✅ Author Profile: A Matlab simulation developer passionate about research, skilled in data processing, modeling simulation, program design, obtaining complete code, reproducing papers, and scientific simulation.

🍎 Previous Review: Follow my personal homepage:Matlab Research Studio

🍊 Personal Motto: Investigate to gain knowledge, complete Matlab code and simulation consultation available via private message.

🔥 Content Introduction

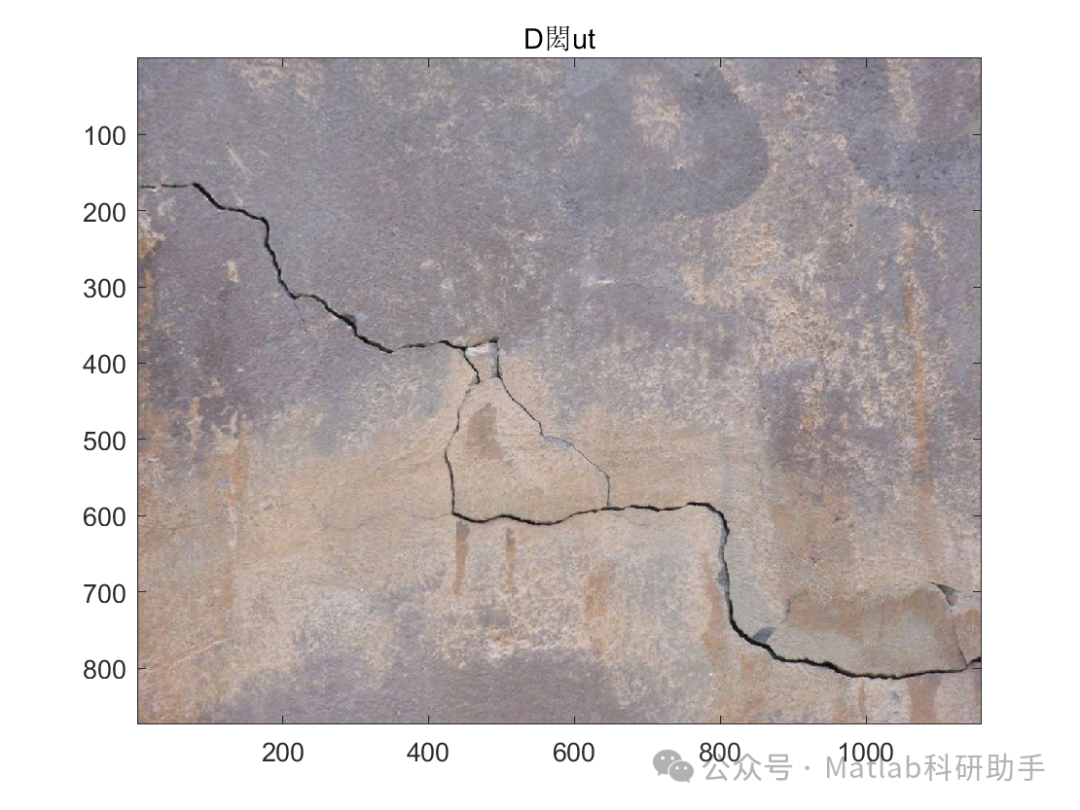

Cracks are precursors to material or structural failure, posing potential safety hazards and economic losses across various engineering fields such as civil, mechanical, and aerospace engineering. Therefore, timely and accurate detection and assessment of cracks are crucial. Traditional crack detection methods are often time-consuming and labor-intensive, with results significantly influenced by subjective factors. With the rapid development of computer vision and image processing technologies, image-based crack detection methods have gradually become a research hotspot, effectively improving detection efficiency and accuracy while achieving automation and intelligence. This article will delve into the background of crack detection, the main technical methods, and focus on the challenges and solutions faced in detecting and marking cracks in images.

