What Is a Robot Control System

If a person only has senses and muscles, their limbs cannot move. This is partly because there are no organs to receive and process the signals from the senses, and partly because there are no organs to send nerve signals that drive the muscles to contract or relax. Similarly, if a robot only has sensors and actuators, its robotic arm cannot function properly. The reason is that the signals output by the sensors do not take effect, and the drive motors do not receive the necessary voltage and current. Therefore, robots need a controller, which consists of hardware and software to form a control system.

The function of the robot control system is to receive detection signals from sensors and to drive the motors in the robotic arm according to the requirements of the operational tasks, just as human activities depend on their own senses. Robot motion control cannot be separated from sensors. Robots need sensors to detect various states. Internal sensor signals are used to reflect the actual motion state of the robotic arm joints, while external sensor signals are used to detect changes in the working environment.

Thus, the combination of the robot’s “nervous system” and “brain” forms a complete robot control system.

What Aspects Does the Robot Motion Control System Include?

Actuators – Servo motors or stepper motors;

Drive mechanisms – Servo or stepper drivers;

Control mechanisms – Motion controllers that perform algorithm calculations for path and motor linkage;

Control methods – If there are fixed execution actions, then a program with fixed parameters should be prepared for the motion controller; if there is a visual system or other sensors, a program with variable parameters should be prepared for the motion controller based on the sensor signals.

Basic Functions of Robot Control Systems

1. Control the motion position of the end effector of the robotic arm (i.e., control the points and movement paths the end effector passes through);

2. Control the motion posture of the robotic arm (i.e., control the relative positions of two adjacent moving components);

3. Control the motion speed (i.e., control the pattern of change in the position of the end effector over time);

4. Control the motion acceleration (i.e., control the speed changes of the end effector during motion);

5. Control the output torque of each power joint in the robotic arm (i.e., control the force applied to the object being manipulated);

6. Provide user-friendly human-machine interaction functions, allowing robots to complete specified tasks through memory and reproduction;

7. Enable the robot to detect and sense the external environment. Industrial robots are equipped with sensors for vision, force, touch, etc., to measure, recognize, and judge changes in working conditions.

Industrial Robot Control Systems

1. Hardware Structure of Industrial Robot Control Systems

The controller is the core of the robot system, and foreign companies have implemented strict controls on our country. In recent years, with the development of microelectronics technology, the performance of microprocessors has increased while prices have decreased. Currently, 32-bit microprocessors are available on the market for 1-2 dollars. High cost-performance microprocessors provide new development opportunities for robot controllers, making it possible to develop low-cost, high-performance robot controllers. To ensure the system has sufficient computing and storage capacity, most robot controllers now use powerful chips such as ARM series, DSP series, POWERPC series, and Intel series.

Moreover, since existing general-purpose chips do not fully meet the requirements of certain robot systems in terms of price, performance, integration, and interfaces, there is a demand for SoC (System on Chip) technology in robot systems, which integrates specific processors with required interfaces to simplify the design of peripheral circuits, reduce system size, and lower costs. For example, Actel integrates NEOS or ARM7 processor cores into its FPGA products to form a complete SoC system. In the field of robot motion controllers, research is mainly concentrated in the United States and Japan, with mature products available, such as those from DELTATAU in the USA and PONTEK in Japan. Their motion controllers are based on DSP technology and adopt an open PC-based structure.

2. Architecture of Industrial Robot Control Systems

In terms of controller architecture, research focuses on functional division and the standardization of information exchange between functions. In the study of open controller architectures, there are two basic structures: one is based on hardware-level division, which is relatively simple. In Japan, architectures are divided based on hardware, such as Mitsubishi Heavy Industries categorizing its PA210 portable general-purpose intelligent robotic arm into a five-layer structure; the other is based on functional division, which considers both hardware and software. This is the direction for research and development of robot controller architectures.

3. Control Software Development Environment

In terms of robot software development environments, most industrial robot companies have their own independent development environments and robot programming languages, such as Japan’s Motoman, Germany’s KUKA, USA’s Adept, and Sweden’s ABB.

Many universities have conducted extensive research on Robot Development Environments and provide many open-source resources for integration and control operations under certain robotic hardware structures. Many related experiments have been conducted in laboratory environments. Existing robot system development environments at home and abroad include Team Bots, v.2.0e, ARIA, V.2.4.1, Player/Stage, v.1.6.5.1.6.2, Pyro.v.4.6.0, CARMEN.v.1.1.1, Mission Lab.v.6.0, ADE.V.1.0beta, Miro.v.CVS-March17.2006, MARIE.V.0.4.0, Flow Designer.v.0.9.0, Robot Flow.v.0.2.6, and more.

From the perspective of robot industry development, there are two demands for robot software development environments. On one hand, there are demands from the end users of robots, who not only use robots but also hope to endow them with more functions through programming. This programming is often realized using visual programming languages, such as the graphical programming environment of LEGO Mind Storms NXT and the visual programming environment provided by Microsoft Robotics Studio.

4. Specialized Operating Systems for Robots

(1) VxWorks: The VxWorks operating system is an embedded real-time operating system (RTOS) designed and developed by Wind River in the USA in 1983 and is a key component of the Tornado embedded development environment. VxWorks features a customizable microkernel architecture; efficient task management; flexible inter-task communication; microsecond-level interrupt handling; support for the POSIX 1003.1b real-time extension standard; and support for various physical media and standard, complete TCP/IP network protocols.

