Wu Zheming, Ge Hongjuan, Hu Yinxiao, Pan Shuyue, Jin Hui, Sang Yiqin

(Nanjing University of Aeronautics and Astronautics, Civil Aviation College, Nanjing, Jiangsu 211106, China)

doi: 10.19708/j.ckjs.2022.07.283

Citation format:

Wu Zheming, Ge Hongjuan, Hu Yinxiao, et al. Component Failure Correlation Analysis of Multi-Electric Aircraft Starter Generator System Based on DEMATEL [J]. Measurement and Control Technology, 2022, 41(10): 32-37.

Abstract

This paper conducts a correlation analysis of the failure coupling relationships between components of the multi-electric aircraft starter generator system, focusing on the strong electrical coupling relationships among components. A simulation model of the multi-electric aircraft starter generator system is established based on Modelica, and the impact mechanisms of different failures and the degree of failure coupling between components are studied through simulation based on changes in key characteristic quantities during fault injection. A method for constructing a direct influence matrix is proposed. The DEMATEL method is used to decouple the direct influence matrix and calculate parameters such as the centrality and causality of component failure impacts. Comparison with Fault Tree Analysis (FTA) results shows that the proposed method for analyzing component failure correlations is correct and reasonable, providing a reference for failure correlation analysis methods in complex electronic and electrical systems.

Keywords

Starter generator system; Correlation analysis; Modelica; DEMATEL

The multi-electric aircraft starter generator system integrates the functions of a starter and generator, making it one of the key systems for multi-electric aircraft operation. In recent years, extensive research has been conducted both domestically and internationally on the principles and performance optimization of starter generator systems, achieving significant progress. However, the analysis of airworthiness safety has lagged behind. The mainstream safety analysis method based on ARP4761 has matured but is inefficient, requiring re-analysis when system changes occur. Model-Based Safety Analysis (MBSA) improves the efficiency of safety analysis by synchronizing the safety analysis model with design changes throughout the product lifecycle.

The failure coupling relationships between components of the multi-electric aircraft starter generator system are complex. Safety analysis methods such as Functional Hazard Analysis (FHA), Preliminary System Safety Assessment (PSSA), Fault Tree Analysis (FTA), and Dependence Diagram (DD) primarily analyze component failure rates, with less focus on the failure coupling relationships between components. The Decision-Making Trial and Evaluation Laboratory (DEMATEL) method is a commonly used method for correlation analysis, widely applied in causal relationship analysis between interrelated factors and the importance analysis of each factor in the system. Zhang Fan et al. used the DEMATEL method to study the correlation and importance of risk factors in complex equipment development projects, achieving risk source identification; Shi Yongsheng et al. improved traditional FMEA using the DEMATEL method to assess the safety of civil aircraft cargo hold power drive units; Liaw et al. calculated weights using the DEMATEL method to complete reliability allocation for military aircraft flight control systems. Typically, the DEMATEL method relies on expert scoring, where the direct influence matrix is determined by expert evaluations. For complex systems like the multi-electric aircraft starter generator system, differences in expert evaluations may exist, lacking an objective reference to reduce errors.

This paper combines the MBSA concept with the DEMATEL method, establishing a simulation model of the multi-electric aircraft starter generator system using Modelica language. By studying the mapping relationship of fault injection responses and impact relationships, the direct influence matrix of component failures is determined. The DEMATEL method is then used to calculate parameters such as centrality and causality of component failure impacts, providing a certain degree of objective reference for expert evaluation metrics and offering insights for analyzing failure coupling relationships between components in complex systems.

1 Construction of the Component Failure Correlation Analysis Model for Multi-Electric Aircraft Starter Generator System Based on Modelica Language

1.1 Process of Component Failure Correlation Analysis for Multi-Electric Aircraft Starter Generator System

The Variable Frequency Starter Generator (VFSG), widely used in multi-electric aircraft, is a three-stage starter generator composed of a main generator, an AC main exciter, a permanent magnet auxiliary exciter, and a rotating rectifier. It can switch between starting and generating functions, providing the torque required for engine start and the power needed for normal aircraft operation. Taking the B787 as an example, during normal operation, four VFSGs can stably output three-phase AC power at 235 V and 400 Hz.

The starting process of the multi-electric aircraft starter generator system is divided into two stages: during the start, constant frequency three-phase AC power and variable frequency three-phase AC power are supplied to the excitation winding of the main exciter and the armature winding of the main generator, respectively. The interaction of the rotating magnetic field drives the rotor speed of the starter generator to continuously increase, completing the engine start. Once the rotor speed of the starter generator reaches 7000 r/min, the system switches to generating mode, and the rotor speed continues to increase under the drive of the aircraft engine, ultimately stabilizing around 12000 r/min, while the starter generator outputs stable three-phase AC power for the aircraft’s loads.

