April 3

At the

3D Printing Research Base of the Three Gorges University in Yichang, Hubei

A two-story experimental building, 8 meters high and covering an area of 100 square meters, has officially topped out.

This small building, which began construction in early March, took only 22 days with 3 workers and is the first in-situ 3D printed two-story building in China ⬇️

How to 3D Print a Two-Story Building?

Traditional brick walls are mostly masonry structures, bonded with mortar. “Our 3D printing uses pure concrete mortar, with columns, walls, floors, and ceilings all printed as a single unit, which has a strength higher than that of traditional bricks and greater printing precision,” said Li Yangbo, the technical leader of the project and an associate professor at the College of Water Resources and Environment at Three Gorges University. All you need to do is set the 3D printer to the required number of layers and layer height, and click one button to start printing automatically.

Nearby is the 3D printer that printed this small building. The printer spans 12 meters, resembling a gantry. Li Yangbo explained that this is a third-generation printer, which took their team three years to develop.

“We have updated over 20 sets of equipment and conducted thousands of experiments to overcome challenges in precision control, structural continuity, and printing stability for large-scale printers,” Li Yangbo said.

During the testing process, Li Yangbo’s research team controlled the deviation of the printer nozzle returning to the same position to within 0.1 millimeters, with shape deviations not exceeding 2 millimeters, and no printing defects appeared in the entire building.

“After exceeding 3 meters, we adjusted the feeding method and also modified the concrete mix ratio, changing from the initial screw pumping to hydraulic pumping, which provides greater pressure and better fluidity, ensuring continuous printing,” Li Yangbo said. During the construction of this building, AI algorithms were also used to plan the printing path, significantly reducing the idle time of the print head and improving printing efficiency.

Is the 3D Printed Two-Story Building Safe?

At the site, the reporter noticed many cracks in the walls of the building. The reporter couldn’t help but ask, “Is the house safe?”

“The cracks appeared because the temperature on the day of pouring was around 30°C, and the wind speed was relatively high, causing the surface moisture to evaporate quickly, which led to the cracks,” Li Yangbo explained. “The cracks only appeared in non-load-bearing walls and are within a normal controllable range, not affecting the overall structural safety.”

Moreover, the overall load-bearing structure of this house consists of a frame system made up of 15 columns and a central beam slab, with the 3D printing forming the shell of the load-bearing columns, while the interior is hollow.

“Once the load-bearing columns are printed to the height of the floor slab, we will insert the rebar cage through the hollow part and weld it to the rebar of the ground beam, forming a whole, and then bind and install the rebar for the second-floor slab beam, proceeding with the concrete pouring for the columns, beams, and floor slabs,” Li Yangbo said.

Additionally, upon close observation, it can be seen that the corners of the walls of this house are all at the same level, with excellent straightness, and the walls are designed with some curved shapes. “The printing of the house was very smooth and even, and the structure of the house is very solid, with a lifespan comparable to that of traditional houses,” Li Yangbo said.

How Will the 3D Printed House Be Used?

According to relevant data, the average price per square meter for self-built houses in rural areas nationwide in 2024 is expected to range from 1000 to 1500 yuan. The cost per square meter for this house is around 1000 yuan, comparable to many rural houses.

“Building this two-story structure using traditional methods would require 5 workers and take 2 months. However, using 3D technology to print the house only takes 1 month, significantly saving on templates and labor costs,” Li Yangbo said. This 3D printer also achieves green construction, allowing materials such as phosphogypsum and construction waste to be used as raw materials, enabling printing in fiberglass, ceramics, and plastics.

Once this house is printed, it will be used for technical experimental testing. After this technology is put into market application, the equipment can be used in municipal pipelines, drainage facilities, landscape sculptures, and other construction scenarios.

