is considered a process difficulty board.2. Analysis of Adhesion Causes① High current density in patterned electroplating leads to excessive copper deposition.② The ends of the flying bar are not clamped, leading to thick plating in high current areas causing adhesion.③ The transformer fault causes the actual production board’s set current to be too high.④ C/S and S/S surfaces are reversed.⑤ The spacing is too small; boards with 2.5-3.5 mil spacing are prone to adhesion.⑥ Uneven current distribution; the copper plating tank has not been cleaned for a long time.⑦ Incorrect current settings (wrong model or wrong board area input).⑧ Equipment failure; PCB boards in the copper tank are protected for too long.⑨ Unreasonable engineering layout design; errors in the effective electroplating area provided by engineering.⑩ PCB line gaps are too small; high difficulty boards with special line patterns are prone to adhesion.

From the photos of the actual boards in Figures 3 and 4, it can be seen that the lines are relatively dense, and the aspect ratio of the engineering design layout differs significantly, which is not conducive to current distribution. The minimum D/F line gap is 2.8 mil (0.070 mm), the minimum hole is 0.25 mm, board thickness: 2.0 mm, aspect ratio 8:1, and hole copper requirement > 20μm. This is considered a process difficulty board.2. Analysis of Adhesion Causes① High current density in patterned electroplating leads to excessive copper deposition.② The ends of the flying bar are not clamped, leading to thick plating in high current areas causing adhesion.③ The transformer fault causes the actual production board’s set current to be too high.④ C/S and S/S surfaces are reversed.⑤ The spacing is too small; boards with 2.5-3.5 mil spacing are prone to adhesion.⑥ Uneven current distribution; the copper plating tank has not been cleaned for a long time.⑦ Incorrect current settings (wrong model or wrong board area input).⑧ Equipment failure; PCB boards in the copper tank are protected for too long.⑨ Unreasonable engineering layout design; errors in the effective electroplating area provided by engineering.⑩ PCB line gaps are too small; high difficulty boards with special line patterns are prone to adhesion.

Effective Improvement Solutions for Adhesion

1. Reduce the current density in the patterned electroplating and appropriately extend the copper plating time.

2. Increase the copper thickness of the board appropriately, while reducing the current density in the patterned electroplating to relatively decrease the copper thickness in the pattern.

3. Change the bottom copper thickness from 0.5 OZ to 1/3 OZ. Increase the copper thickness of the board by about 10μm, reduce the current density in the patterned electroplating, and decrease the copper thickness in the pattern.

4. For boards with spacing < 4 mil, purchase 1.8-2.0 mil dry film for trial production.

5. Other solutions such as redesigning layouts, modifying compensation, adjusting line gaps, and reducing hole rings and pads can also relatively reduce the occurrence of adhesion.

Control Methods for Electroplating Production of Boards Prone to Adhesion with Small Gaps

1. FA: First, test a flying bar board with edge clamps at both ends. After ensuring copper thickness, line width/spacing, and impedance are qualified, etch the flying bar board and pass AOI inspection. If adhesion is found, immediately adjust the current and retest FA.

2. Stripping: For boards with D/F line gaps < 4 mil, appropriately slow down the stripping speed during etching.

3. FA Personnel Skills: When the current indication for boards prone to adhesion appears, pay attention to current density assessment. For general boards with minimum line gaps < 3.5 mil (0.088 mm), control the current density in patterned electroplating to ≦ 12 ASF to avoid adhesion. Except for particularly high difficulty line patterns as shown in the following figure:

This patterned board has a minimum D/F gap of 2.5 mil (0.063 mm). Even under good uniformity conditions in the electroplating line of general manufacturers, it is still difficult to escape the fate of adhesion. It is recommended to use ≦ 10 ASF current density for testing FA.

This patterned board has a minimum D/F gap of 2.5 mil (0.063 mm), with many independent lines and uneven distribution. Even under good uniformity conditions in the electroplating line of general manufacturers, it is still difficult to escape the fate of adhesion. The current density for copper plating in patterned electroplating was 14.5 ASF for 65 minutes, resulting in adhesion. It is recommended to use ≦ 11 ASF current density for testing FA.Personal Insights and SummaryBased on my years of experience in PCB processing, almost every PCB factory faces adhesion issues when producing boards with small line widths and gaps, with the difference being the varying proportions of adhesion defects among different companies. The following factors are analyzed:1. Each company’s PCB structure types are different, leading to varying difficulties in PCB manufacturing processes.2. Each company’s management models and practices differ.3. From my years of accumulated experience, for boards with small gaps, it is crucial to use only low current densities and appropriately extend copper plating times. The current indications should be assessed based on experience to determine suitable current densities and plating times, paying attention to clamping methods and operational procedures. For boards with minimum line spacing ≤ 4 mil, the flying bar board must pass AOI inspection for adhesion issues, which also serves as a quality control and preventive measure, thus significantly reducing the likelihood of adhesion during mass production.I believe that ensuring PCB quality requires not only experience and skills but also effective methods. Additionally, it depends on the execution strength of the production department personnel.Patterned electroplating differs from whole board electroplating, primarily in that it involves electroplating various models of board line patterns. Some boards have uneven line distributions, in addition to fine line widths and spacings, there are sparse lines, isolated lines, and various special line patterns. Therefore, I prefer to use FA (current indication) skills to solve or prevent excessive plating adhesion issues. Small improvement actions yield quick results and have a significant preventive effect.

This patterned board has a minimum D/F gap of 2.5 mil (0.063 mm), with many independent lines and uneven distribution. Even under good uniformity conditions in the electroplating line of general manufacturers, it is still difficult to escape the fate of adhesion. The current density for copper plating in patterned electroplating was 14.5 ASF for 65 minutes, resulting in adhesion. It is recommended to use ≦ 11 ASF current density for testing FA.Personal Insights and SummaryBased on my years of experience in PCB processing, almost every PCB factory faces adhesion issues when producing boards with small line widths and gaps, with the difference being the varying proportions of adhesion defects among different companies. The following factors are analyzed:1. Each company’s PCB structure types are different, leading to varying difficulties in PCB manufacturing processes.2. Each company’s management models and practices differ.3. From my years of accumulated experience, for boards with small gaps, it is crucial to use only low current densities and appropriately extend copper plating times. The current indications should be assessed based on experience to determine suitable current densities and plating times, paying attention to clamping methods and operational procedures. For boards with minimum line spacing ≤ 4 mil, the flying bar board must pass AOI inspection for adhesion issues, which also serves as a quality control and preventive measure, thus significantly reducing the likelihood of adhesion during mass production.I believe that ensuring PCB quality requires not only experience and skills but also effective methods. Additionally, it depends on the execution strength of the production department personnel.Patterned electroplating differs from whole board electroplating, primarily in that it involves electroplating various models of board line patterns. Some boards have uneven line distributions, in addition to fine line widths and spacings, there are sparse lines, isolated lines, and various special line patterns. Therefore, I prefer to use FA (current indication) skills to solve or prevent excessive plating adhesion issues. Small improvement actions yield quick results and have a significant preventive effect.

Some Screenshots of Electronic Books

【Complete Set of Hardware Learning Materials Collection】