In the automation industry, for experienced electromechanical engineers, selecting the right “robot” may be a straightforward task. However, for designers or factories purchasing and integrating robots for the first time, it can be somewhat confusing.

Here, we will discusshow to choose a suitable industrial robot.

First and foremost, the most important factor is to assess the robot being integrated, specifically what application scenario and process it will be used for.

If the application process requires the robot to work alongside humans, especially in semi-automatic lines where workstations need to be frequently changed or moved, collaborative robots (Cobots) should be a great option.

If you are looking for a compact pick and place robot, you might want to choose a SCARA robot.

If you seek a robot for quickly handling small objects, a Delta robot is most suitable for such needs.

In the following discussion, we will focus on multi-axis robots. This type of robot can adapt to a very wide range of applications, from material handling to palletizing, spraying, deburring, welding, and other specialized processes. Currently, industrial robot manufacturers have corresponding robot solutions for almost every application process. All you need to do is clarify what you want the robot to do for you and select the most suitable model from the different types available.

The effective load is the maximum load that the robot can carry in its workspace, ranging from 3Kg to 1300Kg.

If you want the robot to move target workpieces from one station to another, pay attention to the total weight of the workpiece and the robot’s gripper added to its working load.

Additionally, it is particularly important to consider the robot’s load curve, as the actual load capacity may vary at different distances within its operational range.

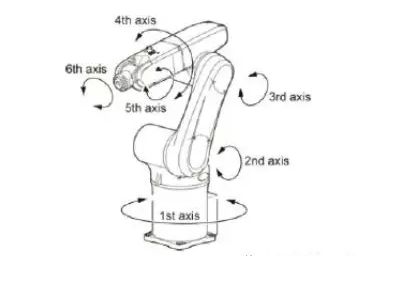

The number of axes configured for the robot directly relates to its degrees of freedom. For a simple linear application, such as moving items from one conveyor belt to another, a simple 4-axis robot is sufficient.

However, if the application scenario is in a confined workspace where the robot arm needs a lot of twisting and turning, a 6-axis or 7-axis robot would be the best choice.

The number of axes generally depends on the application scenario. It is worth noting that, within the constraints of cost, choosing a higher axis count can enhance flexibility. This makes it easier to repurpose the robot for another application process, allowing it to adapt to more tasks without finding the axis count insufficient.

Robot manufacturers tend to use slightly different naming conventions for their axes or joints. Essentially, the first joint (J1) is the one closest to the robot’s base. The subsequent joints are referred to as J2, J3, J4, and so on, up to the wrist end. Other companies, like Yaskawa/Motoman, use letters to name their robot axes.

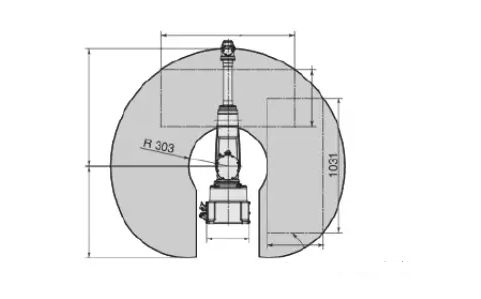

When assessing the target application scenario, it is essential to understand the maximum distance the robot needs to reach. Choosing a robot is not merely based on its effective load; it also requires a comprehensive consideration of the exact distances it needs to cover. Each company provides corresponding range diagrams for their robots, which can help determine whether the robot is suitable for a specific application. The horizontal range of motion of the robot should also consider a non-working area close to and behind the robot.

The maximum vertical height of the robot is measured from the lowest point it can reach (usually below the robot’s base) to the maximum height the wrist can achieve (Y). The maximum horizontal working distance is the distance from the center of the robot’s base to the farthest point the wrist can reach horizontally (X).

Similarly, this factor also depends on your application scenario. Repeatability can be described as the robot’s ability to reach the same position every time it completes routine tasks.

Generally, it ranges from ±0.05mm to ±0.02mm, or even more precise. For example, if you need your robot to assemble an electronic circuit board, you might require a robot with extremely precise repeatability. If the application process is relatively coarse, such as packaging or palletizing, the industrial robot does not need to be that precise.

Additionally, the precision requirements for assembly robots are also related to the transfer and calculation of dimensions and tolerances at various stages of the assembly process, such as the positioning accuracy of incoming materials and the repeat positioning accuracy of workpieces within fixtures. This indicator is represented in 2D with a plus-minus (±) symbol. In fact, due to the non-linear motion of the robot’s repeat points in 3D space, the actual situation can be any position within a spherical space defined by the tolerance radius.

Of course, the integration of current machine vision technology with motion compensation will reduce the robot’s reliance on the precision of incoming materials and enhance overall assembly accuracy.

This parameter is closely related to every user. In fact, it depends on the cycle time required to complete the task. The specifications indicate the maximum speed of the robot model, but we should understand that, considering acceleration and deceleration from one point to another, the actual operating speed will be between 0 and the maximum speed. This parameter is usually measured in degrees/second, and some robot manufacturers may also specify the robot’s maximum acceleration.

The body weight of the robot is an important factor when designing the robot unit. If the industrial robot must be installed on a custom machine or even on a rail, you may need to know its weight to design appropriate support.

Basically, every robot manufacturer provides information about their robot’s braking system. Some robots are equipped with brakes on all axes, while others do not have brakes on all axes. To ensure precise and repeatable positioning in the workspace, a sufficient number of brakes are required. Additionally, in the event of unexpected power loss, robots without brakes on loaded axes will not lock, posing a risk of accidents.

At the same time, some robot manufacturers also provide information on the robot’s moment of inertia. In fact, this will be an additional safety assurance for design. You may also notice the applicable torque on different axes. For example, if your operation requires a certain amount of torque to complete the task correctly, you need to check whether the maximum applicable torque on that axis is appropriate. If the selection is incorrect, the robot may go down due to overload.

Depending on the robot’s operating environment, select a standard that meets a certain protection level (IP rating). Some manufacturers offer the same mechanical arm with different IP protection level product lines for different scenarios. If the robot operates in environments related to food production, pharmaceuticals, medical devices, or flammable and explosive situations, the IP ratings will vary. Generally, for example, standard: IP40, oil mist: IP67, clean ISO level: 3.

☞ Source: Robot Design Handbook ☞ Editor: You Xiaoxiu☞ Reviewer: Wang Ying

☞ Advertising Cooperation: Sun Ha 13811718902

Statement: If any videos, images, or text used in this article involve copyright issues, please notify us promptly, and we will confirm copyright based on the materials you provide and pay remuneration according to national standards or immediately delete the content!

Statement: If any videos, images, or text used in this article involve copyright issues, please notify us promptly, and we will confirm copyright based on the materials you provide and pay remuneration according to national standards or immediately delete the content!