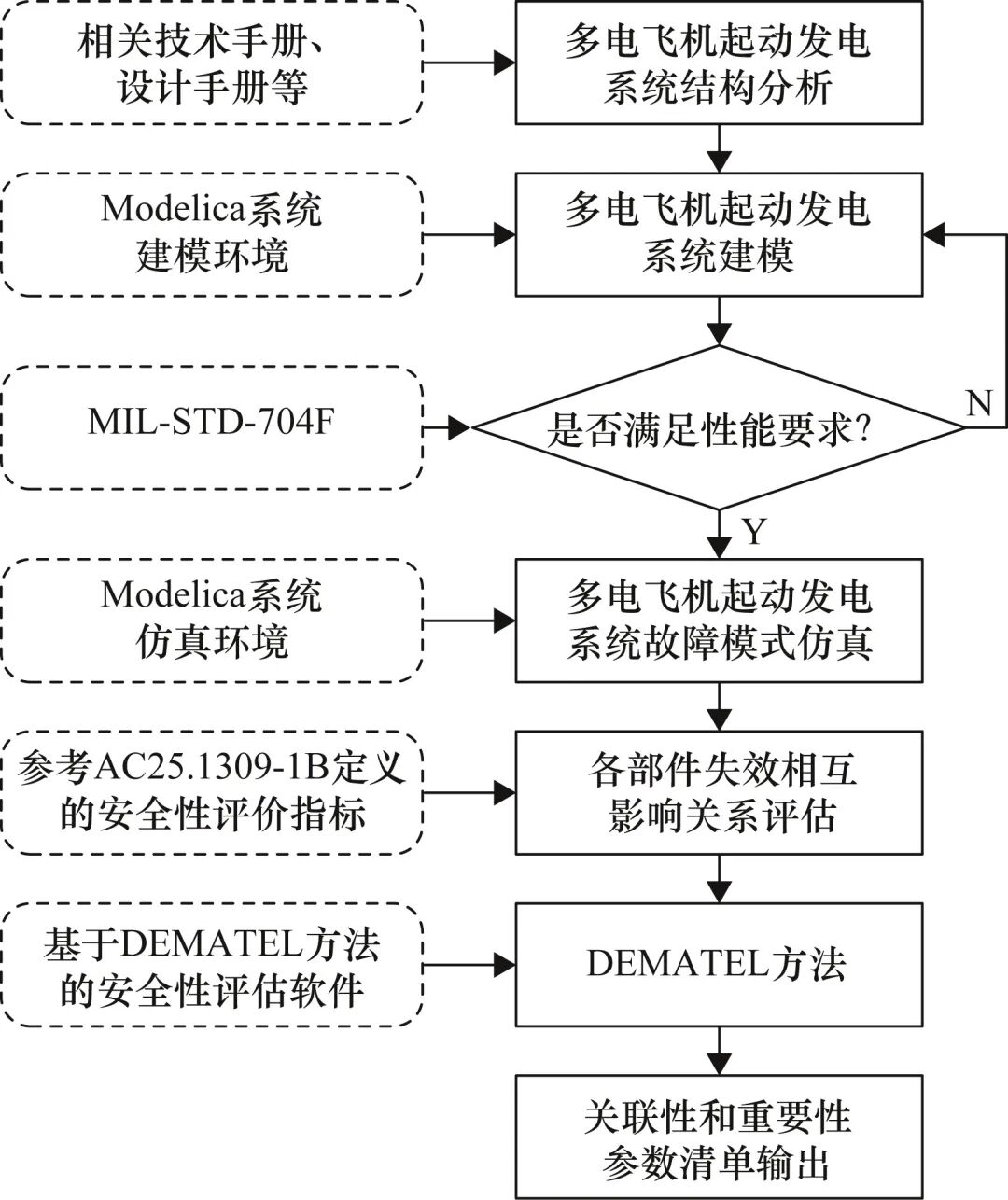

The process of component failure correlation analysis for the multi-electric aircraft starter generator system is summarized in Figure 1 as “Modeling”, “Simulation”, and “Evaluation”, which involves establishing a simulation model based on the working principle of the starter generator system; simulating and analyzing fault waveforms to obtain the impact relationships of component failures; and introducing correlation assessment algorithms to output result lists.

Figure 1 Process of Component Failure Correlation Analysis for Multi-Electric Aircraft Starter Generator System

1.2 Establishment of Modelica Model for Multi-Electric Aircraft Starter Generator System

Modelica is a non-causal modeling language that emphasizes the interrelationships between modules, making it suitable for the correlation analysis of complex systems. This paper utilizes Modelica to build a simulation model of the multi-electric aircraft starter generator system.

