With the rapid development of electronic products, there are many types of circuit boards, including hard boards, soft boards, and rigid-flex boards. Hard boards are ordinary PCB boards that cannot be bent; the vast majority of products use hard boards. Soft boards are flexible boards (FPC), which can be bent to a certain extent and are generally used in thinner or flexible products. Rigid-flex boards combine both hard and soft boards. In this article, we will mainly understand the differences between FPC and PCB.

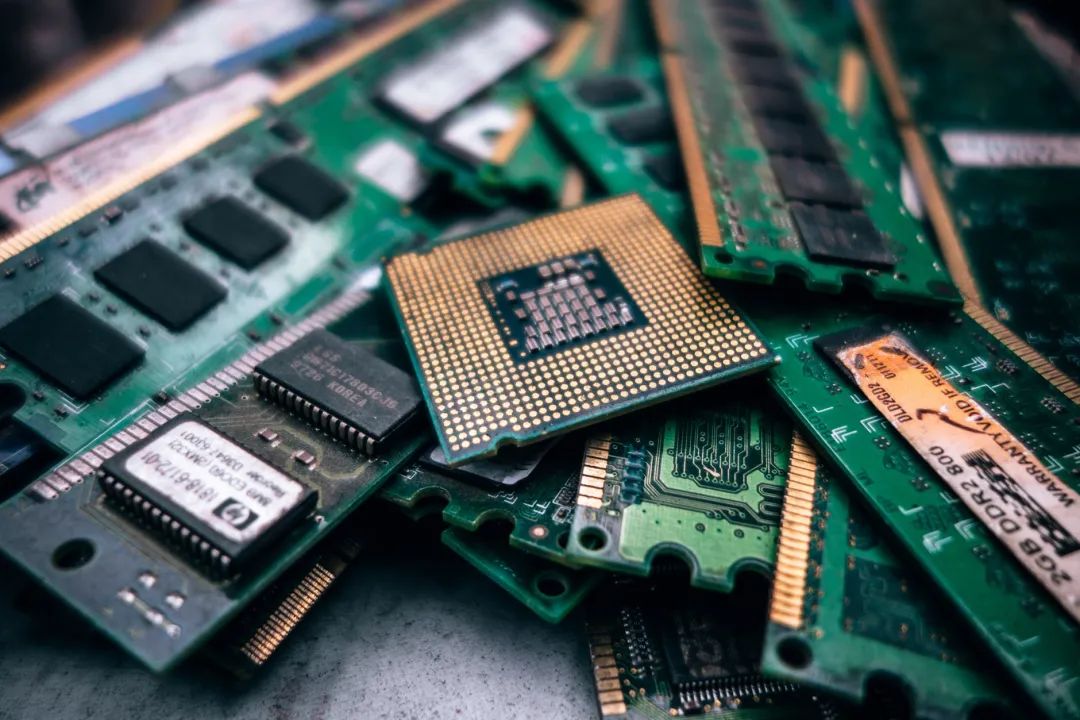

What Is PCB

PCB (Printed Circuit Board), known in Chinese as 印制电路板, is the support for electronic components and the carrier for their electrical connections. In the electronics industry, almost every electronic device, from small electronic watches and calculators to large computers, communication electronic devices, and military weapon systems, requires a PCB for the electrical interconnection of various components.

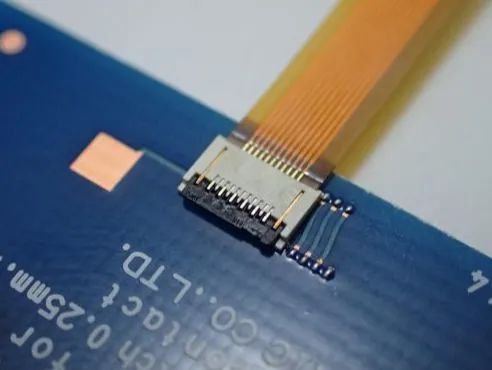

What Is FPC

FPC (Flexible Printed Circuit) is a type of PCB, also known as a “soft board.” FPC is made from flexible substrates such as polyimide or polyester film, offering advantages like high wiring density, lightweight, thinness, flexibility, and the ability to withstand millions of dynamic bends without damaging the wires. It can be moved and stretched according to spatial layout requirements, enabling three-dimensional assembly and achieving integration of component assembly and wire connections, providing advantages that other types of circuit boards cannot match.