Importance and Challenges of Crack Detection

The primary significance of crack detection lies in ensuring structural safety. Whether it is bridges, buildings, aircraft components, or industrial equipment, even minor cracks can expand under prolonged stress, ultimately leading to catastrophic accidents. Additionally, crack detection helps extend the lifespan of equipment; early detection and repair can prevent more severe damage and reduce maintenance costs. Furthermore, in product quality control, crack detection is a key step in ensuring products meet standards and enhancing market competitiveness.

However, detecting cracks in images faces numerous challenges. Firstly, the diversity of cracks, including variations in shape, size, direction, and grayscale features, makes it difficult to establish a universal detection model. Secondly, image noise and interference, such as uneven lighting, surface textures, stains, and scratches, can easily confuse with real cracks, leading to false positives or missed detections. Moreover, for small and blurry cracks, their features are not obvious, making accurate extraction challenging. Finally, practical applications often require real-time and efficient detection capabilities, which impose high demands on the computational efficiency of algorithms.

Main Technical Methods for Crack Detection

Currently, image-based crack detection methods can be categorized into the following types:

1. Traditional Image Processing Methods

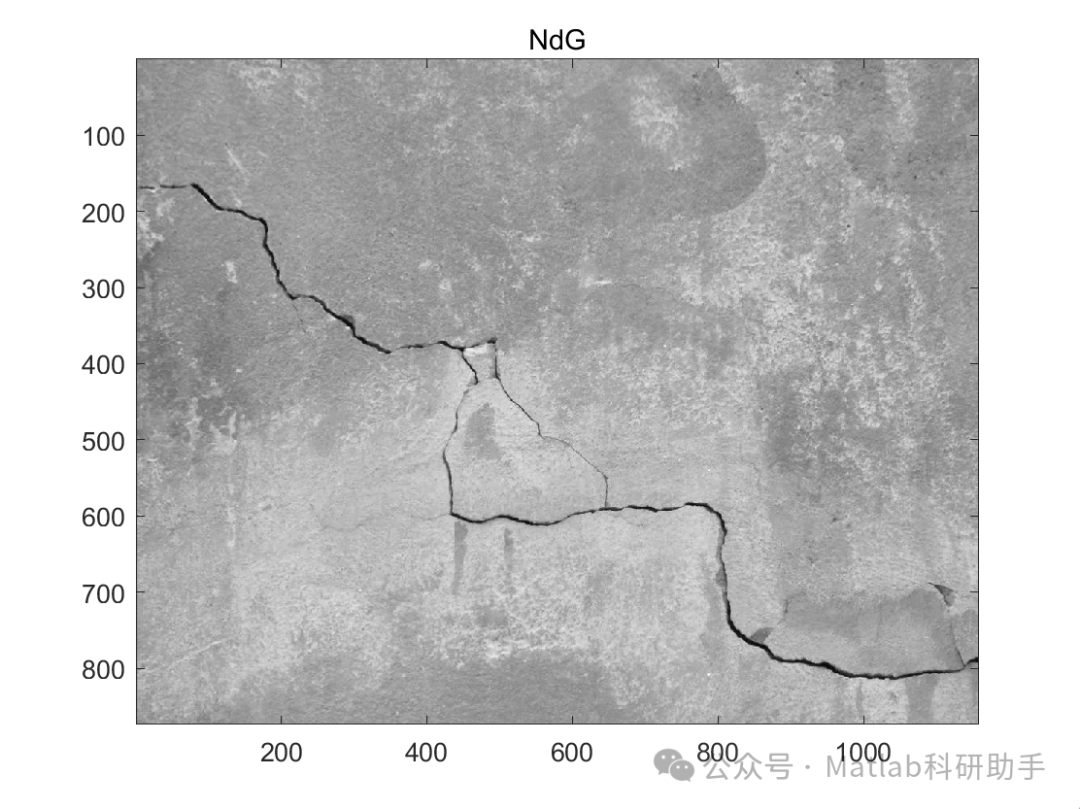

These methods primarily utilize low-level features of images, such as edges, textures, and shapes, to identify cracks.

