Competitive Barriers and Breakthrough Points of Industrial Robot Controllers

The controller is the brain of the industrial robot, responsible for controlling the robot’s working posture, motion trajectory, spatial position, and operation sequence. Industrial robot controllers consist of both hardware and software components, where the hardware mainly includes industrial control computers and teach pendants, while the software primarily consists of control algorithms. In the industrial robot industry, both domestic and foreign leading companies generally adopt a self-sufficient model for overall robot technology and market, and the controllers from different robot manufacturers are often incompatible. Therefore, the competitive landscape of the robots themselves is essentially the competitive landscape of the controllers.

The gap between domestic and foreign controllers mainly lies in the software, particularly the control algorithms (which affect control precision). The breakthrough point for controllers is to be close to the market and customers, accelerate algorithm iteration and upgrades, and form industry barriers; at the same time, actively acquire foreign companies in niche fields to introduce foreign controller technologies.

1. Basic Functions of Controllers

The basic functions of the controller, which are the fundamental requirements of customers for industrial robot controllers, include:

(1) Control of the robot’s position, speed, and acceleration; for industrial robots with continuous trajectory motion, trajectory planning and interpolation calculation functions are also required.

(2) User-friendly human-machine interaction functions, allowing operators of the industrial robot system to program and perform operations using teach pendants, operation panels, and other human-machine interaction devices.

(3) Detection and sensing functions for external environments. To enable industrial robots to adapt to changes in external conditions, they should be capable of measuring, recognizing, judging, and understanding information related to vision, force, touch, etc. In automated production lines, industrial robots should have the ability to exchange information and coordinate work with other devices. The robot controller is shown in the figure below.

Figure: Robot Controller; Data Source: China Robot Industry Alliance (CRIA).

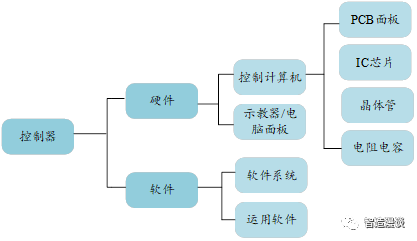

2. Composition of Controller Hardware and Software

The industrial robot controller consists of software and hardware, belonging to a branch of industrial control systems.

Data Source: China Robot Industry Alliance (CRIA), International Federation of Robotics (IFR); Note: In 2019 and 2020, parallel robots were classified as others.