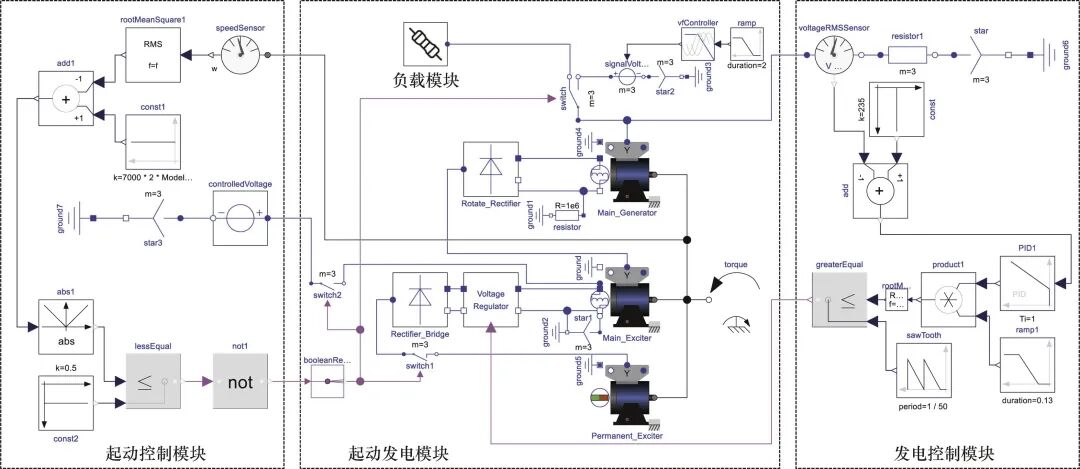

The Modelica model of the multi-electric aircraft starter generator system includes the starting control module, generating control module, starter generating module, and load module, as shown in Figure 2. The starting control module manages the switching between starting and generating functions, providing the external power required during the starting phase; the generating control module stabilizes the output voltage during the generating phase; the starter generating module is the core of the multi-electric aircraft starter generator system, mainly composed of the main generator (Main_Generator), AC main exciter (Main_Exciter), permanent magnet auxiliary exciter (Permanent_Exciter), and rotating rectifier (Rotate_Rectifier). In starting mode, it provides the initial speed for the aircraft engine, and when the engine reaches a certain speed, it switches to generating mode, outputting electrical energy for the load module.

