Taking Fanuc robots as an example!

1 Unable to power on

|

Check and Repair |

Controller Components |

|

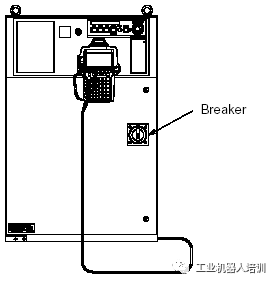

Check 1: The controller circuit breaker is on and has not tripped Repair: Reset the circuit breaker |

|

|

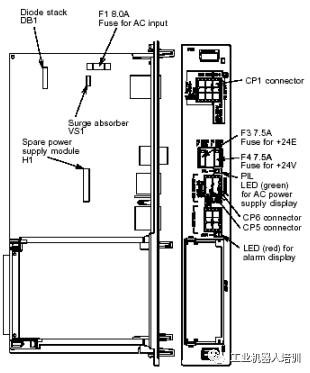

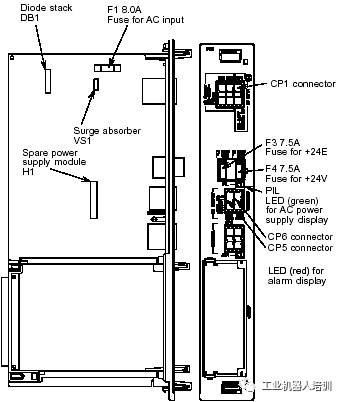

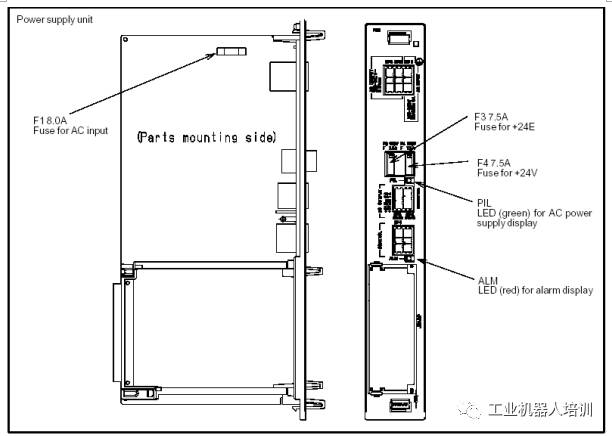

Check 2: Check if the LED indicator on the power supply board (PSU) is lit (GREEN). Repair: If the LED indicator is off, it may be that the 200V power supply for the PSU is missing or the F1 fuse on the PSU is blown: 1 If the 200V power supply is missing, please check the power supply line 2 If the 200V power supply is provided to the PSU, please disconnect the power: A If the F1 fuse is blown, refer to Repair 2 B If the F1 fuse is not blown, please replace the PSU Repair 2: Causes of fuse failure and countermeasures A Check if the CP2 and CP3 connectors between the PSU and other circuit boards are in good contact. B If the surge absorber VS1 is short-circuited, please replace itVS1 order number: A50L-2001-0122#G431K C Diode DB1 short-circuited D Backup power module H1 damaged If B or C has a fault, please replace the corresponding spare parts F1 order number: A60L-0001-0396#8.0A |

|

|

Check and Repair |

Controller Components |

|

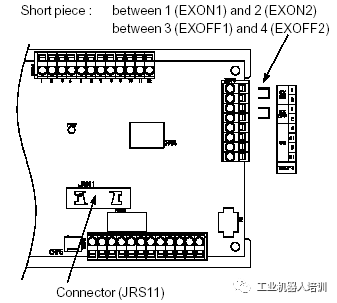

Check 3: Check the signal wiring of EXON1, EXON2, EXOFF1, EXOFF2 on the panel board Repair: If the external power switch function is not used, please short-circuit the signals EXON1 and EXON2, EXOFF1 and EXOFF2; if the external power switch function is used, please check the connection cable. |

|

|

Check 4: Check if the connection cable of JRS11 on the main board or panel board is in good contact. Check 5: Check the 1, 2, 3 above to ensure that the 200V power supply on CP1 is connected properly and the machine ON/OFF switch is normal. Please follow the steps below to check the PSU: If the LED on the PSU (ALM: red) is lit, please check if the external +24V is grounded or connected to 0V. A F4 fuse blown B Replace the PSU F4 fuse order number: A60L–0001–0046#7.5 |

