Flexible control technology with fast cycle times helps improve the efficiency of the hairpin motor stator production line.

Beckhoff’s PC-based control technology powers automotive motor manufacturing.

Recently, machine tool manufacturer GROB Group developed a high-volume production and assembly system to help customers cope with the rapid growth in consumer demand for electric vehicles. GROB adopted Beckhoff’s PC-based and EtherCAT control and drive technology to address key issues such as minimizing processing cycles and accelerating process sequences, successfully completing this task. A precision hairpin motor (named for the coil shape of the motor stator winding resembling a hairpin) dedicated machine tool illustrates the advantages of this optimized scalable automation solution. This solution not only utilizes a compact industrial PC C603x installed with TwinCAT 3 software as the central control platform but is also equipped with an XTS magnetic-driven flexible conveyor system.

GROB Group is an international family-owned business with operations worldwide, headquartered in Mindelheim, Germany. Since its establishment 95 years ago, it has been dedicated to developing and manufacturing various systems and machine tools for globally renowned automotive manufacturers and their suppliers. Its product range includes general machining centers, complex production systems, as well as manual assembly workstations and fully automated assembly lines. This includes motor production systems, as well as power battery and fuel cell production and assembly systems. GROB’s electric vehicle business unit control technology manager Fabian Glöckler explains: “Our products can cover the entire industrial chain in this field, providing customers with complete customized powertrain systems.”

Electric vehicles require powerful control technology.

According to Martin Ellenrieder, head of functional development at GROB’s electric vehicle business unit, the development trends of electric vehicles also impose new requirements on control technology: “Compared to systems for engines, these systems have more precise workstations, shorter PLC cycle times, a higher proportion of drive products equipped in the assembly line, and more complex coupled movements.” The hairpin motor (second generation) also possesses these characteristics, fully equipped with Beckhoff’s control and drive technology. In addition to 4 GROB spindles, it is equipped with a total of 57 NC axes, including 40 solid axes and 5 virtual axes, as well as 12 movers of the XTS magnetic-driven flexible conveyor system (operating as independent servo axes). Additionally, there is an I/O layer composed of EtherCAT and TwinSAFE terminal modules or terminal boxes (270 digital inputs and 150 digital outputs).

The C6030 or C6032 compact industrial PC and TwinCAT software serve as the core part of the control system, achieving a very high output rate based on a processing cycle of only 2.3 seconds for each hairpin winding. Each stator requires about 200 hairpin windings to be produced separately. The entire processing process is very complex, involving a wide range of control tasks: from feeding copper wire to straightening, complex bending, and stripping, to precise pre-insertion into slots:

Feeding line (from coil to straight copper wire, electrical measurement with or without copper wire insulation layer): PC-based control technology is applied for tension control.

Real-time wire stripping: axis positioning, cam, and flying saw.

Feeding: coupling the axis with a second encoder system, switching the encoder system based on the system’s operating state, and switching axes through an interface for dedicated operating modes (with or without wire).

Copper wire detection: conveying and positioning.

Pressing/cutting: cam and dynamic coupling coefficient compensation for material displacement during pressing/cutting through virtual gear function.

2D bending: dynamic cam generated by hairpin winding parameters coupled through dynamic coupling coefficient of virtual gear function.

3D bending: dynamic cam generated by hairpin winding parameters coupled with XTS movers through dynamic coupling coefficient of virtual gear function.

Pre-insertion of hairpin windings: cam or coordinated motion.

Diverse feeding methods/pre-insertion slots and positioning motion of clamping fingers: coupling virtual axes and real axes.

Daniel Gugenberger, head of the electrical design group at GROB’s electric vehicle business unit, explains the differences between the production of windings and engine production: “Traditional assembly processes such as bolt connections, pressing, and manual assembly operations have been largely automated. If manual methods are adopted, the required quality, precision, and speed cannot be achieved.” Due to the system’s high throughput, detailed equipment and process data are crucial, which is where Beckhoff’s PC-based control technology comes into play: “If a complete production process takes only two seconds, suitable analysis tools and high-speed cameras are needed for production inspection and error analysis. Therefore, we often use TwinCAT Scope View oscilloscope software.”

Manufacturing a stator requires about 50 different designs of 200 hairpin windings. They are produced sequentially according to the order placed in the pre-insertion slots. Therefore, online error detection is of great significance.Fabian Glöckler explains: “If there are material or geometric shape errors, the corresponding hairpin winding must be produced again and inserted into the system through an automatic feeding device to ensure it is placed in the correct position. With a large number of motion axes and various specifications of hairpin windings, this also means that the control technology needs to calculate various parameters, bending angles, and cam curves in a timely manner, which is a massive and daunting task.”

Mature automation systems and innovative HMI.

As early as 2004, the first GROB processing machine adopted Beckhoff technology,Martin Ellenrieder recalled: “First, it was the test bench, followed by additional tool changers, and by 2017, the first assembly line also adopted a PC-based automation control system. The system features short control cycles and is highly flexible in meeting future applications and demands, while having numerous interfaces for connecting different bus systems and rich motion control and diagnostic functions. The greatest advantage of TwinCAT software lies in its good openness (for example, it can integrate MATLAB®), thus accelerating the system development process. Therefore, process engineers can easily integrate simulation functions into testing equipment. Other advantages of TwinCAT software include automatic code generation from E-CAD systems to HMI, simple integration of self-developed motion control function blocks, and integrated version control, error tracking, and software testing. Furthermore, TwinCAT software also has high flexibility, allowing us to more easily achieve the standardization of software development.”

