According to the 2020 energy sector industry standards revision plan issued by the National Energy Administration, the China Electric Power Research Institute Co., Ltd. has drafted two power industry standards: “12kV Integrated Column Switch” and “12kV Integrated Ring Network Box”. In June 2021, the Distribution Technology Center of the China Electric Power Research Institute organized over 30 mainstream manufacturing companies of distribution switches and terminals to initiate the implementation of these two standards.

In the past two years, the new regulations have been continuously applied at the device ports. The standards stipulate that the DTU adopts a dual-core design, distinguishing between the real-time core and the management core. The real-time core requires an MCU to ensure protection and high-speed sampling, while the management core requires a high-performance processor to achieve status detection, data reception, analysis, and communication. The hardware interface specifies three Ethernet ports, multiple serial ports, 4G communication, a national encryption chip, and Beidou positioning synchronization.

Beijing Yuanda Innovation Technology Co., Ltd., based on its large power customer base and close cooperation with Shanghai Xianji Semiconductor Technology Co., Ltd., has designed a DTU/FTU minimal system core board using domestically produced high-performance RISC-V core MCU. Customers can fix the external design according to State Grid standards and can also expand custom functions.

The grid automation system generally consists of the following parts: distribution master station, distribution electronic station (usually located in substations, optional), distribution remote terminal (FTU, DTU, etc.), and communication network. The distribution master station is located in the urban dispatch center, while the distribution electronic station is deployed at 110kV/35kV substations. Substations are responsible for communication with the power terminal devices such as DTU/FTU in their jurisdiction, while the master station is responsible for communication between various substations.

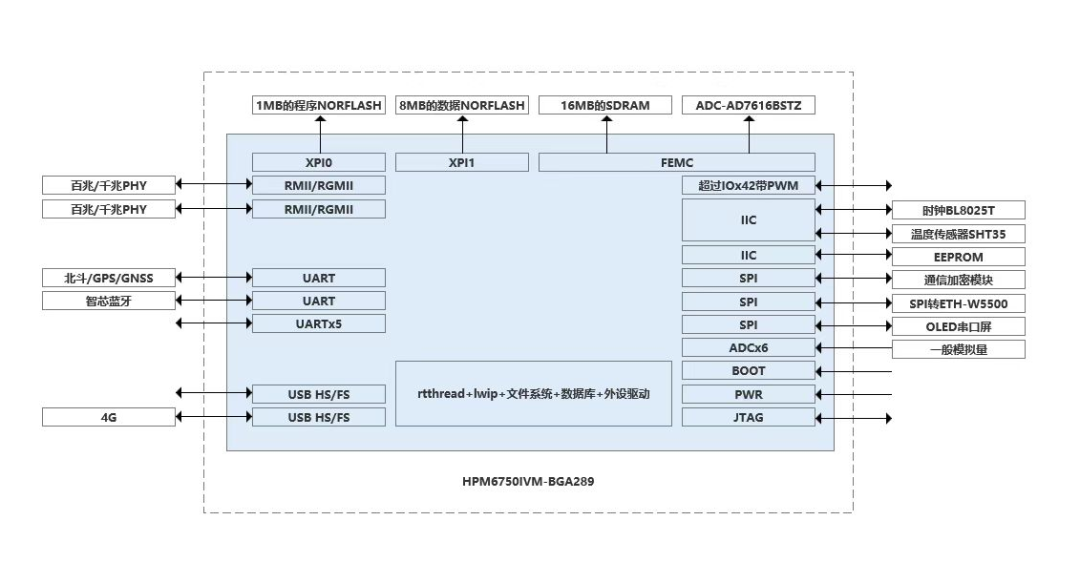

Below is the block diagram of the minimal system board:

Considering the system’s second-level response requirements and the grid’s need for autonomous control, the Yuanda Innovation design team did not choose a design approach using ARM Cortex-A cores running an operating system, but instead opted for the high-performance MCU HPM6750IVM from Xianji Semiconductor. This MCU comes in a BGA289 package with up to 195 GPIOs; 2M SRAM, and flexible external FLASH capacity; an internal DSP unit that supports SIMD and DSP instructions; a fully autonomous dual-core RISC-V with a clock frequency of 816M, setting a performance record of up to 9220 CoreMark and up to 4651 DMIPS for MCUs. The chip operates in a temperature range of -40℃ to 105℃, meeting the stringent working environment of the power industry.

1 16-bit ADC and 3 12-bit ADCs: Supports analog signal acquisition.

The example program for the core board’s FTU/DTU includes the rt-thread operating system, Lwip network protocol stack, flash file system, local database, and corresponding peripheral driver examples, which can greatly assist customers in simplifying development.

At the same time, this solution also has a hardware-compatible single-core version, HPM6450IVM, which can flexibly adapt to various high and low-end application scenarios in the power sector. It supports FreeRTOS, RT-Thread, and is compatible with the lightweight Harmony system.

The international situation is unpredictable, and trade wars are escalating. The safety and stability of the power grid are crucial, and power equipment manufacturers have an increasing demand for domestically produced autonomous and controllable alternatives. Beijing Yuanda Innovation Technology Co., Ltd. has long focused on the power industry, closely following the standards of the State Grid and Southern Grid, providing customized solutions and diversified services such as component supply chains for numerous power equipment manufacturers.

Currently, Beijing Yuanda Innovation Technology Co., Ltd. has launched multiple domestic solutions, widely applied in power equipment manufacturing, and promoted through the “I Love Solutions” platform, contributing to the localization of the power industry.

Editor: Liu Laigang

Contributed by: Beijing Yuanda Innovation Technology Co., Ltd. Xiong Feng

About the Shenzhen Electronics Chamber of Commerce

The Shenzhen Electronics Chamber of Commerce (SECC) was officially registered in January 2003, consisting of enterprises and groups engaged in research, development, production, sales, teaching, and services of electronic information products in Shenzhen, and is a non-profit organization with corporate legal person qualifications. It is a national, provincial, and municipal-level “Four Good” Chamber of Commerce, a 5A social organization in Shenzhen, and a public service demonstration platform for small and medium-sized enterprises in Shenzhen.

SECC currently has over 2,600 registered members, with member products involving the research, production, and sales of automation equipment, artificial intelligence, electronic components, automotive electronics, robotics, digital products, home appliances, and other products, as well as the entire industrial chain of electronic markets, internet trading platforms, innovation research and development centers, testing and certification, and software development.

<< Slide to view the next image >>

To join, please scan the code

Website : www.seccw.com

Phone : 0755-8367 7342

Email : [email protected]

WeChat ID : szdzsh

● Scan to follow us ●