Current Status and Prospects of Aircraft Ground Testing Technology

Wang Hong

(Beijing Great Wall Aerospace Measurement and Control Technology Research Institute, Aviation Industry Corporation of China, Beijing 101111)

Abstract: Testing is an indispensable part of all stages of an aircraft’s life cycle. Aircraft ground testing refers to all testing technologies used during the aircraft development process. This article briefly describes the characteristics and development trends of foreign aircraft ground testing, as well as the current development status in China, and proposes development ideas, suggesting a focus on the overall planning of testing equipment at various stages, in-depth research on fault injection methods, improvement of testing equipment development levels, sharing of testing data, and research on new technologies.

Keywords: Testing technology; Ground testing

1 Concept and Connotation

Testing is an indispensable part of all stages of an aircraft’s life cycle, playing an important role from the demand verification stage to the maintenance testing stage. Among these, the functional verification and system verification testing during the R&D phase and the assembly testing during the production phase are commonly referred to as ground testing. In the modern aircraft development process, the entire aircraft, systems, subsystems, and onboard equipment all require testing. According to development work requirements, after the production of equipment is completed, testing must be conducted to verify whether the equipment meets design requirements; subsequently, the integration and interconnection of onboard equipment occurs, integrating relatively independent subsystems. At the same time, subsystem testing is conducted to verify whether the interface relationships between the onboard equipment that make up the subsystems are compatible and coordinated, and whether the functions and performance of the subsystems meet design, specification, and standard requirements. Following this, comprehensive system testing is conducted to verify whether the interface relationships between subsystems are compatible and coordinated, as well as to comprehensively verify from the perspective of the entire aircraft whether the system’s functions and performance meet design, specification, and standard requirements. The production phase then completes debugging tests and result verification. The entire process is illustrated in Figure 1.

Figure 1 Ground Testing

Aircraft ground testing can be defined as: all basic tests of functions, performance, faults, etc., as well as strength tests, environmental tests, and other specialized tests conducted on the aircraft’s onboard equipment, subsystems, systems, and the entire aircraft from the prototype to the completion of production assembly. The test subjects are real onboard components, and the tests also include onboard equipment that interfaces with the test subjects and the environment created to ensure test credibility, primarily mixing real and simulated conditions. The test content mainly includes onboard equipment testing, subsystem testing, system integration testing, production assembly debugging tests, and inspections (including pre-installation inspections, component testing, and testing after assembly completion). In these tests, the testing system is indispensable, not only to assist in data collection, analysis, inspection, and fault diagnosis but also to evaluate the effectiveness of the tests and assembly consistency to support the tests in achieving their intended purposes and ensuring aircraft quality.

Aircraft ground testing refers to all testing technologies used during the ground testing process, including methods, tools, software, equipment, and data processing algorithms. This article mainly discusses the testing technologies involved in basic tests of functional performance and faults.

Historically, ground testing primarily referred to data collection during the testing process, including data acquisition, control, display, and management. In the development phase, it was mainly used to verify the design performance of the aircraft, while in the manufacturing phase, it was used to inspect manufacturing processes and product quality. With advancements in testing technology, the connotation and scope of ground testing have continuously expanded, increasingly involving research and application of testing support, testing management, and testing evaluation technologies, making testing and experimentation more closely integrated. Modern ground testing technology mainly has the following functions: ① Collecting, displaying, alarming, and managing test data, real-time and post-analysis, data playback, and data reuse; ② Providing testing support equipment, simulating test subjects, interface devices, or data, providing test stimuli, simulating forces and environments experienced by test subjects in the air, and assisting in conducting tests; ③ Achieving integration of testing and testing management, managing all resources and processes involved in testing, synchronizing testing and evaluation; ④ Assisting in debugging during production assembly and inspecting quality; ⑤ Providing fault diagnosis means and achieving fault localization when faults occur during testing and production; ⑥ Evaluating whether tests are successful and whether quality is acceptable.

Ground testing is the most extensive, complex, and costly technology in terms of funding in batch production during the aircraft development and production process, and it is a critical technology that runs through the entire life cycle of aviation products.

2 Foreign Development Trends

The development of ground testing is closely related to the development of testing and testing equipment. The development of foreign ground testing technology has three prominent characteristics.

2.1 Integration, Generalization, Digitalization, Virtualization

Several examples illustrate foreign performance in these areas.