- Edge Detection Algorithms: Cracks typically manifest as abrupt changes in grayscale values within images, thus edge detection operators like Sobel, Canny, and Roberts can be used to extract edge information of cracks. However, these methods are susceptible to noise and struggle to distinguish cracks from other edges.

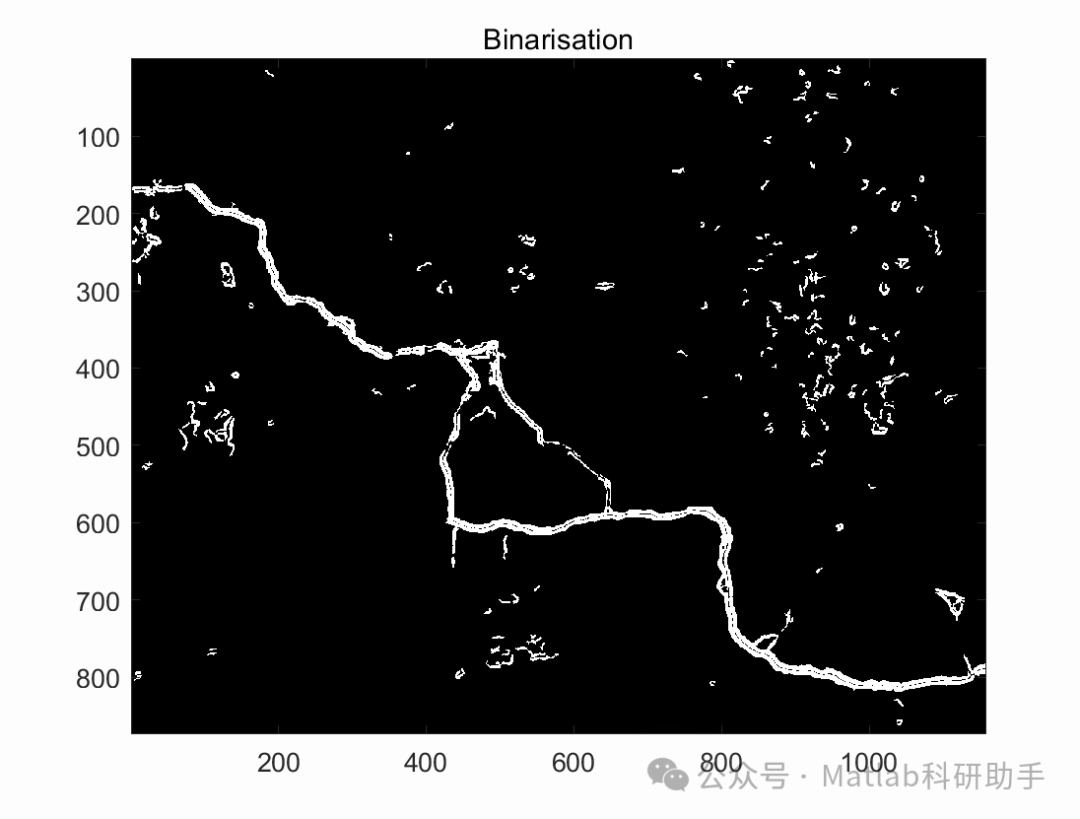

- Morphological Operations: By applying morphological operations such as erosion, dilation, and opening-closing, images can be preprocessed to remove noise and connect broken crack lines, highlighting crack features.

- Threshold Segmentation: For cracks with significant differences in grayscale values compared to the background, appropriate thresholds can be set to separate the crack regions from the background. However, this method requires high contrast and specific lighting conditions.

- Texture Analysis: The texture features of crack regions differ from those of normal areas. By extracting texture features using methods like Gray Level Co-occurrence Matrix (GLCM) and Local Binary Patterns (LBP), and combining them with classifiers for crack identification.

2. Machine Learning-Based Methods

With the advancement of machine learning technologies, an increasing number of studies have applied machine learning algorithms to crack detection.

