This article is submitted by the research team (research group) of the authors.

Quantum dot technology is one of the hottest technologies in the current field of LCD displays. The narrow emission characteristics of quantum dots allow for brighter colors and a wider color gamut, aligning with the future development direction of Liquid Crystal Displays (LCD). Traditional diffuser plates soften the light, ensuring uniform brightness distribution on the output surface. By incorporating quantum dots into the diffuser plates, they also possess the ability to redefine colors and improve color presentation. As a combination of traditional diffuser plates and emerging quantum dot technology, quantum dot diffuser plates are a powerful weapon for LCDs in competition with OLEDs.

Recently, a joint R&D team from Fuzhou University, Mindu Innovation Laboratory, and TCL Electronics Co., Ltd. published a review article titled “Research Progress on Quantum Dot Diffuser Plates for LCD Displays” in the “Liquid Crystal and Display” (ESCI, Scopus, Chinese core journal) 2023, Issue 3, in the column “Quantum Dot Liquid Crystal Display Application Technology“.

The article briefly summarizes the research progress of diffuser plates in LCD displays, focusing on the self-prepared multilayer structure quantum dot diffuser plates, testing and evaluating their optical performance and stability, showcasing the significant importance of uniformity and color gamut enhancement brought by quantum dot diffuser plates and their application prospects in LCDs.

