The Metal 3D Printing Shoe Mold Market Explosion: How LianTai Technology’s Fuees430 is Disrupting a $3.6 Billion Sector?

The shoe mold 3D printing market is approaching 10 billion, with LianTai Technology launching the mass production-grade 3D printer Fuees430.

According to relevant reports, the global market size for metal 3D printed shoe molds reached $1.14 billion in 2023, and is expected to grow to $3.66 billion by 2030, with a compound annual growth rate of 21.47%. Currently, this technology has been widely applied in various product categories including popcorn shoe molds, EVA shoe molds, IP shoe molds, and RB shoe molds, covering mainstream shoe types such as sports shoes, trendy shoes, and children’s shoes.

The traditional shoe mold process is complex, requiring at least eight steps including design, CAD modeling, wooden molds, silicone molds, plaster molds, metal molds, and engraving, which not only results in long cycles and high labor intensity but is also limited by mold precision and processing efficiency. However, with the adoption of metal 3D printing technology, physical shoe molds can be directly formed based on digital models, significantly improving production efficiency and flexibility by eliminating lengthy mold-making processes.

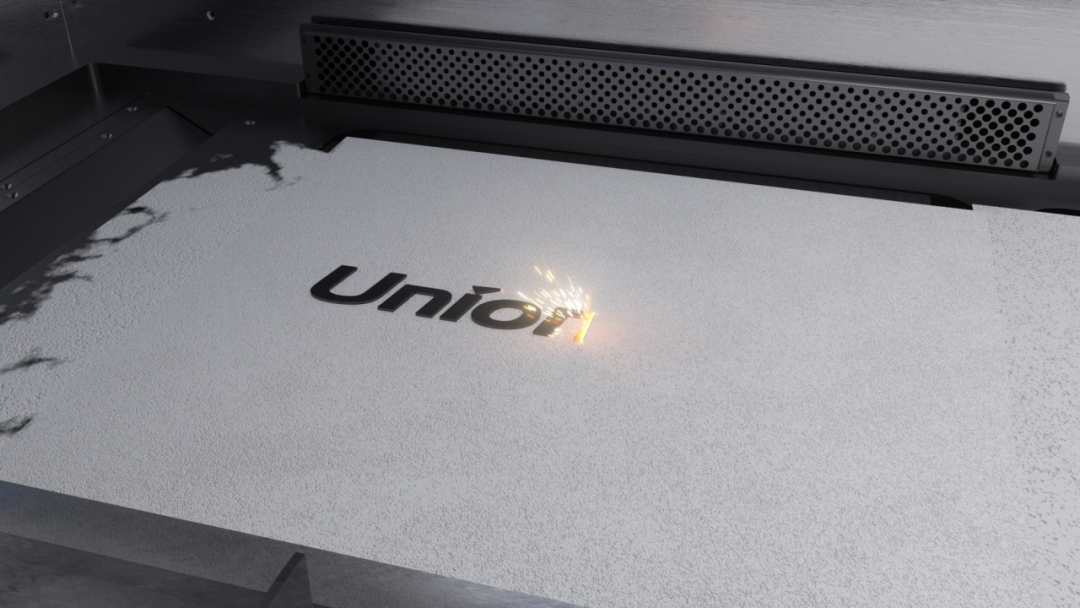

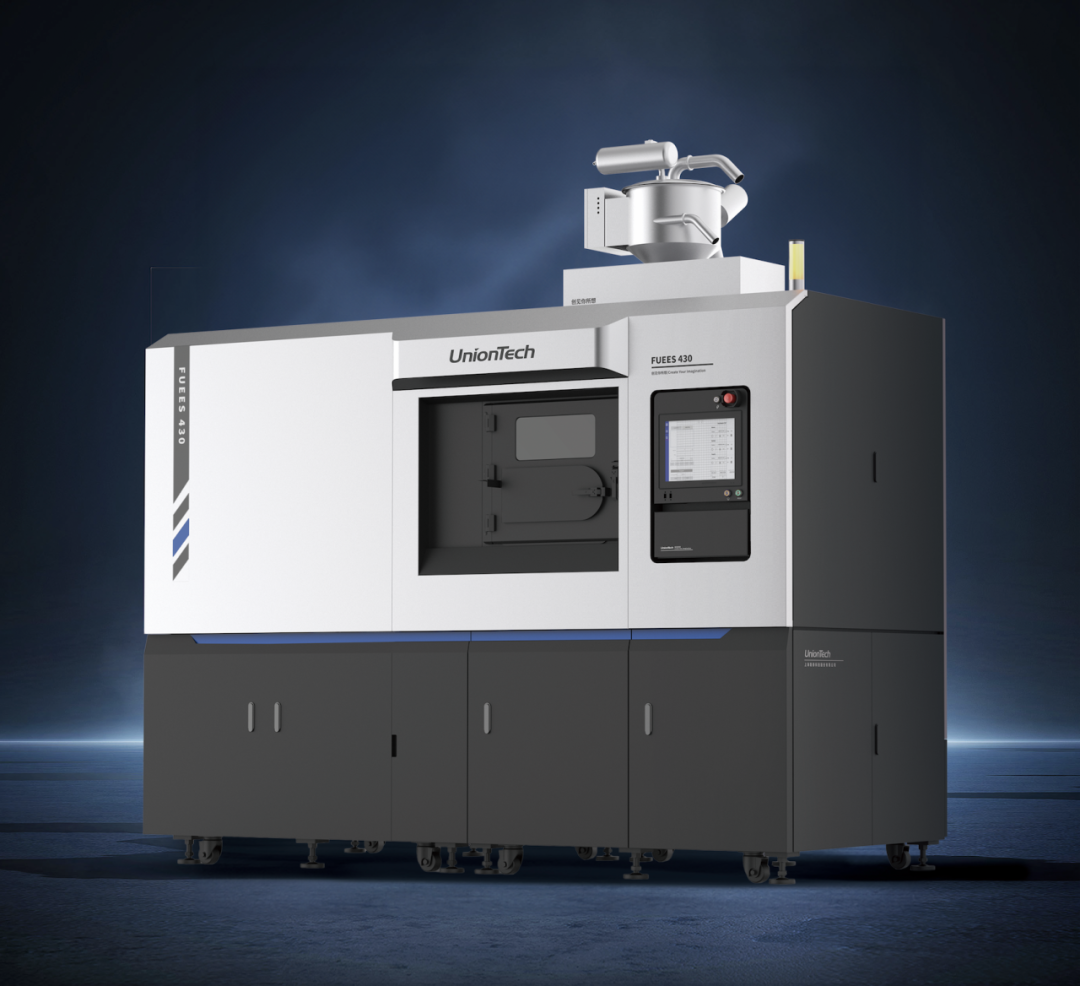

As the market gradually expands, the metal 3D printing shoe mold industry is transitioning from a trial phase to a stage of full competition, with more and more companies adjusting their strategies to gain a competitive edge in this sector. It is against this backdrop that LianTai Technology has launched its first industrial-grade metal 3D printer for mass production of shoe molds—Fuees430, accelerating its entry into this rapidly growing market.

The Fuees430 is an industrial-grade metal 3D printing product launched by LianTai Technology to meet the mass production needs of metal shoe molds, aiming to provide efficient and high-precision additive manufacturing solutions for shoe mold manufacturers. In terms of performance configuration, the Fuees430 has undergone multiple optimization designs tailored for the mass production of shoe molds.