- Support Vector Machines (SVM): By training an SVM classifier, cracks can be distinguished from non-crack regions based on their feature vectors.

- Artificial Neural Networks (ANN): Shallow neural networks can learn complex patterns of cracks for classification.

- Random Forest: An ensemble learning method that constructs multiple decision trees and votes to enhance classification robustness.

These methods typically require manual feature extraction, and the quality of feature extraction directly impacts the model’s performance.

3. Deep Learning-Based Methods

In recent years, deep learning has made groundbreaking progress in image recognition, providing new ideas for crack detection.

- Convolutional Neural Networks (CNN): CNNs can automatically learn high-level features from images, avoiding the cumbersome manual feature extraction process. By constructing CNN models of varying depths, various complex crack patterns can be effectively recognized.

- Fully Convolutional Networks (FCN): FCNs can classify each pixel of an image, achieving pixel-level semantic segmentation to accurately mark the areas of cracks.

- U-Net: A network structure specifically designed for image segmentation, its U-shaped architecture effectively integrates multi-scale information, performing excellently in medical image segmentation and crack segmentation.

- Object Detection Algorithms: Such as YOLO and Faster R-CNN, can treat cracks as objects for detection, not only identifying the presence of cracks but also localizing their positions.

Deep learning methods possess strong feature learning and generalization capabilities, achieving good detection results even in complex environments, making them the future trend in crack detection.

Marking Cracks in Images

Detecting cracks is not just about identifying their presence; it is equally important to accurately mark them for subsequent quantitative analysis and maintenance decisions. Crack marking typically includes the following aspects:

