Click the link at the bottom to read the original article and register for the conference online.

Join the Gaogong Intelligent Automotive Industry Group (Autonomous Driving Group 5, Vehicle Networking Intelligent Cockpit Group 3, Intelligent Commercial Vehicle Group) by adding WeChat: 17157613659 and showing your business card, limited to automotive parts and OEM manufacturers.

In the perception technology of autonomous driving, visual recognition has always been an important part. Common monocular vision can identify obstacles through deep learning algorithms, combined with a large sample library, and determine the distance of obstacles based on the shape and size of the obstacles compared to the recognition library.

This is a common visual recognition method that relies on a complete sample library to identify more obstacles.CEO of Zhijia Technology, Zhou Shengyan, stated, that traditional monocular vision uses deep learning algorithms mostly based on 2D image recognition, lacking the ability to model three-dimensional space, resulting in large perception distance errors.

In actual ADAS front-mounted applications, adopting a sensor fusion technology solution often yields more satisfactory results. However, OEMs searching for ADAS fusion products will find that there are very few visual suppliers that can meet performance requirements, forcing OEMs to choose well-known Tier 1 millimeter-wave radars to ensure the comprehensive performance of the fusion solution.

Therefore, for most independent OEMs, suppliers that can provide high-precision monocular vision solutions are highly favored.

On the eve of the ADAS market explosion, the sprint relies on technology to speak.

Zhou Shengyan stated that the usual recognition accuracy error of monocular vision solutions is around 10%, with better solutions achieving about 6%. OEMs typically require the recognition accuracy error of front-mounted visual recognition solutions to be within 6%. While leading industry manufacturers’ products can meet this requirement, they are often costly, and due to their scarcity, they cannot provide timely service responses to all OEMs.

For domestic ADAS suppliers, the opportunity lies in providing products that are not inferior to those of leading manufacturers while enhancing competitiveness in terms of cost and related services in order to seize opportunities in the competition.

Currently, domestic ADAS standards and related regulations are rapidly advancing, and relevant warning technologies for commercial vehicles are gradually being mandated for application, from limited operating conditions for passenger cars and trucks to a broader range of commercial vehicles. The installation of ADAS equipment in passenger vehicles will also receive higher safety ratings in the corresponding NCAP evaluation system.

The domestic ADAS market is entering a period of explosive front-mounted mass production. Whether domestic manufacturers can seize this opportunity is not enough to rely solely on following leading manufacturers; they must have absolute leading technological competitiveness. In this regard, Zhijia Technology has provided its answer:

Redefining monocular vision to create the world’s highest precision.

In 2019, Zhijia Technology launched the third generation of monocular vision solutions, based on precise distance measurement and three-dimensional construction, as well as self-developed software algorithms, to obtain 3D perception information of target objects.

Under unchanged hardware costs, it can achieve point cloud scanning close to radar accuracy within 50 meters, providing direct distance measurement functionality with an accuracy error of 1%; detecting motor vehicles at 200 meters; detecting pedestrians and small targets at 100 meters, and providing precise three-dimensional posture tracking functionality.

Among these, the accuracy of vehicle detection, pedestrian detection, and cyclist recognition can reach 99%, and the accuracy of static obstacle recognition reaches 98%.

Zhou Shengyan stated that monocular recognition can achieve such accuracy under similar hardware performance and scenarios, which is globally leading, thanks to the team’s originality in software algorithms.

This recognition algorithm can achieve precise positioning of targets and three-dimensional static scene construction, and in terms of slope estimation, the error is less than 0.1 degrees compared to laser radar.

This means that monocular vision solutions have achieved effects comparable to laser radar in certain indicators. Zhou Shengyan stated that when laser radar and cameras perceive the environment, there are actually commonalities, but vision is still in the early stages of deep learning.

Common neural networks are mostly based on 2D image recognition, which can only obtain two-dimensional perception information of the environment. However, monocular vision can actually obtain three-dimensional information of obstacles, but it requires different neural network architectures.

In addition to algorithmic innovation, Zhijia Technology also has real feedback from vehicle manufacturers, accumulating 2 million kilometers of mass production product data and over 700,000 kilometers of comprehensive road condition data, covering 42 mass production vehicle models while ensuring data diversity.

Through the third generation of monocular vision products and unique algorithms, Zhijia Technology has taken the lead in redefining monocular vision.

Solving the pain points of the ADAS industry and driving the development of fusion products.

For domestic ADAS manufacturers, the current opportunities in the domestic OEM front-mounted market first appear in the commercial vehicle sector. To break into the commercial vehicle market, one must have the ability to address industry pain points.

The commercial vehicle market consists of two main areas: buses and trucks, which have significantly different usage environments and face different scenarios.Especially in the heavy truck sector, there are many special and complex application scenarios, leading to urgent industry pain points such as high camera installation positions, large differences between loaded and unloaded heights, and significant pitch fluctuations that need to be resolved.