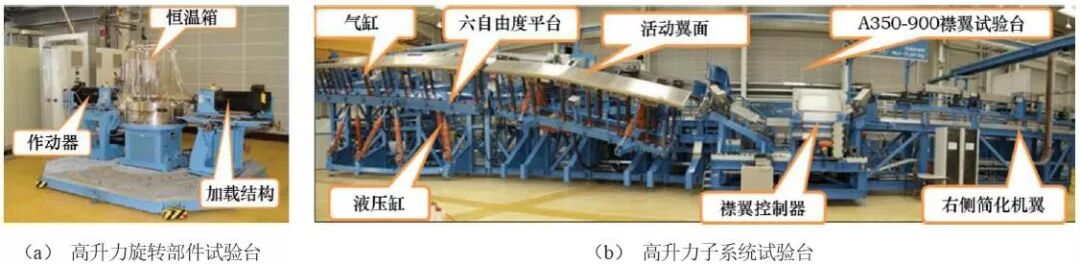

Figure 2 shows Airbus’sA350 high-lift rotating device test bench and high-lift subsystem test bench. All rotating devices such as gear rotating actuators, power drive devices, etc., can conduct functional, performance, and fault tests on the high-lift rotating device test bench (as shown in Figure 2 (a)). At the same time, this test bench is equipped with a constant temperature chamber, allowing tests to be conducted under different temperature environments. The test bench integrates previously separate functional performance tests and environmental tests, as well as test items for different test subjects, which places higher demands on the testing system, including meeting testing requirements for all test subjects, all test items, and all temperature environments, as well as ensuring that the testing equipment itself operates normally under high and low temperatures. From Figure 2 (b), the high-lift subsystem test bench can be seen, where the left wing uses high-lift subsystem onboard components, and a flexible loading system simulates aerodynamic forces to achieve the required actions for testing. The right wing adopts a virtual form, using a computer model to simplify the wing surface’s participation in the test. This form requires the testing system to not only meet actual data collection but also to have the capability to support virtual testing.

Figure 3 shows TechSAT’s ADSII integrated testing system, which is a real-time testing and simulation environment for avionics systems. It is suitable for testing, inspection, and troubleshooting of avionics systems, as well as for system integration and verification before installation. It can also interconnect with systems through buses, executing flight situation reproductions with the participation of onboard subsystems.

Figure 2 High-Lift Test Bench

Figure 3 ADSII Integrated Testing System

Boeing 787 integrated test facilities ITV (Integration Test Vehicle ) and F-35 integrated test facilities VSIF (Vehicle Systems Integration Facility ), consist of onboard equipment from flight control subsystems, hydraulic subsystems, flight control subsystems, avionics systems, etc., demonstrating a higher degree of integration and generalization. In recent years, the concept of virtual iron birds has also been proposed and researched abroad.

2.2 Overall Planning, Centralized Control, Distributed Layout

In the aircraft design phase, the planning of testing equipment is conducted simultaneously, and the use of centralized control and distributed layout for large testing equipment is a significant characteristic of the foreign aviation testing field’s development.

A typical system is the FAL GSE Project proposed by Airbus Defense and Space, which plans the testing equipment for the entire aircraft assembly process to complete ground testing of avionics equipment and cables. The testing equipment utilizes digital device simulators and simulation base stations distributed throughout various parts of the aircraft to achieve simulation and testing of aircraft systems from simple to complex, covering power systems, atmospheric data systems, radio altimeters, flap control systems, engine control systems, landing gear systems, etc. The testing tools provided for a specific aircraft model’s assembly include several categories: simple tools, such as overflow valve simulators; neutral tools, such as communication/navigation testing equipment; complex tools, such as bus analyzers; extremely complex tools, such as wiring test benches; and special tools, such as FAST (Final Assembly System Testing).

FAST mainly completes system function testing and verification during the assembly phase, and its basic architecture is illustrated in Figure 4. Numerous testing base stations are set up on the aircraft, and the collected data is transmitted to their respective I/O nodes based on location. All node data is centralized to the main control computer for management, while other workstations, under the unified coordination of the main control computer, are responsible for data storage, program execution, etc. This represents a typical and complete distributed layout. The aircraft itself is large, with many measurement points distributed throughout various parts, making it very suitable for distributed data collection. Transmitting data to the main control computer for centralized management facilitates overall management of data and control and analysis of the testing process, leading to an increasing number of aviation testing systems adopting this distributed centralized architecture. Another feature of FAST is its Digital Equipment Simulator (DES), as shown in Figure 5. DES provides simulated outputs of various signals to emulate onboard equipment. When the aircraft assembly is completed and testing is required, DES provides simulation functions to replace those devices that cannot be operated for safety or other reasons, such as engines and landing gear; when faults occur during testing, DES can also replace real onboard components suspected of having faults, playing a simulation and tracking role, quickly determining whether the fault originates from the removed onboard component through data flow detection. Faulty onboard components are then quickly confirmed for deeper fault causes through the automatic testing system. The entire process is very straightforward.

Figure 4 FAST Architecture Diagram

Figure 5 Digital Equipment Simulator

2.3 Vertical Integration Testing

In simple terms, vertical integration refers to the use of key technologies such as composable and reconfigurable system architectures to achieve integration of testing from development, production to maintenance support. From the perspective of ground testing, vertical integration is very meaningful as it effectively promotes the resolution of inconsistencies in testing data throughout the life cycle. Lockheed Martin’sF-35 developedLM-STAR is currently the most representative vertical integration comprehensive testing system, featuring a universal open architecture. Subsystems can operate independently or be combined into a comprehensive system to meet complex object testing, providing comprehensive testing capabilities for analog, digital, RF, and optoelectronic systems, supporting interchangeable virtual instrument technology and ATML (Automated Test Markup Language), fully aligning with the standards executed by the U.S. Department of Defense’s automated testing systems and the “Next Generation Testing” (NxTest) technology standards developed by the three military branches.LM-STAR has structural forms at different stages as shown in Figure6.