|

2. Use the LED indicators on the control board to diagnose and eliminate faults

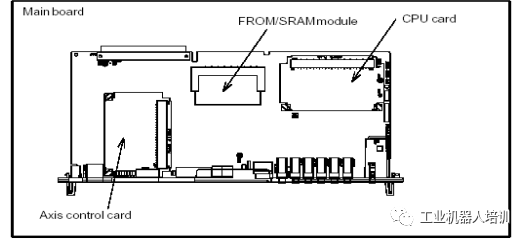

2.1 MAIN BOARD

|

Step |

Repair |

|

1 After power on, all LEDs are lit |

1 Replace the CPU card *2 Replace the MAIN BOARD |

|

2 When the robot system software starts |

1 Replace the CPU card *2 Replace the MAIN BOARD |

|

3 When the robot system starts, the CPU card DRAM initialization is complete |

1 Replace the CPU card *2 Replace the MAIN BOARD |

|

4 When the robot system starts, DRAM and SRAM initialization is complete |

1 Replace the CPU card *2 Replace the MAIN BOARD *3 Replace the FROM/SRAM card |

|

5 When the robot system starts, communication IC initialization is complete |

*1 Replace the MAIN BOARD *2 Replace the FROM/SRAM card |

|

6 When the robot system starts, the basic software loading is complete |

*1 Replace the MAIN BOARD *2 Replace the FROM/SRAM card |

|

7 When the robot powers on and starts the basic software |

*1 Replace the MAIN BOARD *2 Replace the FROM/SRAM card |

|

8 When the robot controller communicates with the TP teach pendant |

*1 Replace the MAIN BOARD *2 Replace the FROM/SRAM card |

|

9 When the robot loads the optional software |

*1 Replace the MAIN BOARD 2 Replace the process I/O board |

|

10 When initializing DI/DO |

*1 Replace the FROM/SRAM card *2 Replace the MAIN BOARD |

Replacing the MAIN BOARD and FROM/SRAM card will result in the loss of user programs and system settings stored in the machine. Be sure to back up before replacing the MAIN BOARD and FROM/SRAM card; also, make sure to back up before installing the robot system software.

|

Step |

Repair |

|

11 SRAM preparation complete |

1 Replace the axis control card *2 Replace the MAIN BOARD 3 Replace the servo amplifier |

|

12 Axis control card initialization complete |

1 Replace the axis control card *2 Replace the MAIN BOARD 3 Replace the servo amplifier |

|

13 Calibration complete |

1 Replace the axis control card *2 Replace the MAIN BOARD 3 Replace the servo amplifier |

|

14 Robot servo system powered |

*1 Replace the MAIN BOARD |

|

15 When executing the program |

*1 Replace the MAIN BOARD 2 Replace the process I/O board |

|

16 When executing I/O operations |

*1 Replace the MAIN BOARD

|

|

17 Initialization completed |

Initialization completed normally |

|

18 Robot normal |

When the robot is normal, LED1 and LED2 will flash continuously |

Replacing the MAIN BOARD and FROM/SRAM card will result in the loss of user programs and system settings stored in the machine. Be sure to back up before replacing the MAIN BOARD and FROM/SRAM card; also, make sure to back up before installing the robot system software.

|

7-segment code |

Fault description and countermeasures |

|

|

Fault: RAM parity error on the CPU card Measure 1: Replace the CPU card Measure 2: Replace the MAIN BOARD |

|

|

Fault: RAM parity error on the FROM/SRAM card Measure 1: Replace the FROM/SRAM card Measure 2: Replace the MAIN BOARD |

|

|

Fault: Communication bus error Measure 1: Replace the MAIN BOARD |

|

|

Fault: DRAM parity error during controller communication Measure 1: Replace the MAIN BOARD |

|

|

Fault: Communication error between controller and PANEL BOARD Measure 1: Check the communication cable between the MAIN BOARD and PANEL BOARD, replace it if damaged Measure 2: Replace the MAIN BOARD Measure 3: Replace the PANEL BOARD |

|

|

Fault: Servo alarm Measure 1: Replace the servo control card Measure 2: Replace the MAIN BOARD |

|

|

Fault: System emergency stop alarm Measure 1: Replace the servo control card Measure 2: Replace the CPU card Measure 3: Replace the MAIN BOARD |

|

|

Fault: System error Measure 1: Replace the servo control card Measure 2: Replace the CPU card Measure 3: Replace the MAIN BOARD |

Replacing the MAIN BOARD and FROM/SRAM card will result in the loss of user programs and system settings stored in the machine. Be sure to back up before replacing the MAIN BOARD and FROM/SRAM card; also, make sure to back up before installing the robot system software.

2.3 PSU LED Indicators

|

Fault description and countermeasures |

|

Fault: ALM LED (red) lit, PSU alarm Measure 1: Check the F4 (+24V) fuse on the PSU, replace if blown Measure 2: Check the +5V, +15V, +24V voltages on the PSU and the related cables and devices connected to it, replace if damaged Measure 3: Replace the PSU |

|

Fault: PIL LED (Green) not lit, PSU’s 200V power supply is missing Measure 1: Check the F1 fuse on the PSU, replace if blown Measure 2: Replace the PSU |