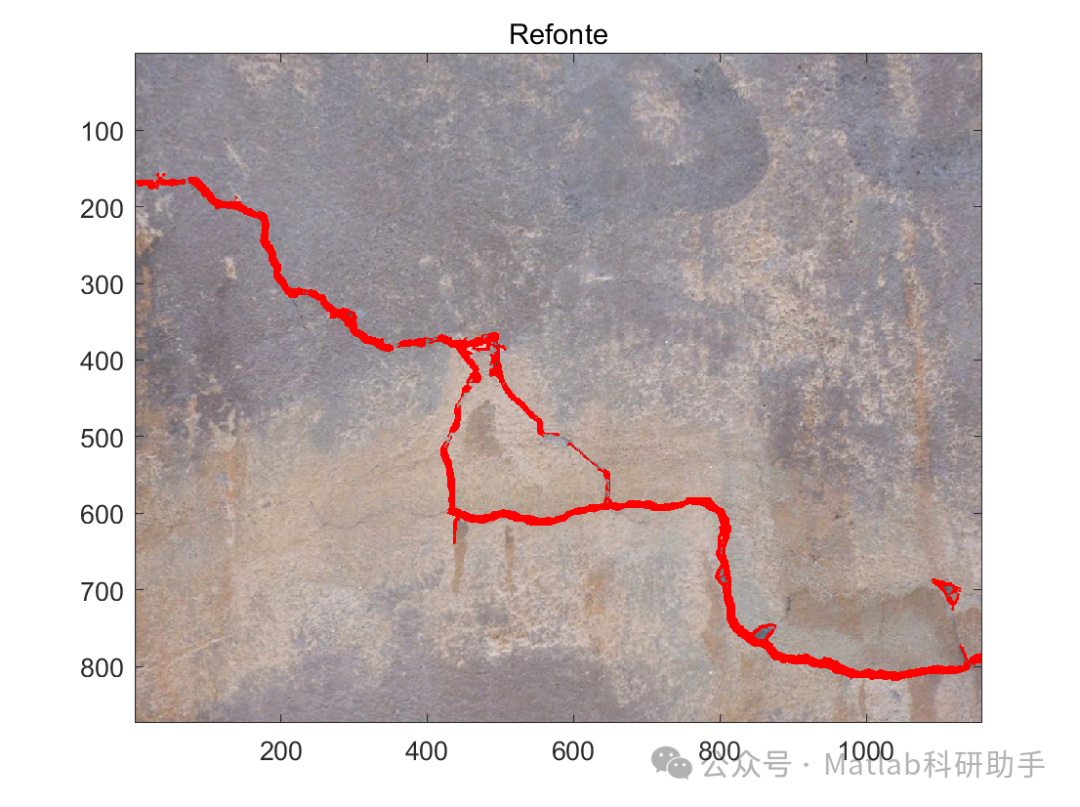

- Location Marking: Precisely marking the geometric location of cracks in images using bounding boxes, masks, or contour lines.

- Geometric Parameter Marking: Measuring geometric parameters such as length, width, direction, and depth (if possible) of cracks.

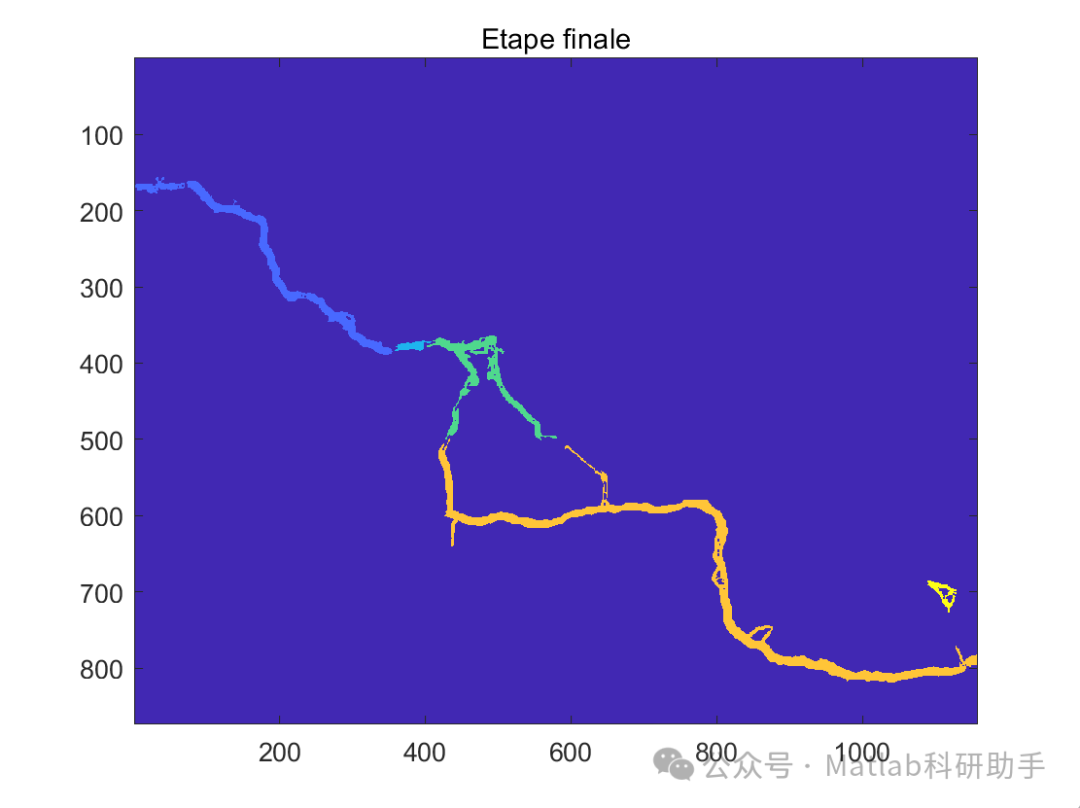

- Type Marking: Distinguishing different types of cracks, such as transverse cracks, longitudinal cracks, shear cracks, and fatigue cracks, which helps in assessing the causes and development trends of cracks.

- Severity Marking: Evaluating the severity of cracks based on indicators such as length, width, or propagation speed, and classifying them to provide a basis for maintenance.

