In today’s rapidly advancing technology, 3D printing technology has swept across various industries like a strong east wind. From complex and precise mechanical parts to lifelike product models, from dreamlike architectural prototypes to personalized daily necessities, 3D printing technology, with its endless creativity and sufficient flexibility, brings imagination into reality, making life more convenient while also surprising us.

In today’s rapidly advancing technology, 3D printing technology has swept across various industries like a strong east wind. From complex and precise mechanical parts to lifelike product models, from dreamlike architectural prototypes to personalized daily necessities, 3D printing technology, with its endless creativity and sufficient flexibility, brings imagination into reality, making life more convenient while also surprising us.

Working Principle of 3D Printing Technology

3D printing technology, also known as additive manufacturing technology, constructs three-dimensional entities by stacking materials layer by layer, representing an innovative production method.Its principle is similar to building a brick house, which can be simply summarized as “layered manufacturing, stacking layer by layer”.

The 3D printing process is not complicated. First, a digital model is created or obtained using computer-aided design software, which is then sliced into a series of very thin cross-sectional layers (i.e., slices), with each layer typically ranging from tens to hundreds of micrometers in thickness. Next, the 3D printer constructs the final object layer by layer based on this slice information using specific technologies and materials.

The 3D printing processes include Fused Deposition Modeling (FDM), Stereolithography (SLA, DLP, LCD), Selective Laser Sintering (SLS), Selective Laser Melting (SLM), 3D Printing (3DP), and Laminated Object Manufacturing (LOM).

A working 3D printer. Image source: Tuchong Creative

Fused Deposition Modeling (FDM) technology involves melting filamentous thermoplastic materials through a heated nozzle, depositing them layer by layer on a platform, and finally solidifying into a three-dimensional object.This technology commonly uses thermoplastic materials as raw materials, such as Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), etc. It has low equipment requirements and is easy to operate, making it suitable for individuals and small studios. Recently popular toys like “Radish Knife” and “Telescopic Sword” have been made using this method.

Stereolithography (SLA, DLP, LCD) utilizes specific wavelengths and shapes of light to irradiate photosensitive resin, which solidifies layer by layer to form the desired shape of the object.This technology has high forming accuracy and smooth surfaces, making it suitable for creating fine models and small parts.

Selective Laser Sintering (SLS) uses a laser beam to scan powder materials, melting and bonding them together to accumulate layer by layer into a three-dimensional object.This technology uses powder as raw materials (such as nylon, metal powder, ceramic powder, etc.), has high forming accuracy, and is suitable for manufacturing complex structural functional parts.

Selective Laser Melting (SLM) has higher laser energy,similar to Selective Laser Sintering (SLS), and can completely melt metal powder to achieve rapid forming of metal parts. This technology commonly uses metal powders (such as titanium alloys, stainless steel, etc.) as raw materials, capable of printing high-strength, high-precision metal parts, widely used in aerospace, medical, and other fields.

3D Printing (3DP) uses powder materials (metal or non-metal) and adhesives as raw materials,utilizing the bonding mechanism to print each component layer by layer.This printing technology produces samples with the same color as the actual product and is currently a more mature color 3D printing technology.

Laminated Object Manufacturing (LOM) uses thin sheet materials (such as paper, plastic film, etc.) and hot melt adhesive as raw materials, accumulating layer by layer through laser cutting and thermal bonding to form the desired object.This technology has fast forming speed and low material costs, making it suitable for creating large structures and shells.

Although 3D printed products have high fidelity, they are limited by the printing raw materials, resulting in high brittleness, making them prone to breakage under external forces. Such products may seem somewhat “powerless” when applied in scenarios requiring high mechanical performance. So, how can we improve the “glass heart” of 3D printed products, ensuring they have a beautiful “appearance” while also possessing the “flexibility” to resist breakage?

On July 3, 2024, Chinese scientists published a research result on 3D printed elastomers in the journal Nature, demonstrating that rubber bands made using this technology can be stretched up to nine times their original length, with a maximum tensile strength of 94.6 MPa, equivalent to bearing nearly 10 kilograms of weight per square millimeter, showcasing exceptional strength and toughness.

The research results were published in Nature. Image source: Nature

Reconciliation of Forming Speed and Product Toughness

In the process of Stereolithography 3D printing (SLA, DLP, LCD), improving production efficiency requires faster forming speeds, which leads to an increase in the crosslink density of materials during the curing process and a decrease in material toughness.Under conventional methods, as material toughness increases, material viscosity also increases, which can lead to reduced flowability and slower forming speeds.The contradiction between the forming speed of 3D printing and the toughness of the finished product has long troubled the entire industry.

Chinese scientists have reconciled these two contradictions.Researchers proposed a phased printing and post-processing strategy by analyzing the photosensitive resin used in Stereolithography 3D printing and breaking down the printing process.They designed a dimethylacrylate DLP (Digital Light Processing) precursor, which contains dynamic hindered urea bonds and two carboxyl groups in its main chain. During the printing forming stage, these key components remain in a “dormant” state, playing a toughening role during the post-processing stage.

