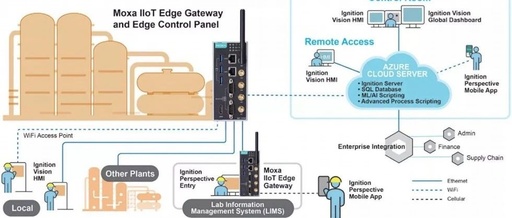

Best Practices for Running SCADA on Edge Industrial PCs

Image Source: Moxa Author | Eddie Lee Utilizing IT/OT convergence technologies, through monitoring and data acquisition (SCADA) software, industrial PCs for edge computing, machine learning software, and cloud connectivity, helps create sustainable applications. A process for measuring and removing hydrogen sulfide (H2S) from natural gas uses sensors, industrial computers (PCs) for edge processing, cloud-based applications, … Read more