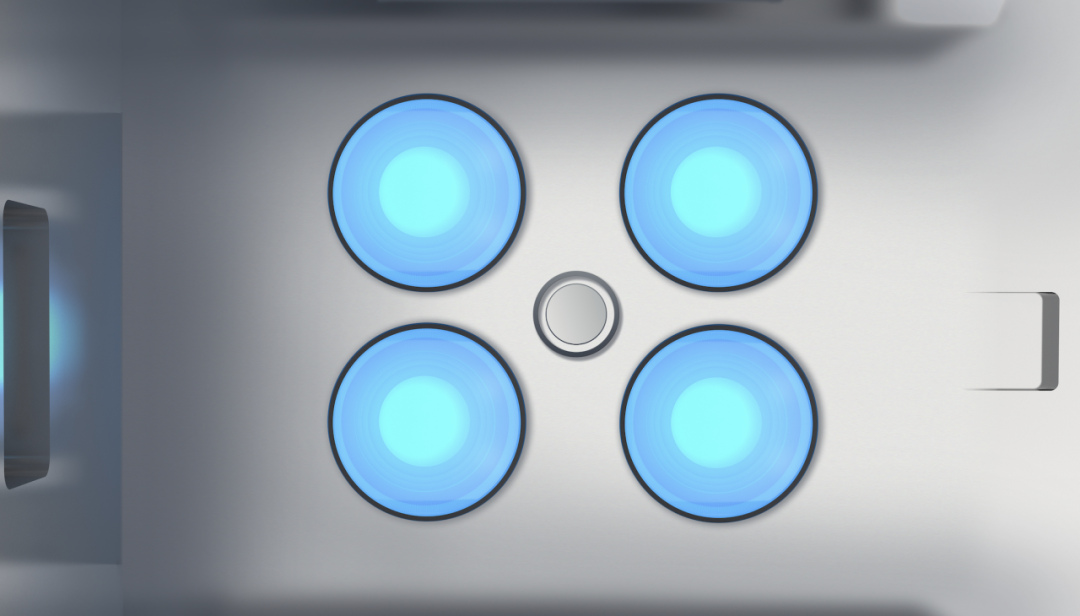

The device adopts a four-laser multi-mirror architecture, significantly enhancing forming efficiency and effectively shortening production cycles; it is equipped with an intelligent monitoring system that allows real-time observation of the forming chamber status, ensuring that the printing process is visible and controllable.

High-speed mirrors achieve scanning speeds of up to 6m/s and jump speeds of 18m/s, supporting efficient printing; high-precision control technology ensures that the printing accuracy is ±0.1mm when L<100 and ±0.1%xL when L>100, with surface roughness as low as Ra<4μm.

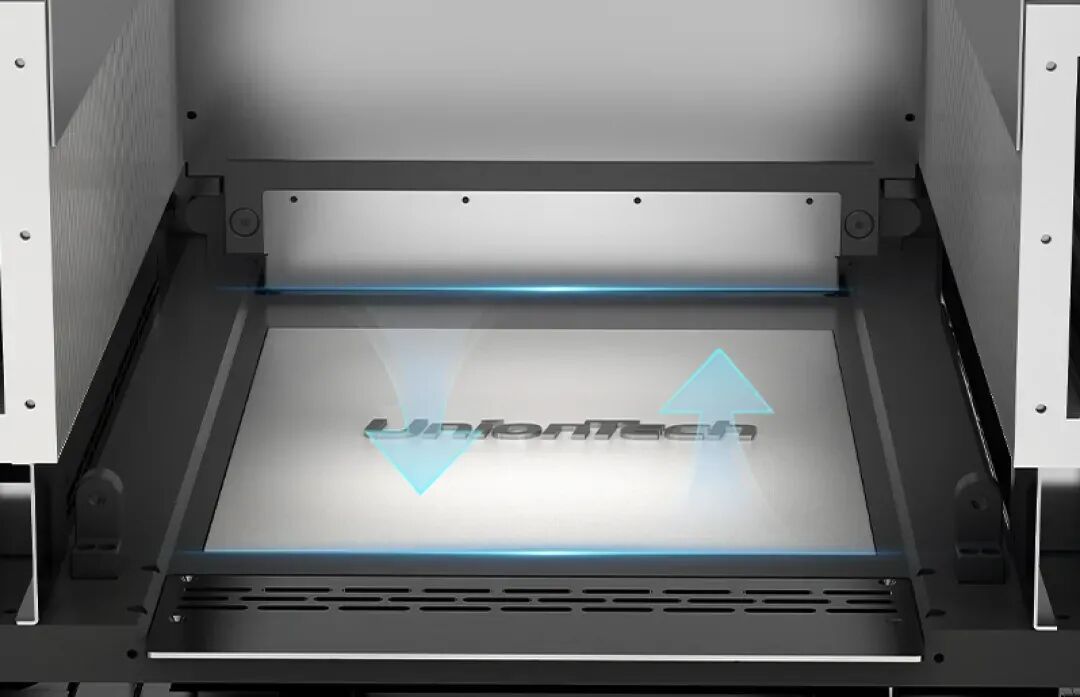

In addition, the Fuees430 also introduces a single-blade bidirectional powder spreading structure, which improves efficiency by about 20% compared to traditional unidirectional powder spreading, and optimizes the airflow design in the forming chamber through wind field simulation and actual measurements, enhancing airflow uniformity and stability, further ensuring printing quality. In terms of specific processes, LianTai Technology has also made several innovations around the core pain points of shoe mold manufacturing.

