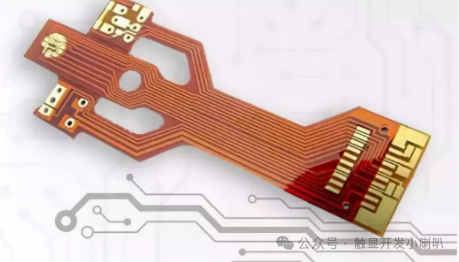

Definition of FPC Reinforcement: FPC (Flexible Printed Circuit) reinforcement boards are rigid materials used to enhance the mechanical strength of specific areas of FPC. They mainly serve the following three purposes:Firstly, to prevent circuit breakage or solder joint detachment caused by bending or twisting;Secondly, to provide support for fragile areas such as connectors and solder joints;Thirdly, to assist in positioning and fixing the FPC during assembly. This article discusses the performance comparison and selection recommendations of common reinforcement materials.1: Comparison of Reinforcement Materials:

They mainly serve the following three purposes:Firstly, to prevent circuit breakage or solder joint detachment caused by bending or twisting;Secondly, to provide support for fragile areas such as connectors and solder joints;Thirdly, to assist in positioning and fixing the FPC during assembly. This article discusses the performance comparison and selection recommendations of common reinforcement materials.1: Comparison of Reinforcement Materials:

|

Material Type |

Thickness Range |

Main Characteristics |

Applicable Scenarios |

|

SUS |

0.1mm-0.3mm |

Extremely high mechanical strength, with electromagnetic shielding function, but heavier and more expensive. |

Automotive electronics, industrial equipment anti-interference scenarios |

|

PI |

0.1mm-0.3mm |

High temperature resistant (above 200℃), bendable, good insulation, but relatively expensive. |

High temperature environments, high-frequency bending scenarios (e.g., foldable screens) |

|

PET |

0.05mm-0.2mm |

Low cost, good flexibility, but poor temperature resistance (≤120℃), suitable for normal temperature environments. |

Common wiring in consumer electronics, low-cost scenarios |

|

FR-4 |

0.1mm-0.5mm |

Strong rigidity, excellent insulation, high temperature resistant (130℃-150℃), but poor flexibility. |

Interface areas requiring high strength support |

| BT | 0.1mm-0.3mm | Excellent dielectric properties, suitable for high-frequency signal transmission, commonly used in precision electronic components, high cost | 5G antenna modules, high-frequency circuits |

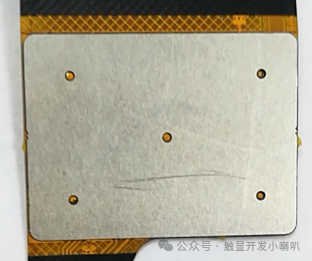

2, Selection Recommendations:2.1 SUSReinforcement boards, generally require grounding through conductive adhesive,effectively preventing electromagnetic noise,applicable for carryingSMDcomponents, when components such as IC packages likeQFN, SOP, BGA, etc., and connectors require high flatness, choose SUS; etched or punched into shape 2.2 PIReinforcement boards, suitable for FPCplugging into ZIFconnectors, or for reinforcing FPCareas carrying small packages of resistors and capacitors with bending requirements,which have excellent mechanical strength, heat resistance, insulation, and chemical resistance; can be punched into shape with FPC

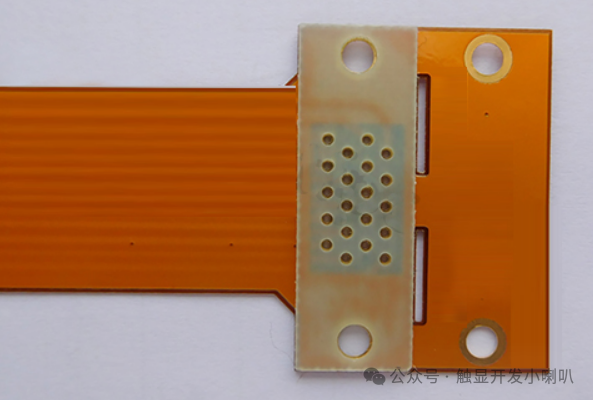

2.2 PIReinforcement boards, suitable for FPCplugging into ZIFconnectors, or for reinforcing FPCareas carrying small packages of resistors and capacitors with bending requirements,which have excellent mechanical strength, heat resistance, insulation, and chemical resistance; can be punched into shape with FPC 2.3 FR-4,requires insulation, suitable for carryingSMDcomponents, reinforcing FPCareas with components likeQFN,connectors, etc. (not recommended for sizes larger than10*10mm), withhigh mechanical strength, excellent thermal conductivity, heat resistance, electrical performance, thermal insulation, and insulation performance; punched into shape

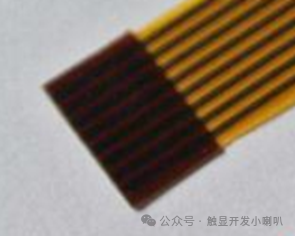

2.3 FR-4,requires insulation, suitable for carryingSMDcomponents, reinforcing FPCareas with components likeQFN,connectors, etc. (not recommended for sizes larger than10*10mm), withhigh mechanical strength, excellent thermal conductivity, heat resistance, electrical performance, thermal insulation, and insulation performance; punched into shape 2.4 PETreinforcement, suitable for FPCfinger reinforcement connected to connectors,with excellent heat resistance, cold resistance, chemical resistance, water resistance, and strength, and high transparency,the material is softer, not suitable for frequent plugging applications, lower cost than PI; punched into shape

2.4 PETreinforcement, suitable for FPCfinger reinforcement connected to connectors,with excellent heat resistance, cold resistance, chemical resistance, water resistance, and strength, and high transparency,the material is softer, not suitable for frequent plugging applications, lower cost than PI; punched into shape 2.5.BT reinforcement, also known asaluminum plate reinforcement, has the best heat dissipation effect, as it usually requires a mold to stamp the aluminum reinforcement shape, making it the most expensive.

2.5.BT reinforcement, also known asaluminum plate reinforcement, has the best heat dissipation effect, as it usually requires a mold to stamp the aluminum reinforcement shape, making it the most expensive.

Follow me for more professional knowledge sharing