AM Yidao Original Content

In this era that pursues speed and convenience, a quietly rising movement is redefining the product lifecycle.

When Philips announced that users could 3D print repair parts at home, and Honda decided to support additive manufacturing parts for the 30-year-old NSX supercar, we are witnessing a profound change in industrial logic.

Why have these corporate giants suddenly betrayed their carefully constructed planned obsolescence systems?

The answer lies in a seemingly simple technological revolution.

As low-cost 3D printers begin to play the role of modern-day appliance healers, with 77% of European consumers clearly expressing a preference for repair over purchase, and Texas passing legislation to enforce repair rights:

These companies, which once profited from a model of replacing broken items, suddenly find themselves at a historical crossroads.

This article explores how 3D printing technology is reshaping the repair rights movement, allowing classic products that should have been forgotten to be reborn.

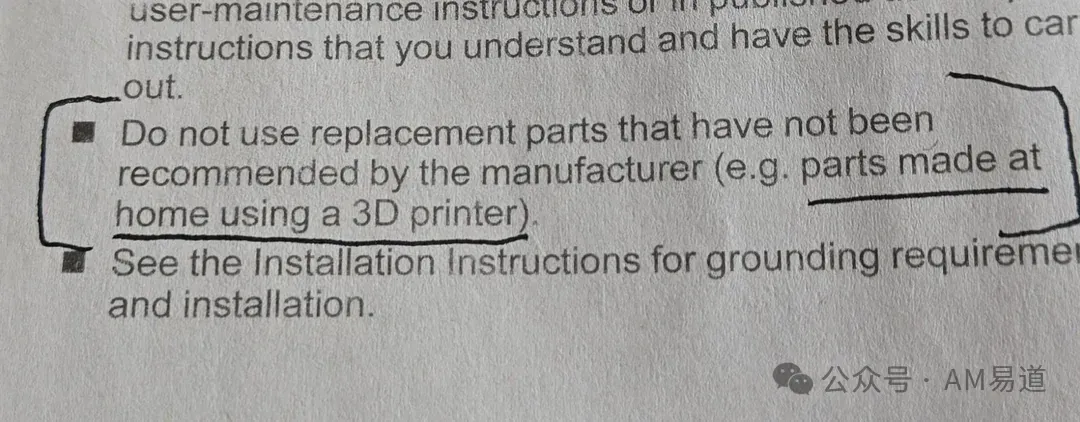

Further Reading: The controversy over major brand washing machine manuals prohibiting 3D printing: Should repair rights be granted to users?

The Return of Repair Culture: From Planned Obsolescence to Sustainable Use

Over the past few decades, the design philosophy of consumer electronics has undergone a fundamental shift.

Manufacturers have gradually realized that encouraging consumers to buy new products rather than repair old devices is more profitable.

This shortsighted strategy has led to a massive amount of junk devices, with cheap components that can fail without warning.

Even more concerning is that even high-end products may contain deliberately designed time bombs—components that are set to fail after a certain period.

This planned obsolescence strategy not only damages brand image but also causes serious environmental issues.

According to data from the UK’s recycling electrical appliances movement, 103,000 tons of electrical appliances are discarded each year, with nearly 500 million FastTech consumer electronics (such as data cables, decorative lights, and mini fans) discarded last year instead of being reused or recycled.

Large smartphone companies go to great lengths to make devices difficult to disassemble and repair, hoping consumers will buy new phones instead of repairing old ones.

Ironically, these new devices often do not offer any meaningful upgrades.

AM Yidao believes that the sustainability of this model is facing unprecedented challenges.