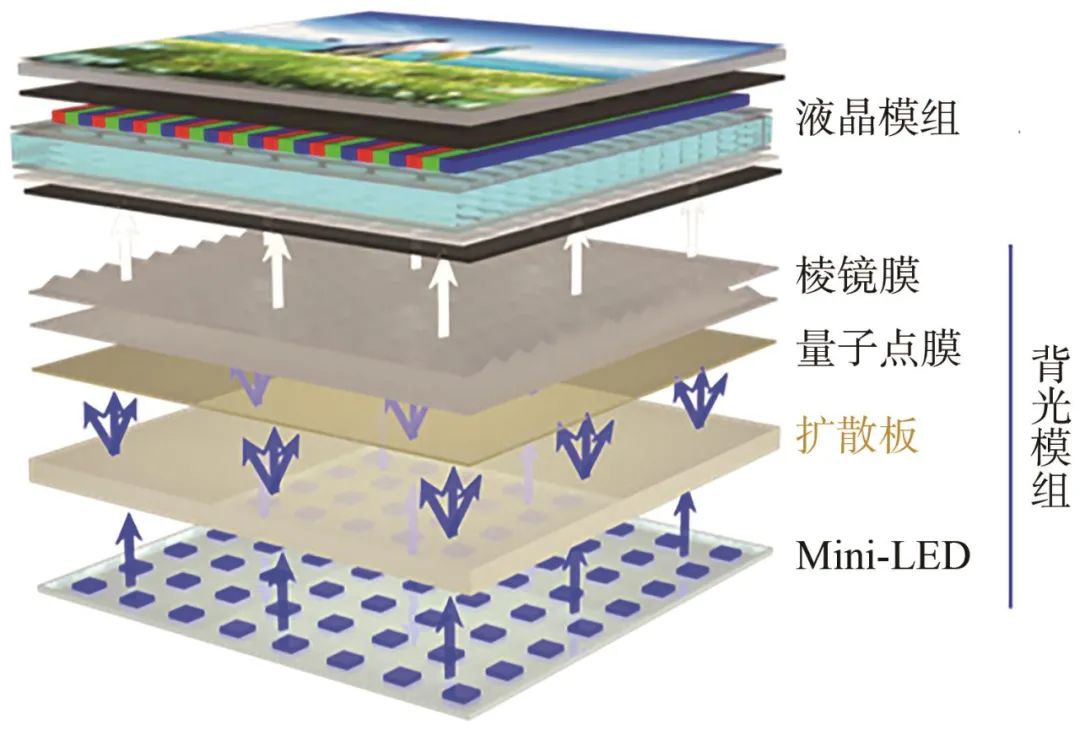

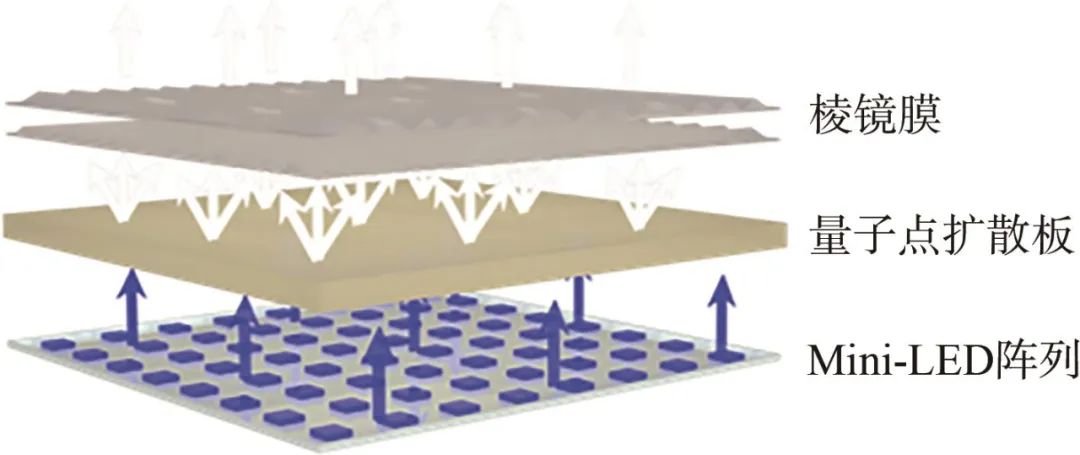

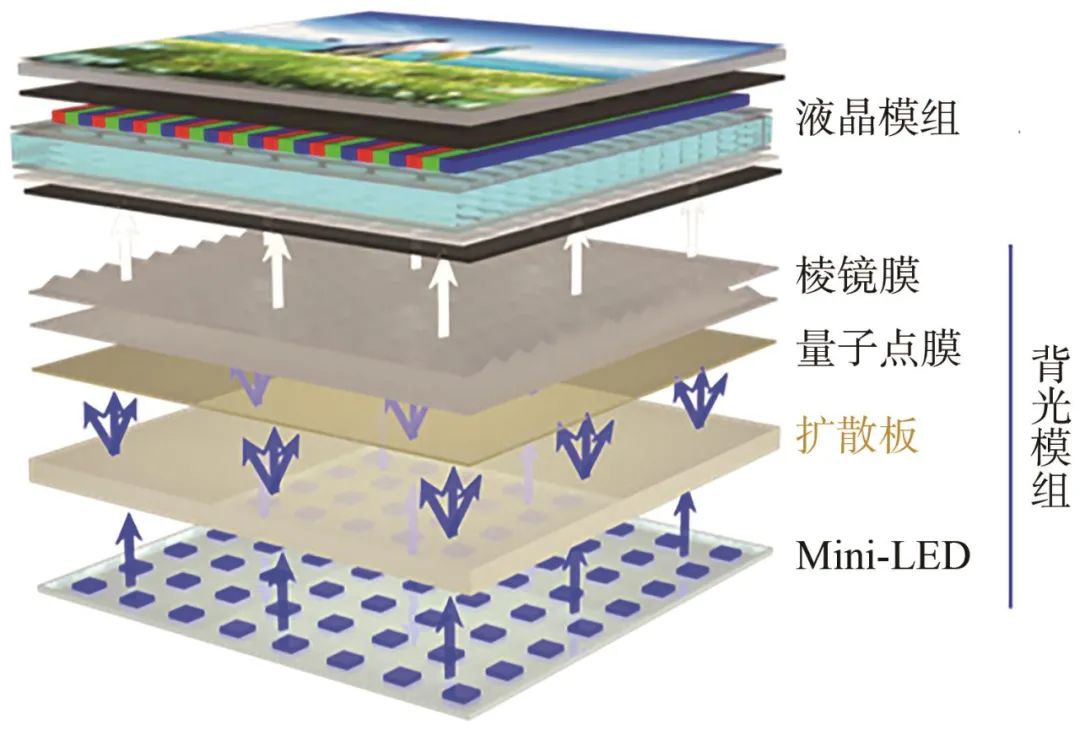

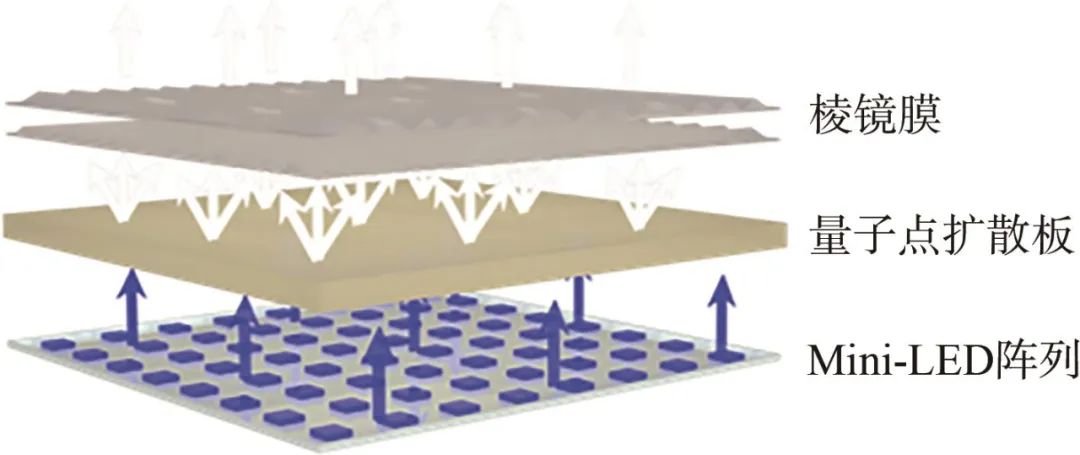

Currently, the backlight structure of LCDs is mainly divided into side-lit and direct-lit types. The direct-lit backlight generally combines Mini-LED with quantum dot color enhancement films, as shown in Figure 1. The backlight module supplies light to the liquid crystal module, controlling the brightness of each display area by adjusting the light transmittance of the liquid crystal layer. Standard LEDs exhibit a Lambertian distribution on the output surface, which can cause uneven brightness in the displayed image, affecting the visual experience. Although changing the light distribution of LEDs can improve the uniformity of the output surface brightness, it is still difficult to achieve complete uniformity without a diffuser plate. The light transmittance and haze of the diffuser plate affect the output brightness and uniformity, which are crucial to the final imaging quality. To achieve better display effects, the backlight module needs to meet the requirements of high brightness, high uniformity, wide color gamut, and local dimming.

Figure 1: Schematic diagram of direct-lit backlight LCD structure based on Mini-LED and quantum dot film

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

Overview of Diffuser Plates for LCD Displays

As we know, light undergoes refraction and reflection when passing through media with different refractive indices. Therefore, by using microstructures on the surface of the diffuser plate or scattering particles, scattering can be induced to enhance the output uniformity. Depending on the principles of light scattering, diffuser plates can be mainly divided intosurface microstructure diffuser plates and particle scattering diffuser plates.