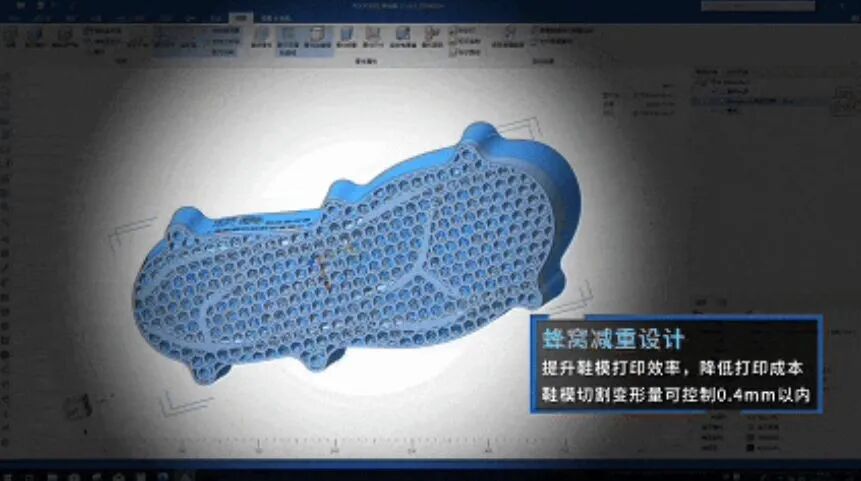

Its metal 3D printing solution can achieve honeycomb weight reduction design, effectively controlling the deformation of shoe molds after cutting to within 0.4mm, significantly improving printing efficiency while greatly reducing material and processing costs.

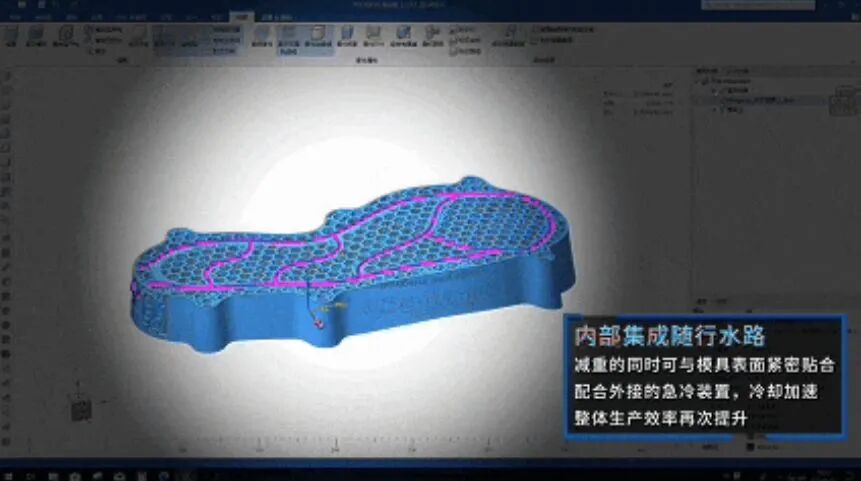

Meanwhile, the device also supports the internal integration of shaped cooling channels design, allowing cooling channels to closely adhere to the mold surface, combined with external rapid cooling devices, to accelerate the cooling process and further enhance overall production efficiency.

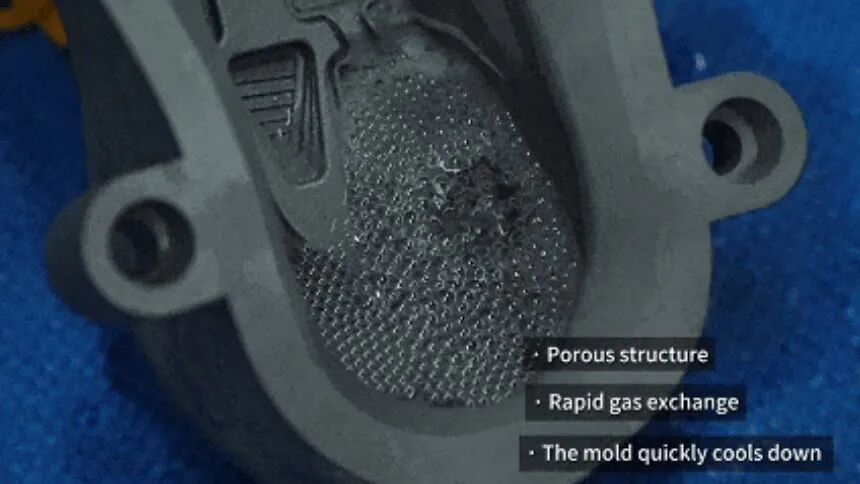

To meet the breathability requirements of shoe molds, LianTai Technology has also developed a perforation-free breathable membrane process. By adjusting parameters, a porous structure and irregular micropores are formed inside the printed surface, achieving efficient gas exchange while ensuring that the holes do not become blocked, optimizing cooling speed and exhaust performance.

It is worth mentioning that its support-free printing process also breaks through traditional limitations, allowing for the printing of complex structures such as small-angle slopes without the need for support structures, significantly enhancing design freedom while optimizing the surface quality and porosity.