1. Functions to be Achieved by the Industrial Robot Control System

The robot control system is an important component of the robot, used to control the manipulator to complete specific work tasks. Its basic functions are as follows:

1. Memory Function: Stores job sequences, motion paths, motion modes, motion speeds, and information related to production processes.

2. Teaching Function: Offline programming, online teaching, and indirect teaching. Online teaching includes two types: teaching box and guided teaching.

3. Peripheral Device Communication Function: Input and output interfaces, communication interfaces, network interfaces, synchronization interfaces.

4. Coordinate Setting Function: Four coordinate systems: joint, absolute, tool, and user-defined.

5. Human-Machine Interface: Teaching box, operation panel, display screen.

6. Sensor Interface: Position detection, vision, touch, force sensing, etc.

7. Position Servo Function: Multi-axis linkage, motion control, speed and acceleration control, dynamic compensation, etc.

8. Fault Diagnosis and Safety Protection Function: Monitoring system status during operation, safety protection under fault conditions, and fault self-diagnosis.

2. Components of the Industrial Robot Control System

1. Control Computer: The scheduling and command institution of the control system. Generally, it is a microcomputer or microprocessor with 32-bit, 64-bit, such as Pentium series CPUs and other types of CPUs.

2. Teaching Box: Teaches the robot’s working trajectory and parameter settings, as well as all human-machine interaction operations, possessing its own independent CPU and storage unit, and communicates with the main computer through serial communication.

3. Operation Panel: Composed of various operation buttons and status indicator lights, it only performs basic functional operations.

4. Hard Disk and Floppy Disk Storage: Peripheral storage for storing robot working programs.

5. Digital and Analog Input/Output: Input or output of various status and control commands.

6. Printer Interface: Records various information that needs to be output.

7. Sensor Interface: Used for automatic detection of information to achieve robot compliance control, generally for force, touch, and vision sensors.

8. Axis Controller: Controls the position, speed, and acceleration of each joint of the robot.

9. Auxiliary Device Control: Controls auxiliary devices cooperating with the robot, such as gripper positioners.

10. Communication Interface: Achieves information exchange between the robot and other devices, generally with serial interfaces, parallel interfaces, etc.

11. Network Interface

1) Ethernet Interface: Enables direct PC communication with multiple or single robots through Ethernet, with a data transmission rate of up to 10Mbit/s, allowing programming of application programs on PC using Windows library functions, supporting TCP/IP communication protocol, and loading data and programs into each robot controller through Ethernet interface.

2) Fieldbus Interface: Supports various popular fieldbus specifications, such as DeviceNet, ABRemote I/O, Interbus-s, Profibus-DP, M-NET, etc.

3. Classification of Industrial Robot Control Systems

1. Program Control System: Applies a certain control pattern to each degree of freedom, allowing the robot to achieve the required spatial trajectory.

2. Adaptive Control System: When external conditions change, to ensure the required quality or to improve control quality with experience accumulation, the process is based on observing the state of the manipulator and servo errors, adjusting the parameters of the nonlinear model until the error disappears. The structure and parameters of this system can change automatically over time and conditions.

3. Artificial Intelligence System: Cannot pre-program motion, but requires real-time determination of control actions based on surrounding state information obtained during motion.

4. Point Control: Requires the robot to accurately control the pose of the end effector, regardless of the path.

5. Trajectory Control: Requires the robot to move along the taught trajectory and speed.

6. Control Bus: International standard bus control system. Uses international standard buses as control buses for the control system, such as VME, MULTI-bus, STD-bus, PC-bus.

7. Custom Bus Control System: A bus defined by the manufacturer for use as the control system bus.

8. Programming Method: Physically set programming system. The operator sets fixed limit switches to implement start and stop program operations, only suitable for simple pick-and-place tasks.

9. Online Programming: Completes the memory process of operational information through human teaching methods, including direct teaching, simulated teaching, and teaching box teaching.

10. Offline Programming: Does not directly teach the robot performing actual operations, but teaches programs away from the actual working environment, using advanced robots and programming languages to remotely generate the robot’s working trajectory.

4. Structure of Robot Control Systems

Robot control systems can be divided into three categories based on their control methods.

