Introduction: In this revolution of micro-scale manufacturing, templates are discarded, magnetic fields are reinterpreted, and “amber” has become the source of inspiration for structural programming.

Image credit: Shan-Gang Wei (Photographer: Wei Shangang)

Micro-magnetic-driven flexible devices are crucial for the development and application of minimally invasive medical technology, flexible smart electronic devices, and microrobotics. Despite significant breakthroughs in related application research, current magnetic domain programming techniques still heavily rely on template-based sequential manufacturing processes, which limit key metrics such as manufacturing precision, operational flexibility, batch preparation efficiency, and response consistency, failing to meet the demands for precise control and swarm control in microrobots.

The joint team from Xi’an Jiaotong University, City University of Hong Kong, and the Max Planck Institute for Intelligent Systems has made significant progress in the field of high-precision batch manufacturing of magnetic-controlled soft robots, proposing a template-free magnetic domain programming strategy inspired by amber, utilizing temperature changes to trigger stress-induced three-dimensional shape deformation in the -LIG-PDMS heterogeneous film, combined with the liquid-to-solid phase transition of polyethylene glycol (PEG, 4000) at a phase change temperature of 65°C to encapsulate the deformed three-dimensional microstructure without templates and achieve saturation magnetization in a strong magnetic field of 1.8T, realizing 20μm resolution programmable three-dimensional magnetization with second-level processing efficiency, significantly improving the programming accuracy and manufacturing efficiency of micro-magnetic devices.

The related research results, titled “Template-Free 3D Programmable Magnetization of Soft Millirobots Induced by Interlayer Stress”, were published in the Proceedings of the National Academy of Sciences (PNAS).Direct submission.

This is the third representative work following the team’s series of papers published in Advanced Science in 2023 and in PNAS in 2024, based on the heterogeneous material system of “dry gel–laser-induced graphene–magnetorheological elastomer.” This work constitutes the “interlayer stress trilogy” in the research of micro soft robot manufacturing. This time, they used an original strategy of “interlayer stress+amber inspiration” to resolve the contradiction between high-precision magnetic domain programming and high-throughput microstructure preparation, truly achieving integrated processing of three-dimensional magnetic structures without molds and assembly, allowing micrometer-scale magnetic-controlled robots to be produced in bulk and with precision.

