Robot controllers are one of the core components of industrial robots, playing a decisive role in the performance of robots and influencing their development to some extent. Commonly used robot controllers include:

1. PLC Controllers

2. Microcontroller Controllers

3. Computer Host CPU Controllers

The basic functions of a robot control system include:

1. Controlling the motion position of the end effector of the robotic arm (i.e., controlling the points and paths the end effector travels);

2. Controlling the motion posture of the robotic arm (i.e., controlling the relative position of two adjacent movable components);

3. Controlling the speed of movement (i.e., controlling the pattern of change in the position of the end effector over time);

4. Controlling the acceleration of movement (i.e., controlling the change in speed of the end effector during motion);

5. Controlling the output torque of each power joint in the robotic arm (i.e., controlling the force applied to the object being operated on);

6. Providing convenient human-machine interaction functions, allowing the robot to complete specified tasks through memory and reproduction;

7. Enabling the robot to detect and sense the external environment. Industrial robots are equipped with sensors such as vision, force, and touch to measure, identify, and judge changes in working conditions.

New Robot Controllers

New robot controllers should have the following features:

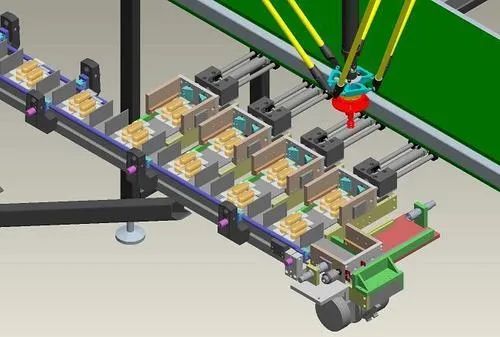

(1) Open system architecture that adopts open software and hardware structures, allowing for easy expansion of functions as needed, making it suitable for different types of robots or robotic automated production lines.

(2) Reasonable modular design for hardware, designed modularly according to system requirements and electrical characteristics, which not only facilitates installation and maintenance but also improves system reliability, resulting in a more compact system structure.

(3) Effective task division where different sub-tasks are accomplished by different functional modules for easier modification, addition, and configuration of functions.

(4) Real-time capability, where the robot controller must be able to handle external interrupts within a determined time and allow multiple tasks to be executed simultaneously.

(5) Network communication functionality to facilitate resource sharing or collaborative work among multiple robots.

(6) Intuitive and visual human-machine interface.

—————————————————————–

Zhuhaijun Control Motor Co., Ltd. specializes in the production and independent research and development of motion control electric motors and their drive control systems, providing quality execution components for industrial automation control systems.

Yunkong Electric Official Website: http://www.motion-con.com

Follow Methods: ① Click the article’s upper right corner or share icon → View official account → Follow ② Add friends → Search number → MOTION-CONTROL-SERVO → Follow ③ Add friends → Find public account → Enter: “Yunkong Servo” or MOTION-CONTROL-SERVO → Follow