1) Centralized Control System: Uses a single computer to achieve all control functions. It has a simple structure, low cost, but poor real-time performance and is difficult to expand. This structure is commonly used in early robots, as shown in the block diagram in Figure 2. In PC-based centralized control systems, the open characteristics of PC resources can be fully utilized, achieving good openness: various control cards, sensor devices, etc., can be integrated into the control system through standard PCI slots or standard serial and parallel ports. The advantages of centralized control systems are: lower hardware costs, ease of information collection and analysis, ease of achieving optimal system control, and good overall coordination. However, its disadvantages are also evident: the system control lacks flexibility, control risks are easily concentrated, and once a fault occurs, its impact is widespread with serious consequences; due to the high real-time requirements of industrial robots, when the system performs a large amount of data calculation, it will reduce system real-time performance, and the system’s response capability to multitasking may conflict with the system’s real-time performance; in addition, the complex wiring of the system can reduce its reliability.

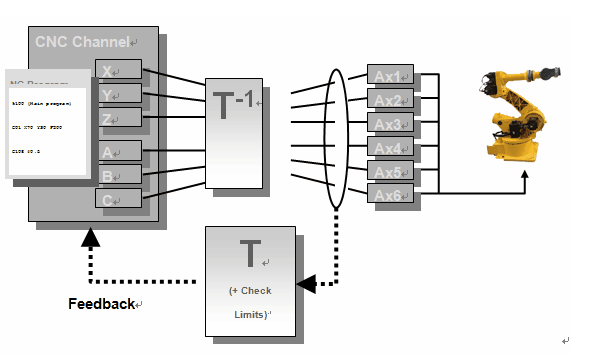

2) Master-Slave Control System: Uses a master and slave two-level processor to achieve all control functions. The master CPU manages, performs coordinate transformation, trajectory generation, and system self-diagnosis, while the slave CPU controls the motion of all joints. Its block diagram is shown in Figure 3. The master-slave control system has good real-time performance, suitable for high precision and high-speed control, but its system expandability is poor, and maintenance is difficult.

3) Distributed Control System: Divides system control into several modules according to the nature and method of the system, each module has different control tasks and strategies. The modes can have a master-slave relationship or an equal relationship. This method has good real-time performance, is easy to achieve high-speed, high-precision control, and is easy to expand, enabling intelligent control. This is currently the popular method, as shown in the control block diagram in Figure 4. The main idea is “distributed control, centralized management,” meaning that the system can comprehensively coordinate and allocate its overall goals and tasks, and complete control tasks through the coordinated work of subsystems. The entire system is decentralized in functionality, logic, and physically, so the DCS system is also known as a decentralized control system. In this structure, the subsystems consist of controllers and different controlled objects or devices, and the various subsystems communicate with each other through networks. The distributed control structure provides an open, real-time, precise robot control system. A two-level control method is often adopted in distributed systems.

The two-level distributed control system usually consists of an upper computer, lower computer, and network. The upper computer can perform different trajectory planning and control algorithms, while the lower computer conducts research and implementation of interpolation subdivision and control optimization. The upper and lower computers coordinate work through communication buses, which can be in the form of RS-232, RS-485, EEE-488, and USB buses. Currently, the development of Ethernet and fieldbus technology provides faster, more stable, and effective communication services for robots. Especially the fieldbus, which is applied in production sites, allows bidirectional multi-node digital communication between microcomputer measurement and control devices, forming a new type of network-integrated full-distributed control system—Fieldbus Control System (FCS). In factory production networks, devices that can be connected through fieldbus are collectively referred to as “field devices/instruments.” From a systems theory perspective, industrial robots, as one of the factory production devices, can also be classified as field devices. The introduction of fieldbus technology into robot systems is more conducive to robot integration in industrial production environments.

The advantages of distributed control systems are: good system flexibility, reduced control system risks, and the use of multi-processor decentralized control, which is beneficial for parallel execution of system functions, improving system processing efficiency and shortening response time.

For industrial robots with multiple degrees of freedom, centralized control handles the coupling relationships between control axes well, allowing for simple compensation. However, when the number of axes increases to make the control algorithm complex, its control performance deteriorates. Moreover, when the number of axes or the control algorithm becomes complex, it may lead to system redesign. In contrast, in a distributed structure, each motion axis is handled by a controller, meaning that the system has less axis coupling and higher system reconfigurability.

Source: Tencent Video, China Robot Network, If there is any infringement, please contact QQ1393125655 for deletion.

Hua Sheng Qi Lian June-August 2017 Industrial Robot Training Course Schedule

Please click the link to view (welcome to call for detailed training documents)

Training Time and Location: June-August Industrial Robot Training Schedule

For various training, please scan the QR code to follow

Training Announcement