(1) Hardware Composition of Controllers

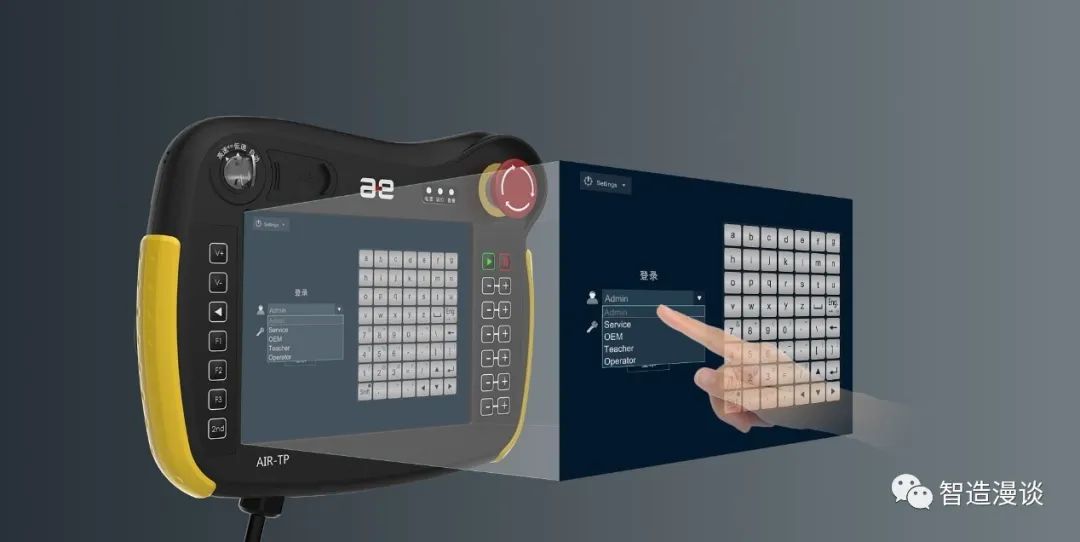

As shown in the figure below, generally, the hardware of the controller consists of a 3.5-inch industrial control computer (which can be regarded as a small computer) and a teach pendant (for teaching programming) / computer panel (for offline programming). The teach pendant / computer panel serves as the human-machine interaction operating device. The industrial control computer comprises a PCB panel (i.e., a circuit board that connects electronic components electrically), IC chips (integrated circuits formed by microelectronic components such as transistors, resistors, capacitors, etc.), transistors (a type of semiconductor device that controls output current based on input voltage), and resistors and capacitors (which impede current and serve functions such as voltage division, current division, and current limiting in circuits).

Figure: Teach Pendant

(2) Software Composition of Controllers

The software consists of control algorithms (commonly developed using C++ or robot programming languages, directly on the computer operating system) and secondary development (custom modifications based on customer requirements, for example, operators using twenty lines of code to invoke tens of thousands of lines of code from the controller manufacturer’s code database to achieve specific movements).

Most industrial robots use teach programming, mainly for applications in handling, palletizing, welding, etc. In teach programming, operators control the industrial control computer through the teach pendant, which is embedded with an operating system that develops application software (similar to apps on mobile phones) using control algorithms within the operating system (commonly Windows PE or Linux systems).

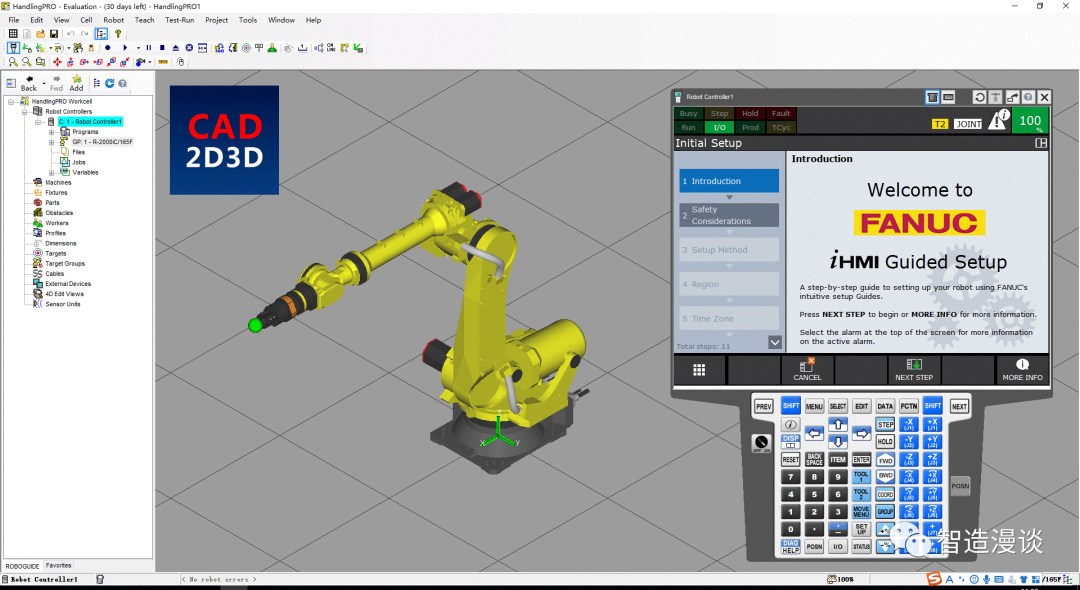

Unlike teach programming, which requires the use of a teach pendant, offline programming requires the use of offline programming software on the computer panel, where the entire working scene is reconstructed in a three-dimensional virtual environment. The operator generates control instructions (i.e., the motion trajectory of the industrial robot) through the offline programming software and transmits them to the industrial robot.