Multilayer FPC Circuit Board

Advantages and Disadvantages of FPC

01

Advantages

1) Can be freely bent, rolled, and folded, arranged according to spatial layout requirements, and moved and stretched in three-dimensional space, achieving integration of component assembly and wire connections;

2) Using FPC can greatly reduce the size and weight of electronic products, meeting the needs for high density, miniaturization, and high reliability in electronic products. Therefore, FPC has been widely used in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras, and other fields or products;

3) FPC also has good heat dissipation, solderability, ease of assembly, and relatively low overall cost advantages. The design of rigid-flex also compensates for the slight shortcomings of flexible substrates in terms of component load capacity.

02

Disadvantages

1) High initial costs: Since FPC is designed and manufactured for specific applications, the costs for initial circuit design, wiring, and photographic base plates are relatively high. Unless there is a special need to use FPC, it is generally advisable not to use it for small quantities;

2) Changes and repairs to FPC are relatively difficult: Once FPC is made, changes must start from the base map or compiled photoplotting program, making modifications difficult. Its surface is covered with a protective film, which must be removed for repairs and restored afterward, which is a challenging task;

3) Size limitations: FPC is usually manufactured using intermittent methods, which are limited by the size of production equipment, making it difficult to produce very long or wide boards;

4) Prone to damage from improper handling: Improper handling by assembly personnel can easily damage flexible circuits, and soldering and rework require trained personnel.

Applications of FPC

Mobile Phones: Emphasizes the lightweight and thinness of flexible circuit boards, effectively saving product volume and easily connecting batteries, microphones, and buttons into one unit.

Computers and LCD Screens: Utilizes the integrated circuit configuration of flexible circuit boards and their thinness to convert digital signals into images displayed on LCD screens;

Portable CD Players: Focuses on the three-dimensional assembly characteristics and thinness of flexible circuit boards, turning bulky CDs into portable companions;

Disk Drives: Whether hard disks or floppy disks, they rely heavily on the high flexibility and ultra-thin thickness of FPC (0.1mm) to achieve rapid data reading, whether for PCs or notebooks;

Latest Uses: Components of hard disk drives (HDD) such as suspension circuits and packaging boards.

Differences Between FPC and PCB

In summary, the differences between FPC and PCB can be simply summarized as follows:

1. FPC is a type of PCB, while ordinary PCB is usually referred to as “hard board,” and FPC is called “soft board.”

2. The volume of FPC is smaller than that of PCB, effectively reducing product volume and increasing portability.

3. FPC is lighter than PCB, which can reduce the weight of the final product.

4. FPC is thinner than PCB, which can improve flexibility and enhance three-dimensional assembly in limited spaces.

5. FPC can be bent and is highly flexible, while ordinary PCB cannot be bent.

In recent years, the consumer electronics market, led by mobile electronic devices such as smartphones and tablets, has experienced rapid growth, with a trend towards miniaturization and lightweight products becoming increasingly evident. Consequently, traditional PCBs can no longer meet product requirements, leading major manufacturers to research new technologies to replace PCBs, among which FPC is becoming the most favored technology and is emerging as a primary connecting component in electronic devices.

Furthermore, driven by emerging markets such as 5G and wearable devices, FPC will also welcome new growth opportunities.

(Content organized from the internet)

During the “epidemic” period, learning cannot stop. Before the end of the pandemic, Kuai Dian Academy will collaborate with Tencent Classroom to continue offering some courses for everyone to learn online for free!

↓↓↓