Currently, the global manufacturing industry is moving towards smart factories!

Building a smart factory requires smarter machines and equipment as a foundation. These machines are equipped with IoT-enabled sensors, intelligent controllers, and HMI/SCADA systems to fully leverage the innovative advantages of digital technology. To fully realize these technological benefits and ensure they operate safely and reliably, an edge computing platform is essential.

Smart Factories Need Smarter Equipment

Just as the automation of machines using PLCs and PACs revolutionized the design of previous generation equipment, smart factories and smart manufacturing are again driving the development in the industrial sector. Applying the concept of digital transformation allows businesses to utilize data collected from control systems and sensors to operate at optimal performance. This approach provides operators with real-time analytics, inputs that help improve Overall Equipment Efficiency (OEE), and data that can be collected and analyzed locally. Data can also be sent to the cloud for deeper analysis across various applications. These applications can include optimized maintenance, flexible supply chains, and increased output from multiple factories engaged in similar production.

Machines and OEM equipment are fundamental elements of production. Smart factories and smart manufacturing can only be achieved through OEM-designed or end-user-specified smart machines. By adopting digital transformation, machine and equipment manufacturers can enhance designs and support the development of new services around equipment performance and maintenance. An important question is, what is the best way to develop the next generation of smart devices or to make existing designs and deployments meet customer needs? The answer is edge computing. Edge computing is a method that can address many critical design requirements.

What is Edge Computing?

Edge computing comes in various forms, broadly defined as any computing that occurs outside of data centers. Given such a broad definition, it is not surprising that many confusing definitions have emerged in the IT industry and the automation and control industry, which we collectively refer to as Operational Technology (OT).

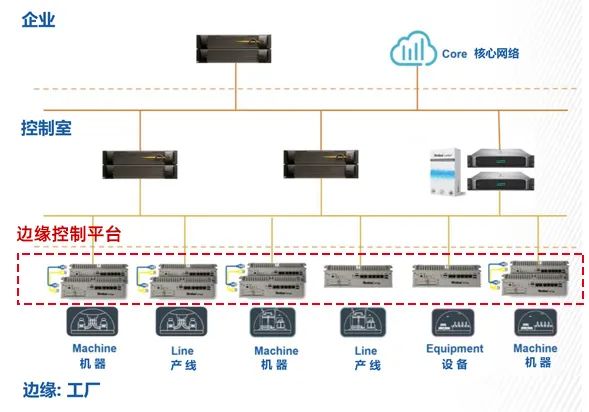

Major analytics firm Gartner has released a simple topology to help everyone understand what types of edge computing might be useful to them. This topology illustrates the infrastructure technology stack, showing the types of servers, devices, or platforms that can be described as edge computing, and their physical endpoint locations at the “edge” of data sources. It indicates the computing capabilities available outside of actual data centers, as well as the types of data collection, analysis, and movement. The edge provides extremely important benefits for device manufacturers and their customers.

Why Smart Machines Need Edge Computing Platforms

According to the aforementioned topology, it is easy to see that edge computing devices are suitable for machine and equipment manufacturers. In fact, today all machines and equipment involve edge devices with PLCs, some of which also have gateway edge devices. In some ways, the industrial PCs and tablet PCs used by machines or equipment fall into this gateway category. They may be the first “touchpoint” of the device edge PLC.

However, the computing and analysis capabilities of IPCs are limited, or face common reliability and availability issues similar to those of typical PCs or servers that are not designed for harsh environments. Therefore, other types of dedicated edge computing platforms are needed to meet customer demands.

When it comes to modernizing machine control and automation systems, the computing edge should be the focus of device manufacturers. Edge computing provides all the necessary features and functionalities for machine and equipment manufacturers to enhance their current designs and transition to providing smarter devices.

Application Architecture of Edge Computing Platforms

Four Fundamental Functions of Edge Computing Platforms

Edge computing platforms provide device and machine manufacturers with new revenue service possibilities, helping to reduce costs and improve total ownership costs. “Machine as a Service” or “Device as a Service” will become possible. Edge computing platforms have the following four fundamental functions.

Different from IPCs and IT Servers

Six Key Features of Edge Computing Platforms

There are various computing platforms available for machine and equipment manufacturers, such as IPCs or traditional IT servers, but dedicated edge computing platforms undoubtedly outperform both. IPCs are suitable for industrial-grade applications but do not provide any redundancy, meaning manual intervention of your machines and customer operations must occur regularly. Traditional IT servers are not suitable for industrial-grade applications and need to be placed in environmentally controlled locations, such as server rooms or data centers, which is not conducive to smart manufacturing. Edge computing platforms need to have the following six key features:

Designed Specifically for OEMs

Edge Computing Platform Stratus ztC Edge

In response to the demand for edge computing in smart machines in the OEM sector, the well-known industrial server manufacturer Stratus Technologies has launched the Stratus ztC Edge, an edge computing platform designed specifically for machine manufacturers. This is a secure, highly automated platform designed for the unique needs of industrial edge computing.

The uniqueness of the ztC Edge series is that it addresses the fundamental challenges faced by machine and equipment manufacturers, with each ztC Edge coming with a pre-integrated virtualization layer and pre-configured, allowing it to be up and running in 30 minutes, enabling quick and easy deployment of redundant SCADA/HMI systems.

Learn More by Downloading

The Technical White Paper “Smart Factories Need Smarter Devices”