Figure: FANUC Robot Offline Programming Animation Simulation Software ROBOGUIDE V9

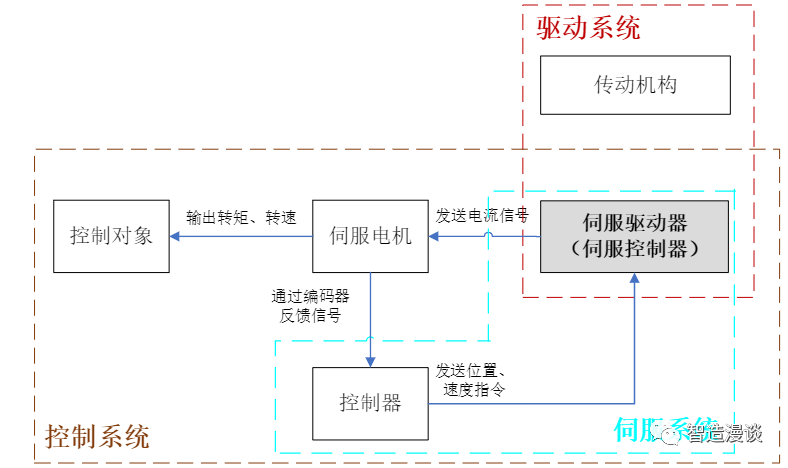

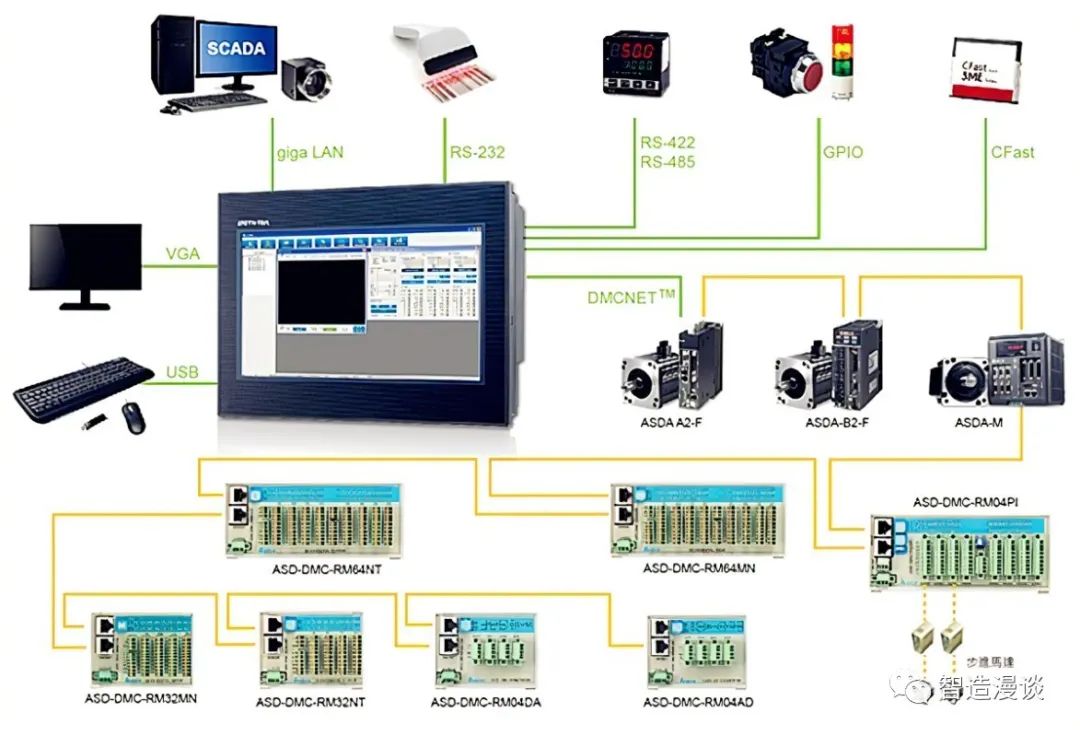

Currently, bus-based control systems are mainstream, connecting the controller to servo drivers via network cables to control the servo drivers, which in turn control the servo motors to achieve robot motion. In simple terms, the working method of the controller software system is equivalent to developing application software through software programming on the computer’s operating system + connecting motors via network cables to achieve robot motion.

