■

1. Introduction to Benchmark Enterprises

Mech-Mind (Shanghai) Robotics Technology Co., Ltd. (hereinafter referred to as Mech-Mind) is committed to accelerating the intelligent upgrade of various industries through AI+3D technology. The company’s self-developed sensors and software products have served industries such as automotive, lithium batteries, logistics, 3C, and construction machinery, with typical applications delivered in bulk covering unordered loading and unloading, unpacking and stacking, visual guidance positioning/assembly, precision measurement, defect detection, and steel plate sorting.

Mech-Mind has accumulated deep expertise in core technologies such as optical/mechanical/electrical core components, imaging algorithms, visual recognition algorithms, artificial intelligence algorithms, robotic algorithms, and industrial software. A complete product line of intelligent robot infrastructure has been formed, including self-developed high-performance Mech-Eye industrial-grade 3D cameras, Mech-Eye 3D laser profile measurement instruments, Mech-Vision machine vision software, Mech-DLK deep learning software, Mech-Viz robot programming software, and Mech-MSR 3D measurement and detection software. The company’s products have been sold to over 50 countries and regions, achieving the deployment of over 10,000 3D cameras globally, and have experienced rapid growth and consistent recognition in multiple mainstream national markets.

Mech-Eye High-Performance 3D Vision Sensor

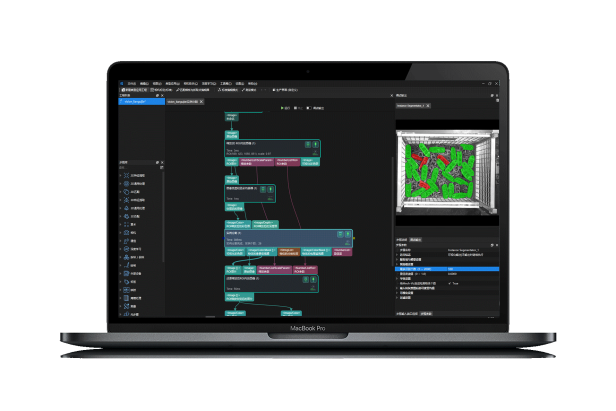

Mech-Vision Machine Vision Software

Mech-DLK Deep Learning Software

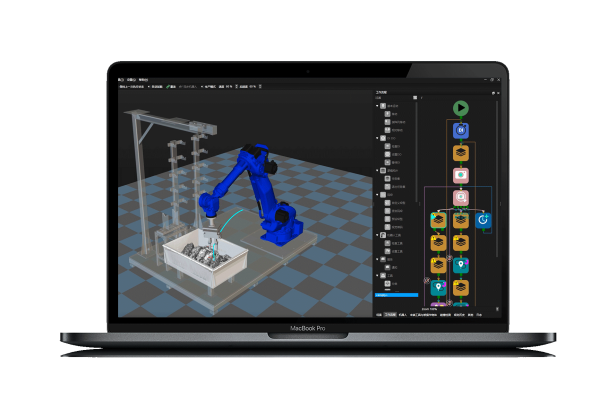

Mech-Viz Robot Programming Software

Mech-Mind High-Performance Industrial Grade 3D Vision Sensors and Series Platform Software

2. Highlights of Mech-Mind AI+3D Vision Technology

Mech-Eye Industrial Grade 3D Camera

1. Advanced Imaging Technology

The Mech-Eye industrial 3D camera adopts advanced 3D vision imaging algorithms, improving point cloud accuracy by 90% compared to traditional modes, easily handling situations like reflective walls and plastic wrapping, significantly increasing the success rate of recognizing various reflective objects under complex working conditions.

2. Self-Developed 3D Vision Algorithms

Capable of handling complex incoming material scenarios such as reflection, misalignment, tight fitting, and unordered stacking, with a recognition success rate exceeding 99.99%. With strong adaptability, it quickly achieves accurate recognition of new product specifications, supporting various incoming material methods on site.

3. Intelligent Grasping Planning

Can identify the number of top-layer objects and stacking methods, intelligently planning grabbing and placement strategies. Combined with motion simulation and collision checking, it optimizes the robot’s motion trajectory, predicting potential collisions during robot movement, better coping with tightly arranged robot applications, and enhancing operational stability.

3. Mech-Mind Robot Application Scenarios

1. New Energy Battery Workshop|3D Vision Guided Battery Module Assembly

Project Site

This project site is a battery workshop of a large new energy vehicle manufacturer. In the lithium battery pack stage, multiple battery modules need to be assembled with busbars, BMS, and other components to form a complete battery pack, resulting in a large demand for loading and assembly of battery modules. The Mech-Mind 3D vision system provides a more flexible and intelligent solution for such scenarios.

The Mech-Eye PRO S high-precision structured light industrial 3D camera can generate structurally complete and detailed 3D point cloud data for reflective and precision-structured battery modules. The Mech-Vision built-in advanced 3D vision algorithms can achieve high-precision positioning of key features of battery modules, generating accurate pose information in real-time to guide the robot in grabbing. Based on advanced AI algorithms, the Mech-Mind 3D vision system can adapt to different sizes and profiles of modules for positioning recognition, effectively coping with positional deviations and angular tilts of battery modules, greatly enhancing the flexibility of the production line.

Mech-Mind integrates powerful, easy-to-use, and stable 3D vision products with lithium battery processes to automate the loading and assembly of battery modules. The intelligent robot workstation supports flexible manufacturing of lithium batteries, with single-line capacity increased by over 2 times, providing guarantees for new energy vehicle manufacturers in terms of process execution quality, capacity targets, and cost control.

2. A Large Manufacturing Plant|3D Vision Guided Carton Unpacking and Stacking

Project Site

This project serves a large manufacturing plant. The enterprise has a large demand for unpacking and stacking different specifications of cartons/foam boxes, with high manual handling intensity and insufficient mechanical handling flexibility, making it difficult to meet the material turnover needs of the enterprise. The client introduced Mech-Mind’s AI+3D vision technology to transform the production line for automation and flexibility.

The client selected the flagship camera Mech-Eye DEEP for logistics handling scenarios. This 3D camera can produce high-quality images of complex patterns and strapped boxes on site, with advantages such as a large field of view and depth of field, performing well in large pallet and stack-type unpacking scenarios. The Mech-Vision built-in advanced 3D vision and deep learning algorithms can accurately recognize closely fitted boxes, generating precise poses and guiding robots to complete the handling of large boxes.

Mech-Mind’s AI+3D technology helps create an intelligent robot unpacking and stacking workstation, with work efficiency increased by over 10 times. Automation has been achieved on site, with production efficiency reaching 16,000 boxes per day.

In the future, Mech-Mind will continue to optimize and improve AI+3D vision-related hardware and software products, ensuring that product technology maturity and usability can be widely applied in various industrial scenarios, helping industries improve production quality and efficiency. At the same time, Mech-Mind will continue to deepen its global layout, accelerating the large-scale implementation of AI+3D vision and artificial intelligence technologies, empowering global industrial intelligence.

If you like it, please give a thumbs up!