Industrial Robot Controller Reliability Testing Project

Officially Launched!

Theme Overview

The controller is the brain of the robot, defining its functions and behaviors, and is a reflection of the core competitiveness of robot products. The controllers used by well-known foreign robot companies are all independently developed. In recent years, domestic robot companies have gradually adopted self-developed controllers to enhance the localization rate of key components and the technical level of products. Reliability issues are a bottleneck restricting the large-scale development of domestic robots, severely affecting the product’s reputation.

The reliability assessment is a technical service launched by the National Robot Testing and Assessment Center (Headquarters) to address the poor reliability of domestic robots. It aims to verify whether the product’s reliability meets the specified requirements in a third-party manner, while the test results can provide a basis for failure analysis and corrective measures taken.

In this test, the MTBF target value for a domestic robot controller is 20000h. Today, we will introduce the key points of reliability assessment for controllers used in industrial robots.

● Terminology Explanation

Mean Time Between Failures (MTBF)

The average time between consecutive failures.

Reliability Assessment Test

A reliability assessment test refers to the testing conducted to determine the numerical value of the product’s reliability characteristics.

Test Cycle

The combination sequence of various test conditions (operating conditions and environmental conditions) based on actual use as specified by relevant product standards.

Failure

The state in which the product cannot perform its specified functions is called a failure.

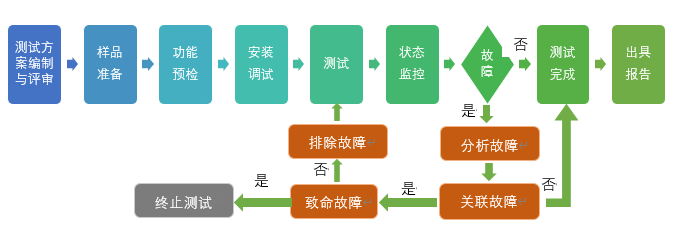

● Test Procedure

● Failure Classification, Criteria, and Modes

Failure Classification: Critical Failure, Major Failure, Minor Failure, and Slight Failure;

Failure Criteria: Loss of sample function, state errors, and all abnormal states are classified as failures, which should be determined as related or unrelated failures based on failure phenomena;

Failure Modes: The proposed phenomena of failure occurrence.

●Test Samples and Test Plans

Test samples must meet:

1. Qualified products

2. Passed the early failure period and entered the random failure period

3. Produced by sampling

4. Passed pre-inspection

Test Plan:

1. Choose a timed cutoff plan with or without replacement

2. Choose confidence level

3. Calculate cumulative related test time

● Confirmation of Test Conditions

Working Conditions:

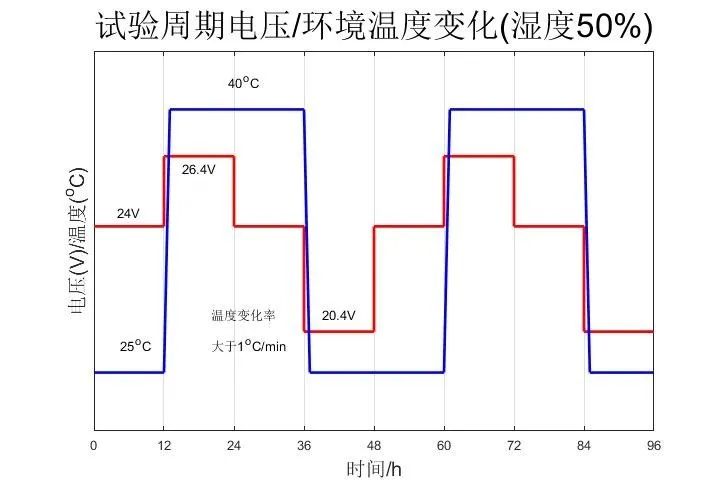

a) Test cycle: 48 hours per test cycle.

b) Functional modes: All functional modes as specified by product technical standards and product manuals.

c) Program operation: Typical working procedures.

d) Load conditions: Determined based on actual working conditions.

Environmental Conditions:

Power supply conditions and climate conditions vary periodically, as shown in the figure below:

● Data Processing

The calculation formula for the one-sided confidence lower limit with a confidence level of 80% is as follows:

T*: The accumulated related test time until the specified cutoff time;

mL: The one-sided confidence lower limit of the mean time between failures;

r: The total number of equivalent failures in the reliability test;

●Technical Documents

Reliability Test Standards

Reliability Test Outline

Reliability Test Plan

Reliability Test Records

Reliability Test Report

● Test Photos

●New Technology: Rapid MTBF Assessment

Facing the increasing demand for product reliability levels, the MTBF index generally reaches tens of thousands of hours, while the current agile delivery methods for products limit the time for reliability assessment tests. How to quickly assess reliability levels has become a focus of attention. The National Robot Testing and Assessment Center (Headquarters) has developed a rapid MTBF assessment plan based on traditional reliability models and robot working characteristics, which will greatly shorten the test cycle and meet the enterprises’ needs for product reliability level assessment.

The National Assessment Center and the Shanghai Robot Industry Technology Research Institute

The National Assessment Center, as a third-party service organization co-established by the state and research institutes, has six major functions: standard formulation and revision, testing, certification, training, information services, and international exchanges. The National Assessment Center provides strong support for robot testing and certification work in China. It will play a guiding and promoting role in the formulation and revision of robot testing standards, the construction of testing laboratories’ software and hardware, the improvement of certification implementation rules, talent cultivation in the robot field, information platform building, and international cooperation.

The Shanghai Robot Industry Technology Research Institute was jointly funded by the Shanghai Electric Science Research Institute (Group) Co., Ltd., Shanghai University, and the Putuo District Government of Shanghai under the care and guidance of the Shanghai Municipal Party Committee, Municipal Government, and relevant committees such as the Science and Technology Commission and the Economic and Information Commission. It serves as an implementation carrier for the R&D and transformation functions of robots in Shanghai, bearing the historical mission of promoting the transformation and upgrading of the robot industry, cultivating high-quality robot enterprises, and facilitating the internationalization of the “Made in China” brand, contributing to the construction of a globally influential science and technology innovation center in Shanghai.

Currently, the National Assessment Center and the Shanghai Robot Industry Technology Research Institute are promoting complementary advantages, deepening collaborative cooperation, and jointly promoting the orderly and healthy development of the robot industry.

Contact Information:

(86)021-62574990-640

17721341131

|

Testing | Certification | Training Value-Added Services: Standard Research | Information Services | International Exchange |