Everything You Didn’t Know About PCBs

Recently, the Chief Information Officer Association of Dongguan City (CIO) conducted a special interview with Guo Rongwei of Shengyi Electronics Co., Ltd. (hereinafter referred to as “Shengyi Electronics”) in the 13th issue of the “Digital Salon” on digital transformation and information construction.

Host: Please introduce yourself, Mr. Guo.

Guo Rongwei:I come from Shengyi Electronics and have been in the electronics industry for nearly 30 years. I graduated from South China University of Technology. After graduation, I worked in some large enterprises in planning management, supply chain management, and information construction. Later, I worked in a professional IT company engaged in software development and project management. As a project leader or project director, I have implemented 20 to 30 large ERP construction projects and have considerable experience in ERP, information technology, smart manufacturing project management, and digital transformation in the electronics industry.

I joined Shengyi Electronics in 2007. Let me briefly introduce Shengyi Electronics. The company was established in 1985 and is headquartered in Dongguan Dongcheng, with over 30 years of history. The company has always focused on the electronics circuit industry and is a national high-tech enterprise specializing in the manufacture of high-precision, high-density, and high-quality printed circuit boards. It is currently listed on the Sci-Tech Innovation Board.

Shengyi Electronics has several characteristics: one is that the company attaches great importance to a standardized management system. The company established a quality system early on and was the second company in Dongguan to establish a quality system. Based on the quality system, the company has established various management systems and has obtained hundreds of technical patents. At the same time, the company also pays great attention to digitalization and smart manufacturing. I have been responsible for overseeing the entire information and digital construction for over 15 years at Shengyi Electronics, and I led the team to win the excellent QC group in Dongguan, Guangdong Province. In 2013, the company carried out digital construction and information construction for the entire new factory, leading the team in ERP implementation and has received honors such as Dongguan’s intelligent manufacturing demonstration project and industrial Internet demonstration project multiple times. Last year, the company was recognized as one of the first intelligent factories in Dongguan, and I was also honored as a pioneer in digital transformation. I have a background in enterprise management and have long been engaged in IT-related work, so I tend to think about the entire digital transformation and digital construction from a management perspective.

I joined Shengyi Electronics in 2007. Let me briefly introduce Shengyi Electronics. The company was established in 1985 and is headquartered in Dongguan Dongcheng, with over 30 years of history. The company has always focused on the electronics circuit industry and is a national high-tech enterprise specializing in the manufacture of high-precision, high-density, and high-quality printed circuit boards. It is currently listed on the Sci-Tech Innovation Board.

Shengyi Electronics has several characteristics: one is that the company attaches great importance to a standardized management system. The company established a quality system early on and was the second company in Dongguan to establish a quality system. Based on the quality system, the company has established various management systems and has obtained hundreds of technical patents. At the same time, the company also pays great attention to digitalization and smart manufacturing. I have been responsible for overseeing the entire information and digital construction for over 15 years at Shengyi Electronics, and I led the team to win the excellent QC group in Dongguan, Guangdong Province. In 2013, the company carried out digital construction and information construction for the entire new factory, leading the team in ERP implementation and has received honors such as Dongguan’s intelligent manufacturing demonstration project and industrial Internet demonstration project multiple times. Last year, the company was recognized as one of the first intelligent factories in Dongguan, and I was also honored as a pioneer in digital transformation. I have a background in enterprise management and have long been engaged in IT-related work, so I tend to think about the entire digital transformation and digital construction from a management perspective.

Source: Shengyi Electronics ESG Report

Host: Mr. Guo, could you briefly introduce the pain points, difficulties, challenges, and opportunities in the digital transformation of the electronic circuit industry?

Guo Rongwei:Printed circuit boards (PCBs) are the mother of the electronics industry. Why do I say this? Because all electronic components must be built upon it, using it for electrical connections. PCBs have several characteristics: first, from the perspective of the industrial chain, they are in the midstream. Both upstream and downstream are large enterprises; upstream are large suppliers like copper-clad boards and copper foils, and downstream are large companies in automotive electronics, terminal computers, servers, and aerospace. Therefore, the PCB industry’s profits can only be enhanced through technological capabilities and cost efficiency management.

Secondly, from the product characteristics, it is a flexible manufacturing industry. It is a completely customer-customized product, personalized customization; customers will not want any surplus products. Unlike televisions or cars, which can be sold at a reduced price, surplus products are useless to customers. Another important point is that PCBs have long process flows. For mid-to-high-end products, there are at least 50 major processes, and it can exceed 100 processes. Since the products are customer-customized, the process parameters and equipment requirements for each process are different. This creates a pain point in PCB production. Because PCBs cannot be produced like an automobile assembly line with automated assembly, they can only be produced in independent work centers, and the transportation of intermediate products relies on manual carts and other methods. Due to the many processes, each process involves various types of equipment, covering optical, electronic, mechanical, and chemical industries, and because the products are designed by customers, the parameters on each machine are different. Based on these differences, traditional methods can only allow employees to adjust parameters according to product requirements and process specifications.