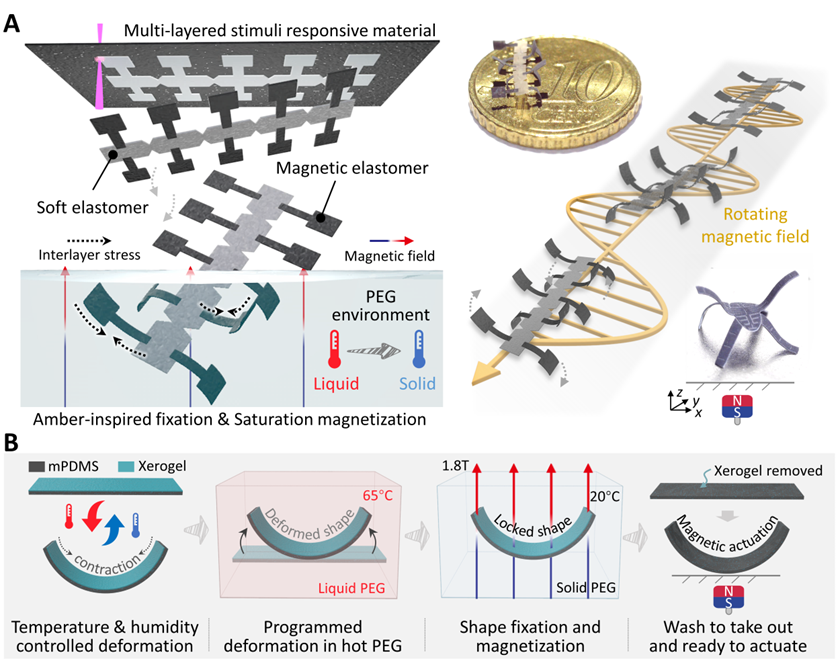

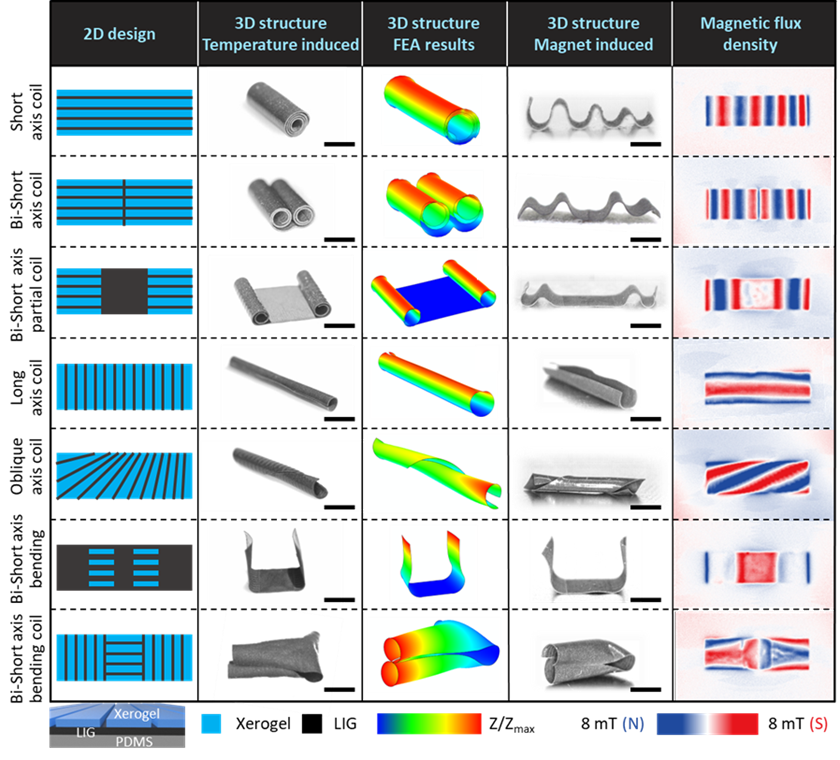

Figure 1: Schematic diagram of interlayer stress-assisted three-dimensional magnetic domain template-free programming

✦A New Paradigm for Three-Dimensional Magnetic Domain Programming: Discarding Templates, Writing Deformations

The mainstream magnetic programming methods for micro-magnetic robots currently rely on two types of process flows:①Template-induced magnetization: the structure must first be “folded” before magnetization, with precision limitations, difficulty in miniaturization, and low preparation efficiency;②Magnetic field-assisted 3D printing: prone to unsaturated magnetization and insufficient magnetic response.

Focusing on the above challenges of efficient micro-scale preparation and high-precision magnetic domain programming, the team proposed the “template-free three-dimensional magnetic domain programming” strategy that completely breaks this limitation. They used temperature/humidity-sensitive dry gel to construct interlayer stress between laser-induced graphene (LIG) and magnetorheological elastomer (PDMS-NdFeB, mPDMS) by immersing the structure in liquid PEG at 65°C, causing the dry gel layer to shrink due to dehydration, triggering spontaneous bending deformation of the structure; then cooling to room temperature for curing, PEG “freezes the fine three-dimensional morphology like amber; then saturating magnetization with a strong magnetic field of 1.8T to distribute the magnetic domains according to the target morphology; finally, washing away the water-soluble PEG and dry gel layer, resulting in a magnetorheological elastomer structure with precise three-dimensional magnetic response capability. The entire process does not rely on any molds or assembly processes, achieving high precision and batch molding and saturation magnetization of millimeter-scale structures.