• Surface Microstructure Diffuser Plates

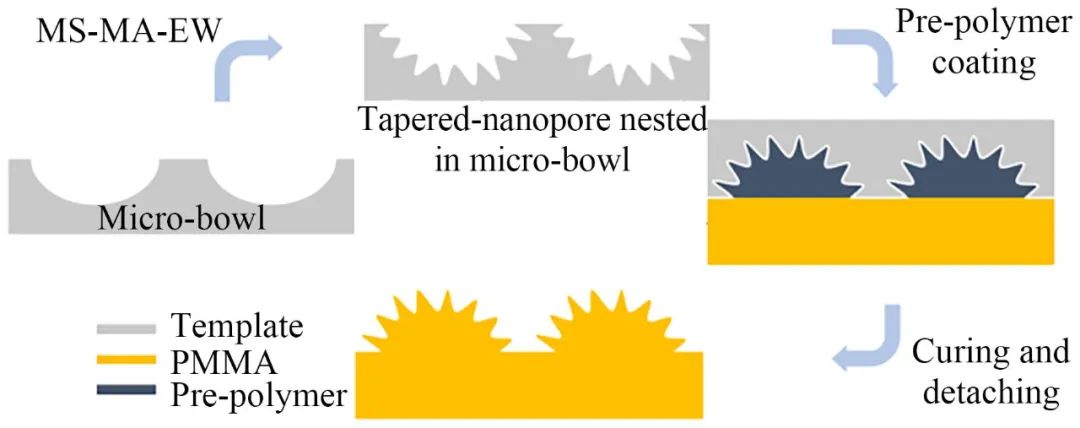

Surface microstructure diffuser plates have periodic microstructures on their surfaces, such as micro-lens arrays, free-form surface microstructures, and prism structures. The differences in refractive index caused by these microstructures lead to light being refracted in different directions, thus altering light distribution and achieving high illuminance uniformity. In 2021, MA et al. prepared a biomimetic diffusion film using a template-assisted thermal polymerization method, as shown in Figure 2. The conical nano-wavy hierarchical structure of this diffusion film provides excellent anti-soiling performance while meeting the requirements of high transmittance and high haze over a wide wavelength range.

Figure 2: Schematic diagram of the manufacturing process of micro-bowl structures and conical nano-wavy hierarchical structures on polymers

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

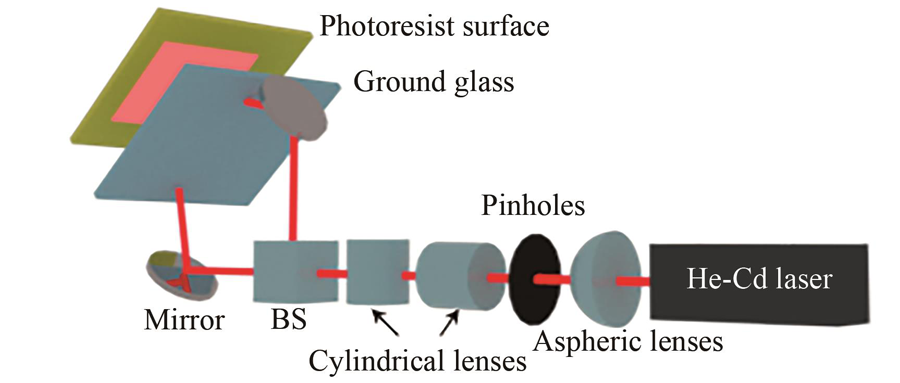

Additionally, holographic diffusion films formed by spot exposure are also a type of surface microstructure diffuser plate, which has the advantages of fine display effects, high transmittance, and controllable scattering light angles. The microstructure height probability density of traditional holographic diffusion films follows a Gaussian distribution, limiting the field of view. Increasing the light scattering angle will lead to brightness loss. To solve this problem, in 2021, Yang et al. used photoresist as the holographic recording medium and frosted glass as the rough surface. As shown in Figure 3, they prepared a holographic diffusion film with a scattering spot field surface microstructure. This diffusion film features a flat-top scattering light intensity distribution with high energy efficiency, improving brightness uniformity and display brightness, making it suitable for the LCD backlight field.