Figure 2 Modelica Model of the Starter Generator System

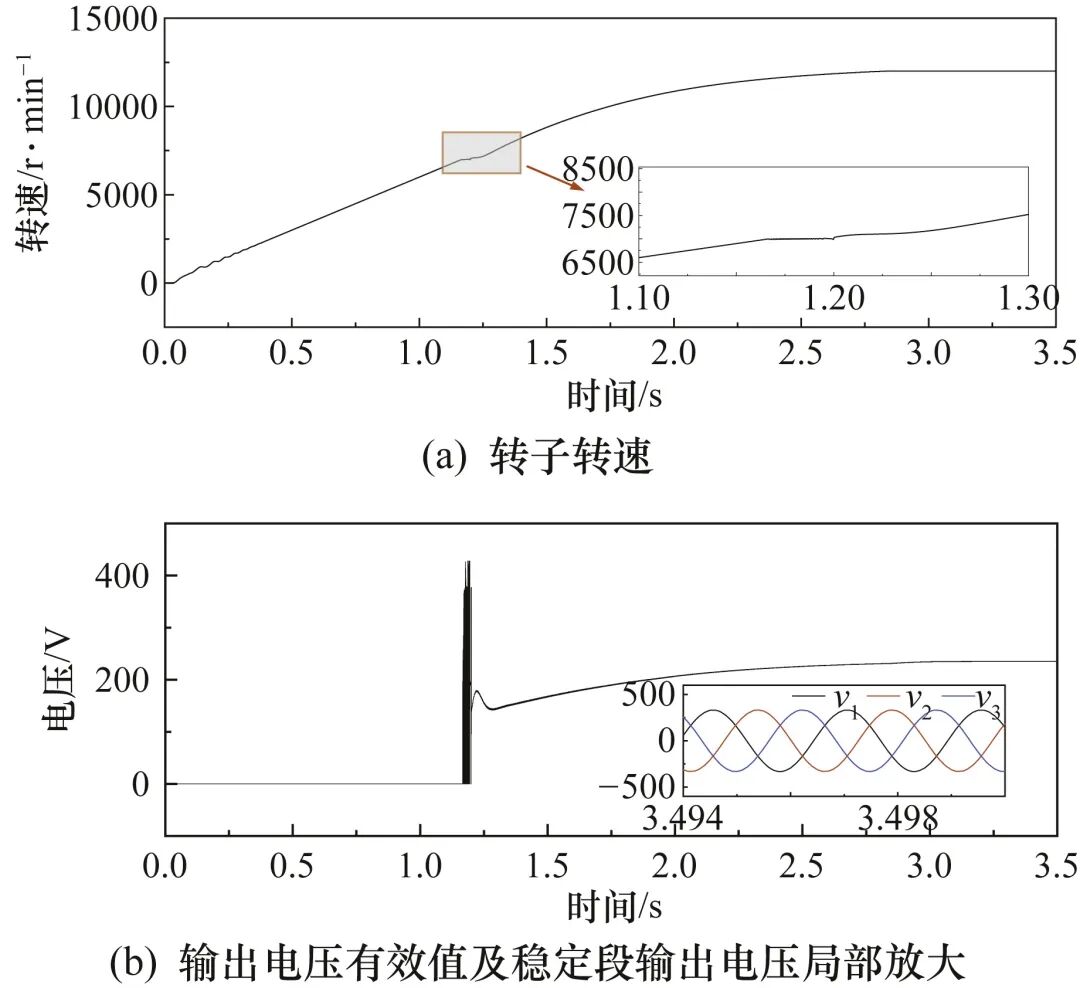

Using the Modelica model, the starting/generating process of the multi-electric aircraft starter generator system under normal conditions is simulated, with the simulation results shown in Figure 3. As seen in Figure 3(a), except for minor fluctuations during the switching between starting and generating, the rotor speed maintains a reasonable growth rate, reaching the rated speed of 12000 r/min within 3 seconds and entering a stable state. Analyzing Figure 3(b) reveals that during the switching period, the effective value of the output voltage from the main generator instantaneously increases to about twice the normal level. Due to the short duration, this will not significantly impact the safety of related components; when stable, the effective value of the output voltage from the main generator is 234.99374 V, with a maximum value of 332.46075 V, and the waveform approximates an ideal sine wave with a frequency of 400 Hz, meeting the power quality standards specified in MIL-STD-704F.

Figure 3 Normal Waveform of the Starting Generating Process

1.3 Determination of Risk Causal Factors

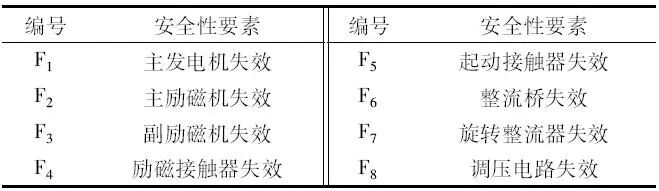

The failures in the multi-electric aircraft starter generator system are primarily caused by the failure of key components. Based on the mechanism of the multi-electric aircraft starter generator system and its main components, the risk causal factors can be identified as the failures of key components, including the main generator failure, main exciter failure, auxiliary exciter failure, excitation contactor failure, starting contactor failure, rectifier bridge failure, rotating rectifier failure, and voltage regulation circuit failure, totaling eight interrelated influencing factors, as shown in Table 1.

Table 1 Risk Causal Factors of the Multi-Electric Aircraft Starter Generator System

2 Component Failure Correlation Analysis of Multi-Electric Aircraft Starter Generator System Based on DEMATEL Method

2.1 Confirmation Method for Direct Influence Matrix Based on Fault Injection

There exists a complex interrelationship among the risk causal factors of the multi-electric aircraft starter generator system, and the DEMATEL method can be used to decouple these complex relationships. The DEMATEL method is a structured modeling approach that utilizes graph theory and matrix tools to visualize complex causal relationships, playing an important role in analyzing causal relationships between system elements and identifying key elements. By using the direct influence matrix of each element in the system, the influence degree and affected degree of each element can be calculated, leading to the calculation of centrality and causality of each element, ultimately completing the correlation analysis among the elements.

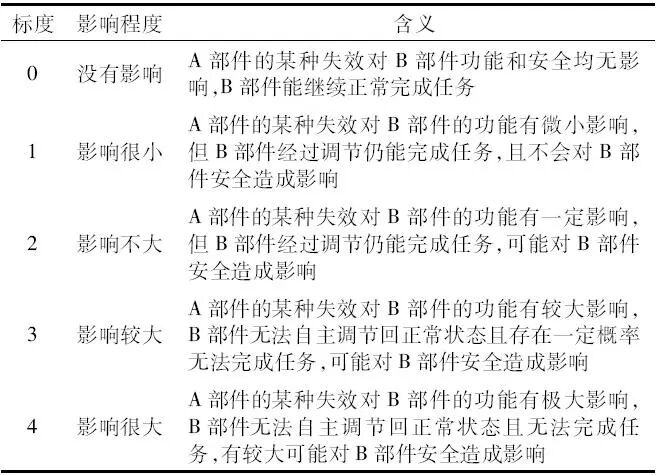

By simulating different fault scenarios through fault injection and changing key parameters, the qualitative relationships among safety elements are determined. Referring to AC25.1309-1B, a 0-4 scale for evaluating the influence relationships of components in the multi-electric aircraft starter generator system is established to quantify the qualitative relationships, constructing the direct influence matrix. The meanings of the 0-4 influence relationship evaluation scale are shown in Table 2.

Table 2 Influence Relationship Evaluation 0-4 Scale

2.2 Determination of Direct Influence Matrix

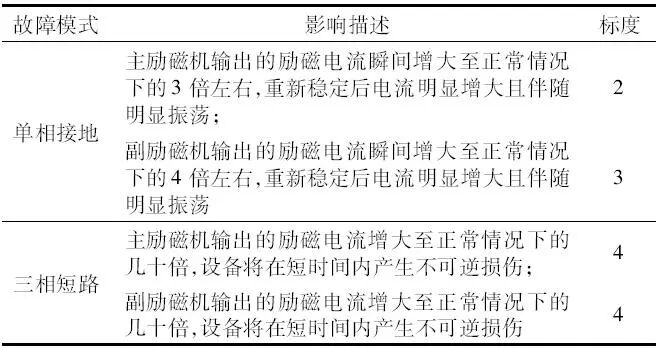

This paper takes the failure of the main generator (F1) in the three-stage synchronous variable frequency starter generator as an example to illustrate the construction method of the direct influence matrix. For the main generator, its typical fault modes include single-phase ground fault, two-phase ground fault, and three-phase short circuit fault.