(3) Control Methods of Controllers

The mainstream control method for industrial robot controllers is PC-Based control. Currently, industrial control methods are divided into PLC control, PC-Based control, and dedicated control. PLC refers to microcontrollers, which have a simple system and a straightforward programming model (such as ladder diagrams), but due to the simplicity of the code, they cannot achieve complex programming, making them unsuitable for complex motion trajectories such as multi-axis linkage in industrial robots; PC-Based control allows programming in C++, meeting the algorithm requirements for complex movements of industrial robots; dedicated control generally meets the needs of a specific industry, has a higher value, but is less cost-effective for industrial robots.

Figure: Touchscreen PC-Based Controller

(4) Industrial Robot Controllers Do Not Depend on High-End Chips

Currently, the motion control precision of industrial robots reaches 0.1mm, which is still significantly different from the micron-level precision of machine tools. At this level, the operating system built into the controller does not yet require high-end chips like FPGAs. Domestic companies have the capability to produce chips used in industrial robots, so in terms of industrial robot control systems, hardware does not constitute a barrier to the strength gap between domestic and foreign companies.

(5) Controller Algorithms Form Competitive Barriers, Algorithm Iteration is Based on In-Depth Understanding of Customer Industries

The level of control algorithms directly affects motion precision, and the quality of algorithms is mainly influenced by the understanding of customer processes, requiring time and project experience accumulation. In industries where industrial robots are widely used, such as automotive and 3C, foreign leading companies have a strong first-mover advantage, making it difficult to shake their advantage in controller algorithms.

The algorithm iteration process is closely integrated with downstream customers. In providing services to customers, industrial robot companies continuously optimize their algorithms through a process of problem identification, algorithm optimization, and problem resolution to improve the control precision of controllers. It is worth mentioning that while reverse engineering foreign industrial robot manufacturers’ controllers can significantly shorten the catch-up time, it cannot completely break through the leading advantages of foreign controllers due to the following reasons: (1) Reverse engineering typically only reveals the ‘what’ but not the ‘why’, and some functions cannot be fully realized; (2) The four major foreign families usually produce and use their own controllers, servo systems, and other components, resulting in higher integration and better performance of the industrial robots.

3. Market Landscape of Controllers

In the industrial robot industry, the controllers of leading domestic and foreign industrial robot companies are generally self-produced and used, and the controllers from different robot manufacturers usually cannot achieve compatibility. Therefore, the competitive landscape of the robots themselves is essentially the competitive landscape of the controllers.

4. Breakthrough Points for Domestic Controllers

(1) Utilize the Vast Market to Accelerate Algorithm Iteration and Upgrades in Emerging Fields, Forming Barriers

Firstly, the rapid pace of technological change in emerging industries requires high customization in industrial robot design, and foreign industrial robot manufacturers are slow to respond to changes in the domestic market, making it increasingly difficult to meet customer customization requirements;

Secondly, due to the impact of the COVID-19 pandemic, foreign industrial robot production lines have been affected, leading to significantly extended delivery cycles, and overseas service personnel are also unable to provide timely service due to isolation factors, making it difficult to meet the needs of downstream emerging industry customers;

Finally, although domestic industrial robots have certain precision gaps compared to foreign competitors, their product performance is sufficient to meet general flexible requirements, and they also have advantages such as high cost-effectiveness and fast service response speed. Therefore, domestic industrial robots have great potential in emerging market fields.

Benefiting from the above factors, as the industrial robot market in emerging industries (such as lithium batteries, photovoltaic subfields, and collaborative robots) has not yet established a competitive landscape, and foreign industrial robot manufacturers are limited by the pandemic in terms of extended delivery cycles and inability to provide timely service, domestic robot manufacturers should seize this opportunity to fully utilize this market gap to form a first-mover advantage, strengthen their understanding of customer production processes, and continuously promote the algorithm iteration process to establish algorithm barriers in the application of controllers in niche industries.

