——— A Simple Method for Raising and Lowering the Blade

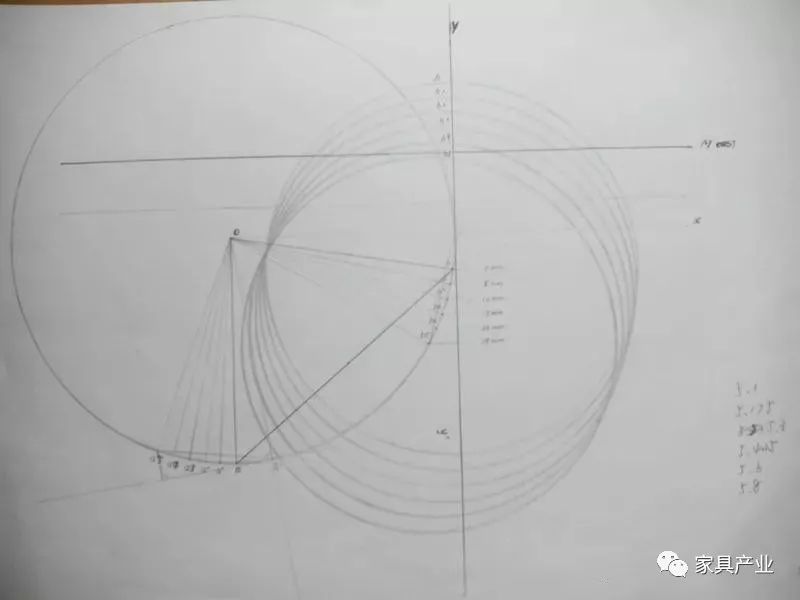

The principle is very simple and can often be seen in daily life. It involves the rotation of a triangle. One vertex is the axis (the center), and the other two vertices are referred to as the active angle and the passive angle. The active angle and passive angle rotate around the axis simultaneously.

Let: the axis be O, the active angle vertex be a, and the passive angle vertex be b. When oa = ob (isosceles triangle) rotates around O, the trajectory of active angle a coincides with the trajectory of passive angle b. The distance traveled by active angle a on its trajectory equals the distance traveled by passive angle b on its trajectory. When oa > ob or oa < ob, we have: the distance of active angle a / the distance of passive angle b = oa / ob.

In practical application for making the table saw, the active angle a is the locking point for adjusting the blade height, and the passive angle b is the center of the blade. The longer the travel of active angle a, the easier and more accurately the blade height can be controlled.

