1. What is 3D Printing Technology

2. The Process of Medical 3D Printing

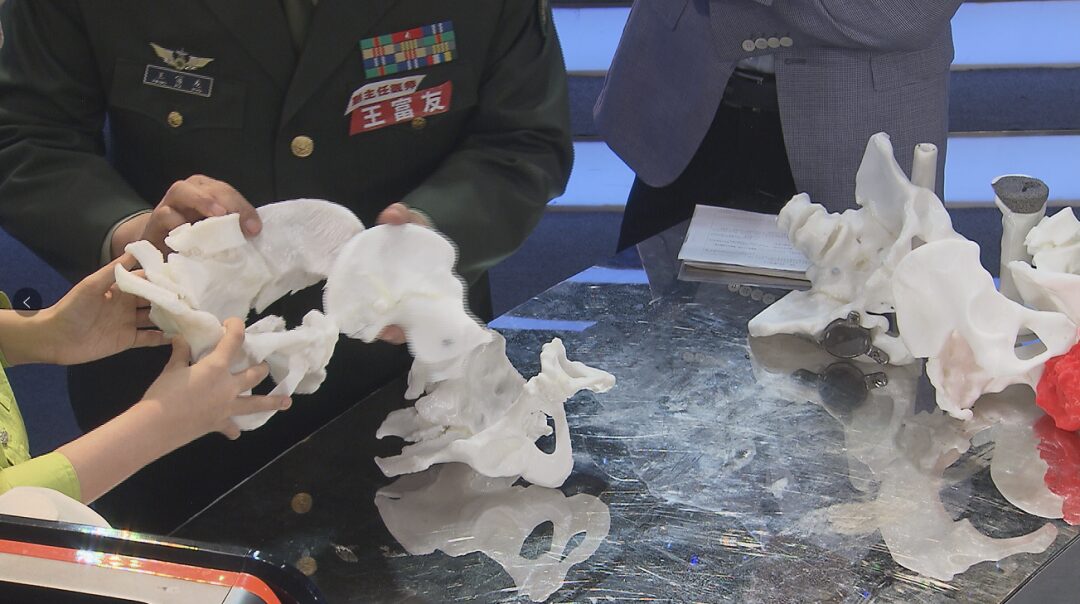

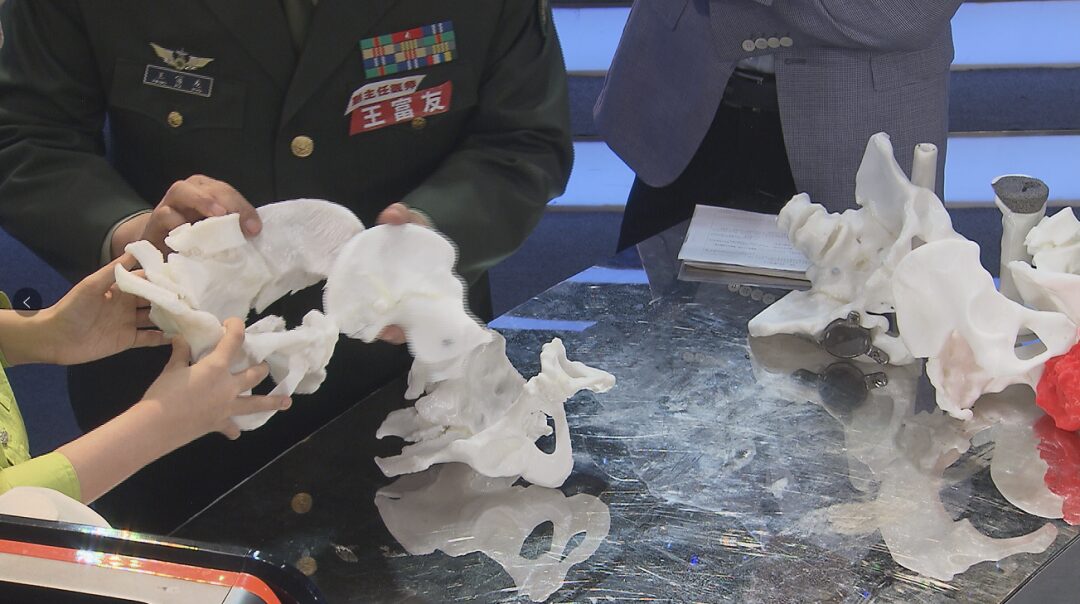

3. Applications of 3D Printing in Orthopedics

1. Preoperative Planning

1. What is 3D Printing Technology

2. The Process of Medical 3D Printing

3. Applications of 3D Printing in Orthopedics

1. Preoperative Planning