Focusing on automation training for 14 years

Focusing on automation training for 14 years Jicheng Training Network

Jicheng Training Network

Before understanding how a PLC controls a servo motor, we need to clarify two questions: How does a PLC control a servo motor? And how to design a servo system? We will start from these two questions and detail how PLCs control servos and how they complement each other!

1. How Does a PLC Control a Servo Motor?

Before answering this question, it is essential to understand the purpose of a servo motor. Compared to ordinary motors, servo motors are primarily used for precise positioning. Therefore, when we talk about controlling a servo, we are essentially referring to controlling the position of the servo motor. In fact, servo motors also have two other operating modes: speed control and torque control, although these are less commonly used.

Speed control is generally achieved using a frequency converter. Using a servo motor for speed control is typically applied in scenarios requiring rapid acceleration and deceleration or precise speed control. Compared to frequency converters, servo motors can reach thousands of revolutions per minute within a few millimeters, and since servos operate in a closed loop, their speed is very stable. Torque control mainly involves controlling the output torque of the servo motor, again due to the fast response of servo motors. By applying these two types of control, servo drives can be treated as frequency converters, usually controlled by analog signals.

The primary application of servo motors remains position control. Position control involves two physical quantities that need to be controlled: speed and position. Specifically, it is about controlling how fast the servo motor reaches a specific location and stops accurately.

The servo drive controls the distance and speed of the servo motor by receiving pulse frequency and quantity. For example, if we agree that the servo motor rotates one full turn for every 10,000 pulses, then if the PLC sends 10,000 pulses in one minute, the servo motor will complete one turn at a speed of 1 r/min. If it sends 10,000 pulses in one second, the servo motor will complete one turn at a speed of 60 r/min.

Thus, the PLC controls the servo motor by controlling the pulses sent. The most common method is to physically send pulses using the transistor output of the PLC, which is typically used in low-end PLCs. In contrast, mid to high-end PLCs transmit the number and frequency of pulses to the servo drive via communication.

For example:

Profibus-DP, CANopen, MECHATROLINK-II, EtherCAT, etc.

These two methods differ only in their implementation channels; fundamentally, they are the same. For our programming purposes, they are also the same. This is what I want to convey: learn the principles and apply them broadly, rather than learning for the sake of learning.

Regarding program writing, there is a significant difference. Japanese PLCs use an instruction-based approach, while European PLCs use function blocks. However, the essence is the same. For instance, to control a servo for absolute positioning, we need to control the PLC’s output channels, pulse count, pulse frequency, acceleration and deceleration times, and know when the servo drive has completed positioning and whether it has hit the limit. Regardless of the PLC type, it ultimately involves controlling these physical quantities and reading motion parameters; only the implementation methods differ.