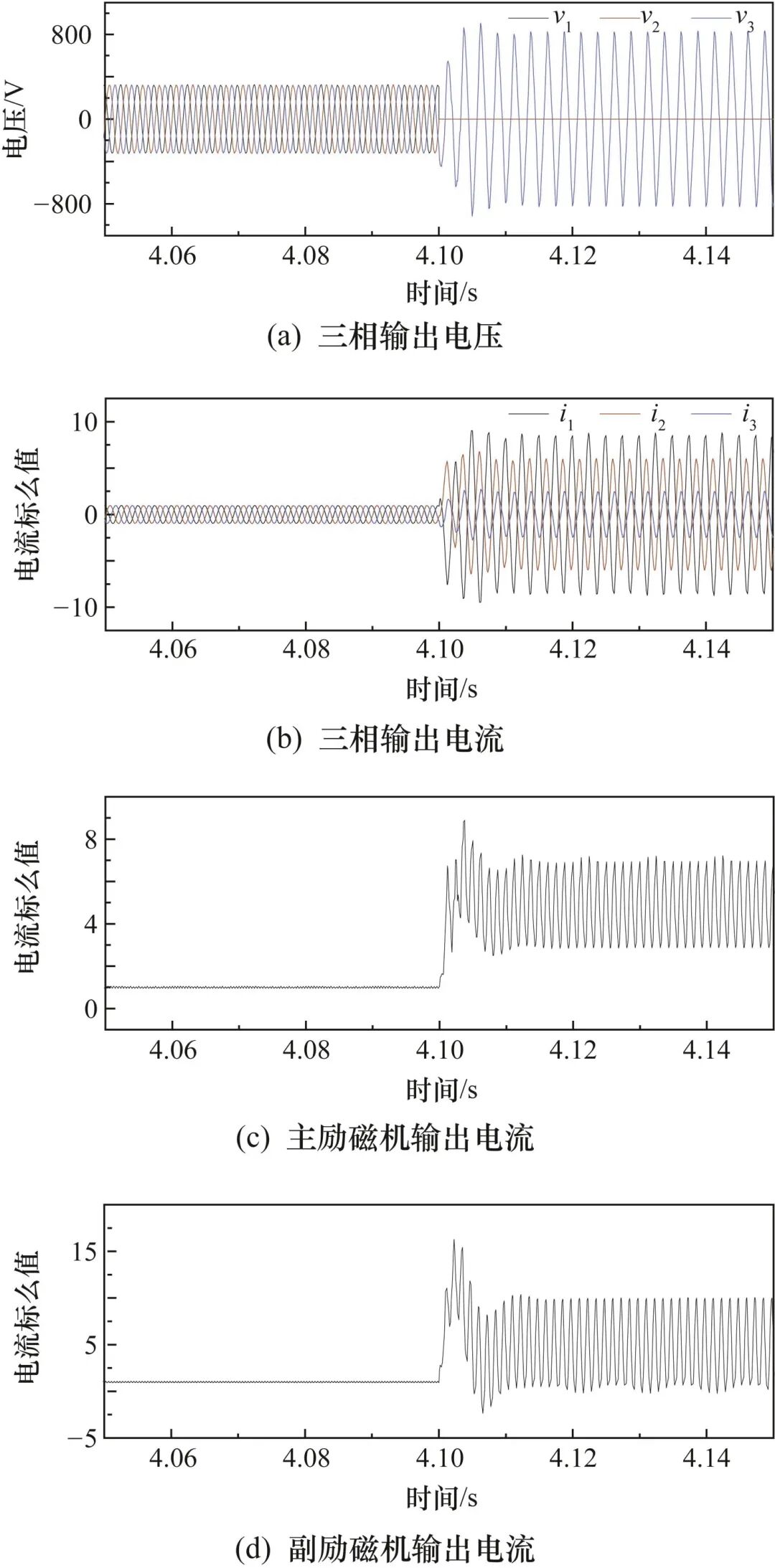

When a two-phase ground fault occurs in the main generator, the voltages of the two grounded phases rapidly drop to 0, the current magnitude increases, and significant three-phase imbalance occurs; the excitation current output from the main exciter instantaneously increases to about 8 times the normal level, and after stabilizing, the current significantly increases with noticeable oscillation; the excitation current output from the auxiliary exciter instantaneously increases to about 15 times the normal level, and after stabilizing, the current significantly increases with noticeable oscillation. The simulation waveform of the two-phase ground fault is shown in Figure 4. Analysis indicates that when a two-phase ground fault occurs in the main generator, the impact degree on the main exciter is 3, and the impact degree on the auxiliary exciter is 4.

Figure 4 Simulation Waveform of Two-Phase Ground Fault

Using the same method, the main generator’s single-phase ground fault and three-phase short circuit fault are analyzed, with the impact degrees of the main generator faults on the main exciter and auxiliary exciter shown in Table 3.