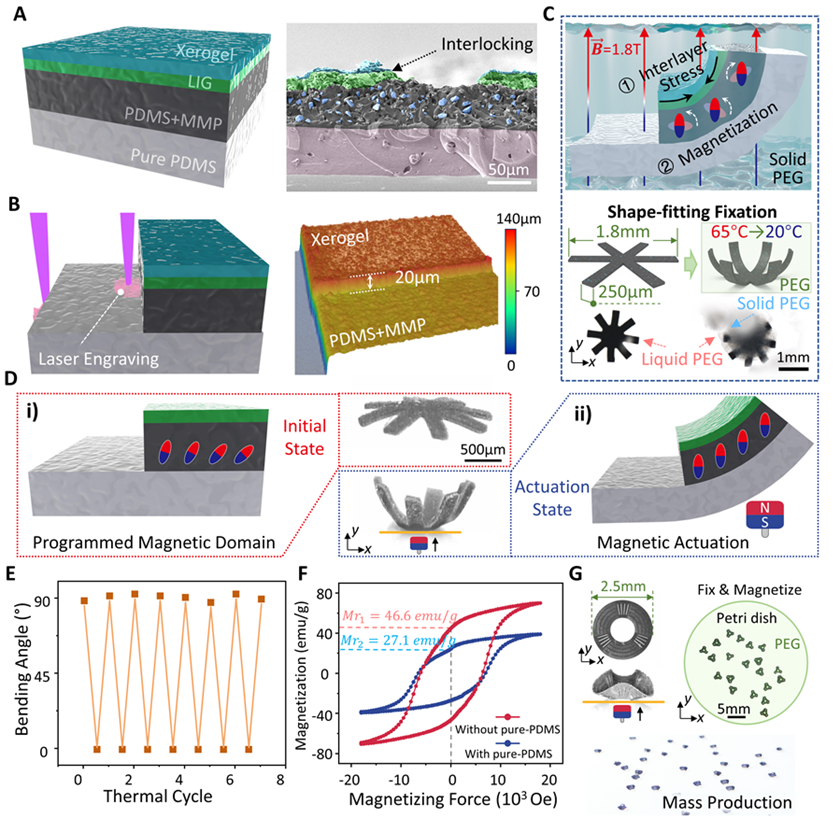

Among them, utilizing the interconnected three-dimensional pore structure and excellent conductivity of LIG, it serves as a porous flexible electrode for alginate hydrogel electrodeposition, thus achieving a stable interconnection between the superhydrophilic hydrogel layer and the superhydrophobic mPDMS layer based on micro-scale mechanical locking (mechanical interlocking). After light-avoiding drying for 24h, a heterogeneous material with second-level response speed to temperature/humidity is obtained. Subsequently, by finely controlling parameters such as femtosecond/picosecond laser pulse energy, localized cutting and removal of the heterogeneous material can be achieved (Z direction resolution 2μm, X/Y direction resolution 20μm), thus achieving localized/directional programmable control of interlayer stress and integrated molding of micro-scale devices.

Figure 2: Three-dimensional magnetic domain programming process induced by interlayer stress

Polyethylene glycol (PEG, 4000) has the advantages of low liquid-to-solid phase change temperature (53-58°C) and water solubility. Inspired by the natural phenomenon that amber can preserve fine three-dimensional morphology of organisms from millions of years ago, the team used PEG as “resin” and placed the two-dimensional flexible microdevices programmed with interlayer stress into liquid PEG (65°C) to induce interlayer stress and drive the flexible microdevices to deform into the preset three-dimensional structure under the synergistic effect of temperature and the strong hygroscopicity of PEG. Thanks to the in-situ driving advantage of interlayer stress, we can batch place various designed microdevices into PEG and cool for curing without the need for designed templates and manual fine operations. After fixing, the samples can be uniformly placed in a strong magnetic field of 1.8T for saturation magnetization, greatly enhancing the programming accuracy, batch preparation efficiency, and batch consistency of flexible microdevices. Finally, the samples are placed in deionized water for stirring/ultrasonication to dissolve PEG and remove the dry gel layer, thus completing the preparation of magnetic-driven microdevices.

(Video of the experiment on liquid-to-solid phase change locking of flexible microdevices)

✦Characterization of Magnetization Performance: Revealing the Relationship Between Stress Distribution and Magnetic Domain Programming