In addition to applications in the construction manufacturing field,with the support of 3D printing technology,the story of Nezha being “reborn” using lotus root in the movie “Nezha 2”is also becoming a reality⬇️

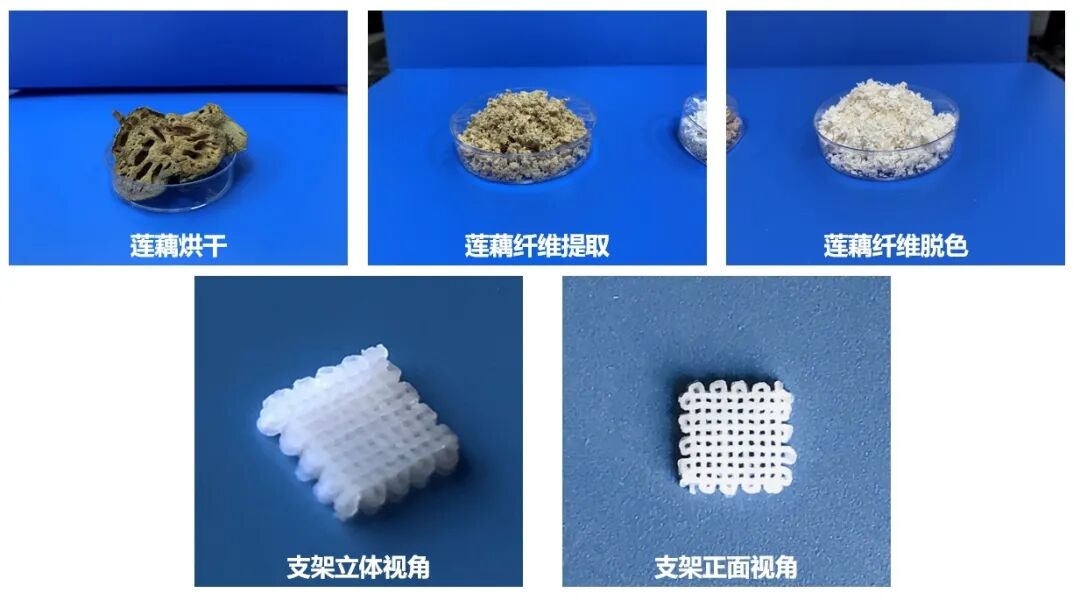

The story of Nezha being reborn using lotus root has been widely discussed since the success of “Nezha 2.” Recently, in Wuhan, Hubei, a research team has dedicated ten years to studying lotus root, achieving the true concept of “rebirth using lotus root”: extracting lotus root fibers to create customized materials through 3D printing, which can effectively promote bone cell proliferation.

Lotus Root Fiber “Reconstructs Bones” and Promotes Bone Growth and Healing

In ancient times, people believed that “lotus root breaks but the threads remain” is similar to human blood vessels. In widely circulated folklore, “making Nezha” does not use lotus powder; instead, Taiyi Zhenren uses lotus root for bones and lotus flowers for flesh to allow Nezha to be reborn. This is likely because ancient people also believed that the fibers of lotus root could provide support.

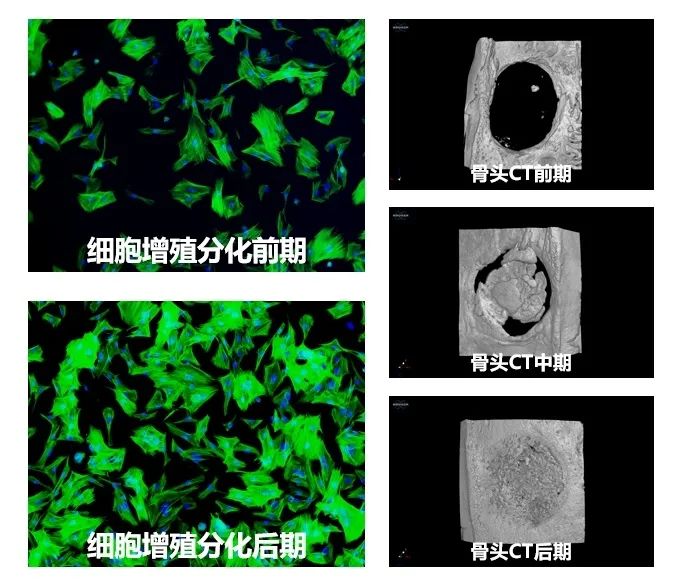

Dr. Jiang Xueyu from the College of Food Science and Engineering at Wuhan University of Light Industry explained to reporters that lotus root contains a large amount of fiber. The team’s research results show that using extracts from lotus root fibers, customized bone scaffolds can be made using 3D printing technology according to the condition of bone defects, fixing the fractured skeleton in the body and allowing cells to grow along the lotus root fibers, accelerating bone tissue reconstruction.