Figure 6 LM-STAR Adopting the Same Architecture at Various Stages

3 Current Development Status in China

In China, ground testing of onboard equipment is mostly conducted by the equipment development units themselves in self-developed testing environments. The level of testing equipment used in the aviation field varies widely, and there are many reasons for the poor effectiveness of testing equipment. One significant aspect is that some onboard equipment development units and testing equipment development units do not fully understand the products during the early stages of new product development. The testing requirements proposed by onboard equipment designers are not very complete, and the testing equipment formed by testing technicians based on these requirements can meet the current needs. However, as onboard equipment designers deepen their understanding of the products and their tests, they will inevitably propose more testing requirements, which will lead to the testing equipment having to be completed in a patchwork manner, affecting the system level. Therefore, testing technicians must closely cooperate with product developers from the beginning, deeply understand the objects being tested, and remind users of potentially overlooked testing requirements from a testing perspective. At the same time, the design of the testing system should be as flexible as possible, allowing for the insertion and expansion of new requirements, which also requires mutual understanding between supply and demand sides, rational treatment of technology, and recognizing that flexibility has limits; the expansion of requirements must have boundaries.

As there is currently no true subsystem integration unit in the domestic aviation field, subsystem ground testing is basically conducted at the chief designer unit, while system integration testing is conducted based on connections at the subsystem test bench. In terms of test bench design, test design, or the functional performance of testing systems, the domestic level is generally comparable to that of foreign countries, but there is still a significant gap in the depth and breadth of fault testing. The Aviation Industry Corporation of China’s North Control Institute has developed testing systems for the flight control subsystems of ARJ21, C919, and AG600, all adopting a centralized control and distributed layout architecture, achieving comprehensive management during the flight control iron bird test process, simulation of test stimuli, aircraft attitude simulation, flight parameter simulation, data collection, analysis, and processing functions, providing support for aircraft development verification.

Figure 7 shows the ARJ21 flight control iron bird test system.

Figure 7 ARJ21 Flight Control Iron Bird Test System

After several years of development, domestic aircraft have achieved integrated testing of avionics and flight control during the assembly phase, while the electromechanical systems are still in a state of individual testing. Subsystems such as fuel, environmental control, hydraulic, and braking systems are equipped with their own testing equipment, requiring multiple sets of testing equipment to be used repeatedly during assembly. Research has been conducted on integrated testing systems developed for assembly plants, but they have not yet been fully applied. Future efforts should focus on developing electromechanical integrated testing technology, ground integrated testing technology for the entire onboard system, and vertical integration testing technology.

4 Outlook

To better support the conduct of ground testing, research on ground testing technology should be strengthened in the following areas:

① Strengthen the overall planning of testing equipment at various stages, promote consistency in ground testing equipment and testing data, and significantly enhance capabilities in data collection, analysis, and management to better support product design optimization, testing optimization, fault diagnosis, and predictive capabilities.

② As the degree of integration of onboard products increases, fault impact analysis becomes more complex. Testing technology should delve into more fault injection methods, simulation stimulus implementation methods, and more powerful fault diagnosis technologies to improve ground testing efficiency.

③ Improve the development level of testing equipment, strengthen interconnectivity with product design data; promote sharing of testing data between testing equipment to reduce maintenance and troubleshooting time.

④ Closely monitor testing requirements while focusing on the development of testing technology itself, enhancing the environmental adaptability of testing equipment, non-contact testing, high-precision synchronization, and real-time technologies to promote testing development with advanced testing technologies.

Ground testing encompasses the entire process of aircraft development and production, and is an essential part of aircraft development. However, there are still top-level issues in China such as a lack of standards, lack of overall planning, and lack of management systems, as well as fundamental issues such as low engineering levels of software and hardware testing resources. Researchers in aviation products and testing technologies need to pay attention to these issues and work together to improve the level of domestic ground testing technology, providing strong support for the development and production of aviation products.

Author Biography

Wang Hong, female, PhD in engineering, researcher, graduated from Northwestern Polytechnical University with a major in computer applications. She is currently the deputy director of the Beijing Great Wall Aerospace Measurement and Control Technology Research Institute, mainly engaged in research on aircraft ground testing, automatic testing, testability, fault diagnosis, and prediction. She is a senior expert in fault diagnosis at the Aviation Industry Corporation of China, having received one first prize and two second prizes for aviation science and technology advancement. She currently serves as a member of the Reliability System Engineering Expert Group of the Equipment Development Department, deputy leader of the Automatic Testing Expert Group of the Air Force Aviation Equipment, and vice chairman of the Testing Technology Branch of the Chinese Society of Aeronautics and Astronautics.