In the field of medical rehabilitation, braces (orthotics) are essential tools for helping patients restore limb function. However, traditional brace manufacturing has long production cycles and low comfort levels. The emergence of 3D printing technology is fundamentally changing this situation—from “one size fits all” to “tailored to fit,” rehabilitation braces are entering the era of personalization!

01What is 3D printing technology3D PRINTING SUPPORT

3D printing technology (additive manufacturing) breaks through the technical limitations of traditional manufacturing through digital modeling and layered processing, enabling the rapid formation of complex geometric components with precision.

Orthotics, as external fixation devices for the human movement system, effectively improve limb dysfunction through biomechanical intervention, primarily serving four core functions in clinical practice:Replacing musculoskeletal load with mechanical support to maintain joint stability; implementing protective immobilization at the injury site to accelerate tissue repair; correcting structural deformities using the three-point force principle; and establishing functional compensation in conjunction with rehabilitation training.

This external assistive device can be personalized according to individual anatomical characteristics and pathological needs, significantly enhancing the rehabilitation effectiveness for patients with movement system diseases.

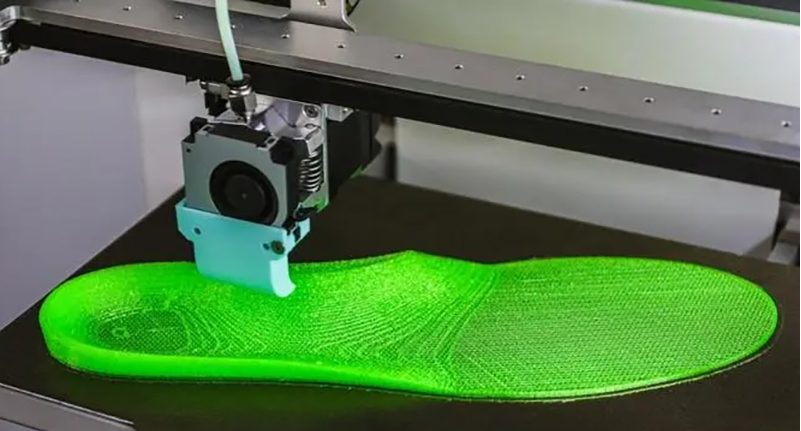

Printing formation

023D Printed Braces vs Traditional Braces3D PRINTING SUPPORT

Traditional brace manufacturing relies on manual craftsmanship, requiring rehabilitation therapists to complete complex processes such as design measurement, hand drawing, plaster modeling, and sample adjustments based on clinical prescriptions. Patients must undergo fitting training and repeated modifications before they can be delivered for use, resulting in a long overall cycle that depends on the technician’s experience.

In contrast, the digital production process of 3D printed braces includes the following core steps: ① First, clarify the functional requirements and fitting areas of the brace; ② Reconstruct the patient’s anatomical structure into a digital model through 3D scanning or medical imaging (CT/MRI), and use CAD software for biomechanical compatibility design; ③ Perform topology optimization and data conversion on the model, matching 3D printing parameters; ④ Select biocompatible materials for layered manufacturing; ⑤ Combine patient feedback for dynamic optimization.

This technology significantly shortens the brace development cycle through precise personalized data integration and rapid formation capabilities, while achieving dual improvements in anatomical fit and mechanical compatibility, providing an efficient solution for the customized production of rehabilitation aids.

| 3D Printed Braces vs Traditional Braces | ||

| Comparison Item | Traditional Braces | 3D Printed Braces |

| Manufacturing Process |

Manual measurement, plaster shaping, repeated adjustments |

Scan data → Modeling → Direct printing |

| Comfort Level | Heavy, prone to sweating | Lightweight, breathable design |

| Fitting Range | Simple structures |

Complex deformities can also be accurately fitted |

03Clinical Applications: Full Coverage of Upper Limb, Lower Limb, and SpinePROTECT YOUR HEALTH (Upper Limb Rehabilitation)

Radial Fracture:3D printed braces provide more stable fixation without affecting daily activities.