Materials printed from lotus root fibers

Compared to traditional treatment methods using steel nails,customized lotus root fiber scaffolds not only avoid issues such as poor adaptability and large surgical exposure but also effectively reduce patient rejection.Lotus root fiber scaffolds degrade at a rate that perfectly matches the rate of new bone growth, eliminating the need for a second surgery to remove them. This technology is currently in the animal testing phase. If successfully promoted to clinical applications, it could significantly reduce treatment costs for fracture patients and alleviate suffering.

Lotus root fiber scaffolds promote bone cell proliferation

Lotus Whole Powder “Reconstructs Flesh” and the Wind Fire Wheel Can Also Be Eaten Directly

Professor Yi Yang from the College of Food Science and Engineering at Wuhan University of Light Industry explained to reporters that the team has been dedicated to researching lotus root for ten years. In addition to the medical applications of lotus root fibers, the team has achieved multiple results in the processing of functional food bases and the creation of health products from lotus root.

Professor Yi explained that the lotus powder we usually eat is more accurately called “lotus starch,” which is made by repeatedly washing lotus root puree. During the extraction of lotus starch, the polysaccharides and polyphenols in the lotus root are discarded. However, if the lotus root is ground into powder directly for consumption, the nutrients can be preserved, but the taste is poor.

Professor Yi Yang’s team has researched how to use “lotus whole powder” to replace traditional “lotus starch.” Lotus whole powder retains almost all the nutrients of lotus root and is a whole-component health food that can also serve as a functional food base. Currently, the team has developed lotus whole powder products, and fish cakes and biscuits made with lotus whole powder have completed pilot production. Lotus whole powder can also be fermented with lactic acid bacteria to improve the nutrition of lotus root while protecting the viability of lactic acid bacteria, producing high-activity probiotic products.

During the research process, Professor Yi also discovered that lotus whole powder, after gelatinization, has good rheological and gel properties, which can be used in the design and development of emerging products such as 3D printed foods and foods for swallowing difficulties. “What is printed can be eaten directly, and colors can be added with matcha or other colored ingredients,” Professor Yi explained, “Using 3D printing, we can create various beautiful and healthy desserts. As long as there is a model, we can make Nezha or the Wind Fire Wheel.”

Professor Yi Yang’s team created the “Wind Fire Wheel” using lotus whole powder

Printing Toys, Printing Food, Printing Cars

……

With the update of intelligent manufacturing technology,

3D printing is accelerating its integration into our production and life

On March 17, at the 11th Asian 3D Printing and Additive Manufacturing Exhibition, 3D printed exhibits were displayed. Xinhua News Agency reporter Zhang Jiansong reported.

Some opinions suggest that 3D printing has a wide coverage in the manufacturing industry, especially in new materials, new energy, and high-end equipment, with significant application potential, serving as an important force in promoting the transformation and upgrading of traditional manufacturing. Market analysis indicates that in the future, 3D printing will fully support industries such as advanced aircraft, robotics, and organ drug screening models, with the potential to create a trillion-yuan market scale increment. Experts state that high performance, high efficiency, and low cost are the future development directions of 3D printing technology. However, currently, there is still a gap in the stability and economic applicability of large-scale 3D printing manufacturing in China, requiring further improvement in technology research and development and industrial support policy systems.

On March 17, at the 11th Asian 3D Printing and Additive Manufacturing Exhibition, 3D printed Nezha crafts were displayed. Xinhua News Agency reporter Zhang Jiansong reported.

If you had a 3D printer,

what would you want to print the most?

Come and tell us in the comments 🤩

Source: Comprehensive from the All-China Federation of Trade Unions WeChat Official Account, People’s Daily Client, Xinhua News Agency, Yangtze Cloud News

Editor: Liu Xiaoxiao, Zhang Yingjun

Review: Zheng Li, Qu Xinyue