The compact industrial PC C6030 or C6032 (if more interfaces are needed) is connected to the CP3918 multi-touch control panel with customer-customized button extensions. “The industrial PC provides sufficient computing power, helping us reliably achieve the goal of reducing PLC cycle time to 4 milliseconds. Additionally, its design is very compact, and installation options are flexible.”Fabian Glöckler said. In terms of human-machine interface, the focus is on convenient and error-free machine operation, so the company has long been using Beckhoff’s TwinCAT HMI software. “We have successfully implemented such a large HMI project by closely cooperating with Beckhoff, especially Beckhoff’s Munich branch from the very beginning. Our cooperation has been fruitful, for example, in the automatic association between HMI and PLC programs and multilingual implementation. Ultimately, Beckhoff customized an HMI software based on our requirements for intuitiveness, ease of use, clear parameter display, and rich diagnostic functions, providing a unified and innovative operating solution for all our systems.”

Achieving complex motion control through servo axes and XTS.

AX5000 servo drives are used to control multiple rotary axes, some of which are driven by compact EL72xx and EP72xx drive terminal modules and AM8000 servo motor controls. Martin Ellenrieder believes that single-cable technology offers them a special advantage in this case: “Single-cable technology can significantly reduce wiring workload and minimize the risk of errors. The AX5000 servo drives are compatible with various encoder interfaces and are equipped with the AX5805 TwinSAFE option card, enabling safe drive functions, which is also an important reason for our choice of using AX5000.”In addition, the TwinCAT software platform can also provide rich functional components such as TwinCAT NC PTP, NC Camming, or NC Flying Saw, and most importantly, these functional components can be freely combined.

Beckhoff’s XTS system provides functional complements for rotary axes. A 3-meter-long oval guide system equipped with 12 movers conveys each hairpin winding to a linear gantry, completing the final insertion process. Daniel Gugenberger believes that XTS enhances the flexibility of the system and can easily add new functionalities, bringing significant application advantages. He added: “In addition to traditional conveying tasks, we also use XTS for flexible positioning at different processing locations (bending and camera stations). The XTS system is modular in design and compact, allowing us to easily integrate different workstations. The conveying system can also flexibly control the distance based on component status (no component, first bending, second bending), shortening cycle times and decoupling various processing steps, providing us with further competitive advantages, such as the different processing times not directly impacting the entire machine tool.”

According to Martin Ellenrieder, the TwinSAFE system integrated safety functions offer high flexibility in safety applications. In addition to drive-based safety technology, TwinSAFE logic module EL6910 is also used as a dedicated safety controller. The distributed safety applications of various machines and systems along the production line communicate with each other through the EtherCAT Automation Protocol (EAP). “This cross-control system safety communication is a very important aspect of ensuring machine safety, as our customers often use a large number of interconnected systems.”Martin Ellenrieder summarized.

More information:

www.beckhoff.com/automotive

www.beckhoff.com.cn/automotive

Image Translation

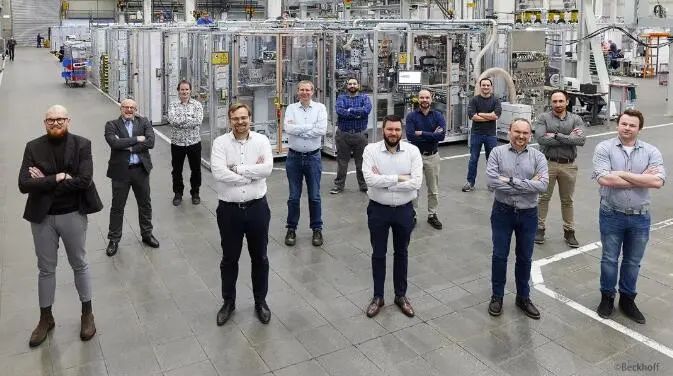

Close team collaboration (from left to right) is key to the successful development of precision hairpin motor processing dedicated machine tools:Tilman Plaß and Darius Wala (from Beckhoff),Oliver Schernau and Fabian Glöckler (from GROB),Karsten Schätzle (Beckhoff),Thomas Thurnhuber,Daniel Gugenberger and Florian Pichler (all from GROB),Florian Schütt (Beckhoff),Martin Ellenrieder,Andreas Reißer and Thomas Greißel (all from GROB).

GROB’s motor stator (right) contains multiple windings made of hairpin windings (left).

In addition to Beckhoff’s compact drive products, GROB also uses AX5000 servo drives, mainly to control AM8000 servo motors using single-cable technology (OCT) to minimize installation space and wiring workload.

A C6030 compact industrial PC provides optimal computing power for centralized control of all process sequences.

The internal structure diagram of the machine tool shows the complexity and diversity of the motion sequences, down to the XTS magnetic-driven flexible conveyor system (foreground).