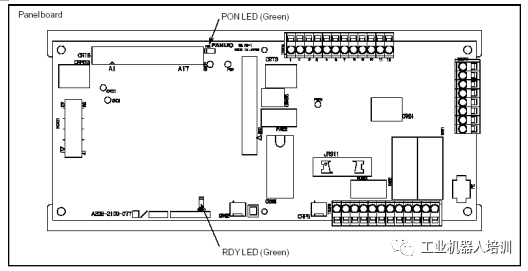

2.4 PANEL BOARD LED Indicators

|

LED |

Fault and countermeasures |

|

RDY |

Fault: This LED (GREEN) not lit indicates communication interruption between the PANEL BOARD and MAIN BOARD Measure 1: Check the communication cable between the MAIN BOARD and PANEL BOARD, replace if damaged Measure 2: Replace the MAIN BOARD Measure 3: Replace the PANEL BOARD |

|

PON |

Fault: This LED not lit indicates failure of +24V voltage conversion to +5V voltage on the PANEL BOARD Measure 1: Check the CRM63 connector, +24V input power Measure 2: Replace the PANEL BOARD |

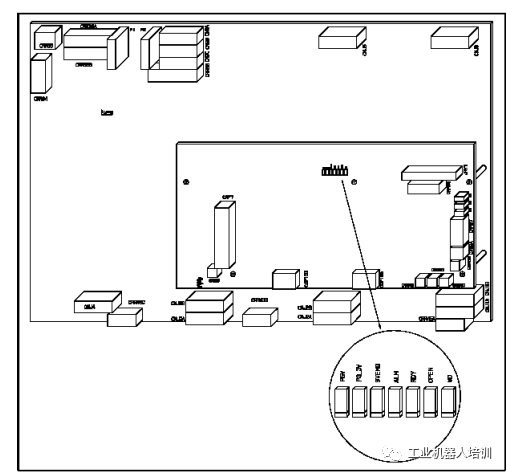

2.5 PROCESS I/O LED Indicators

|

LED |

Fault and countermeasures |

|

Process I/O CA/CB/DA

|

Fault: Communication error between MAIN BOARD and PROCESS I/O board Measure 1: Replace the I/O board Measure 2: Replace the MAIN BOARD Measure 3: Replace the I/O communication cable |

|

Process I/O CA/CB/DA

|

Fault: I/O board fuse blown Measure 1: Replace the fuse Measure 2: Check the peripheral cables Measure 3: Replace the I/O board |

2.6 Servo Amplifier LED Indicators

|

LED |

Color |

Description |

|

P5V |

Green |

Lit: Servo amplifier +5V power supply normal Off: 1; Check the robot RP1 connection cable 2; Replace the servo amplifier |

|

P3.3V |

Green |

Lit: Servo amplifier +3.3V power supply normal Off: Replace the servo amplifier |

|

SVEMG |

Red |

Lit: The robot has an emergency stop signal input (replace if no emergency stop signal input) Off: Robot normal (replace servo amplifier if there is an emergency stop signal) |

|

ALM |

Red |

Lit: Servo amplifier fault alarm |

|

RDY |

Green |

Lit: Servo amplifier ready to drive the motor Off: If the motor can operate, replace the servo amplifier |

|

OPEN |

Green |

Lit: Communication between servo amplifier and MAIN BOARD normal Off: 1; Check the communication cable between the servo amplifier and MAIN BOARD 2; Replace the servo control card 3; Replace the servo amplifier |

|

WD |

Red |

Lit: 1; Replace the servo amplifier 2; Replace the servo control card 3; Replace the CPU card 4; Replace the MAIN BOARD |

|

D7 |

Red |

Lit: 1; Check internal cables of the controller 2; Replace the emergency stop board 3; Replace the servo amplifier |

Compiled by Ji Ge, please indicate the source when reprinting.

Link: How to Become an Industrial Robot Application Engineer?

Link: How to Become an Industrial Robot Application Engineer?

Link: How to Become an Industrial Robot Application Engineer?

We are not just porters of dry goods

Just a step away from becoming an industrial robot master

Guidance Vehicle Robot Academy, cradle of robotic craftsmen

< Previous classic articles >

-

【Dry Goods】Introduction to Fanuc Robot Electrical Hardware, Very Comprehensive!

-

【Dry Goods】Backup and Restore of Fanuc Robots, Zero Point Calibration, Essential for Engineers!

-

【Viewpoint】A Shallow Analysis of the Automation Industry, Deep Good Article!

-

Why You Shouldn’t Buy Cheap Automation Equipment?

-

Foxconn Automation Production Line Video, A Visual Feast!

-

Non-standard Automation, You Are Only One Cognition Away from the BOSS, Deep Good Article!

-

Explore the Largest Mobile Phone Manufacturer in Dongguan, The Scene After Replacing Humans with Machines!

-

China Acquires This German Company for 30 Billion, The Whole of Europe is in a Panic…

-

Huawei Automation Production Line, Shocking!

-

Automated Conveyor Belts, So Advanced!

-

Fully Automated Cigarette Production Line, Amazing to Watch!

-

Working Principles of Various Sensors in Animated GIFs, Dry Goods!

-

10 Workers + 386 Robots, 80 Cadillacs Every Day!

-

Automation in Killing Chickens and Pigs is Nothing, Come and See Automation in Killing Fish!

-

Five Major Misconceptions in Factory Automation Transformation, Don’t Make Them!