Table 3 Impact Degree of Main Generator Faults on Main Exciter and Auxiliary Exciter

By averaging the impact degrees of the three fault modes, the impact degree of the main generator failure (F1) on the main exciter failure (F2) is determined to be 3, and the impact degree on the auxiliary exciter failure (F3) is 3.67. By completing simulations for different fault scenarios using the same method, the direct influence matrix O is obtained as

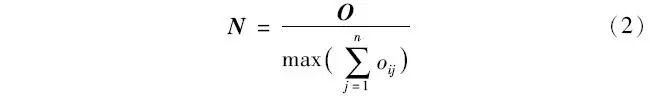

2.3 Comprehensive Influence Relationship Calculation and Analysis

The direct influence matrix O is normalized using the row sum maximum method, which involves calculating the maximum sum of each row in the direct influence matrix O and dividing each element of O by this maximum value to obtain the normalized direct influence matrix N as

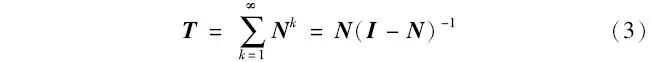

Based on the normalized direct influence matrix N, a comprehensive influence matrix T is established:

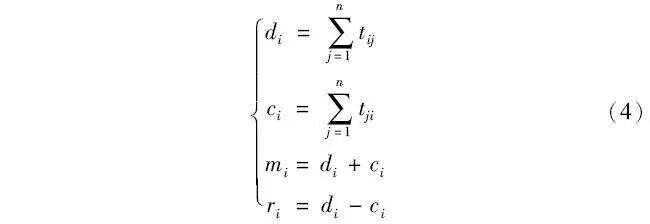

Using the comprehensive influence matrix T, the influence degree di, affected degree ci, centrality mi, and causality ri of each safety element in the starter generator system are calculated, with the formulas as follows:

The comprehensive influence relationships of each risk causal factor are shown in Table 4.

Table 4 Comprehensive Influence Relationships of Each Risk Causal Factor

From the perspective of the working mechanism of the starter generator system, failures of the main generator and main exciter directly lead to the system’s inability to function normally; failures of the auxiliary exciter or abnormal operation of the voltage regulation circuit directly affect the normal voltage output of the generator, thus impacting the normal operation of the system. On one hand, as shown in Table 4, the centrality ranking reflecting the importance of risk causal factors is consistent with the working and failure mechanisms of the starter generator system. On the other hand, from the perspective of failure mechanisms, components like contactors and voltage regulation circuits are more likely to lead to other risks, resulting in positive causality; while main components like the main generator are more susceptible to influences from other factors, resulting in negative causality. Therefore, the analysis results presented in Table 4 align with the failure mechanisms and influence relationships of the system.

2.4 Comparative Analysis of Component Importance Based on FTA

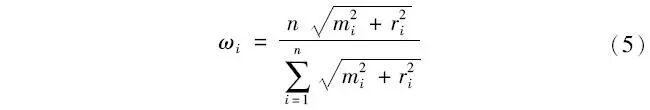

Using the data from Table 4, the DEMATEL importance ωi of each component in the starter generator system is calculated, with the formula as follows:

The importance of each risk causal factor is shown in Table 5.