For deep learning methods, pixel-level crack masks can be directly output through semantic segmentation or instance segmentation models, achieving precise crack marking. By integrating technologies such as Computer-Aided Design (CAD) and Geographic Information Systems (GIS), marked crack information can be incorporated into larger management systems, enabling visualization and intelligence in structural health monitoring.

Conclusion and Outlook

Image-based crack detection technology plays an increasingly important role in ensuring engineering safety, extending equipment lifespan, and improving product quality. From traditional image processing to machine learning, and now to cutting-edge deep learning, crack detection methods continue to evolve, significantly enhancing detection accuracy and efficiency. In particular, deep learning, with its powerful feature learning and generalization capabilities, has become key to solving complex crack detection problems.

In the future, crack detection technology will develop in the following directions:

- Multimodal Data Fusion: Combining various detection methods such as infrared, ultrasound, and laser to obtain more comprehensive information, improving the robustness and accuracy of crack detection.

- Lightweight and Real-time: Developing smaller and more efficient deep learning models to meet the needs of embedded devices and real-time detection.

- Few-shot Learning and Transfer Learning: Addressing the scarcity of crack samples by utilizing few-shot learning and transfer learning techniques to enhance model generalization capabilities.

- Explainable AI: Enhancing the interpretability of crack detection models, allowing engineers to understand the basis for model judgments and increasing trust in detection results.

- Automated Diagnosis and Decision-making: Integrating crack detection with expert systems and decision support systems to achieve automated diagnosis, assessment, and maintenance recommendations for cracks.

⛳️ Results

🔗 References

[1] Ding Jianjun. Research on Eddy Current Detection Method for Surface Cracks of Steel Balls Based on VI [D]. Wuhan University of Technology, 2007. DOI:10.7666/d.y1365685.

[2] Li Rongxuan, Shi Dongdong. Research on Machine Vision Detection of Surface Cracks in Workpieces [J]. Automation Instrumentation, 2017, 38(9):5. DOI:10.16086/j.cnki.issn1000-0380.201709020.

[3] Li Hanlin. Application Research of Finite Element Analysis in Crack Detection of Marine Diesel Engine Shaft System [D]. Jimei University [2025-07-04]. DOI:10.7666/d.d051009.

📣 Sample Code

🎈 Some theoretical references are from online literature; please contact the author for removal if there is any infringement.

👇 Follow me to receive a wealth of Matlab e-books and mathematical modeling materials

🏆 Our team specializes in guiding customized MATLAB simulations in various research fields, helping to realize research dreams:

🌈 Various intelligent optimization algorithm improvements and applications

Production scheduling, economic scheduling, assembly line scheduling, charging optimization, workshop scheduling, departure optimization, reservoir scheduling, 3D packing, logistics site selection, cargo location optimization, bus scheduling optimization, charging pile layout optimization, workshop layout optimization, container ship loading optimization, pump combination optimization, medical resource allocation optimization, facility layout optimization, visual domain base station and drone site selection optimization, knapsack problem, wind farm layout, time slot allocation optimization, optimal distributed generation unit allocation, multi-stage pipeline maintenance, factory-center-demand point three-level site selection problem, emergency life material distribution center site selection, base station site selection, road lamp post arrangement, hub node deployment, transmission line typhoon monitoring devices, container scheduling, unit optimization, investment portfolio optimization, cloud server combination optimization, antenna linear array distribution optimization, CVRP problem, VRPPD problem, multi-center VRP problem, multi-layer network VRP problem, multi-center multi-vehicle VRP problem, dynamic VRP problem, two-layer vehicle routing planning (2E-VRP), electric vehicle routing planning (EVRP), oil-electric hybrid vehicle routing planning, hybrid flow shop problem, order splitting scheduling problem, bus scheduling optimization problem, flight shuttle vehicle scheduling problem, site selection path planning problem, port scheduling, port bridge scheduling, parking space allocation, airport flight scheduling, leak source localization

🌈 Time series, regression, classification, clustering, and dimensionality reduction in machine learning and deep learning