(2) Windows CE: Windows CE has good compatibility with the Windows series, which is undoubtedly a significant advantage for the promotion of Windows CE. Windows CE provides a rich operating system platform for establishing dynamic applications and services for handheld and wireless devices. It can run on various processor architectures and is typically suitable for devices with certain memory constraints.

(3) Embedded Linux: Due to its open-source nature, users can modify it as needed. Most of it complies with the GPL, is open source, and is free. It can be slightly modified for use in the user’s own system. There is a large developer community, so specialized talent is unnecessary; anyone familiar with Unix/Linux and C can work with it. A wide range of hardware is supported. Embedded Linux is essentially the same as regular Linux, and almost all hardware used in PCs is supported by embedded Linux. Moreover, source code for drivers of various hardware can be obtained, greatly facilitating the writing of custom drivers for proprietary hardware by users.

(4) μC/OS-Ⅱ: μC/OS-Ⅱ is a well-known open-source real-time kernel designed specifically for embedded applications, suitable for 8-bit, 16-bit, and 32-bit microcontrollers or digital signal processors (DSP). Its main features include open-source code, good portability, solid-state, customizability, preemptive kernel, and determinism.

(5) DSP/BIOS: DSP/BIOS is a real-time multitasking operating system kernel designed and developed by TI specifically for its TMS320C6000TM, TMS320C5000TM, and TMS320C28xTM series DSP platforms. It is one of the components of TI’s Code Composer StudioTM development tools. DSP/BIOS mainly consists of three parts: a multithreaded real-time kernel; real-time analysis tools; and a chip support library. Using real-time operating systems to develop programs allows for the convenient and rapid development of complex DSP programs.

5. Robot Servo Communication Bus Technology

Currently, there is no dedicated servo communication bus for robot systems internationally. In actual applications, common buses such as Ethernet, CAN, 1394, SERCOS, USB, RS-485, etc., are typically used according to system requirements. Most communication control buses can be categorized into two types: serial bus technology based on RS-485 and line driver technology, and high-speed serial bus technology based on real-time industrial Ethernet.

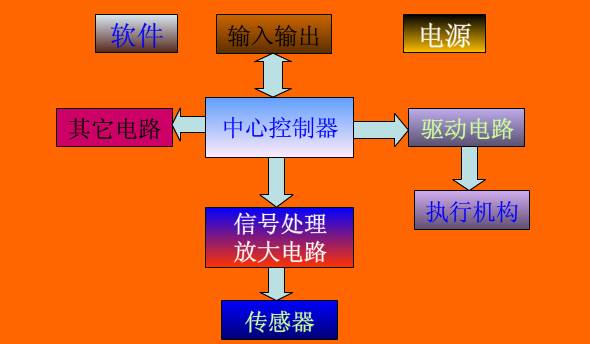

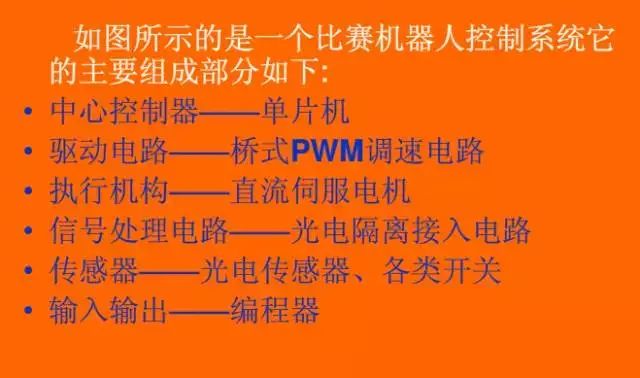

Intelligent Robot Control Systems

1. Open and Modular Control System Architecture: Adopts a distributed CPU computer structure divided into a Robot Controller (RC), Motion Controller (MC), opto-isolated I/O control board, sensor processing board, and programming teaching box, etc. The Robot Controller (RC) and programming teaching box communicate via serial/CAN bus. The main computer of the Robot Controller (RC) completes motion planning, interpolation, and position servo, as well as main control logic, digital I/O, sensor processing, etc., while the programming teaching box handles information display and key input.

2. Modular and Hierarchical Controller Software System: The software system is built on an open-source real-time multitasking operating system, Linux, utilizing a layered and modular structure design to achieve openness. The entire controller software system is divided into three levels: hardware driver layer, core layer, and application layer. Each of the three levels addresses different functional needs and corresponds to different levels of development, with each level containing several functionally opposing modules that collaborate to achieve the functions provided at that level.

3. Robot Fault Diagnosis and Safety Maintenance Technology: Diagnosing robot faults through various information and performing corresponding maintenance is a key technology for ensuring robot safety.

4. Networked Robot Controller Technology: Currently, the application engineering of robots is evolving from single robot workstations to robotic production lines, making the networking technology of robot controllers increasingly important. The controller features networking capabilities through serial ports, field buses, and Ethernet, enabling communication between robot controllers and between robot controllers and host computers, facilitating monitoring, diagnosis, and management of robotic production lines.

Source: Global Intelligent Manufacturing

Business Cooperation: 010—88379790 ext 822, 802

Disclaimer: This article is a network reprint, and the copyright belongs to the original author. Due to numerous reprints, we cannot confirm the true original author, hence only the source is indicated. If the videos, images, or texts used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright according to the proof materials you provide and pay remuneration according to national standards or delete the content immediately! The content of this article represents the views of the original author and does not necessarily reflect the views of this public account or its authenticity.