Table 5 Importance of Each Risk Causal Factor

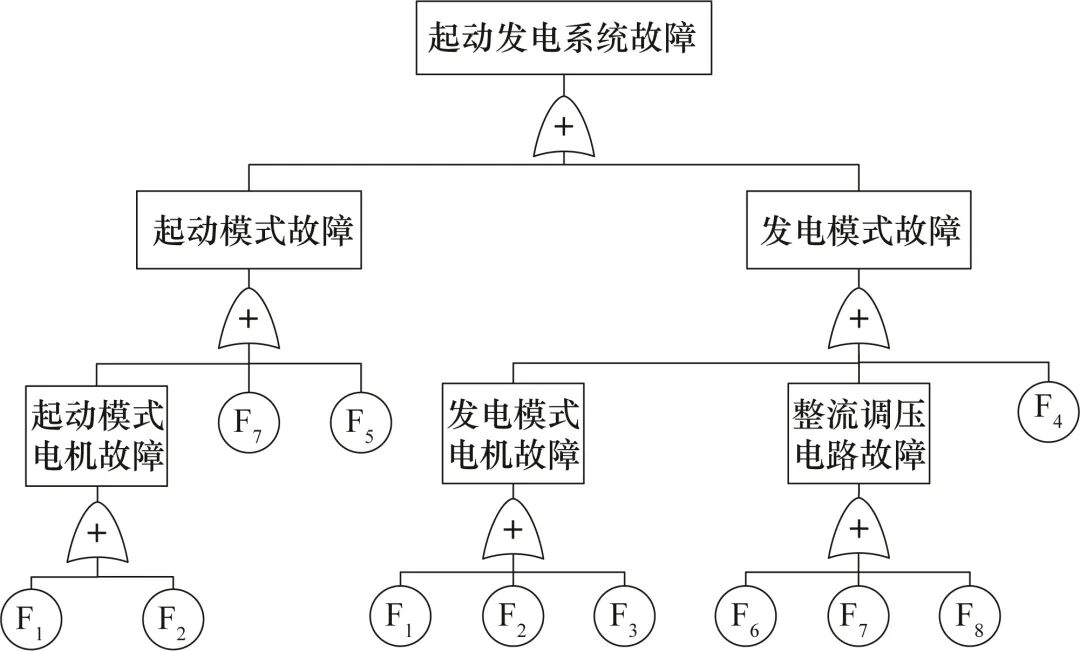

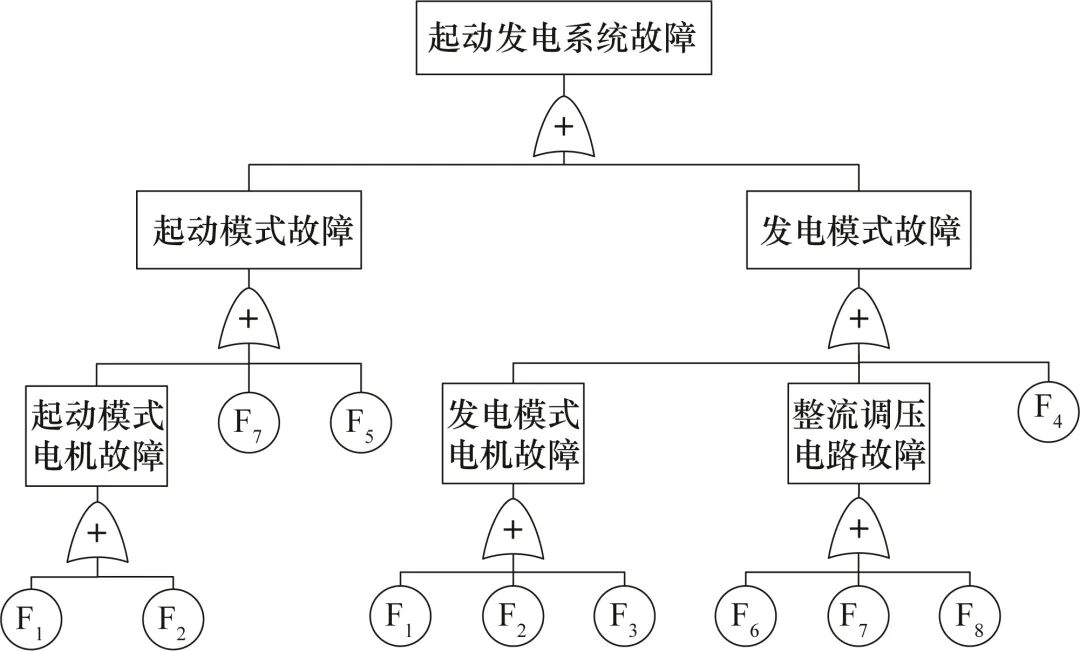

Based on simulation analysis, the relative probability importance of each component in the starter generator system is analyzed using the FTA method. The risk causal factors listed in Table 1 are treated as bottom events to establish the fault tree of the starter generator system, as shown in Figure 5. The occurrence probabilities of each risk causal factor are obtained from MIL-HDBK-217F, and the relative probability importance is calculated, with results shown in Table 5.

Figure 5 Fault Tree of the Starter Generator System

The importance of each component in the starter generator system is primarily determined by the system structure and operational mechanisms. Therefore, the importance rankings of components calculated using the DEMATEL method are generally consistent with those calculated using the FTA method. Meanwhile, the DEMATEL method calculates importance based on the impact degree of component failures, while FTA calculates importance based on the failure rates of components. Since there is no strict monotonic mapping relationship between the impact degree of failures and failure rates, slight differences exist in the importance rankings obtained from the two methods. Analyzing the data in Table 5 shows that the component failure correlation analysis method used is correct and reasonable.

3 Conclusion

A simulation model of the multi-electric aircraft starter generator system was built using Modelica language, and the simulation results met relevant standard requirements, proving the correctness and effectiveness of the model. The simulation results based on fault injection constructed the direct influence matrix of component failures in the multi-electric aircraft starter generator system, providing a certain degree of objective reference for expert scoring methods. The DEMATEL method was used to calculate parameters such as centrality and causality to characterize component failure correlations, addressing the traditional safety analysis methods’ lack of focus on failure coupling relationships. The comparison of component importance rankings obtained from the DEMATEL method and FTA method demonstrates the correctness of this approach. The component failure correlation analysis method based on changes in key characteristic quantities and DEMATEL can be applied to the failure correlation analysis of components in other complex systems.

