Microrobots have advantages such as small size, light weight, high thrust-to-weight ratio, and high flexibility. They can be classified into two categories based on size: The first category includes robots in the nano to micro size range, generally driven by external forces, mainly used in biomedical fields. The second category includes robots in the micro to centimeter size range, which are slightly larger and can carry loads for communication, control, monitoring, etc. They can move along pre-programmed routes and complete tasks under human supervision. This article focuses on micrometer-level microrobots, which can be deployed in environments where medium to large robots and unmanned platforms are difficult to operate, such as building large-scale distributed covert monitoring networks, reconnaissance in narrow gaps, and monitoring precision manufacturing processes.

1. DARPA’s “Short-Range Independent Microrobot Platform” (SHRIMP) Project

In 2018, the U.S. Defense Advanced Research Projects Agency (DARPA) launched the “Short-Range Independent Microrobot Platform” (SHRIMP) project to develop microrobots sized from micrometers to millimeters, weighing a few grams, and untethered, for environmental reconnaissance, search and rescue in small spaces, disaster relief, infrastructure inspection, manufacturing process monitoring, Mars surface exploration, and equipment maintenance. DARPA aims to use these robots in the air or on the ground, capable of crawling, sliding, rolling, jumping, or flying like insects, avoiding obstacles, throwing, lifting, and pulling objects, as well as climbing slopes.

Currently, the project has awarded 17 contracts to 15 institutions including Carnegie Mellon University, Purdue University, and the University of Pennsylvania, with a total contract value of $11.91 million.

2. Key Technologies of Microrobots

The key technologies of microrobots mainly include actuation schemes, power supply solutions, and micro-sensors. Additionally, compared to macro-sized robots, microrobots need to focus more on adhesive forces, surface forces, friction forces, etc., rather than gravity, buoyancy, and inertial forces.

Due to their small size, microrobots generally cannot use pneumatic or electric motor drive schemes and require new types of actuators. Currently, domestic and international developments in microrobot actuation schemes include the use of piezoelectric ceramics, shape memory alloys, shape memory polymers, and electromagnetic actuators.

1. Piezoelectric Ceramics

Lead zirconate titanate and other piezoelectric ceramics are currently the most widely used actuator materials in microrobots. Piezoelectric ceramics can change shape with voltage variations, have high resolution, and do not consume energy to maintain state, but have fewer degrees of freedom and exhibit hysteresis and other nonlinear phenomena, affecting open-loop control accuracy.

Harvard University has developed various piezoelectric ceramic-driven, tethered-powered microrobots, including RoboBee flying robots, the HAMR series quadruped robots, and MilliDelta vibrating robots.

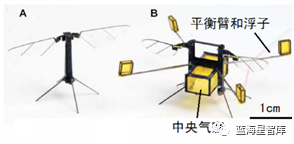

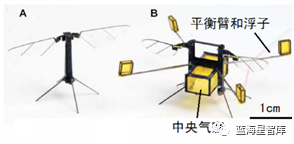

The RoboBee robot was first developed in 2013, initially capable of simple takeoff and landing. By 2016, it could dock on vertical walls, and in 2017, it achieved amphibious capabilities. The water-land amphibious RoboBee robot weighs 175 mg, has four stabilizing arms and floats to ensure stability. An electrolytic plate is inserted into a central gas chamber; when the robot approaches the water surface, the plate decomposes water into hydrogen and oxygen, helping the robot overcome surface tension approximately ten times its weight to emerge from the water. Sparks ignite the hydrogen-oxygen mixture, propelling the robot out of the water, and the stabilizing arms flap to achieve flight. The robot’s flapping frequency underwater is 9–13 Hz, which can increase to 220–300 Hz in the air.

The HAMR microrobot operates at a driving voltage of 200V, originally designed for quadrupedal movement, capable of running and crawling. In April 2018, Harvard University added RF communication capabilities (HAMR-F), and in December, developed an electro-adhesive climbing robot (HAMR-E). The HAMR microrobot measures 4.5 cm in length and imitates insect leg designs, independently controlling 8 piezoelectric actuators through a microcontroller and electronic components, equipped with an inertial measurement unit for linear motion feedback. The RF communication type HAMR-F weighs 2.8g and can move at a speed of 17.2 cm/s; the electro-adhesive climbing type HAMR-E weighs 1.48g and can climb conductive surfaces at speeds of 1.2 mm/s and 4.6 mm/s, with a horizontal speed of 140 mm/s.