The Revival of Repair Rights Driven by Policy

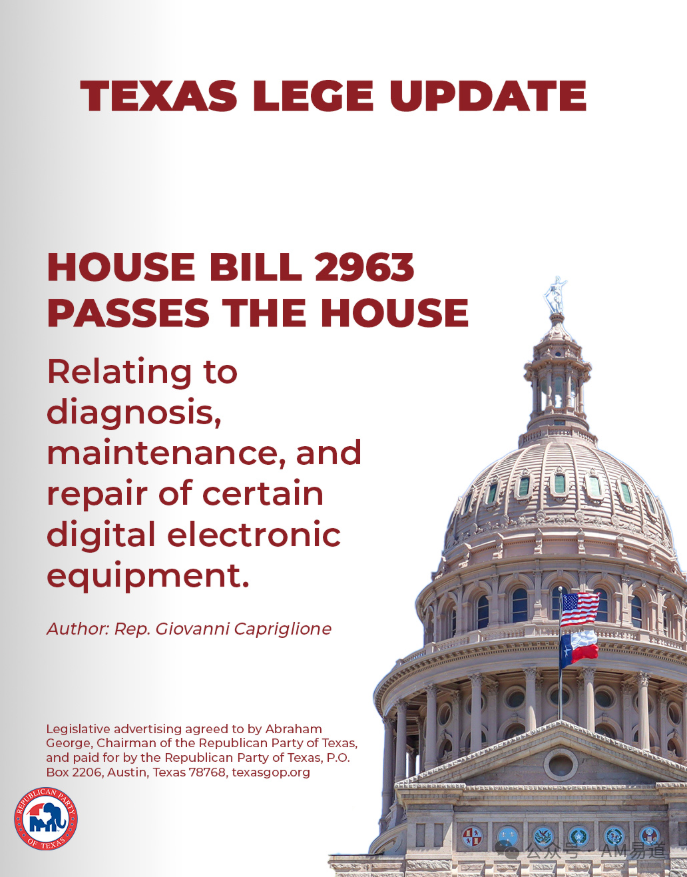

This year, Texas Governor Greg Abbott signed HB 2963, a law that protects citizens’ repair rights, ensuring that manufacturers provide adequate instructions, repair parts, and support for consumers seeking to repair damaged items.

This is just one of many such laws beginning to gain support across the United States.

The core demand of the repair rights movement is to restore the balance between intellectual property rights and personal property rights.

When consumers purchase a product, they should have the right to repair, modify, or even upgrade that product, without being hindered by artificial technological barriers.

Low-Cost 3D Printing Systems: Game Changers

The proliferation of additive manufacturing technology is fundamentally changing the repair ecosystem, allowing customers to manufacture rare and outdated production parts as needed.

Even if a product is discontinued and parts are no longer available, repair personnel can update and upgrade their beloved products.

Let’s look at some cases:

Philips Fixables: A Pioneering Exploration of Official Repair Documentation

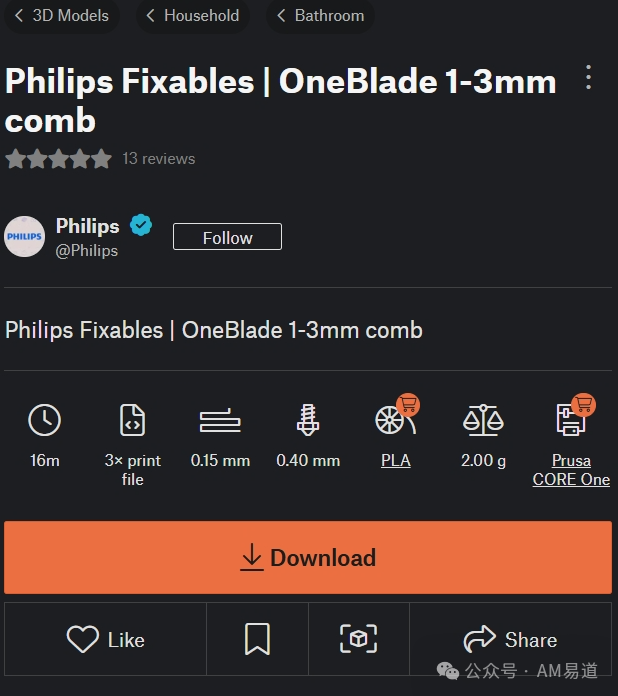

One of the most notable corporate transformations this year is Philips’ Fixables project.