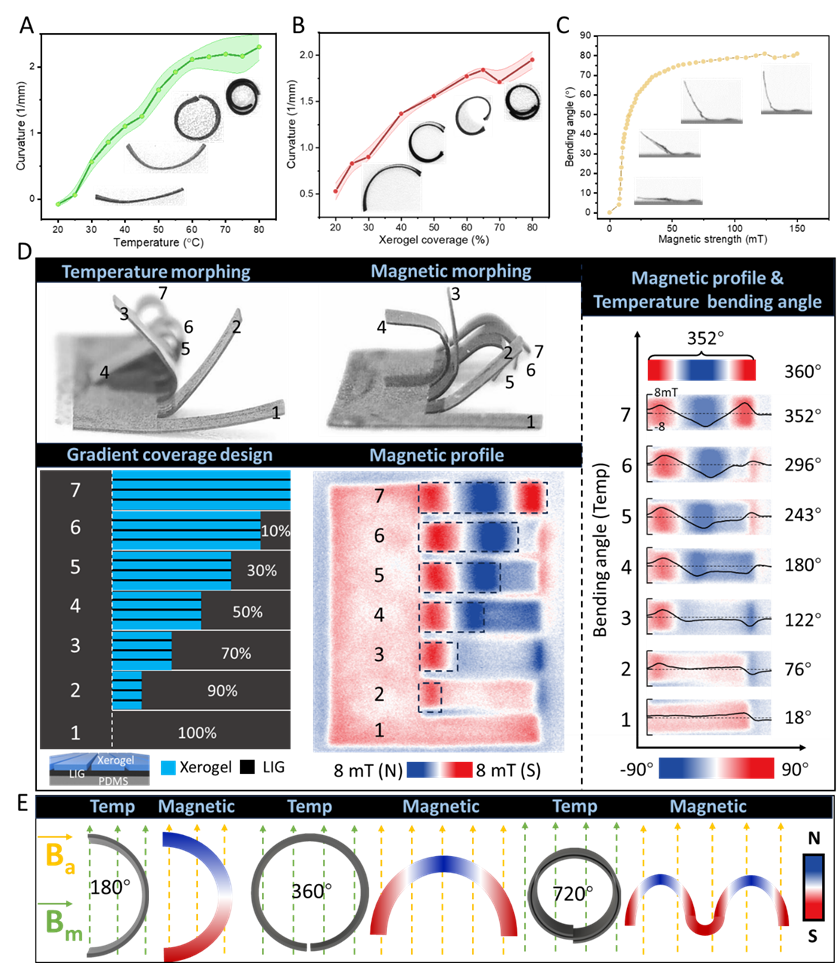

To achieve precise programming of three-dimensional deformation of multilayer structures, the research team first tested the response of typical strip structures at different temperatures (Figure 3A). The experiments found that increasing temperature accelerated the dehydration shrinkage of the dry gel, significantly enhancing the strain and stress of the structure, thereby increasing the degree of deformation. Under the condition of 60°C, the test results of strips with different dry gel coverage ratios indicated (Figure 3B) that the bending angle can be precisely controlled by adjusting the coverage area of the dry gel.

After in-plane magnetization, the bending angle of the strip structure increased with the increase of magnetic field strength and tended to saturate when exceeding 50mT (Figure 3C). To explore the relationship between deformation mechanisms under temperature and magnetic field, the research designed seven fixed-end structures with different dry gel coverage ratios (Figure 3D), finding that the magnetic domain distribution was highly consistent with the temperature-induced bending angle, with bending angles ranging from 18° to 352°. Interestingly, temperature-driven deformation mainly achieves unidirectional deformation, while magnetic field-driven deformation can achieve bidirectional deformation according to the direction of the magnetic domains. When the temperature-induced bending angle is less than 180°, the magnetic-driven deformation is basically consistent with it; however, due to the bipolarity of the magnetic domains, the magnetic-induced bending angle usually does not exceed 180°. Once the temperature-induced deformation exceeds 180°, the magnetic-driven shape transitions from a half-circle bend to a wavy structure (Figure 3E), reflecting the complementary and coupling characteristics between the two driving methods.

Figure 3: Design and characterization of stress and magnetic domain programming

✦What is written is not just deformation, but also“coding”

Through programmable laser patterning, the team can layer-write magnetic responsive/non-responsive areas on the material surface:①Using femtosecond/picosecond lasers to locally remove the magnetic layer;②Programming the stress distribution of the dry gel layer with laser cuts to control the three-dimensional morphology of microstructures;③Activating preset interlayer stress through temperature to produce spontaneous deformation. Ultimately, this spatially distributed“stress+magnetic domain” becomes the “programming language for deformation, allowing robots to complete complex responsive actions such as bidirectional bending, wavy shapes, and pop-up structures in a magnetic field. To demonstrate the powerful capabilities of interlayer stress-assisted programming, the research team designed various two-dimensional pattern structures, including short-axis spirals, double short axes, and their local variants. Experiments and finite element simulations were highly consistent, both showing predictable three-dimensional deformation. Notably, when the temperature-induced bending angle exceeds 180°, the magnetic domain distribution shows a turning point, and the curvature of the wave accurately reproduces the temperature-induced shape.