Figure 2 Sixth Generation HAMR Microrobot

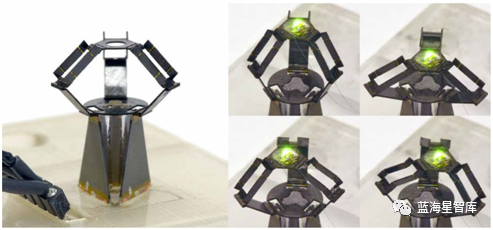

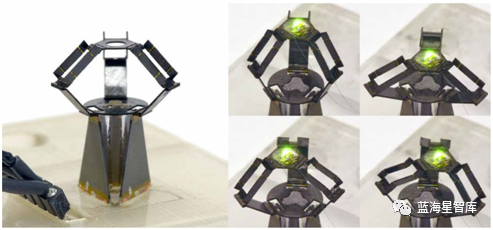

The MilliDelta vibrating robot was jointly developed by Harvard University and Asia University in Korea in 2018. The robot is manufactured using printed circuit micro-electromechanical systems technology, measuring 15mm×15mm×20mm, with a total weight of 430mg and an effective load of 1.31g, driven by piezoelectric actuators independently controlled at three points: the substrate, double-link rod, and top plate, capable of performing high-precision micro-manipulation in manufacturing and medical fields at a frequency of 75 Hz.

Figure 3 MilliDelta Robot

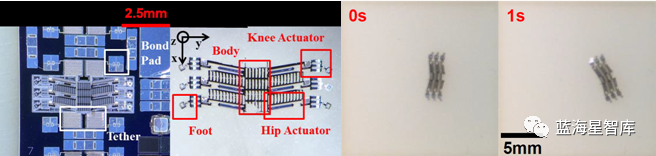

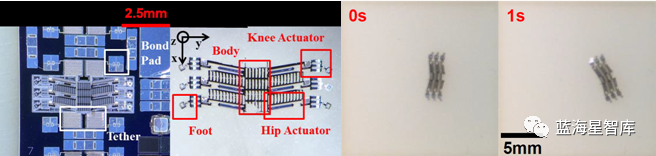

Additionally, the University of Michigan developed a hexapod micromembrane robot measuring 5mm×2mm in 2017, also using lead zirconate titanate piezoelectric thin film actuators, and improved the brittleness of the piezoelectric film with poly(chloro-para-xylylene) (Parylene C). The robot’s legs, hips, and knees are equipped with actuators, allowing alternating actuation to drive the robot’s movement. The excitation voltage is 10–20V, and the maximum swing amplitude of the robot’s legs is 50–100μm. In the future, it can be equipped with power sources or use wireless charging methods for power supply.

Figure 4 University of Michigan Hexapod Micromembrane Robot

The control of piezoelectric actuators can be adjusted in an open-loop manner by regulating voltage and can also be achieved through motion capture systems, buzzing motion detectors, and self-sensing piezoelectric materials for closed-loop control. In 2018, Harvard University proposed a method for self-sensing feedback control of piezoelectric actuators based on the stress generated on the surface of the piezoelectric material by actuator motion and the resulting current, achieving feedback control of actuator speed. Under actuation voltages of 25–200V and amplitudes of 1-2000Hz, this method achieves a control accuracy of 10% for actuator speed and has been validated in RoboBee and HAMR robots.

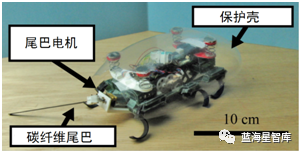

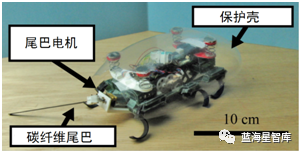

Somewhat larger microrobots can be driven by micro motors. A typical case is the VelociRoACH cockroach-like robot developed by the University of California, Berkeley. The robot measures 7.5 cm in length, 4.5 cm in height, and weighs 53.6 g. Due to its larger size, the VelociRoACH cockroach-like robot is motor-driven, powered by a 300 mAh lithium polymer battery. In 2017, researchers added a tail to the robot, enabling it to complete rapid rolls on surfaces of varying roughness; after adding the tail, it weighed 77.5 g.

Figure 5 VelociRoACH Cockroach-like Robot with Tail

Additionally, Korea’s Hanbat University developed an electromagnetic actuator similar to a motor, referencing the design of brushless DC motors, utilizing the relative oscillation between permanent magnets and electromagnets under alternating current input for actuation. The electromagnetic actuator drives a microrobot measuring 20mm×11mm×9mm, weighing 3g, with a maximum movement speed of 0.79 body lengths/s. The size of the electromagnetic actuator is 10mm×11mm×9mm.