2.1 BP time series, regression prediction, and classification

2.2 ENS sound neural network time series, regression prediction, and classification

2.3 SVM/CNN-SVM/LSSVM/RVM support vector machine series time series, regression prediction, and classification

2.4 CNN|TCN|GCN convolutional neural network series time series, regression prediction, and classification

2.5 ELM/KELM/RELM/DELM extreme learning machine series time series, regression prediction, and classification

2.6 GRU/Bi-GRU/CNN-GRU/CNN-BiGRU gated neural network time series, regression prediction, and classification

2.7 Elman recurrent neural network time series, regression prediction, and classification

2.8 LSTM/BiLSTM/CNN-LSTM/CNN-BiLSTM long short-term memory neural network series time series, regression prediction, and classification

2.9 RBF radial basis neural network time series, regression prediction, and classification

2.10 DBN deep belief network time series, regression prediction, and classification

2.11 FNN fuzzy neural network time series, regression prediction

2.12 RF random forest time series, regression prediction, and classification

2.13 BLS broad learning system time series, regression prediction, and classification

2.14 PNN pulse neural network classification

2.15 Fuzzy wavelet neural network prediction and classification

2.16 Time series, regression prediction, and classification

2.17 Time series, regression prediction, and classification

2.18 XGBOOST ensemble learning time series, regression prediction, and classification

2.19 Transform various combinations time series, regression prediction, and classification

Directions cover wind power prediction, photovoltaic prediction, battery life prediction, radiation source identification, traffic flow prediction, load prediction, stock price prediction, PM2.5 concentration prediction, battery health status prediction, electricity consumption prediction, water body optical parameter inversion, NLOS signal identification, precise prediction of subway stops, transformer fault diagnosis

🌈 In image processing

Image recognition, image segmentation, image detection, image hiding, image registration, image stitching, image fusion, image enhancement, image compressed sensing

🌈 In path planning

Traveling salesman problem (TSP), vehicle routing problem (VRP, MVRP, CVRP, VRPTW, etc.), drone 3D path planning, drone collaboration, drone formation, robot path planning, grid map path planning, multimodal transport problem, electric vehicle routing planning (EVRP), two-layer vehicle routing planning (2E-VRP), oil-electric hybrid vehicle routing planning, ship trajectory planning, full path planning, warehouse patrol

🌈 In drone applications

Drone path planning, drone control, drone formation, drone collaboration, drone task allocation, drone secure communication trajectory online optimization, vehicle collaborative drone path planning

🌈 In communication

Sensor deployment optimization, communication protocol optimization, routing optimization, target localization optimization, Dv-Hop localization optimization, Leach protocol optimization, WSN coverage optimization, multicast optimization, RSSI localization optimization, underwater communication, communication upload and download allocation

🌈 In signal processing

Signal recognition, signal encryption, signal denoising, signal enhancement, radar signal processing, signal watermark embedding and extraction, electromyography signals, electroencephalography signals, signal timing optimization, electrocardiogram signals, DOA estimation, encoding and decoding, variational mode decomposition, pipeline leakage, filters, digital signal processing + transmission + analysis + denoising, digital signal modulation, bit error rate, signal estimation, DTMF, signal detection

🌈 In power systems

Microgrid optimization, reactive power optimization, distribution network reconstruction, energy storage configuration, orderly charging, MPPT optimization, household electricity

🌈 In cellular automata

Traffic flow, crowd evacuation, virus spread, crystal growth, metal corrosion

🌈 In radar

Kalman filter tracking, trajectory association, trajectory fusion, SOC estimation, array optimization, NLOS identification

🌈 Workshop scheduling

Zero-wait flow shop scheduling problem (NWFSP), permutation flow shop scheduling problem (PFSP), hybrid flow shop scheduling problem (HFSP), zero idle flow shop scheduling problem (NIFSP), distributed permutation flow shop scheduling problem (DPFSP), blocking flow shop scheduling problem (BFSP)

👇