Philips announced a new initiative called “Philips Fixables,” aimed at encouraging self-repair of certain products by providing officially drafted 3D printable replacement components.

This project is currently available for free download on Prusa’s Printables platform, starting with a single razor comb accessory, but Philips promises that more parts and components will be available.

AM Yidao believes that the value of this model lies not in individual components, but in the mindset shift it represents—from selling products to supporting the entire lifecycle of products.

Importantly, consumers must follow Philips’ recommended printing settings to ensure that replacement parts are strong enough to replace the original parts.

Further Reading: Discussing the implications of Philips listing 3D printing schematics on repair rights transfer.

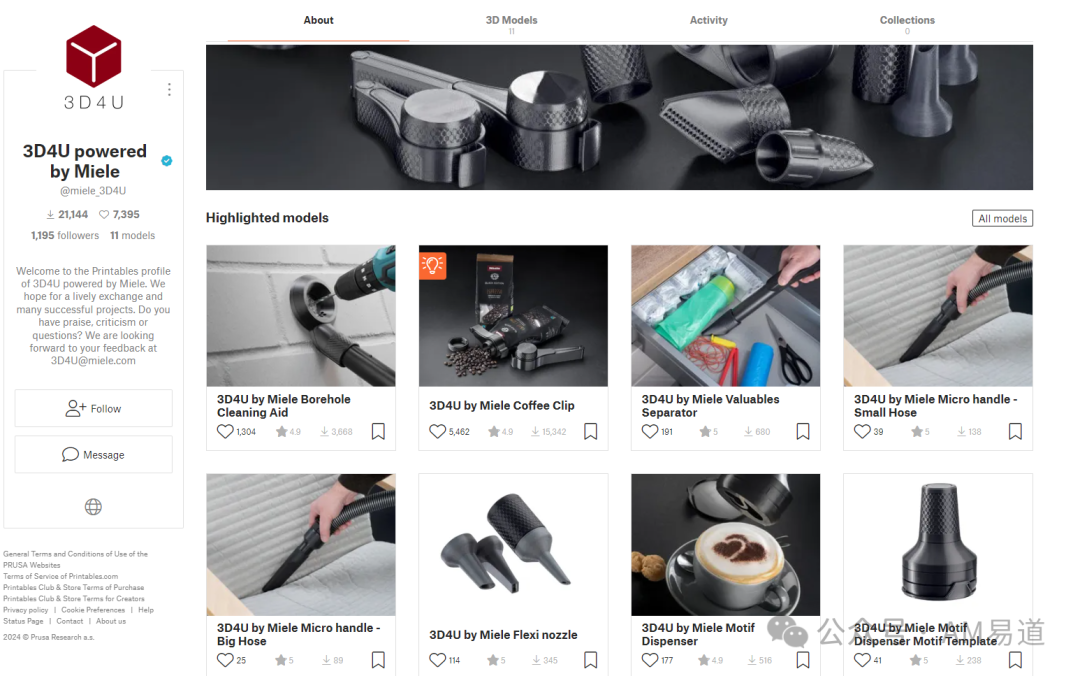

Appliance giant Miele’s model sharing

Another appliance giant, Miele, has begun sharing some accessory models on the Printables platform, actively integrating into this open ecosystem.