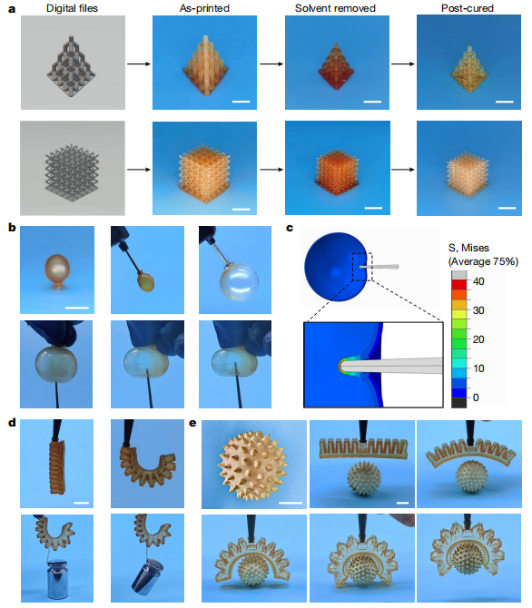

a. 3D printed objects and their dimensional changes during post-processing; b. Puncture resistance of 3D printed balloons; c. Modeling of mechanical puncture force; d-e. Testing of 3D printed pneumatic grippers lifting heavy objects. Image source: References [1]

At the 90°C post-processing stage, the hindered urea bonds in the 3D printed product dissociate to generate isocyanate groups, which, on one hand, form amide bonds with the side-chain carboxyl groups, and on the other hand, react with water adsorbed by carboxylic acids to form urea bonds.The chemical bond changes occurring within the molecules connect the single network structure in the material into an interpenetrating network structure similar to “hand-in-hand”, bringing more hydrogen bonds and reinforcing the internal structure of the material.It is precisely due to the changes in the internal structure of the material that the 3D printed product has a greater buffer space when subjected to external forces, similar to the energy absorption effect during vehicle collisions, improving the product’s impact resistance and anti-fracture ability, resulting in higher toughness.

Experimental results show that a film with a thickness of only 0.8 millimeters, made using the DLP precursor, exhibits extremely strong puncture resistance, allowing it to withstand a force of 74.4 Newtons without breaking. Even under high-pressure inflation conditions, the 3D printed pneumatic gripper can still lift a copper ball weighing 70 grams with sharp spikes on its surface without breaking, demonstrating the exceptional toughness and structural strength of 3D printed products.

Wide Applications of 3D Printed Elastomers

In the field of sports equipment, 3D printed elastomers provide personalized, high-performance gear for athletes.For example, customized insoles and protective gear utilize the shock-absorbing and supportive characteristics of elastomers to optimize athletes’ performance and enhance wearing experience. Especially in extreme sports and high-impact activities, 3D printed elastomer materials can significantly reduce the impact athletes experience during sports, protecting their joints and muscles from injury.In the automotive and aerospace fields, 3D printed elastomers are used in lightweight shock-absorbing components and seals.These components, through complex structural designs, can reduce weight while maintaining high performance.In the electronics field, products such as smart speakers, smart wristbands, and phone cases can all be printed using elastomer materials.These products not only possess excellent softness and elasticity but also have high wear resistance and durability, meeting consumers’ diverse demands for product appearance and performance.In the industrial manufacturing sector, 3D printed elastomer technology is used to manufacture various industrial molds and drive belts.These components need to withstand significant mechanical stress and vibration, and elastomer materials, with their excellent elasticity and fatigue resistance, become the ideal choice. Manufacturing these components using 3D printing technology not only improves production efficiency but also reduces manufacturing costs.The advent of 3D printed elastomer technology further expands the application scenarios of 3D printed products, bringing more colorful possibilities to our lives.

References

[1] Fang, Z., Mu, H., Sun, Z. et al. 3D printable elastomers with exceptional strength and toughness[J]. Nature,2024.[2] Walker, D. A., Hedrick, J. L. & Mirkin, C. A. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface[J]. Science,2019. [3] Zhang, X., Tang, S., Zhao, H. et al. Current status and key technologies of 3D printing technology[J]. Materials Engineering,2016.[4] Huang, J., Jiang, S. Will 3D printing technology trigger the “third industrial revolution”?[J]. New Materials Industry,2013.

Planning and Production

Produced by丨Science Popularization China

Author丨Shi Chang, PhD in Physical Chemistry

Supervised by丨China Science Popularization Expo

Editor丨Dong Nana

Reviewed by丨Xu Lai, Lin Lin

Images in this article are sourced from copyright libraries

Reproducing this content may lead to copyright disputes. For original text and images, please reply “Reprint” in the background.

Light up “Looking”

Let’s gain knowledge together!