Figure 4: Programming of complex strip structures and uniform magnetic field-driven deformation

✦Cooperative Active and Passive Deformation, Driving Ring Structure Expands Design Dimensions

Due to the dry gel being coated only on one side of the heterogeneous material, and the interlayer stress being primarily in a contraction mode, the deformation direction from two-dimensional to three-dimensional is limited, restricting the flexibility of robot structure design. To achieve bidirectional deformation, the research team introduced an auxiliary “pop-up ring” design around the target structure (Pop-up ring) that can guide the structure to deform upwards or downwards. After removal, the central area can still maintain passive deformation, thus completing the last link in the design toolbox. In the “ant structure,” the central structure is actively decoupled, and three pairs of legs are driven by dry gel and pop-up rings, achieving upward and downward bending in opposite directions, simulating real walking gaits. The pop-up ring consists of alternating dry gel-covered areas (active) and removed (passive) areas, forming reverse bending through stress transmission, achieving precise control of local regions within the structure.

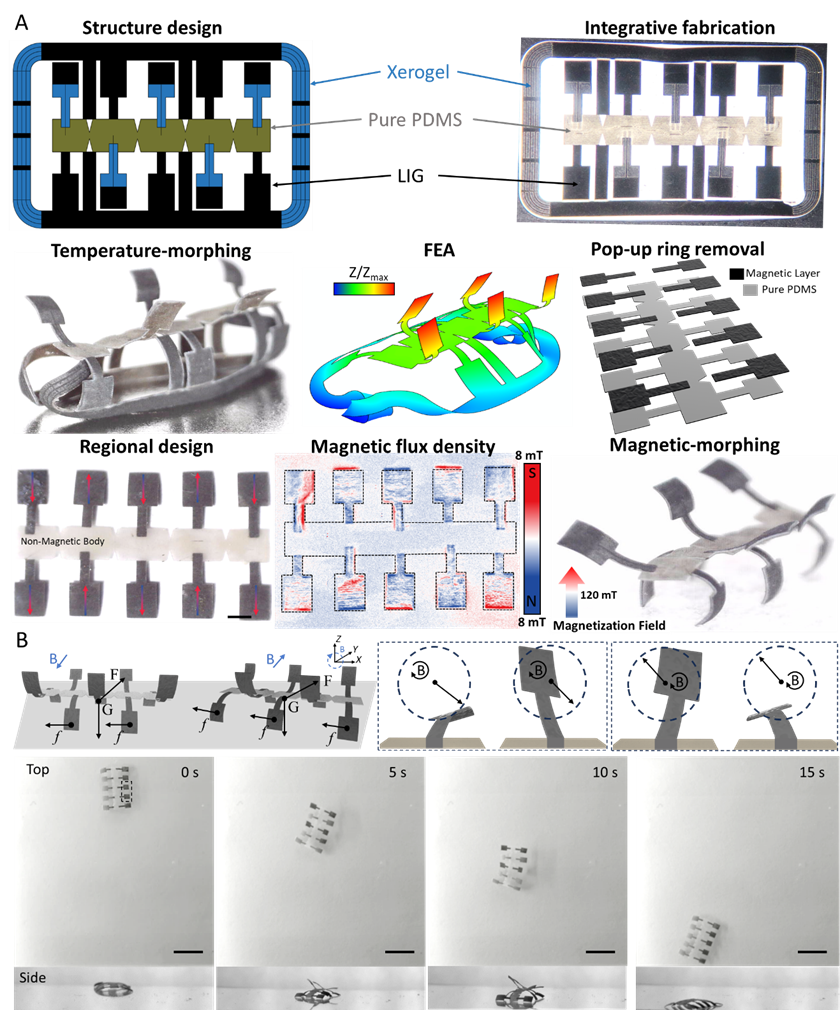

Figure 5: Magnetic domain programming and three-dimensional driven deformation based on cut-paper structures

The research further demonstrated the use of “magnetic responsive cellular arrays” for encrypted information (cell size 300×900μm): the structure appears disordered at first, but when exposed to a magnetic field, it immediately reveals the letters “M”, “P”, “I”, or “star” patterns. When the rotating magnetic field changes, the information is once again “hidden” — the information hiding and reappearing under magnetic field control is achieved in sub-millimeter flexible structures, reflecting the high precision, high efficiency, and high response consistency of the developed magnetic domain programming process.

Figure 6: Patterned magnetic storage of information in superstructures

✦“Selective Magnetic Response” Aids Efficient Movement of Flexible Microrobots

To demonstrate the superiority of the proposed template-free magnetic domain programming strategy, the research team designed and fabricated a multi-legged soft robot with efficient walking capabilities (Figure 7). Its main body is made of non-magnetic materials, while the legs on the left and right are programmed with opposite magnetization directions, allowing for precise control under alternating magnetic fields, mimicking crawling gait movements.

