On July 7, Yaskawa Electric (China) Co., Ltd., one of the four major robotics giants, held a product launch event at the 6th China International Robot Exhibition, unveiling the new generation of compact robots, the MOTOMAN-GP series, specifically designed for the 3C industry, along with the accompanying control cabinets. This “artifact” tailored for the 3C industry is set to once again stir up a wave of robotics technology in the industry. Attendees included Junji Takeda from Yaskawa Electric Corporation, Kiyoshi Nishikawa, General Manager of Yaskawa Electric (China) Co., Ltd., and Jianliang Chen, Deputy Secretary-General of the China Robot Industry Alliance, who all delivered speeches at the event.

Speed and Precision at Yaskawa’s Best

During the launch event, Hiroyasu Hirota, Head of the Robotics Division at Yaskawa Electric, provided a detailed introduction to the specifications and features of the GP series robots and the new generation of robot control cabinets. The newly launched models include GP7, GP8, GP12, and the corresponding control cabinets YRC1000 and YRC1000micro. Compared to previous compact robots released by Yaskawa, the GP series products represent another technological innovation.

In response to the production speed requirements of the Chinese 3C industry, the GP series arms have been designed with a lightweight structure and equipped with the latest drive control technology, achieving the highest levels of speed and precision in Yaskawa’s history. The GP7 and GP8 models have improved their composite speed by approximately 30% compared to previous models, significantly reducing cycle times and greatly enhancing overall efficiency. Additionally, considering the operational environments of most factories, the GP series robots are designed to meet the IP67 standard, enhancing their resistance to water and dust, making them more suitable for various environments.

The new generation GP series robots are suitable for various applications including the handling, assembly, dispensing, loading and unloading, and polishing of small components, making them perfect for the rapidly evolving electronics industry that demands high precision and space efficiency. The new generation of robot control cabinets, YRC1000 and YRC1000micro, utilize a new control method to accommodate diverse global voltage and safety specifications, enabling the GP robots to achieve optimized functionality.

Expanding Capacity to Meet Demand

In the first half of this year, robot sales surged, leading to longer delivery times across the industry. Kiyoshi Nishikawa, General Manager of Yaskawa Electric, stated that Yaskawa Electric achieved local production of industrial robots in Changzhou in 2013, with annual output continuously increasing. Moreover, the main components of the newly launched GP series products are sourced from Yaskawa’s own products, allowing for shorter delivery times. To meet the strong demand in the Chinese market, Yaskawa Electric’s third factory is expected to be completed in the spring of 2018.

Future Product Development Continues with the GP Series

Regarding the future development strategy for Yaskawa robots, Hirota mentioned in a media interview that in the first half of this year, Yaskawa primarily launched the GP series compact robots, with the GP7 having a maximum payload of 7KG and a maximum horizontal reach of 927mm; the GP8 has a maximum payload of 8KG and a maximum horizontal reach of 727mm. In the second half of this year and into 2018, larger payload and reach GP series robots will be introduced based on this series. Additionally, Yaskawa will further strengthen cooperation with local Chinese enterprises to expand its market share in China.

Exciting Presentations at Yaskawa CIROS Exhibition

Yaskawa Electric showcased 11 sets of robotic products, presenting numerous industrial robot automation solutions.

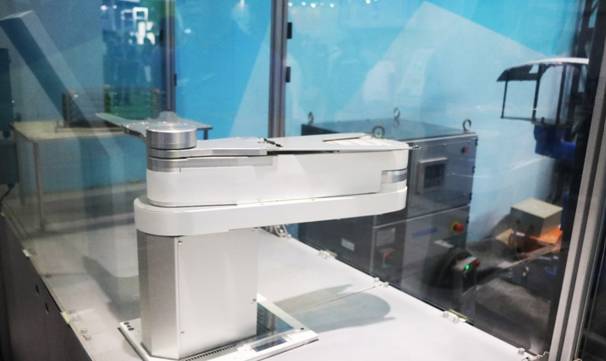

Semi-Conductor Handling System (MR124)

The semi-conductor wafer handling system, composed of the 5-axis robot MR124 and the position detector PVR1130, features a lightweight and low-inertia arm, capable of generating optimal individual and composite movements, producing the best trajectories with high precision and a large range of motion.

Automatic Ballpoint Pen Assembly System (GP8*3)

The demand for robotic automation in the assembly processing line of small components is increasing. In response to this market application demand, the automatic ballpoint pen assembly system has been launched. The new high-speed robot GP8, with an IP67 protection rating for all axes, effectively suppresses dust, and the compact control cabinet with a volume of only 15L expands its application range and shortens cycle times.

Collaborative Robot (MOTOMAN-HC10)

The development direction for 3C electronics manufacturing enterprises is agile manufacturing, flexible manufacturing, and lean manufacturing. The high precision, high flexibility, and high accuracy characteristics of industrial robots align with this development direction and manufacturing trend. The MOTOMAN-HC10 is based on the international standard ISO10218-1, enabling safe and flexible collaboration with humans in environments without safety barriers.

Coordinated Actions of Dual Robots and Three-Axis Positioners (Three-Axis POS Positioner + MA1440 Dual Robot Coordination)

The coordinated actions of dual robots and three-axis positioners effectively utilize both sides of the workstations for switching, significantly improving production efficiency for users. Additionally, symmetrical welding with dual robots reduces workpiece welding deformation, achieving optimal welding process requirements.

3D Vision Handling System (MH180 + MOTOSIGHT-3D)

MOTOSIGHT-3D is Yaskawa’s latest rapid 3D vision handling function, capable of visually locating and accurately grasping workpieces placed in any orientation within a material basket, achieving high precision recognition and sorting for oily workpieces and those with complex curved structures.

CNC Loading and Unloading System (MH12)

This proposal for CNC loading and unloading automation is for aluminum casings of mobile phones and tablets. Previously, the operation method involved using a dedicated linear 3-axis machine for parallel handling. By implementing robotics, loading and unloading operations and reverse operations have been achieved, accommodating various workpieces and saving space.

Large Spot Welding System (MS210)

The system consists of the six-axis robot MS210, welding gun, gun exchange device, and interactive signal system, capable of achieving stable and high-speed spot welding actions, providing you with a perfect solution.

For more exciting content, please click

New dining experience! A UK restaurant uses a super cool roller coaster robot to serve dishes to guests!

Watch your privacy! Hackers can monitor brainwaves to steal account passwords

Want to experience a tornado? Try this VR project!

Toyota launches its first care robot: can be used to care for the elderly or disabled

Who is more reliable for future healthcare, humans or chatbots?

Long press the QR code to follow the public platform

Submission email: [email protected]

Contributions are rewarded!