Honda NSX: Additive Manufacturing Solutions for Supercar Repairs

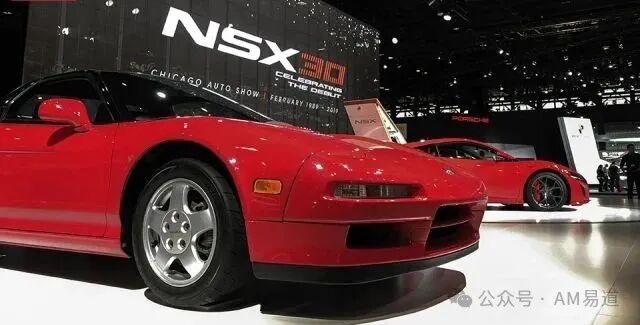

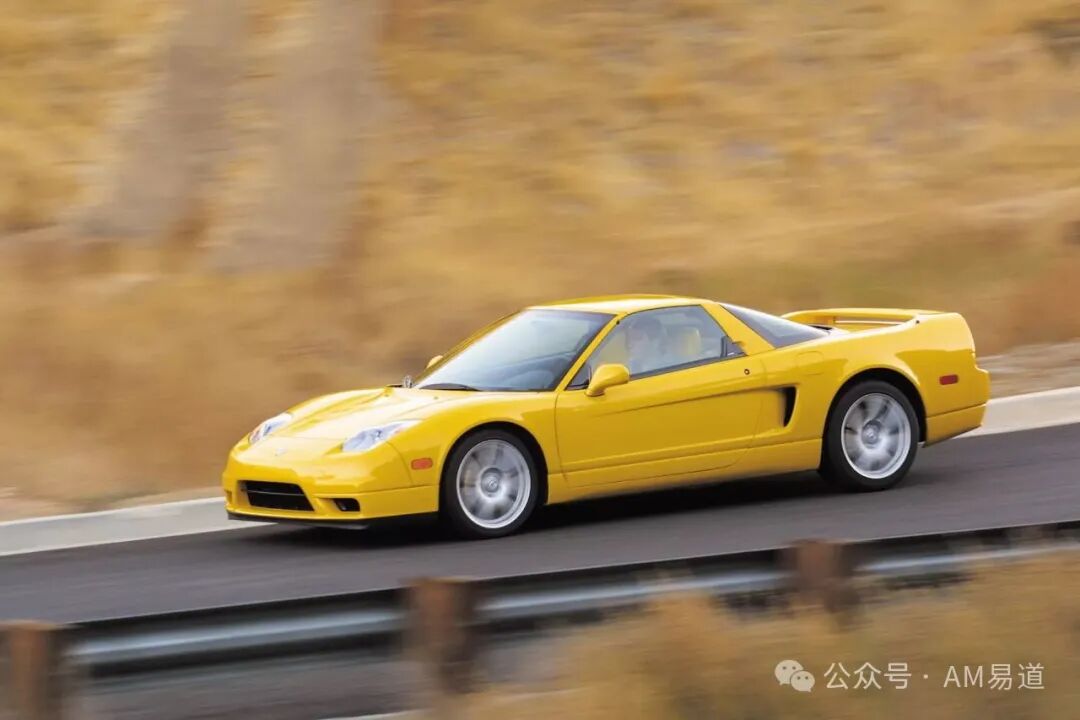

In the automotive sector, Honda’s support strategy for its classic NSX supercar is even more shocking.

Honda will create “genuine compatible parts” for its most popular cars in Japan using a combination of approved suppliers, remanufacturing, and even 3D printing.

This 90s supercar killer has now become a collector’s item, with the first generation NSX discontinued in December 2005, making it extremely rare with fewer than 20,000 units produced.

Thirty years later, finding parts for this collectible car has become nearly impossible.

Honda has stated it will begin sourcing and providing consumers with genuine compatible parts and part printing information.

For example, the door frame component shown below has already been 3D printed and installed.

This strategy not only ensures that the NSX can remain on the road for a long time to come but also demonstrates the brand’s commitment to quality, brand integrity, and customer promise.

Further Reading:

Understanding how 3D printing is quietly profiting in the automotive aftermarket.

Ford opens a library of 3D printing files for parts: Owners can print exclusive components!