The robot’s structure consists of three types of regions: the dry gel area for temperature-induced deformation, the LIG area after removing the dry gel for laser patterning, and the pure PDMS area that suppresses magnetic response, facilitating regional functional control. The introduction of the “pop-up ring” during the manufacturing process enables opposite deformation, allowing each leg to selectively bend upwards and downwards, assisted by finite element simulation design (Figure 7A). The final structure retains only the central robot area, with the non-magnetic body effectively reducing resistance in the gradient magnetic field.

In a uniform magnetic field of 120 mT, the legs on both sides of the robot bend upwards and downwards, achieving coordinated gait. Compared to traditional methods that require multiple assembly steps or custom template-based processing, this work achieves rapid manufacturing of complex structures in just seconds through direct laser processing, truly realizing template-free, high-precision, and batch production of magnetic-controlled soft robots.

Figure 7: Programming manufacturing and motion testing of magnetic-controlled micro crawling robots

✦Looking Ahead: Nanoscale, Intelligent Collaboration, Medical Scenarios

Dr. Zheng Zhiqiang, co-corresponding author of the paper, stated that the series of works from the team has detailed the physical field response mechanism of this system from theoretical and process perspectives, developing high-precision programmable preparation processes. This research work published marks a perfect conclusion to the “interlayer stress trilogy” in the study of micro soft robot manufacturing. They plan to target biomedical applications in the future, further reducing the size of magnetic-controlled soft robots to 10 μm or less; combining magnetic fields+electric fields+humidity/temperature and other multi-physical field response coupling to achieve more complex driving modes; integrating with sensors and drug carriers to realize medical soft system integration, exploring applications in intravascular navigation, targeted release, and tissue repair.

Dr. Han Jie, the first author of the paper, stated that the initial goal is a preparation strategy with strong material inclusivity, expanding the design and manufacturing toolbox for fine microstructures and flexible intelligent systems. This system is not limited to the combination of dry gel, laser-induced graphene, and magnetorheological elastomer; the developed mechanical interlocking strategy can support stable bonding at heterogeneous material interfaces, and the layer-by-layer fine processing strategy can support high-precision programming of interlayer stress and mechanical behavior. The amber-inspired template-free programming strategy can support fixing any micro three-dimensional structure, enriching the toolbox to inject new momentum into the field’s development. Meanwhile, the team will continue to focus on stress control of micro-scale flexible materials and the application exploration of micro-robots in the biomedical field.

✦Research Team Introduction

This research was jointly completed by the School of Physics at Xi’an Jiaotong University, City University of Hong Kong, and the Max Planck Institute for Intelligent Systems.

Dr. Han Jie, a young teacher at the School of Physics at Xi’an Jiaotong University, and Dr. Wang Shuicheng from City University of Hong Kong are co-first authors of the paper, while Academician Metin Sitti from the Max Planck Institute for Intelligent Systems, Professor Dong Lixin from City University of Hong Kong, and Dr. Zheng Zhiqiang are corresponding authors. Special thanks to Sinan Ozgun Demir, Francisco Jesús, Feinan Zhao, Gaurav Gardi, Cem Balda Dayan, Saadet Baltaci, and Muhammad Turab Ali Khan for their help and discussions. This research work was supported by the National Natural Science Foundation and the Hong Kong Research Grants Council, among other projects.

Public Account Introduction:“Interlayer Stress Trilogy”①——Multi-physical field response; “Interlayer Stress Trilogy”②——Decoupling of driving.

References:

[1] Zheng, Zhiqiang, Jie Han, Sinan Ozgun Demir, Huaping Wang, Weitao Jiang, Hongzhong Liu, and Metin Sitti. “Electrodeposited superhydrophilic‐superhydrophobic composites for untethered multi‐stimuli‐responsive soft millirobots.” Advanced Science 10, no. 23 (2023): 2302409.

[2] Zheng, Zhiqiang, Jie Han, Qing Shi, Sinan Ozgun Demir, Weitao Jiang, and Metin Sitti. “Single-step precision programming of decoupled multiresponsive soft millirobots.” Proceedings of the National Academy of Sciences 121, no. 13 (2024): e2320386121.

Paper Link:

https://www.pnas.org/doi/10.1073/pnas.2426846122

Source: Frontiers in Polymer ScienceDisclaimer: The views expressed are solely those of the author. If there are any scientific inaccuracies, please leave a comment below for correction!