Figure 6 Hanbat University Microrobot

Shape memory alloys are solid materials with a predetermined shape (usually materials that exhibit thermally elastic martensitic phase transformation) that can change shape under stimuli such as current, temperature, magnetic fields, and stress. For example, a predetermined shape at high temperatures can revert to that shape after cooling and reheating. The most typical shape memory alloy is NiTi alloy, which is strong, ductile, corrosion-resistant, and low-cost, making it widely used. Other examples include copper-based and iron-based alloys like CuZnAl. Shape memory alloys have strong bending deformation capabilities but relatively poor linear deformation capabilities (about 8%) and can be made into linear “artificial muscle” actuators.

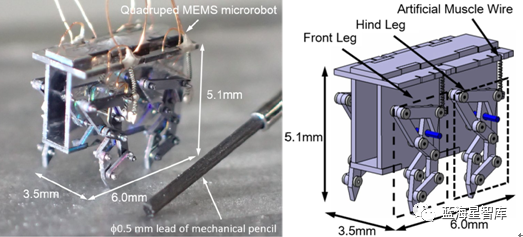

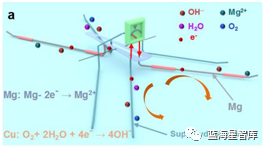

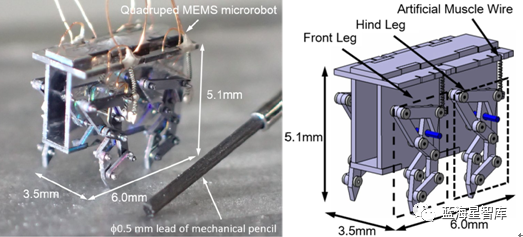

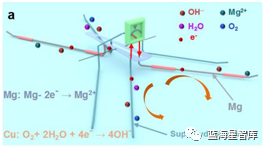

In 2017, a Japanese university used NiTi alloy (TOKI’s BMX50 artificial muscle wire) to construct linear actuators and developed a quadrupedal MEMS microrobot measuring 3.5mm×6.0mm×5.1mm. The actuator is electrically driven, and the legs form a four-bar mechanism, converting the actuator’s linear motion into gait motion. In 2019, the Institute of Nano Energy and Systems at the Chinese Academy of Sciences developed a water strider-like microrobot, measuring about 14 cm in total length (main body length of 5.5 cm, thickness of 2 mm), weighing about 1.65 g, using a NiTi alloy actuator, self-powered with a voltage of 1.38V, and a movement speed of 1.45 cm/s. The robot’s legs are made of magnesium-copper alloy wire coated with a TiO2 superhydrophobic coating, allowing for buoyancy, and it generates electricity by reacting with a 3wt% NaCl aqueous solution for self-powering.

Figure 7 Japanese University Quadrupedal MEMS Microrobot

Figure 8 Chinese Academy of Sciences Water Strider-like Microrobot

Shape memory polymers operate similarly to shape memory alloys; these predetermined high molecular weight materials can revert to their original shape under thermal, electrical, optical, or chemical stimuli. Shape memory polymers include polystyrene, polyimide, polyvinyl chloride, and other polymer materials and their fiber or particle-reinforced materials. Currently, the main types used as actuators in microrobots are liquid crystal elastomers, dielectric elastomers, and hydrogels. Shape memory polymers are generally easy to process, low-cost, but have lower actuation force compared to shape memory alloys.

Dielectric elastomers consist of an elastomer sandwiched between two flexible electrodes; when voltage is applied, charge separation occurs, creating electrostatic pressure that causes the elastomer to deform. Dielectric elastomers can produce significant stress, and their fracture toughness and power-to-weight ratio are comparable to natural muscle. Dielectric elastomer actuators can achieve modular manufacturing, allowing for the construction of robots with different functions through various module configurations. However, compared to piezoelectric actuators, dielectric elastomers have excessively high driving voltages and low power density, which can be optimized through material improvements and reduced contact resistance. In 2019, Harvard University developed a micro flying robot driven by dielectric elastomer films. The dielectric elastomer is composed of a mixture of Ecoflex 0030 and Sylgard 184, with a single actuator power density of 600W/kg, driving voltage of 800~1300V, capable of lifting a 160mg biplane flying robot with a lift of about 1.8mN, rising 1.5cm within 90ms.