Trends in Agricultural Machinery from Casting to Digitalization

In the field of agricultural machinery repair, 3D printing has brought about a typical process change.

Traditionally, manufacturing outdated parts required mold makers to spend days creating wooden casting molds, which were then sent to foundries to cast parts in cast iron or other materials.

Now, the digital process is as follows: scan the part with a scanner, load the information into a computer, use slicing software to layer the scanned results, and then print it out.

AM Yidao believes that this seemingly simple process change actually represents a fundamental shift from physical molds to digital assets.

In practical applications, K.R. Hough’s Traction Engineering company has even used scanning and 3D printing to reconstruct an entire tractor.

From engine blocks, pistons, cylinder heads to parts of the radiator, Hough has rebuilt the above Best Model 30 orchard tractor for a collector.

The success of this complete reconstruction project proves the feasibility of additive manufacturing in complex mechanical repairs.

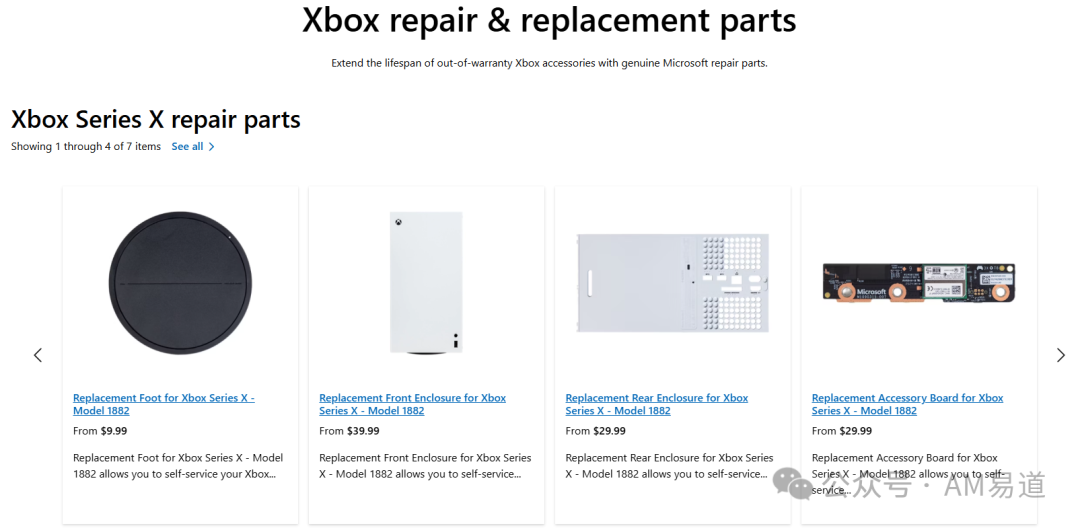

Microsoft Xbox’s Trend Choices

In the consumer electronics sector, Microsoft has announced that it will begin providing official repair parts for Xbox Series and Xbox Series X consoles, listing several new parts stores that offer comparable replacement components, along with key installation guides.

Due to small issues like damaged charging ports or unresponsive buttons, many of these devices are discarded. By providing repair guides and replacement parts, this economically viable approach has already proven successful.

iFixit: A Community-Driven Repair Ecosystem

iFixit is an online platform dedicated to the repair rights community, where self-repairers can find a wealth of critical data on electronic products. Many brands voluntarily collaborate with it.

This platform not only provides original manuals, repair guides, and tips but also tells users where to obtain parts for old and beloved electronic products.

AM Yidao believes that iFixit’s successful model demonstrates the value of open-source repair information.

iFixit repair instructions are available in multiple languages, including English, German, French, Spanish, Dutch, Italian, Korean, and Japanese, and this global knowledge sharing is building a truly sustainable repair ecosystem.

Challenges and Prospects: Technological Barriers and Business Realities

The challenges facing 3D printing repairs are more complex than they appear on the surface.