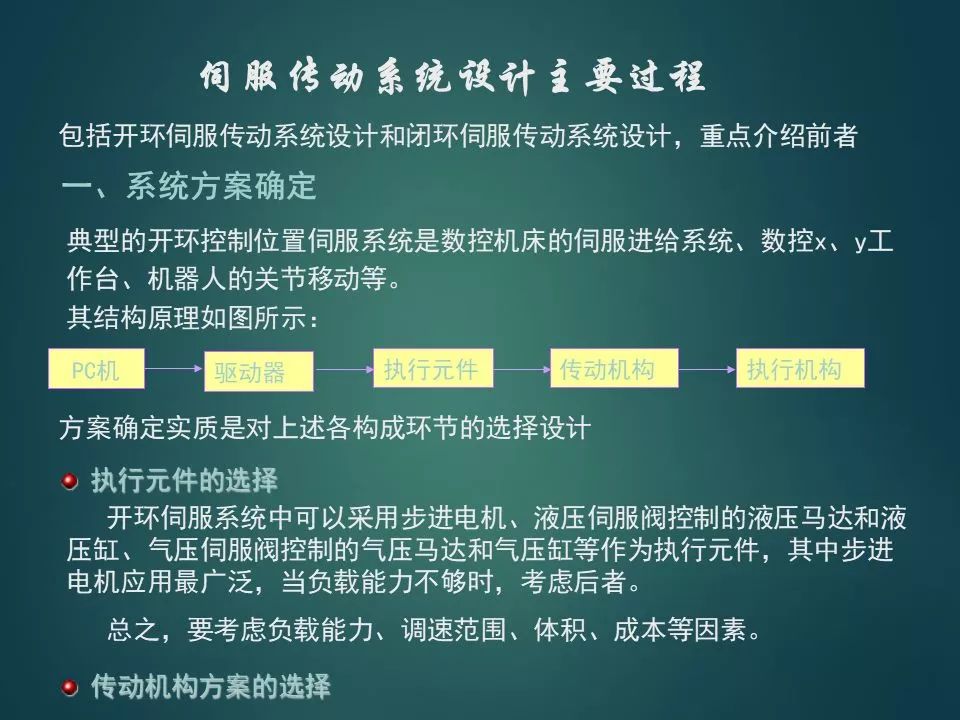

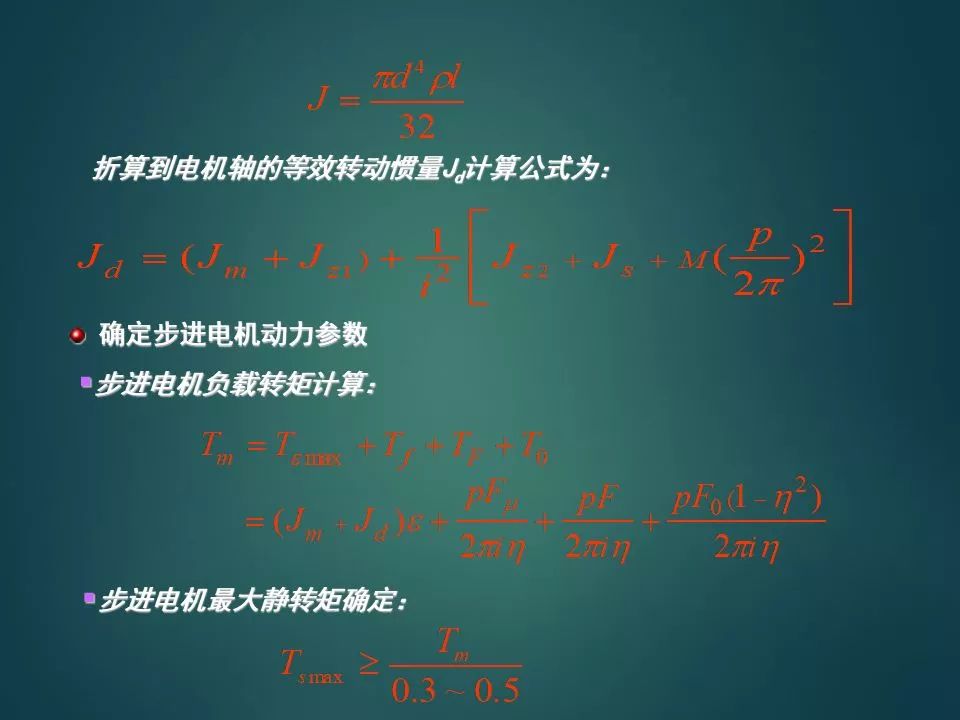

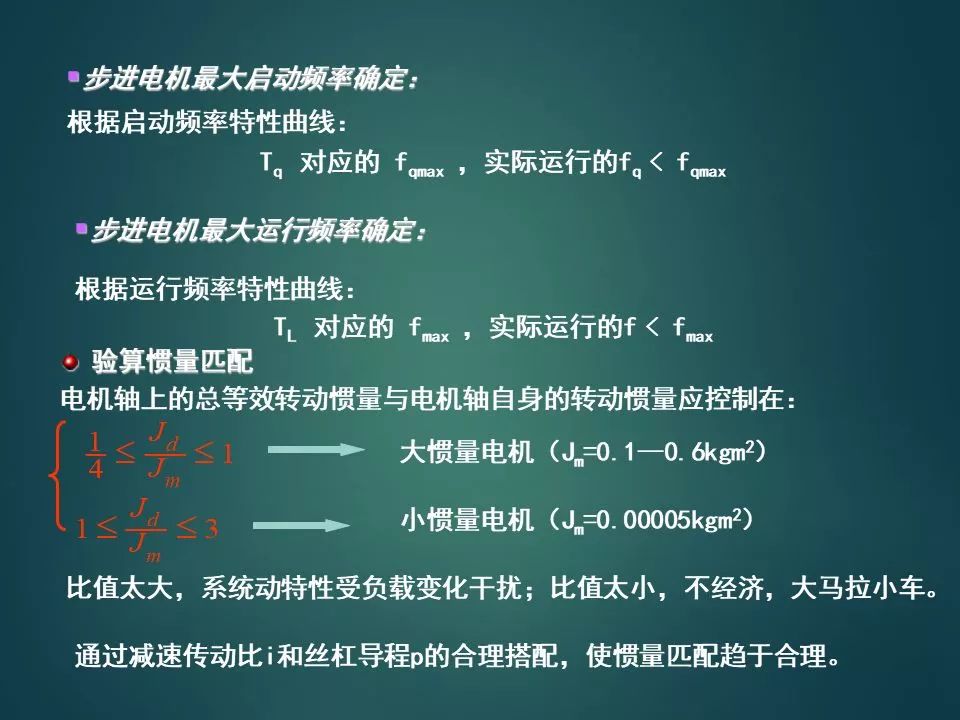

2. How to Design a Servo System?

Source: Internet, copyright belongs to the original author, please delete if infringing

Previous Recommendations

1. 2021 Latest Complete Electrician Question Bank (National Version)

2. Electrician’s Secret Toolkit (Electrician Simulation Software + 16 Sets of Electrical Industry PPT)

3. Master Says: If You Don’t Know CAD, Don’t Expect to Be an Electrical Engineer (Includes CAD Software Package)

Click here if you like

Click here if you like Free PLC and Electrician Courses, click to read the original text

Free PLC and Electrician Courses, click to read the original text