Figure 3: Schematic diagram of the exposure recording experiment

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

• Particle Scattering Diffuser Plates

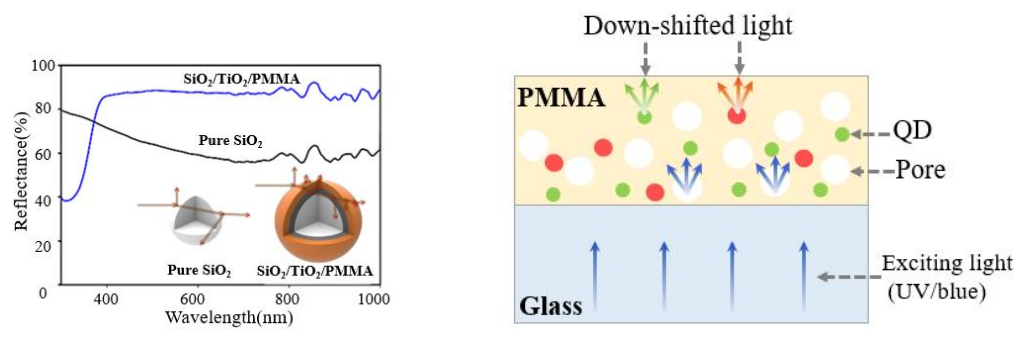

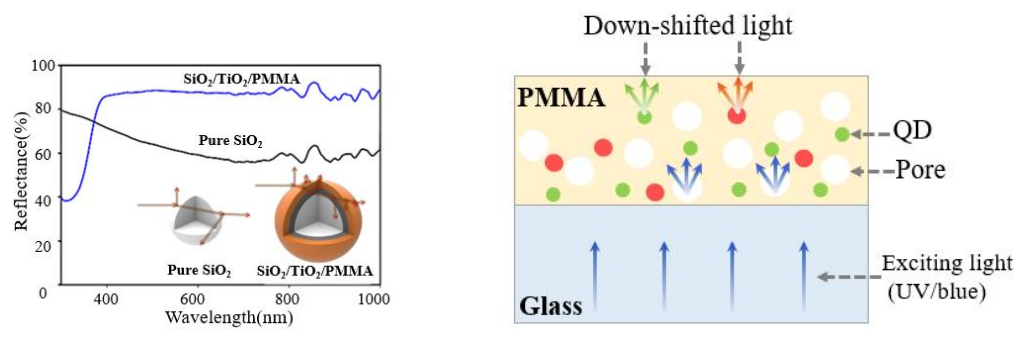

Particle scattering diffuser plates have simple structures and uniform light scattering advantages, generally using polymers such as PC, PMMA, and PS as substrates, with light scattering agents including organic/inorganic particles, polymer microspheres, and core-shell structured microspheres. The type and amount of scattering agents affect the performance of the diffuser plates; an excessively high concentration of scattering particles can enhance the scattering performance of the diffuser plate but may also lead to decreased transmittance, affecting light efficiency. In addition to pure scattering particles, the number of scattering events increases when light passes through core-shell structured microspheres, which can widen the field of view of the diffuser plate. Therefore, core-shell structured microspheres are also suitable as scattering agents, and there have been many studies in this area, such as SiO2/CeO2/poly(VTMS) microspheres and ZrO2@PMMA@polysiloxane microspheres. In 2020, Son et al. proposed a single-core double-shell SiO2/TiO2/PMMA nanoparticles with a gradient refractive index. As shown in Figure 4 (left), compared to pure SiO2 particles, these single-core double-shell nanoparticles exhibit superior light scattering performance. It is worth noting that most core-shell structured core materials are opaque, affecting the transmittance of the diffuser plates.Hollow particles have advantages in achieving high transmittance and lightweight properties.As shown in Figure 4 (right), similar to hollow particles, foamed mixed diffusion films create bubbles within the film, replacing the role of microspheres that increase light pathways, and the hollow structure of the bubbles reduces light energy loss.

Figure 4: Diffuse reflection spectra of pure SiO2 and SiO2/TiO2/PMMA double-layer nanoparticles; Schematic diagram of foamed mixed films

Source: ACS Applied Materials & Interfaces, 2020, 12(27): 30862-30870.fig.3; Liquid Crystal and Display, 2023, 38(3):304-318.

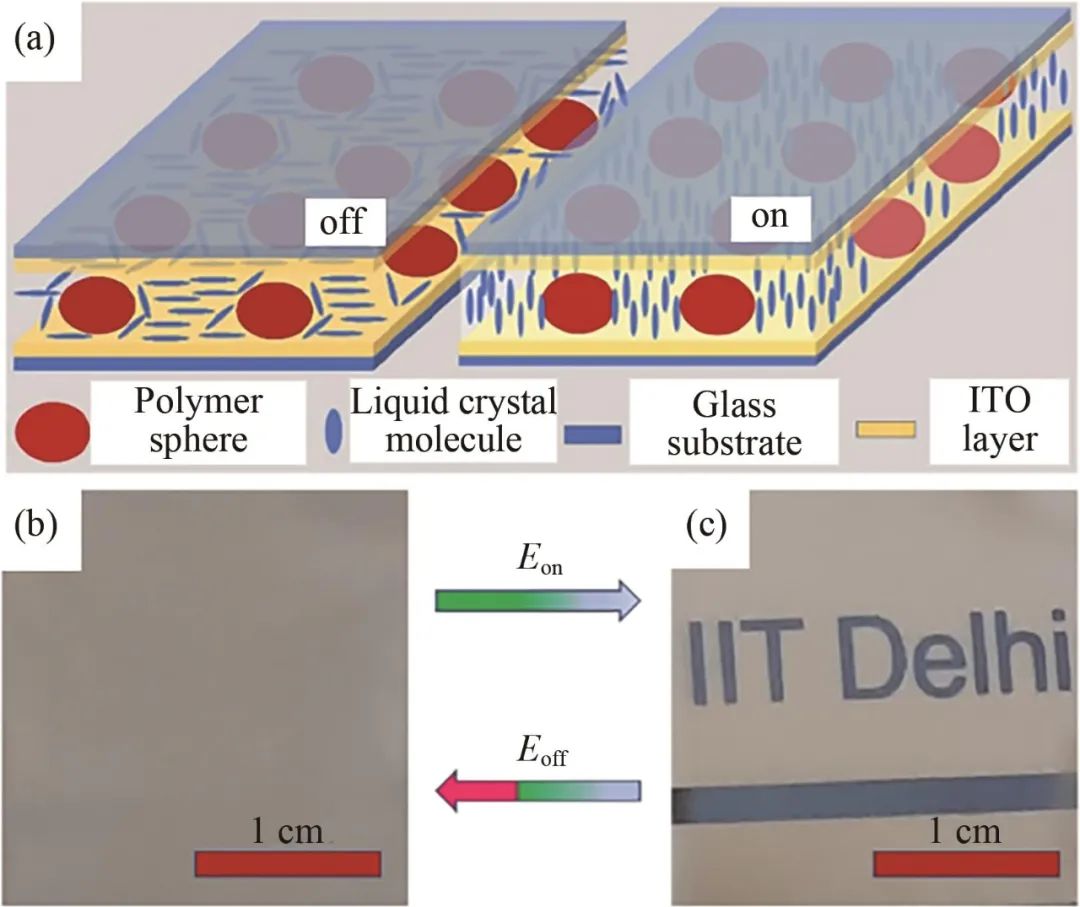

Furthermore, many studies have been conducted on the application of surface polymer microparticle films and polymer liquid crystal composite films as diffusion films. In 2022, Kumari et al. prepared a polymer microsphere-filled liquid crystal film (PFLCs), which can control its scattering state by applying an external electric field, as shown in Figure 5. The transmittance of polymer liquid crystal composite films, controlled by the electric field, allows for state switching, providing a new idea for multifunctional applications of diffusion films.