Hemiplegic Patients:Compared to traditional thermoplastic plates, 3D printed orthotics significantly alleviate wrist spasms.

(Lower Limb Rehabilitation)

Ankle-Foot Orthosis (AFO): The 3D printed version is 17% lighter with a more reasonable stress distribution.

Plantar Fasciitis:Custom braces reduce plantar damage and enhance comfort.

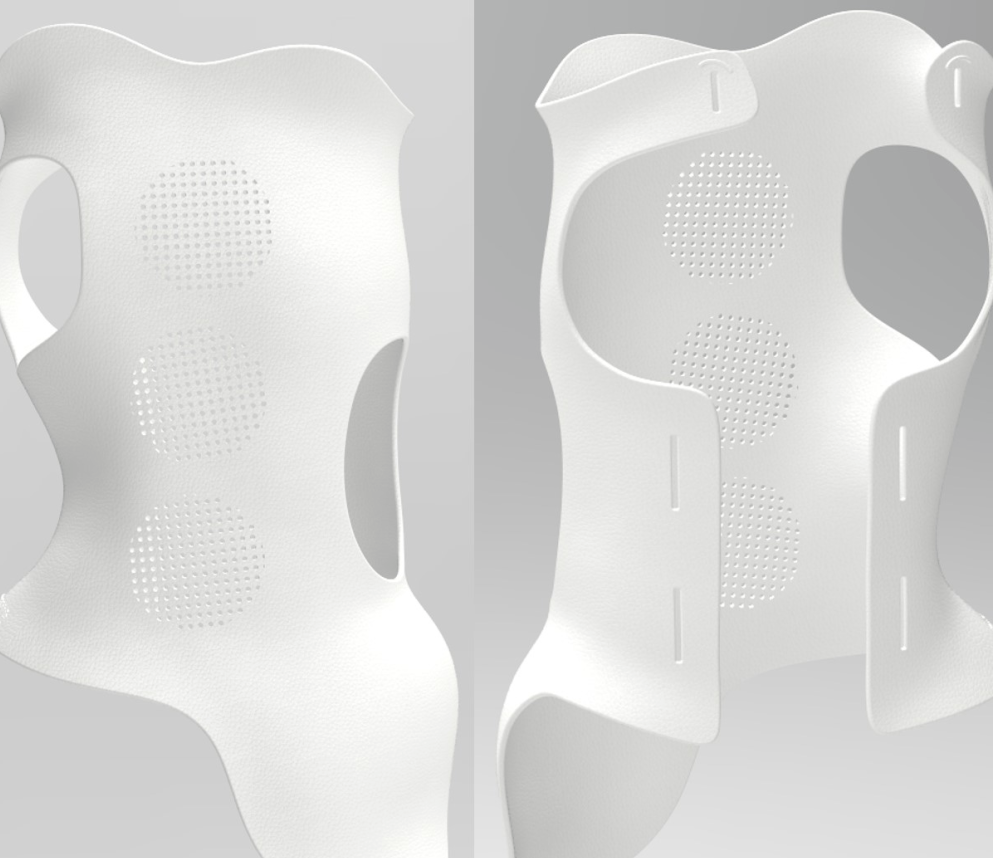

(Scoliosis)

(Scoliosis)

Through topology optimization and subtractive design, 3D printed braces are both aesthetically pleasing and fitting, increasing patient willingness to wear them.

With advancements in materials science and AI modeling, 3D printed braces may become the “gold standard” in rehabilitation therapy in the future, even integrating sensors for real-time monitoring of rehabilitation progress!

From “fixation” to “functional optimization,” 3D printing technology is redefining rehabilitation braces. It is not only an upgrade of medical tools but also a respect for patient dignity and quality of life. We believe that in the near future, more patients will enjoy the precision and comfort brought by technology!

Delin Prosthetics and Orthotics Beijing Co., Ltd.