END

Hot Articles (Swipe Up to Read)

Article Recommendation | Lv Zuopeng: Application of HHT Time-Frequency Analysis Method Based on Wavelet Packet and EMD in Bearing Fault Diagnosis of Aviation Test Equipment

Article Recommendation | Wang Hong: Intelligent Testing and Monitoring Technology for Aviation Onboard Systems

Article Recommendation | Xin Wenhui: Dual Closed-Loop Temperature Control System for Semiconductor Lasers

Article Recommendation | Li Dapeng: Atmospheric Parameter In-Situ Detection System and Experiment Based on Near-Space Airship

Article Recommendation | Jiao Xiaofeng: Overview of CO2 Detection Technology Based on TDLAS

Article Recommendation | Chen Haiming: Online Calibration Method for Magnetic Sensors in Backup Attitude Systems

Article Recommendation | Ren Dantong: Personnel Behavior Recognition Method for Smart Factories Based on Dual Light Fusion

Article Recommendation | Li Shuhao: Research on Integrated Monitoring Technology in Bearing Fault Diagnosis

Article Recommendation | Zhuo Li: Pedestrian Multi-Attribute Collaborative Recognition Method Based on ResNet50 and Channel Attention Mechanism

Article Recommendation | Liang Minjian: Research on Mechanical Fault Classification of Escalators Based on One-Dimensional Convolutional Neural Networks

Article Recommendation | Hou Qilin: Remaining Useful Life Prediction of Aviation Lithium Batteries Based on Indirect Health Indicators and Echo State Networks

Article Recommendation | Chen Peng: An End-to-End Natural Scene Text Detection and Recognition Model

Article Recommendation | Hou Feng: Remote Sensing Image Retrieval Based on Deep Feature Dictionary Learning and Largevis

Article Recommendation | Wang Xinyao: Global Inertial Navigation and Integrated Navigation Method Based on Earth Coordinate System

Article Recommendation | Chen Lijing: Fault Diagnosis of Aviation Inverters Based on Multi-Class SVM

Article Recommendation | Li Mingfei: Discussion on Image Enhancement and Flow Field Density Processing of Blade Shadow Test

Article Recommendation | Liu Qiuyu: Flexible Pressure Sensors Based on Capacitor-Resistor Conversion Principle

Article Recommendation | Li Lei: Research on Data-Driven Fault Prediction Methods

Article Recommendation | Yan Junjie: Automatic Precision Assembly Technology of Satellite Antenna Modules Based on Machine Vision

Article Recommendation | Yao Yanling: Research on the Diagnosis Model of Engine Surge Based on CNN-Seq2Seq

Article Recommendation | Guan Li: Overview of Electric-Hydraulic Actuation Technology Research for Aircraft Flight Control Actuation Systems

Article Recommendation | He Yunze: Analysis of Acoustic Emission Signals of Power Devices in Inverter Circuits

Article Recommendation | Xie Li: Defect Detection of Circuit Board Components Based on Improved YOLOv4 Network

Article Recommendation | Wang Yizhou: Short Video Fingerprint Extraction Based on R(2+1)D Twin Network

Article Recommendation | Han Han: Overview of No-Reference Image Quality Assessment Based on Deep Learning

Article Recommendation | Wang Jiulong: Research on Fatigue Testing Technology of Helicopter Tail Rotor Blades

Article Recommendation | Sun Weihong: Research on Portable ECG Monitoring System Based on Flexible Electrodes

Article Recommendation | Zhang Meiju: Research Status and Development Trends of Ceramic Substrate Thin Film Thermocouples

Article Recommendation | Ouyang Lin: Fatigue Driving Detection Algorithm Based on Driver’s Facial Temporal Data

Article Recommendation | Zhang Wenli: Multi-Target Tracking Algorithm Based on Improved Transformer with Anchor-Free Network

Article Recommendation | Liu Junqian: Research Progress of Silicon-Based and Graphene-Based Resonant Pressure Sensors

Article Recommendation | Jiang Chao: Overview of Image-Based UAV Battlefield Situation Awareness Technology

Article Recommendation | Zhang Feiyang: Overview of Alertness Detection Research Based on Physiological Signals

Article Recommendation | Qiu Fang: Research on Autonomous Management Software Architecture for Control Systems of Deep Space Exploration Spacecraft

Article Recommendation | Wang Yanshan: Research Progress of Graphene Flexible Pressure/Strain Sensors

Article Recommendation | Wang Hong: Research on Testing Technology System Architecture for Civil Aircraft

Article Recommendation | Liu Yawei: Overview of Digital Twin and Application Research for Aircraft Structural Health Management

2021 Collection of Excellent Papers in Computer and Automation Technology

2021 Collection of Excellent Papers in Aerospace

2020 Collection of Excellent Papers in Aerospace

2020 Collection of Excellent Papers in Computer and Automation Technology

Journal Dynamics (Swipe Up to Read)

Notice on Call for Papers for the “Gas Turbine Engine Measurement and Control Technology” Column of Measurement and Control Technology

Measurement and Control Technology continues to be selected as a “Core Journal of Chinese Science and Technology”

Journal Directory (Swipe Up to Read)

2023 Issue 2

2023 Issue 1

2022 Issue 12

2022 Issue 11

2022 Issue 10 Special Issue on Intelligent Testing Technology for Onboard Systems

2022 Issue 9 Special Issue on Advanced Sensors and Atmospheric/Meteorological Measurement Technology

2022 Issue 8

2022 Issue 7

2022 Issue 6

2022 Issue 5

2022 Issue 4

2022 Issue 3

2022 Issue 2

2022 Issue 1