Figure 4: Diffuse reflection spectra of pure SiO2 and SiO2/TiO2/PMMA double-layer nanoparticles; Schematic diagram of foamed mixed films

Source: ACS Applied Materials & Interfaces, 2020, 12(27): 30862-30870.fig.3; Liquid Crystal and Display, 2023, 38(3):304-318.

Furthermore, many studies have been conducted on the application of surface polymer microparticle films and polymer liquid crystal composite films as diffusion films. In 2022, Kumari et al. prepared a polymer microsphere-filled liquid crystal film (PFLCs), which can control its scattering state by applying an external electric field, as shown in Figure 5. The transmittance of polymer liquid crystal composite films, controlled by the electric field, allows for state switching, providing a new idea for multifunctional applications of diffusion films.

Figure 5: (a) Prepared PFLC sample model; (b) Closed state of the sample after applying an electric field and (c) Open state

Source: ACS Applied Polymer Materials, 2022, 4(1): 64-73.fig.6

Application of Quantum Dot Diffuser Plates in LCDs

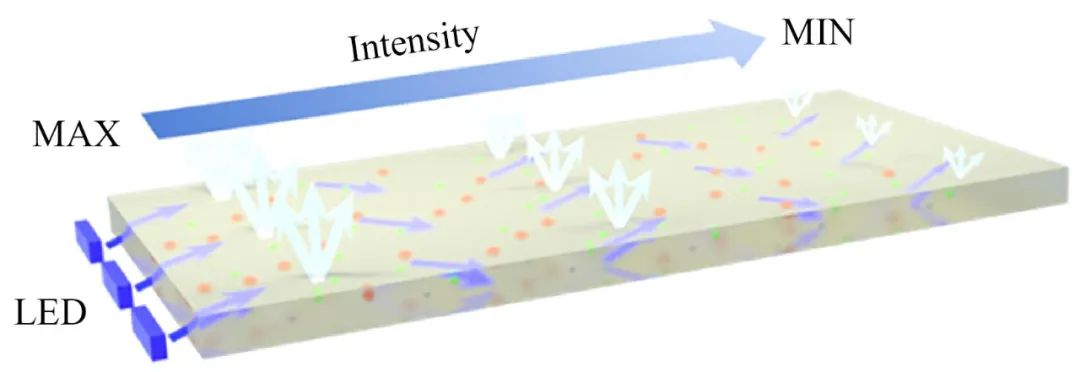

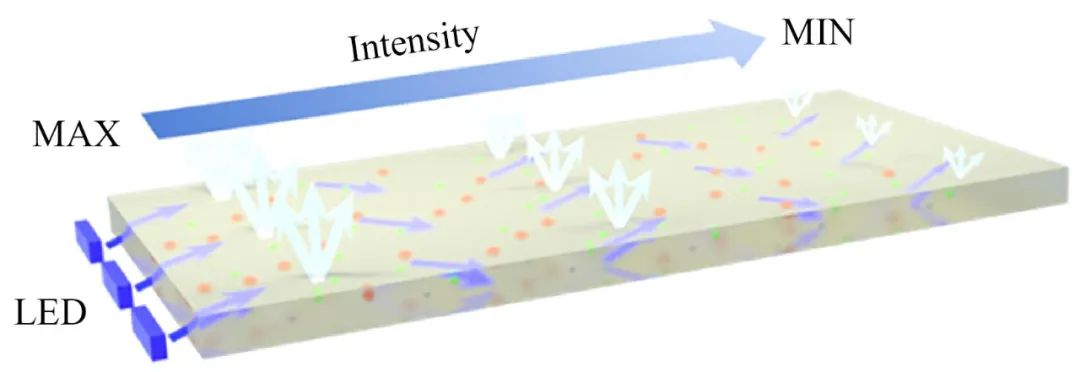

Quantum dot photoluminescence technology has been well-established in LCD backlighting, with various embedding schemes developed such as QD on chip, QD on edge, QD on surface, and QD on plate. The color gamut of quantum dot LCD TVs in the market has significantly improved, providing a better visual experience. However, stability issues remain one of the “roadblocks” for the application of quantum dots in LCDs. Quantum dots are sensitive to temperature, water, UV light, and oxygen conditions, making them prone to fluorescence quenching in the environment. Encapsulating quantum dots in polymers or glass ceramics is an effective way to further enhance the environmental stability of quantum dots. In 2021, Chen et al. embedded quantum dots into PC substrates through injection molding to produce a quantum dot light guide plate (QD-LGP), meeting the structure of QD on plate. Its luminescent characteristics differ slightly from traditional light guide plates, where blue light incident from the edge is simultaneously absorbed and scattered by the quantum dots, continuously converting and consuming during propagation until it disappears, as shown in Figure 6. This light loss means that the concentration of quantum dots at different positions needs to be precisely controlled during production. Therefore, for large-sized displays, using a direct-lit light input method with quantum dot diffuser plates remains a better solution.

Figure 6: Schematic diagram of light emission and intensity decay of QD-LGP

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

Quantum dot diffuser plates belong to particle scattering type diffuser plates and possess the characteristic of scattering light. Typically, quantum dot diffuser plates use polymers such as PMMA and PS as matrices, produced through a melt extrusion process with quantum dots uniformly dispersed within. Compared to quantum dot films, quantum dot diffuser plates eliminate the need for expensive barrier films, and the polymer matrix helps reduce quantum dot agglomeration, further enhancing the stability of quantum dots. The backlight structure of quantum dot diffuser plates is shown in Figure 7, which includes a prism film, a quantum dot diffuser plate, and a blue Mini-LED array from top to bottom. Comparing Figures 1 and 7, it can be seen that the basic working principle for generating uniformly bright white light with quantum dot diffuser plates is similar to that of quantum dot films, both exhibiting excellent color performance. Quantum dot diffuser plates combine the characteristics of quantum dot films and diffuser plates, simplifying the backlight structure. Therefore, in the manufacturing of medium to large-sized TVs, quantum dot diffuser plates hold advantages over quantum dot film structures.