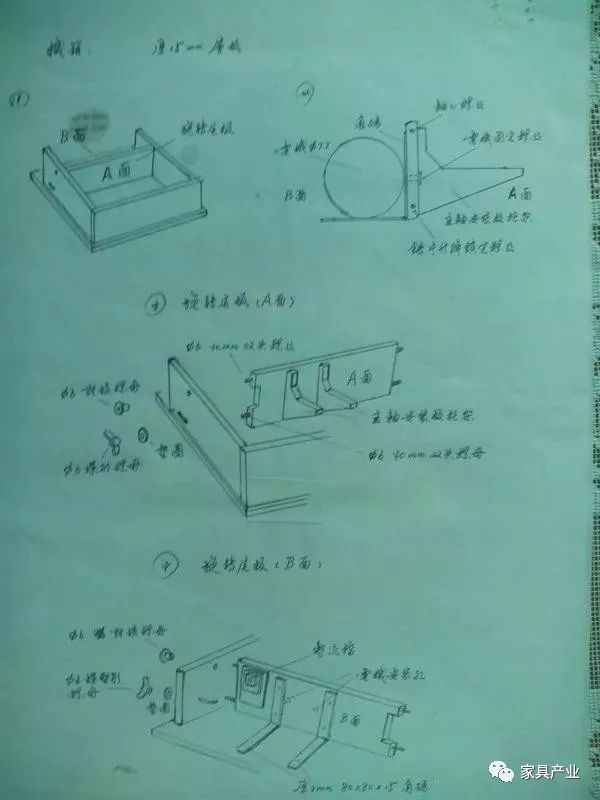

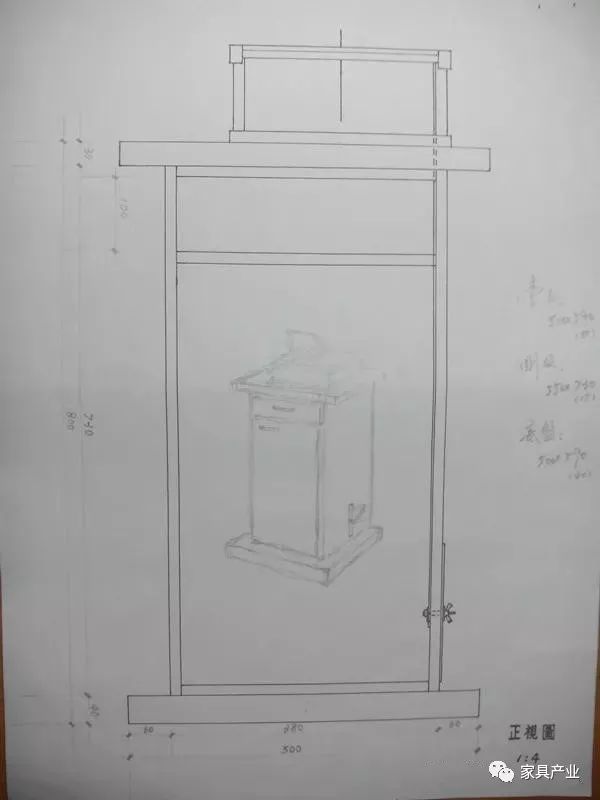

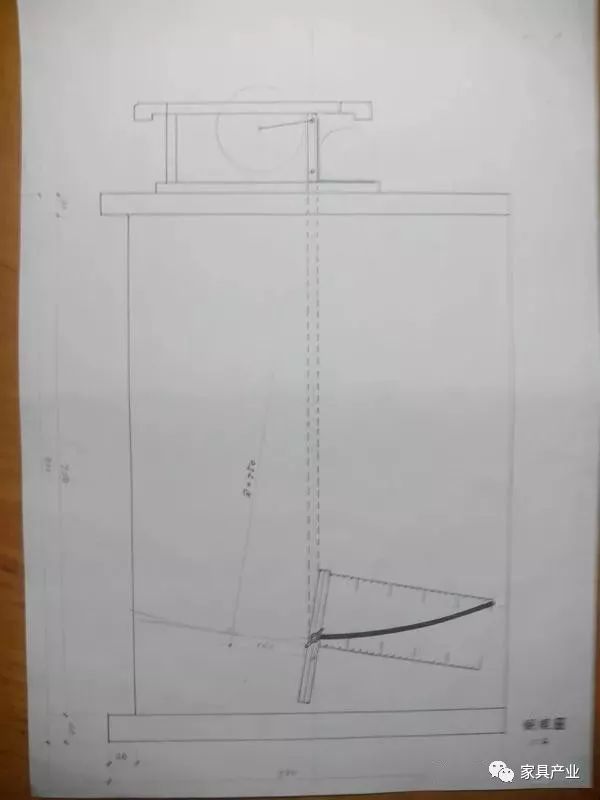

Based on the above principle, I made a table saw using an isosceles triangle with R = 75mm. Since this is an experimental project, I used scrap wood, which is a bit rough, but it’s workable.

After testing, the blade raising and lowering function is basically feasible. However, to achieve more precise blade height adjustments, a magnifying glass can be installed to extend the travel of active angle a.