Based on extensive mass production experience in commercial vehicles, Zhijia Technology’s products not only possess strong competitiveness in addressing the pain points faced by heavy trucks but also generate a certain degree of product freedom, allowing for flexibility in vehicle size, dynamic changes in camera installation positions, and eliminating most misrecognition scenarios, etc.

The resolution of these pain points significantly reduces or even avoids the probability of heavy truck AEBS experiencing false braking or missed braking.

This high-performance monocular product naturally performs well in the market, with Zhijia Technology already securing over 80% of the domestic front-mounted bus AEBS market and at least 5 contracts in the truck sector.

Zhou Shengyan stated that based on different customer needs, the company’s monocular vision solution integrated with millimeter-wave radar can achieve higher accuracy and perception redundancy for OEM adoption.

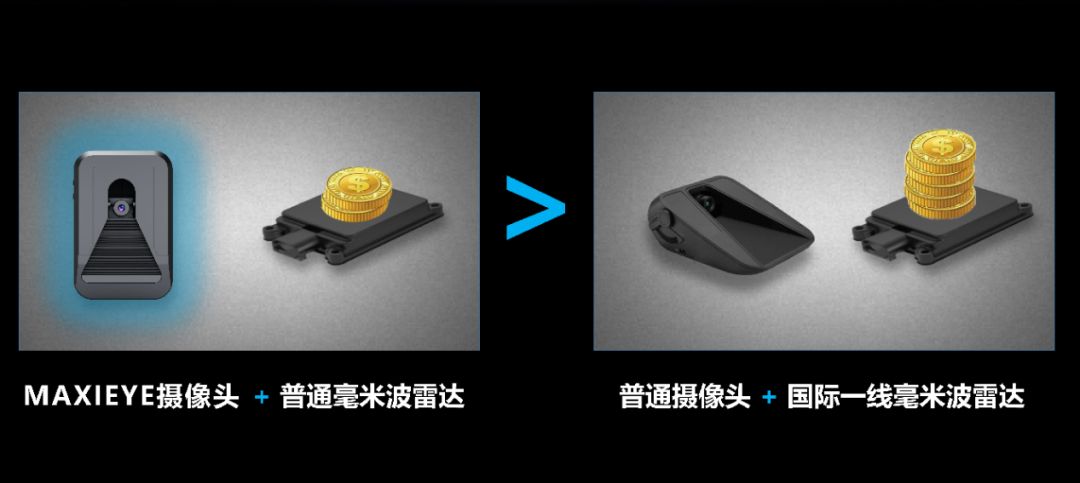

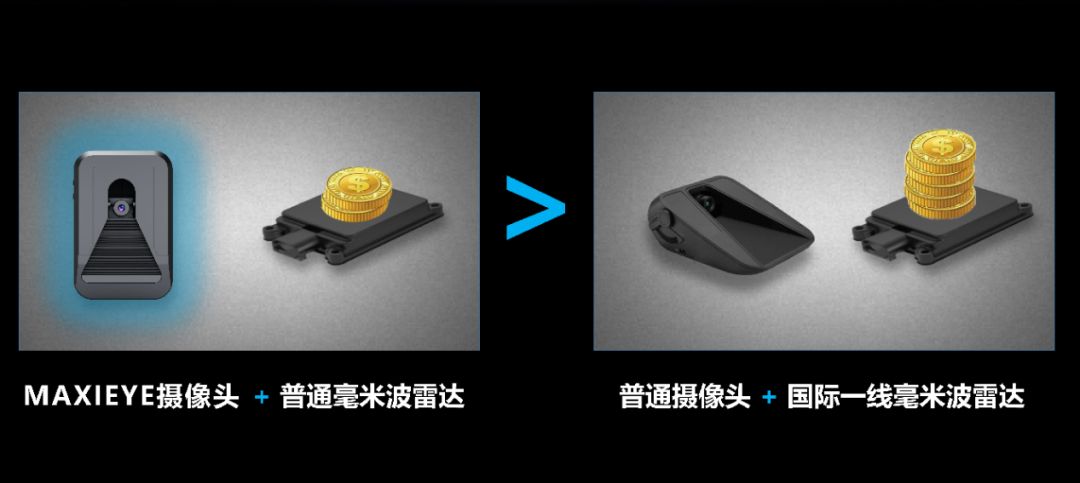

Due to its advantages in vision, the fusion solution does not have to use internationally leading millimeter-wave radar brands, but can select domestic millimeter-wave radar, compensating for and enhancing overall fusion performance through high-precision vision to meet OEM requirements.

This result forms a flexible, high-quality, and cost-effective pure domestic ADAS solution; it also further enhances OEM’s freedom and voice in selecting radar.