Figure 7: Schematic diagram of the backlight structure of quantum dot diffuser plates

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

Currently, the quantum dots used in diffuser plates are mostly II-VI semiconductor quantum dots. Recently, perovskite quantum dots have gained popularity in display research due to their simple synthesis, wide color gamut, and tunable spectra. However, their stability remains one of the challenges limiting their application. It has been demonstrated that ligand modification, ion doping, and encapsulation can effectively improve their stability. A significant amount of research has been conducted to address the weak water and oxygen stability of perovskites. With continuous performance optimization, perovskite quantum dots show great application prospects in backlight displays. The application of perovskite quantum dots in diffuser plates combined with polymers is also worth further exploration.

Preparation and Testing of Multilayer Quantum Dot Diffuser Plates

• Preparation of Multilayer Quantum Dot Diffuser Plates

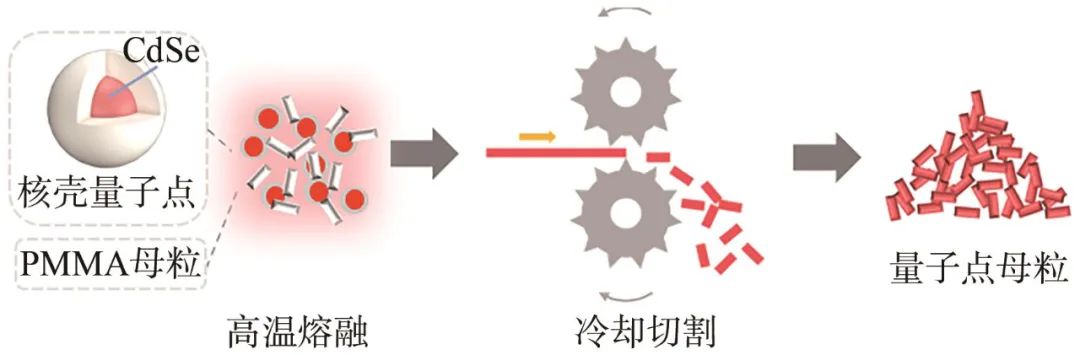

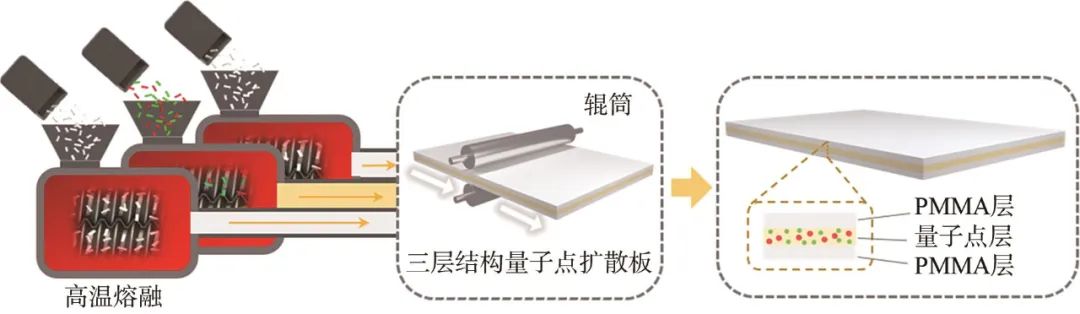

Multilayer structured quantum dot diffuser plates (QD-DP) are prepared using a multilayer melt co-extrusion method, resembling a sandwich where the middle layer is PMMA filled with mixed quantum dots, with red and green quantum dots uniformly distributed within, possessing light scattering and color conversion functions. The top and bottom layers are pure PMMA layers, which offer good water and oxygen resistance, effectively protecting the quantum dots. Figure 8 illustrates the manufacturing process of quantum dot master pellets. The quantum dot solution is mixed with PMMA master pellets, and the mixture is melt-extruded into strips at 220°C-245°C using a twin-screw extruder, then cooled and cut to obtain quantum dot master pellets. Thanks to the protective core-shell structured quantum dots and PMMA layers, the quantum dot master pellets maintain good stability.

Figure 8: Manufacturing process of quantum dot master pellets

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

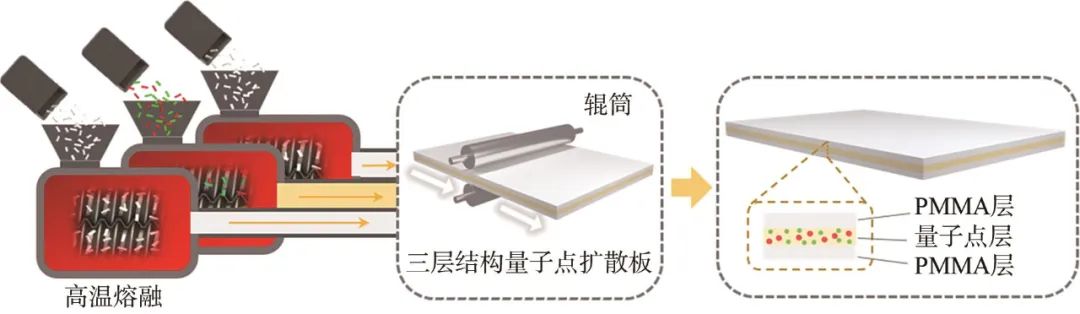

The specific preparation process of QD-DP is shown in Figure 9. The melted materials are simultaneously extruded by three extruders and molded into a complete multilayer diffuser plate. The composition and dimensions of QD-DP can be freely adjusted, with thickness controlled by the spacing of the rollers, making the manufacturing process highly flexible. After the high-temperature melt mixing process, quantum dots can be fully dispersed within the functional layer. Measurements indicate that the cadmium content of QD-DP is about 25ppm, complying with the low cadmium standard (<100 ppm) of European regulations. Thus, in terms of environmental requirements, quantum dot diffuser plates also have certain advantages over quantum dot films. In terms of cost, a lower quantum dot concentration can further reduce manufacturing costs, facilitating the penetration of QD technology into mid- to low-end display products.

