1 Introduction

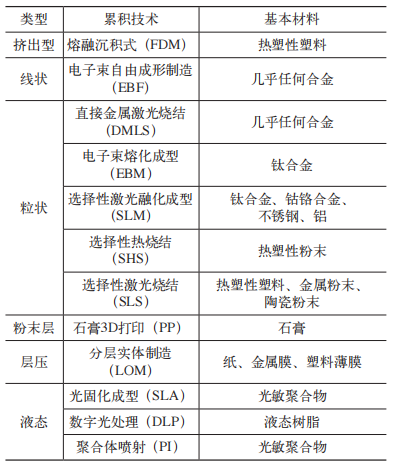

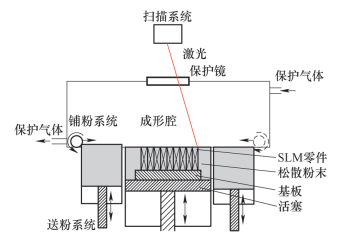

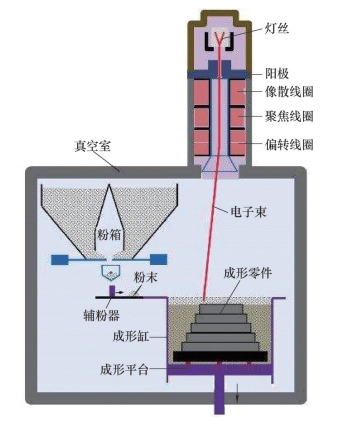

2 3D printing technology has become the main body of additive manufacturing technology