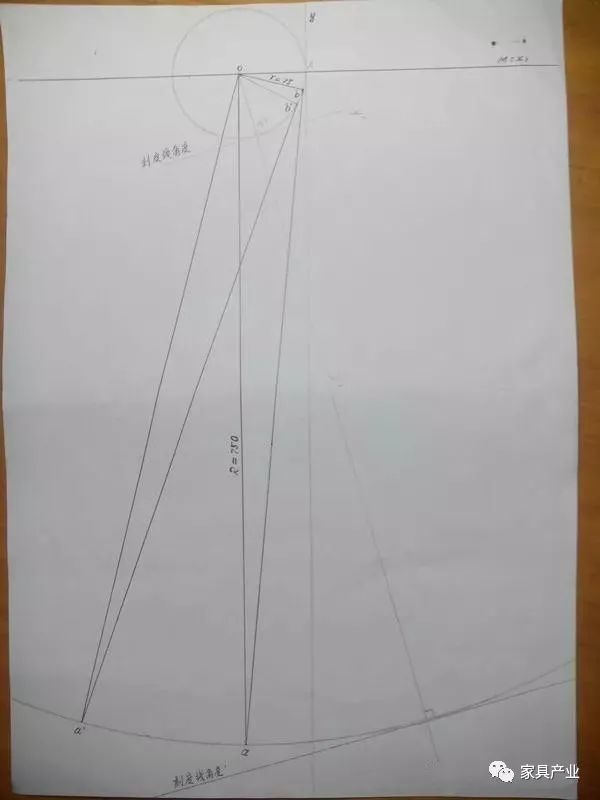

First, fix the table saw to the edge of the workbench (you can also make a special cabinet or frame for it). Extend oa, considering that the general workbench height is about 800mm, so I chose 10 times the original 75mm — 750mm. According to the triangle principle, the travel of active angle a will also be expanded 10 times.

Find a steel rod that is 770-780mm long (ordinary steel, stainless steel, aluminum alloy, or even a 1m long steel ruler can work) and fix it to the edge of the rotating tailboard.

Measure 750mm from the axis to make a hole. Then, through the inner side of the table saw’s side plate, through the bottom of the machine box and the surface of the workbench. On the outside of the workbench’s side plate, draw an arc with the axis as O and 750mm as the radius to create a blade adjustment control groove, then install screws, washers, butterfly nuts, and add a piece of transparent organic glass or plastic about 200mm long and 15-20mm wide, with a straight line marked in the middle as a scale.

Next, install the scale. From the principle diagram, it can be seen that the raising and lowering of the blade is a function of the travel of passive angle b on its rotating trajectory, which can be calculated point by point, but it’s too cumbersome and unnecessary. It can be achieved geometrically.

Construct a right-angle coordinate system on the principle diagram, drawing a horizontal line at the center as the x-axis, and creating a vertical line (tangent) at the intersection of the x-axis and the trajectory line as the y-axis. Thus, the y-axis effectively becomes the scale line for the blade height adjustment. The corresponding arc (trajectory) on it becomes the accurate position.

Then rotate around the center. When ob coincides with oa, enlarge it 10 times. After debugging, attach a paper scale or a straight ruler parallelly above the y-axis at this angle and the top of the blade adjustment control groove. OK! It’s done.

Move the scale to align it up and down, and the position of the locked nut will then be the correct position. Imagine, when the scale is moved 10mm, the blade raises or lowers by 1mm; move 5mm, the blade raises or lowers by 0.5mm. This precision is sufficient.

Although the method is a bit rough, it is simple, inexpensive, effective, and easy to make. The downside is that it is not very portable and debris removal is not very convenient.

IKEA Changsha store opens tomorrow, 22 specialized stores may face reshuffling!

Why do teak furniture production processes require watering and sun exposure?

Furniture giants are laying off staff one after another! Can the “gecko self-rescue” method turn the tide?

Source: Woodworking Tools Forum

Furniture Industry (jiajucy)

This platform reprints articles with indicated sources for the purpose of providing more information to readers, and does not represent endorsement of their views or positions. If there are any infringements, please contact us in a timely manner.

The furniture industry shares effective information daily. Follow us to achieve mutual success!Service content: new media brand communication, brand soft articles, community communication, in-depth reporting; Enterprises are welcome to cooperate and submit articles, QQ: 948701495

【Recommended Haodian Workshop Furniture】

Official WeChat account: Haodian Workshop Furniture (hdgf_zggn)