Figure: Robot Assembly of Power Batteries

(2) Actively Acquire Foreign Niche Companies to Introduce Foreign Controller Technologies

Domestic controller manufacturers have accelerated the pace of introducing foreign controller technologies through investments and acquisitions, such as New Times and Estun.

1. In 2010, New Times, focusing on electrical drive and motion control, entered the industrial robot field. Since 2013, New Times has acquired companies such as Zhongweixing, Xiaoaoxiangrong, and Huitong Technology, with Zhongweixing specializing in automation control systems. Subsequently, they partnered with foreign motion control giant B&R.

2. Estun, which has successively entered the fields of CNC systems for metal forming machine tools, electro-hydraulic servo systems, and AC servo systems, laid out intelligent industrial robots in 2012 and acquired TRIO and Italian ROBOX in 2017. TRIO is one of the leading companies in the global motion control industry, with products covering packaging machinery, 3C electronic machinery, printing machinery, industrial robots, and food production lines. ROBOX, founded in 1975, designs and produces electronic controllers for robots and motion control systems, with products covering dozens of control axes. Through the acquisition of TRIO and ROBOX, Estun, as a manufacturer of industrial robots, will further enhance its controller production level.

Figure: MC508 – UK TRIO (Cuiou) 8-Axis Robot Motion Controller MC508

Terminology

1. Teach Pendant:Also known as a teaching box / teaching instrument / teaching programmer, it is the interface for interaction between the robot and humans, connected to the robot control system via a cable.

2. PCB Panel: Also known as a printed circuit board, it is the support for electronic components and the carrier for electrical connections between electronic components. It is called a “printed” circuit board because it is made using electronic printing technology.

3. IC Chip: An integrated circuit formed by placing a large number of microelectronic components (transistors, resistors, capacitors, etc.) on a plastic base to create a chip. IC chips include wafer chips and packaged chips, and the corresponding IC chip production line consists of wafer production lines and packaging production lines.

4. Transistor: A type of solid-state semiconductor device (including diodes, triodes, field-effect transistors, thyristors, etc., sometimes specifically referring to bipolar devices) that has various functions such as detection, rectification, amplification, switching, voltage regulation, and signal modulation. As a variable current switch, a transistor can control output current based on input voltage. Unlike ordinary mechanical switches (such as relays, switches), transistors use electrical signals to control their opening and closing, allowing for very fast switching speeds, with laboratory switching speeds exceeding 100GHz.

5. Resistors and Capacitors: Capacitors impede current. The term capacitor-resistor refers to the combination of resistors and capacitors, as places that use resistors generally also require capacitors. A resistor impedes current in a conductor, serving functions such as voltage division, current division, and current limiting in circuits. A capacitor is a physical quantity that characterizes the ability of a capacitor to store charge, a property of non-conductive materials: when two opposing surfaces of a non-conductive material maintain a potential difference (as in a capacitor), energy is stored in that non-conductive material due to the movement of charge. Capacitors serve functions such as filtering, coupling, bypassing, timing, and resonance in circuits.

6. C++ Language: A general-purpose programming language developed based on C language, which is statically typed and supports multiple programming paradigms, including procedural programming, data abstraction, object-oriented programming, generic programming, and principle-based design.

7. Robot Programming Language: A programming description language that can succinctly describe the working environment and the robot’s actions, allowing complex operations to be implemented through as simple a program as possible.

8. Secondary Development: In simple terms, it refers to customizing and modifying existing software to extend functionality to achieve desired features, generally without changing the core of the original system.

9. PLC Control: Refers to industrial control through a Programmable Logic Controller (PLC). A programmable controller is modularly composed of an internal CPU, instruction and data memory, input/output units, power modules, and digital/analog units.

10. PC-Based Control: Uses a PC (industrial control computer) as the control core, adding fieldbus communication control cards, and connecting remote I/O modules via communication cables to form industrial control.

11. Dedicated Controller: A highly integrated industrial control system generally designed for a specific industry, with high value, while being less cost-effective for industrial robots.