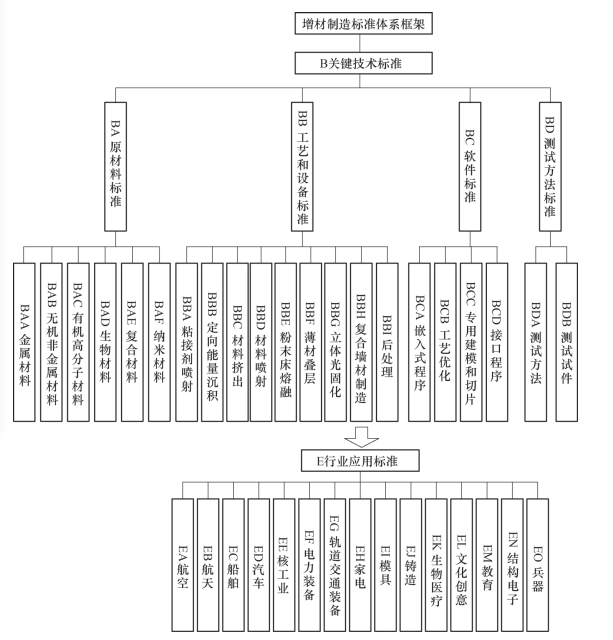

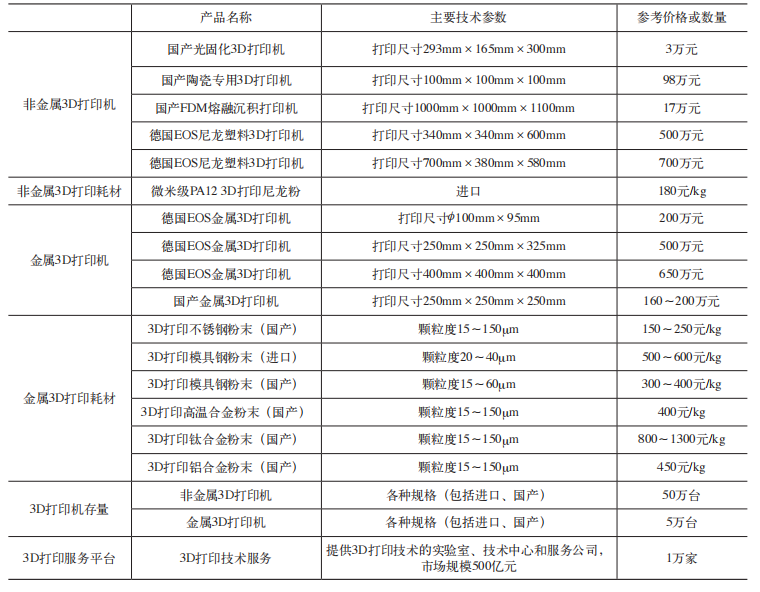

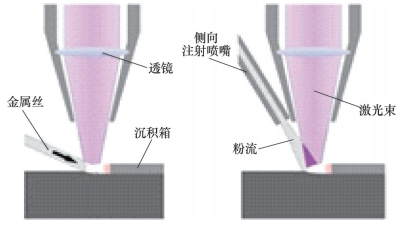

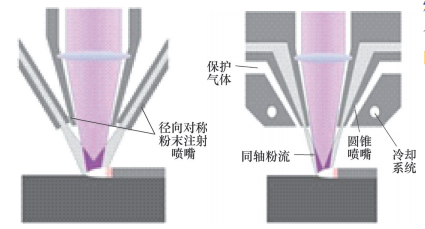

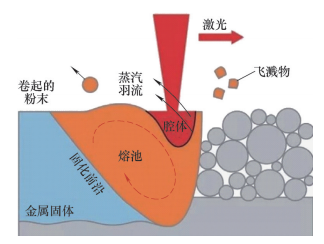

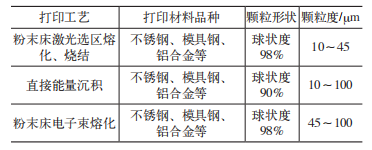

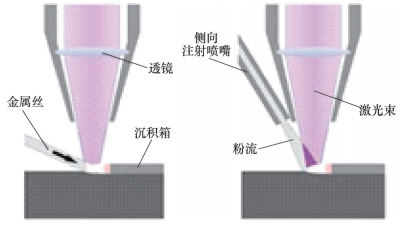

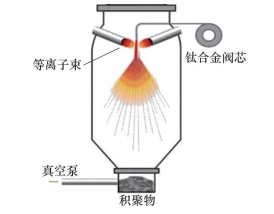

3 Metal 3D printing has established a relatively complete industrial chain

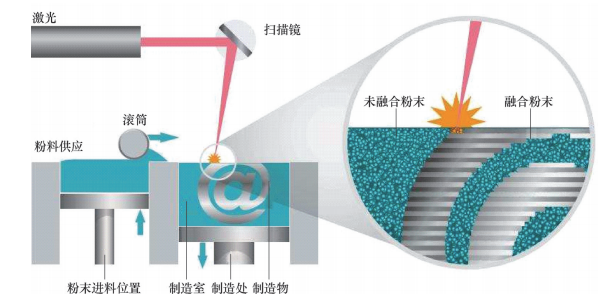

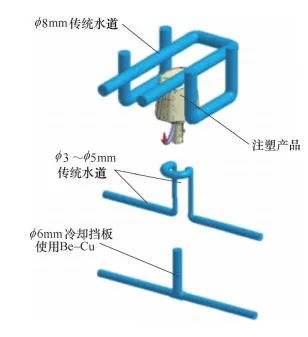

4 Metal 3D printing technology has been successfully applied in the mold manufacturing field

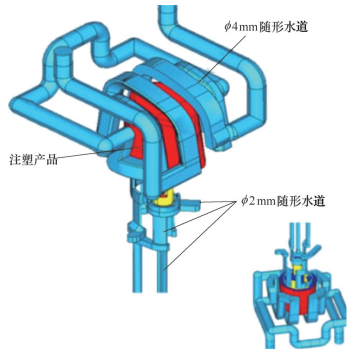

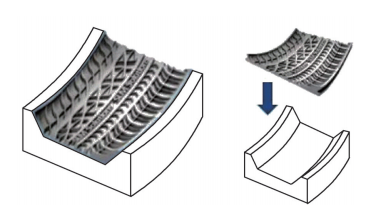

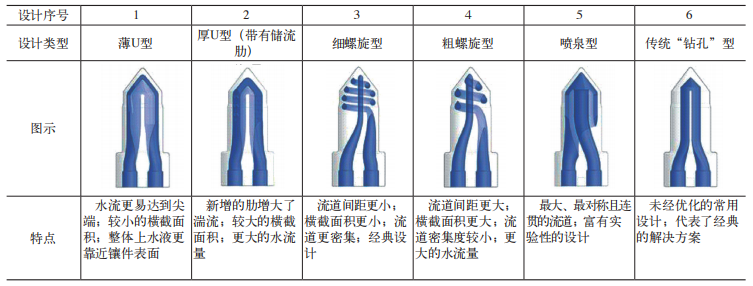

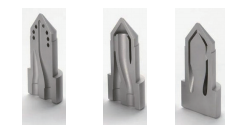

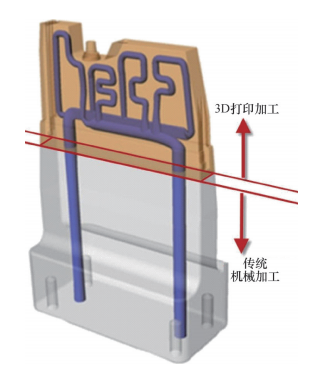

b)Conformal Cooling Channels (After Improvement)Figure 5 Optimization Design of Cooling Channels in Injection Molds

b)Conformal Cooling Channels (After Improvement)Figure 5 Optimization Design of Cooling Channels in Injection Molds

5 Metal 3D Printing Technology: An Important Link in Intelligent Mold Design and Manufacturing

6 Conclusion