Figure 9 Harvard University Micro Flying Robot

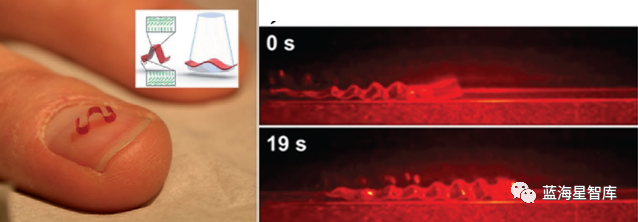

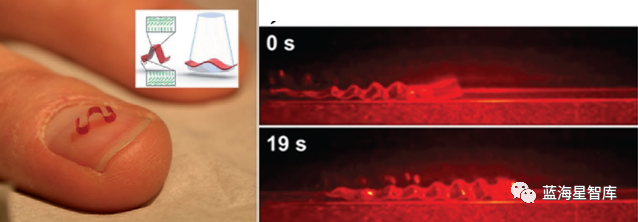

Liquid crystal elastomers are low cross-link density polymer networks formed by chemically bonded liquid crystal monomers, such as acrylate-based liquid crystal elastomers, that can change shape reversibly through internal liquid crystal phase transitions under heating, lighting, electric fields, magnetic fields, or changes in pH. In 2016, the University of Warsaw in Poland developed a caterpillar-like microrobot measuring 14.8mm in length and 3.8mm in width using liquid crystal elastomer films, capable of being driven by external thermal stimuli or thermal effects generated by light absorption, with an average speed of 0.1~0.5mm/s. In 2017, Tampere University of Technology in Finland developed a caterpillar-like microrobot measuring 8~13mm in length and 2mm in width, capable of crawling through anisotropic thermal expansion induced by low-intensity uniform visible light (150mW/cm2).

Figure 10 Tampere University (Left) and Warsaw University (Right) Caterpillar-like Microrobots

Hydrogels can cause swelling under temperature changes, achieving reversible size changes, and by altering the water content of the tissue, can achieve bending or twisting, such as poly(N-isopropylacrylamide) (PNIPAM). The issue with hydrogel materials is that the volume changes are not uniform; they can be combined with inorganic nanoparticles and other materials to achieve complex deformations.

(2) Power Supply Solutions

The power supply solutions for microrobots generally include self-powering and external power supply.

Self-powering solutions include zinc-air batteries, lithium-ion batteries, triboelectric nanogenerators, and contact-type electrochemical generators. In terms of power source types, DARPA currently favors zinc-air primary batteries with the highest power density. In 2019, under the DARPA SHRIMP project, the University of Pennsylvania developed a high-voltage zinc-air battery by combining multi-layer electrodeposition MEMS processing methods with in-situ bipolar nickel current collectors and electro-deposited porous positive electrodes. The output voltage of a single battery is 1.3V, with a capacity of 2.26mAh, achieving an energy density of 1720Wh/L and a power density of 760W/L.

External power supply generally includes light-driven, thermal-driven, magnetic field-driven, and vibration field-driven methods. Among these, changing magnetic fields and vibration fields generally do not exist in the natural environment and require artificial deployment, making them unsuitable for reconnaissance microrobots. Light-driven microrobots suitable for reconnaissance typically require uniform, stationary light fields without time or spatial modulation, allowing for spontaneous movement and even interaction with the environment. Thermal-driven microrobots can adopt electric or light-driven power supply schemes.

Due to size limitations, microrobots generally use embedded or integrated sensors, and materials that can serve as both actuators and sensors. Commonly used sensors include liquid metal strain sensors, graphite ink curvature sensors, LED-photoresistor displacement sensors, piezoresistive strain sensors, triboelectric tactile sensors, electromagnetic speed sensors, and capacitive strain sensors.

Microrobots are highly flexible and covert, suitable for reconnaissance in microenvironments such as gaps and monitoring precision processing, thereby expanding the application range of traditional medium to large robots. Currently, the most mature untethered microrobot solutions use piezoelectric ceramics or micro motors for actuation and zinc-air batteries or lithium-ion batteries for power supply.

Currently, the main issues faced by microrobots include two aspects: firstly, most robots still use tethered or external drives, and to improve practicality, further development and integration of high energy density power sources are needed; secondly, programmable control methods for smart materials such as shape memory alloys and shape memory polymers need to be developed to control the actions of microrobots.

With the advancement of high energy density power sources, micro-manufacturing processes, smart materials, and integrated sensors, there is hope to build autonomous or remotely controlled microrobot swarms and flexible intelligent response microrobots in the future, establishing new monitoring sensor networks through decentralized, large-scale deployment.

(Lanhai Star: Ma Xiaocheng)