12. FPGA Chip: A Field Programmable Gate Array, developed further from programmable devices like PAL (Programmable Array Logic) and GAL (Generic Array Logic). It appears as a semi-custom circuit in the ASIC (Application-Specific Integrated Circuit) field, addressing the shortcomings of custom circuits and overcoming the limitations of the number of gate circuits in original programmable devices. From the perspective of chip devices, FPGAs constitute typical integrated circuits in semi-custom circuits, containing digital management modules, embedded units, output units, and input units.

13. Microprocessor: A central processing unit composed of one or a few large-scale integrated circuits.

14. Offline Programming: Involves reconstructing the entire working scene in a three-dimensional virtual environment through software on a computer, allowing the software to automatically generate the robot’s motion trajectory (i.e., control instructions) based on the size, shape, and material of the parts to be processed, while simulating and adjusting the trajectory in the software, ultimately generating the robot program to be transmitted to the robot.

15. Teach Programming: Refers to programming completed by manually guiding the robot’s end effector (such as grippers, tools, welding guns, spray guns, etc. installed at the end of the robot’s joint structure) or by manually operating a mechanical simulation device, or using a teach pendant (a handheld device connected to the control system for programming or moving the robot).

16. Interpolation Calculation: Involves inputting basic data (such as the starting and ending coordinates of a straight line, the starting and ending coordinates of an arc, and the center coordinates) into a CNC system, using certain algorithms to calculate and issue feed instructions to the corresponding coordinates based on the calculation results.

References

1. Song Xiaogang, “Research and Development of China’s Strategic Emerging Industries: Industrial Robots”

2. “Expansion in Emerging Fields and High Cost-Effectiveness Will Accelerate the Domestic Replacement of Industrial Robot Controllers” Guangzheng Hengsheng

3. “Industry 4.0: From Motion Control to Robots, Favoring Integrated Models” CITIC Construction Investment Securities

4. “2019 China Industrial Robot Industry Deep Report” Head Leopard Research Institute

5. Zhihu user joQN5K, “What is the current hardware and software architecture of industrial robots and collaborative robots?”

6. NetEase: “Without Mastering Core Algorithms, How Big is the Gap Between Domestic and Foreign Industrial Robots?”

7. Zhihu user 3stones: “Control Algorithm Notes – Iterative Learning Control”

8. “General Automation Monthly Report on Mechanical Equipment: Manufacturing Industry Stabilizes and Recovers, Industrial Robot and Machine Tool Output Remains High” Dongwu Securities

9. “Industrial Robots: Accelerating Import Substitution + Expanding Application Scenarios, Domestic Capital Welcomes Golden Development Period” Debon Securities

10. CSDN Blog user guanguanmeng: “Choosing Between Robot Teach Programming and Offline Programming”

—— E N D ——

Contributed by: San Shilei Warden Linda

Typesetting: Linda

Editor: San Shilei

Long

Press

Concern

Note

Follow us to learn more about intelligent manufacturing knowledge~

Previous Recommendations

Special Memorandum on Inventory Matters of Industrial Robots

Special Memorandum on Revenue Recognition of Industrial Robots

In-Depth Observation: The Application of Industrial Robots in the Automotive Industry and Current Hot Tracks

Development of Key Components of Industrial Robots in China (II) – The Development of Nabtesco and Harmonic Drive and Its Implications for Domestic Reducer Companies

Development of Key Components of Industrial Robots in China (I) – Reducers

Development of the Industrial Robot Industry in China (III) – Problems in Industrial Development

Development of the Industrial Robot Industry in China (II) – Current Status of Industrial Development

Development of the Industrial Robot Industry in China (I) – Development History of the Industry

Mechanical Parts of Industrial Robots (III)

Mechanical Parts of Industrial Robots (II)

Mechanical Parts of Industrial Robots (I)

Sensing Parts of Industrial Robots (II)

Sensing Parts of Industrial Robots (I)

Control Parts of Industrial Robots

Classification and Technical Parameters of Industrial Robots

What are Industrial Robots?