Quality control is the biggest challenge.

Philips has explicitly warned that deviating from recommended printing settings (such as reducing fill rates to save time or materials) may result in parts being too weak or unusable.

This strict parameter requirement exposes the gap between consumer-grade devices and industrial applications.

From a cost perspective, not all repairs are economically viable.

Technological compatibility is also a key issue.

Currently, most consumer-grade printers use polymer materials, while true industrial applications often require metals, ceramics, or composites.

Although there are stainless steel and carbon fiber printing devices on the market, they are expensive and may not meet the strength requirements for certain applications.

Deeper issues lie in the conflict between intellectual property protection and open-source repair.

When manufacturers provide official 3D printing files, they are essentially opening their design intellectual property. Where is the boundary of this openness? Which components will be opened, and which will continue to be protected?

The answers to these questions will determine the ultimate direction of the repair rights movement.

Investment Perspective: Opportunities in Additive Manufacturing within the Circular Economy

From an investment perspective, this trend represents a significant shift towards a circular economy.

Investors should focus on companies that can achieve affordable 3D printing and sustainable spare parts, as this trend expands the circular economy.

AM Yidao believes that companies supporting repairable hardware are finding ways to stand out in competition. As competition intensifies, more companies are expected to join the repair rights movement in the future.

The collective shift of corporate giants is not coincidental.

As technological advancements make repairs feasible, as laws and regulations begin to enforce consumer rights, and as environmental awareness becomes a new business driver, savvy entrepreneurs realize:

Rather than passively waiting for market disruption, it is better to actively embrace change, transforming repair rights from a cost center into a new value creation point.

In Conclusion: New Technology, New Logic, New Thinking

From a technical perspective, additive manufacturing has proven its feasibility in complex repair applications, but the real challenge lies not in the technology itself, but in how to establish a sustainable business ecosystem.

We need to redefine the relationship between manufacturers and users: from product sellers to long-term partners in the product lifecycle.

AM Yidao believes that the profound significance of this shift lies in:

Establishing a new value creation model.

In this model, technical knowledge, new manufacturing capabilities, repair needs, and brand loyalty form a self-reinforcing positive cycle.

This article is not just about the story of 3D printing; it is about how the entire manufacturing industry is finding a sustainable path to coexist harmoniously with consumers, the environment, and the future, driven by technology.

As appliance healers bloom everywhere, and repair rights become a basic right, we may be witnessing the birth of a better commercial civilization.

Looking forAM Yidao part-time editors, with over 5 years of experience in the 3D printing industry, regardless of professional field, income model is flexible. Looking forward to collaborating with partners who have deep thinking abilities, writing skills, and creative interests to create quality content together. Interested parties please add yihanzhong to submit resumes and representative works.

Corporate Partner Program: Become an AM Yidao industry partner and receive free access to resources for customer acquisition, financing, overseas expansion, and industry-academia-research-government connections.Reader Reminder: Add amyidao to join the reader group (note to join), to obtain original source links or content that is inconvenient to publish, and to discuss everything about 3D printing with AM Yidao’s like-minded readers.AM Yidao also suggests readers star the public account to receive updates from AM Yidao in a timely manner.Disclaimer:AM Yidao has no commercial cooperation, sponsorship, employment, or other interests with the companies mentioned in the article.AM Yidao ImageImages and videos are sourced from the internet and are for auxiliary reading purposes only, with no commercial intent.All rights belong to the original author. If there are any infringement issues, please contact the rights holder in a timely manner, and we will delete it as soon as possible. The copyright of the images in this article belongs to the copyright holder, and the AM Yidao watermark is automatically added for auxiliary reading and does not represent ownership of the images. For image usage, please consult the relevant copyright parties. AM Yidao articles do not constitute any investment advice, and AM Yidao is not responsible for any direct or indirect losses caused by the use of the information in this article.