Figure 9: Schematic diagram of the process for preparing multilayer QD-DP through three-layer melt co-extrusion

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

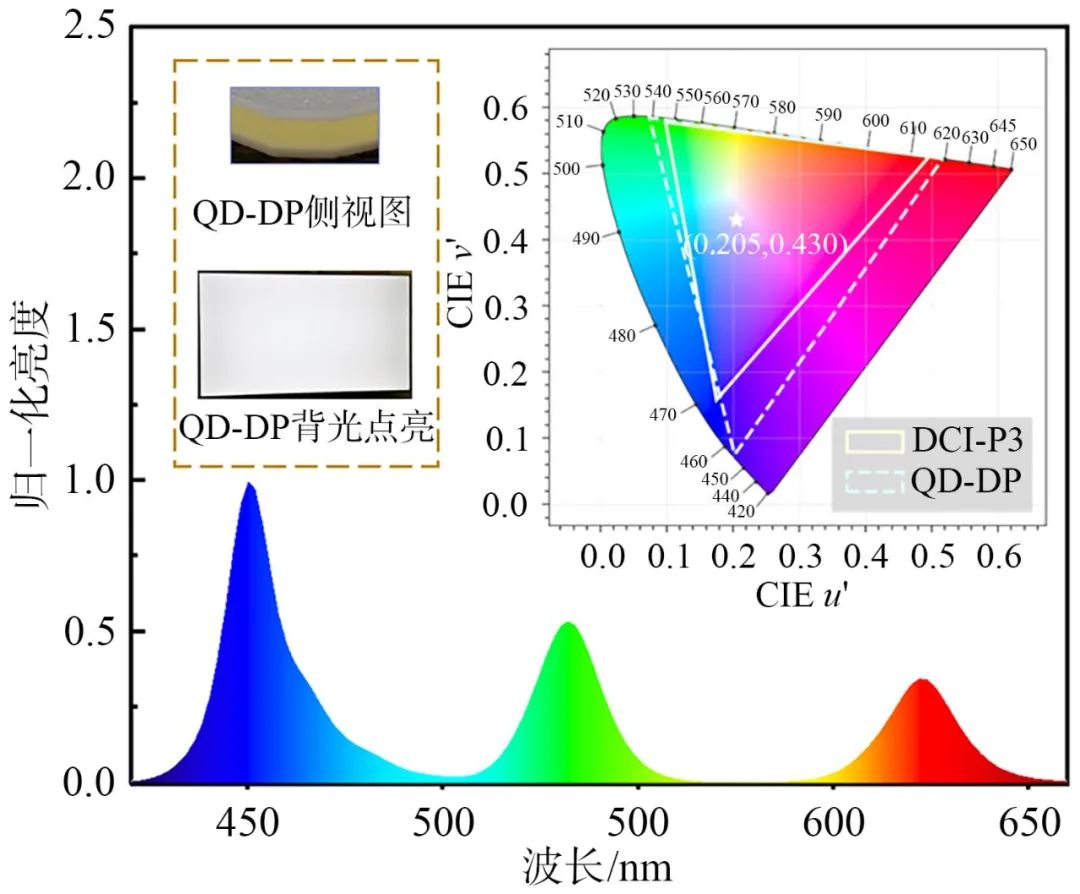

For quantum dot backlight devices, color conversion performance should be the primary focus. The photoluminescence effect of QD-DP under blue illumination is shown in Figure 10. From the backlight illumination diagram, it can be seen that the light emitted by the Mini-LED, after passing through the scattering particles and quantum dots within the plate, exits uniformly. Using a nine-point method to measure the brightness of the output surface, the uniformity exceeds 80%. To verify its fluorescence characteristics, a spectrometer was used to test the normalized white light spectrum of QD-DP during operation, showing that the half-widths of blue/green/red light are less than 20nm/25nm/25nm, with a color gamut coverage reaching 99.58% of the DCI-P3 standard, meeting the requirements for high color gamut displays.

Figure 9: Schematic diagram of the process for preparing multilayer QD-DP through three-layer melt co-extrusion

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

For quantum dot backlight devices, color conversion performance should be the primary focus. The photoluminescence effect of QD-DP under blue illumination is shown in Figure 10. From the backlight illumination diagram, it can be seen that the light emitted by the Mini-LED, after passing through the scattering particles and quantum dots within the plate, exits uniformly. Using a nine-point method to measure the brightness of the output surface, the uniformity exceeds 80%. To verify its fluorescence characteristics, a spectrometer was used to test the normalized white light spectrum of QD-DP during operation, showing that the half-widths of blue/green/red light are less than 20nm/25nm/25nm, with a color gamut coverage reaching 99.58% of the DCI-P3 standard, meeting the requirements for high color gamut displays.

