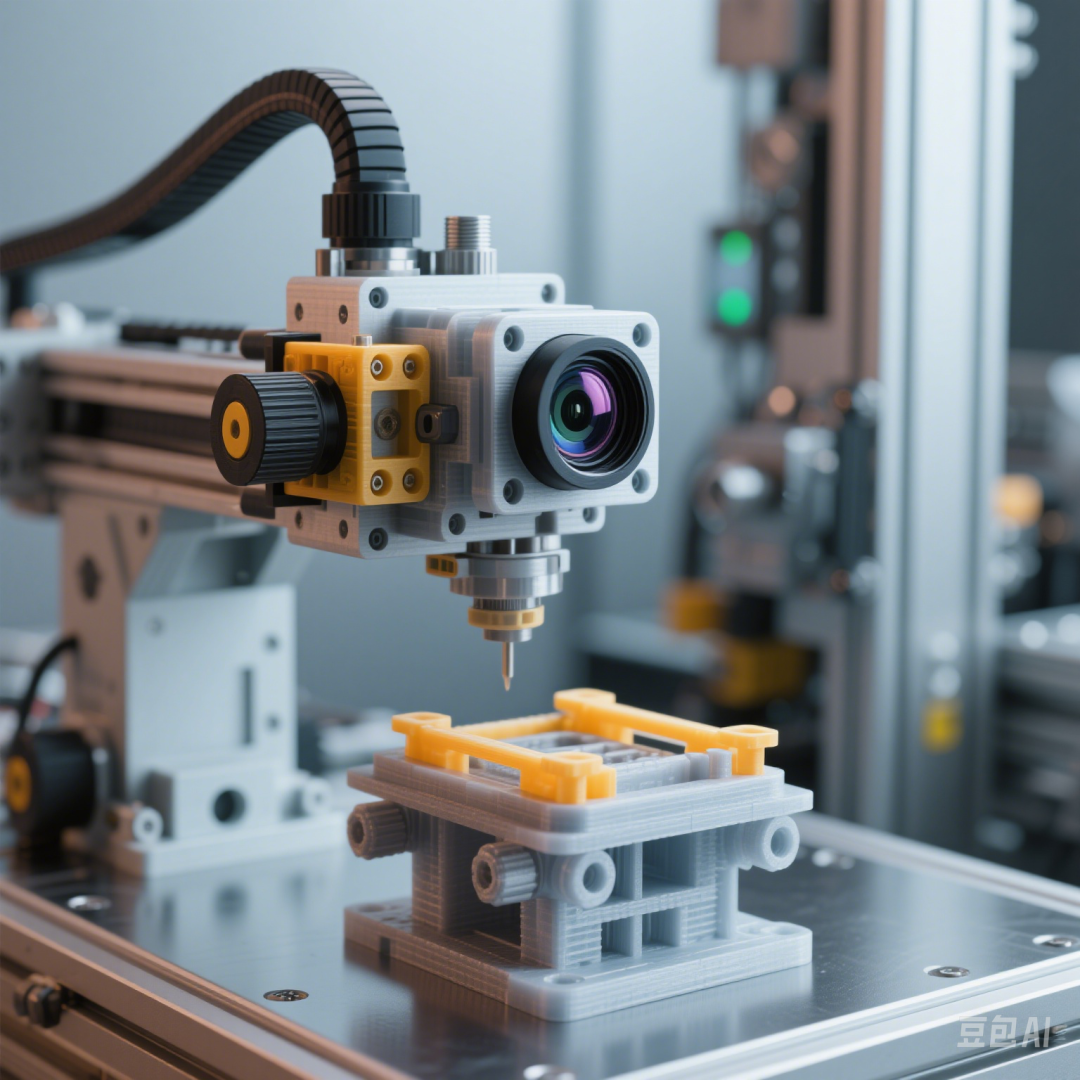

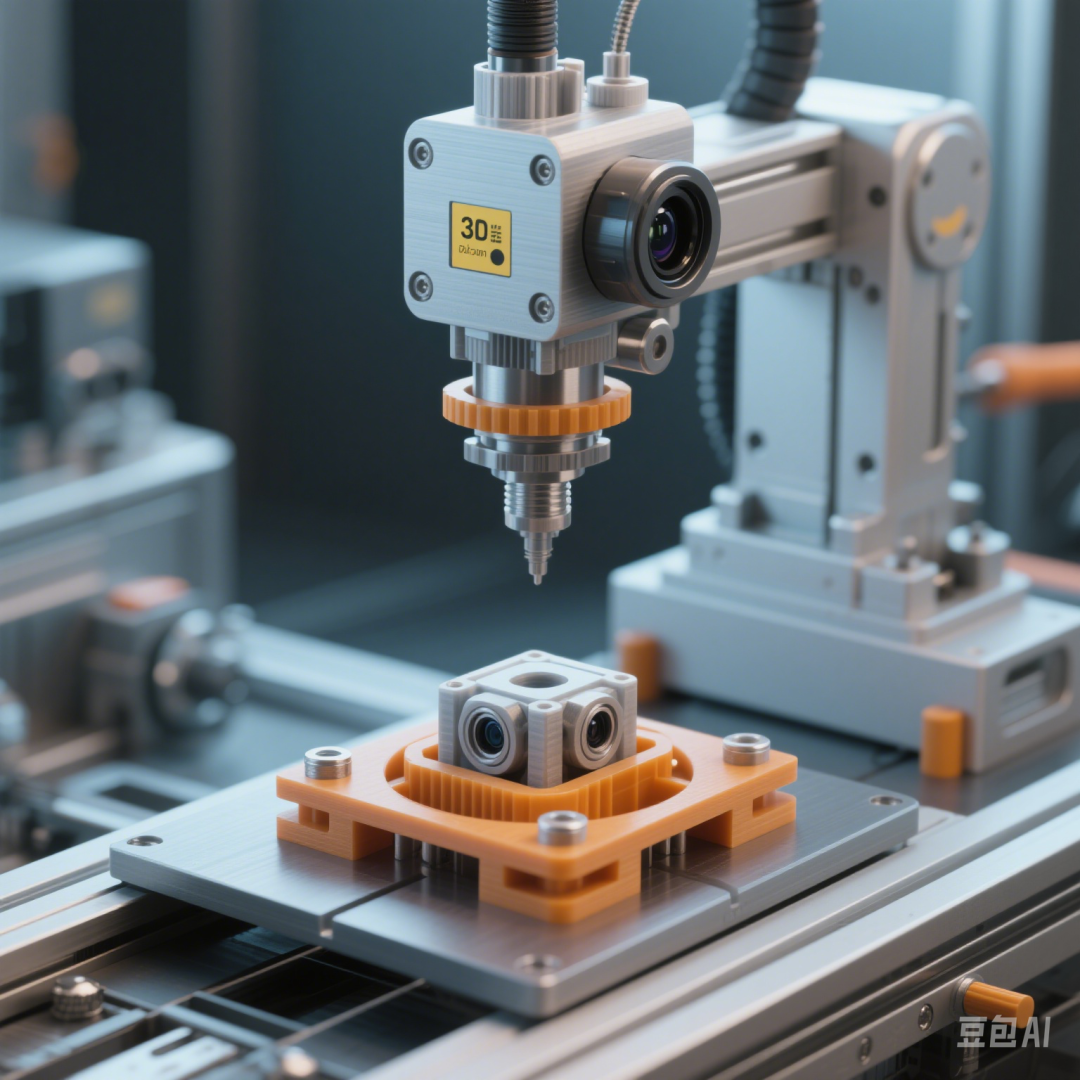

Machine Vision + 3D Printing

ANNUAL REPORT

Lightweight, High Precision, Low Cost

In industrial inspection scenarios,

have you encountered the following issues?

Complex structure of visual inspection equipment, time-consuming installation and debugging?

Traditional metal brackets are bulky and inconvenient to move?

High costs for custom sensor brackets in special scenarios?3D printing technology

With its unique manufacturing advantages,

it is quietly integrating deeply with machine vision inspection equipment,

bringing a new transformation to the industry.

How does 3D printing empower machine vision inspection equipment?

1. Lightweight Structure

Topology optimization design + high-performance materials reduce equipment weight by over 40%, alleviating the burden of equipment weight.

2. Integrated Design

Print embedded sensor brackets (such as lens mounts and light source slots) to eliminate assembly errors.

3. Rapid Iteration

Complete customized equipment accessory prototypes in 24 hours, reducing trial and error costs by 70%.

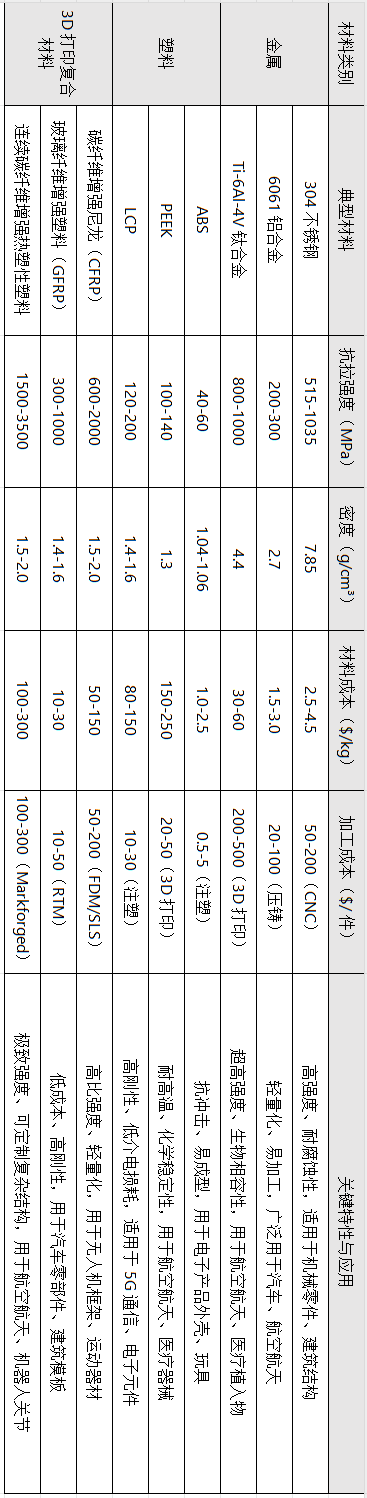

Comparison of various material properties. Please flip your phone to view.

Data sourced from the internet.

3D printing technology offers a high degree of design freedom and rapid prototyping capabilities, allowing complex design concepts to be quickly transformed into physical objects. In the manufacturing of machine vision inspection equipment, it can achieve complex structural designs that are difficult to accomplish with traditional processing techniques. Additionally, in some special inspection scenarios, traditional generic equipment may not meet the requirements, while 3D printing technology can customize inspection equipment components based on specific inspection objects and environments, enabling the equipment to better adapt to complex working conditions and improve inspection efficiency.

As technology continues to advance, the integration of 3D printing with machine vision inspection equipment will become even closer. In the future, we may see more intelligent and personalized inspection devices that will play an important role in more fields, providing strong momentum for the development of intelligent manufacturing.