Figure 10: Spectral diagram of QD-DP backlight, side view, backlight illumination diagram, and color gamut diagram in the CIE1976 coordinate system

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

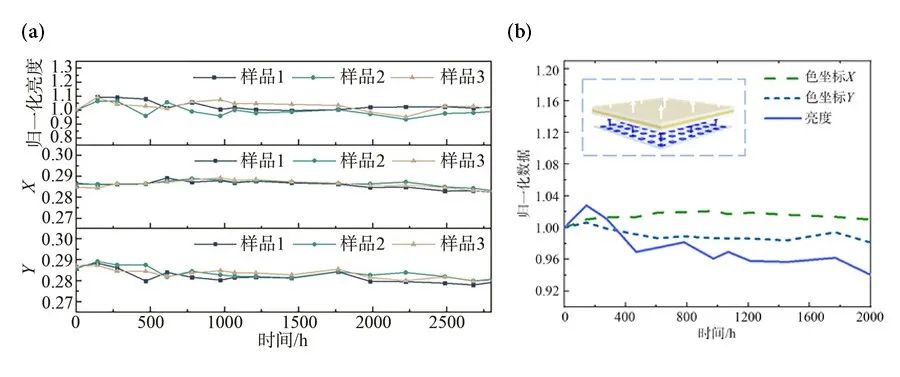

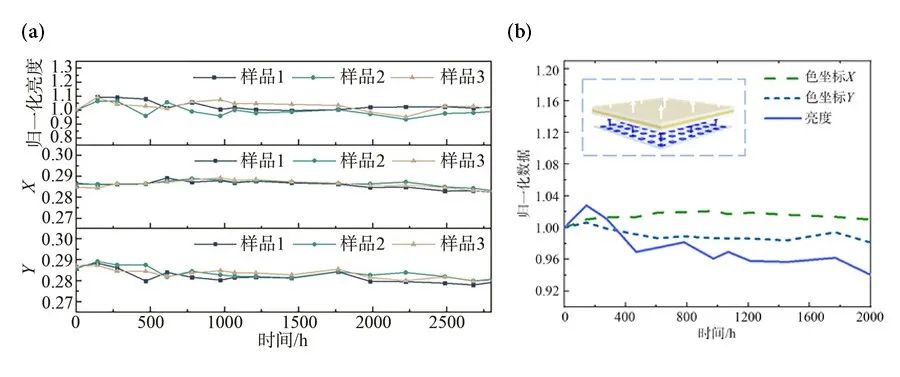

In addition to color performance, the stability of the diffuser plate is also crucial. To this end, aging tests were conducted on the prepared QD-DP samples, with results shown in Figure 11(a). After being stored in a high-temperature and high-humidity environment (60°C/90%) for 2500 hours, the brightness and color coordinates of QD-DP fluctuated by less than 10%, with no significant impact on the quantum dots inside the plate due to extreme conditions. This is attributed to the PMMA layers in the three-layer structure, which can isolate water and oxygen, greatly reducing the quenching of internal quantum dots. Under conditions of 45°C/85%, three QD-DP samples underwent aging experiments with blue light exposure, as shown in Figure 11(b), with the effective working life (T95) of this QD-DP exceeding 1000 hours. This is partly because quantum dots are evenly dispersed in the diffuser plate, avoiding the impact of high temperatures caused by long-term operation of LEDs on quantum dot lifespan. In conclusion, the three-layer structure of QD-DP can isolate the quantum dots within the plate from contact with water and oxygen in the environment, reducing the probability of quenching and deactivation of quantum dots, thereby improving their operational stability and lifespan. Additionally, the performance of QD-DP is comparable to that of quantum dot film products, and its simple production process facilitates large-scale production, making it more competitive in the application of medium to large-sized displays.

Figure 11: (a) High-temperature and high-humidity storage test data of QD-DP (b) Light decay characteristics curve of QD-DP under blue light exposure

Source: Liquid Crystal and Display, 2023, 38(3):304-318.

Quantum dot diffuser plates belong to particle scattering type diffuser plates, serving both color conversion and light homogenization functions, which can replace commercial quantum dot films combined with traditional diffuser plate solutions. When combined with the regional dimming technology of Mini-LEDs, high contrast and precise color reproduction can be achieved. Compared to quantum dot film solutions, quantum dot diffuser plates have an integrated structure, eliminating the need for expensive barrier films, significantly reducing costs. Furthermore, multilayer quantum dot diffuser plates (QD-DP) have protective PMMA layers, effectively enhancing the stability of quantum dots within the plate, and their color conversion performance meets the requirements for high color gamut displays.

In summary, the preparation process of quantum dot diffuser plates is simple and cost-effective, coupled with color rendering performance comparable to quantum dot films, making them a highly promising backlight solution for LCDs with high color gamut. Currently, manufacturers like TCL and Hisense have achieved stable mass production and delivery of quantum dot products using quantum dot diffuser plates, gaining recognition from an increasing number of users. With more manufacturers joining the market, the market share of quantum dot diffuser plates in mid- to low-end products is expected to further increase. In the future, it is anticipated that the stability of QDs may be further enhanced, and their structure can be simplified and expanded for more application scenarios.

Paper Information

Ye Daochun, Xie Hongxing, Li Sijie, Ji Honglei, Xu Huaishu, Li Yang, Sun Lei, Chen Enguo, Xu Sheng, Ye Yun, Yan Qun, Guo Tailiang. Research Progress on Quantum Dot Diffuser Plates for LCD Displays [J]. Liquid Crystal and Display, 2023, 38(3):304-318.

https://cjlcd.lightpublishing.cn/thesisDetails#10.37188/CJLCD.2022-0318

Corresponding Author Introduction

Chen Enguo, Professor and PhD supervisor at Fuzhou University/Mindu Innovation Laboratory, mainly engaged in research on optoelectronic display technology, covering material preparation, device processing, optical design simulation, and system applications, involving AR/VR near-eye displays, micro-displays, micro-projection, quantum dot luminescence and display, etc. He has presided over national key R&D projects, general projects of the National Natural Science Foundation, published more than 100 papers, and authorized more than 50 national invention patents.