Although the PCB industry is indeed a high-tech industry, traditionally, achieving flexible manufacturing requires a lot of manpower, which naturally leads to low efficiency, high error rates, and high costs. On the other hand, PCBs, being the mother of the electronics industry, have a stable growth trend, and the industry is gradually shifting to China, presenting significant market potential.

In recent years, the government has promoted industrial pilot programs and “Made in China 2025,” which has led to the flourishing development of automation, smart manufacturing, and digitalization, bringing great opportunities to the entire industry. This can enhance the management and manufacturing of enterprises, thereby improving operational efficiency, which is both an opportunity and a challenge we face.

Host: Can you introduce what system software Shengyi Electronics uses in the production process? How is it segmented and what is the division of labor?

Guo Rongwei:The process of implementing digitalization or information technology in the company has a long history. During this process, the company has used many software or information systems, but there is a clear segmentation strategy: classification and grading, with distinct priorities and responsibilities. All digital architectures have an important core: the SAP ERP system, which is the only core and the heart of the entire architecture.

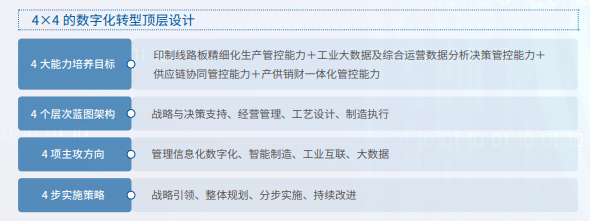

In addition, from a business perspective, it is divided into four levels from top to bottom: strategic and decision support level, operational management level, design and process level, and manufacturing execution level.

Source: Shengyi Electronics ESG Report

Each level has a core system, and there are also other auxiliary systems. Starting from the strategic decision knowledge level, the core is the comprehensive budget and performance management system. This system connects the enterprise’s strategy upwards and links to our ERP system downwards to realize the implementation of the strategy, serving as a bridge. Moving to the next level: the operational management level has more systems, but it still revolves around one core: SAP ERP. Around this core, it manages the key elements of people, finance, materials, processes, and data through different systems. For example, in terms of people, there are talent management systems and cloud recruitment platforms; in finance, there are shared finance systems, capital management systems, and consolidated reporting systems; in materials, there are SRM and CRM; in processes, besides BPM, there are also our self-developed mobile office and safety prevention systems; in data, there are data warehouses, BI, and various AI big data applications, which we use at the operational management level.

In the design and process level, we utilize PCB industry-specific design software along with our self-developed process management system, integrating the company’s SAP database to achieve the PCB industry’s PLM system. Finally, at the manufacturing execution level, the core is the MES system, which receives production planning instructions from ERP and various design requirements from the design and process level, and drives production equipment, testing instruments, and intelligent logistics (AGV) through a digital industrial platform. Through these four levels, from strategy implementation to equipment operation, we form an integrated information system. This is some of the systems we have applied in digital transformation.

Host: Digital transformation has no standard answer. In your opinion, is it more appropriate to adopt a disruptive or incremental approach?

Guo Rongwei:This question indeed has no standard answer. From my experience, whether disruptive or incremental is merely a method, a means, not an end. The core purpose of digital transformation is to look at the effectiveness, especially business effectiveness. Based on this starting point, the choice of model should depend on our actual situation. Often, many companies lack sufficient internal and external resource preparation at the beginning of digital transformation. Externally, digital transformation, especially in manufacturing, tends to focus on smart manufacturing. However, the best practices and general management models in the industry are different.Unlike ERP, which has significant universality, there are many mature cases or best practices in the industry, but digital transformation in smart manufacturing has many practical situations for each company, so its universality is not so strong. In this case, there are often not many mature cases or consultant resources available externally.

Internally, the conditions are even more insufficient. First, most employees may not know what digital transformation is, what benefits it brings, or how to implement it. Secondly, most companies often lack talent for digital transformation.Digital transformation talent is often a composite talent; they must understand IT, digitalization, and the business of the enterprise, especially both business and IT to a certain extent. Such talent is indeed hard to come by.Finally, companies may also lack various information systems, such as whether devices are all connected to the network or whether equipment has undergone digital transformation. Often, companies do not have these conditions.In this case, how to begin digital transformation? Our recommendation is to find the easiest breakthrough point, the most realistic point that can yield benefits, and focus efforts on breaking through that point. Once successful, it will demonstrate that digital transformation is indeed effective, and at the same time, it will accumulate our work experience and possibly cultivate some talent.After the first successful step, we can gradually expand to more aspects and points for breakthroughs.

In this process, we can also cultivate a large number of digital talents within the enterprise. Through continuous improvement and the process of achieving results, we can promote awareness and enable most employees in the enterprise to possess information capabilities and literacy. Once the conditions are ripe, we can implement full-process digitalization. Therefore, this process is often incremental, but it cannot be generalized. We see some cases where it may be disruptive, for example, if our business undergoes fundamental changes or if we implement a new business and establish a new production base while our previous digitalization is already mature. In such cases, it is also possible to adopt a completely new disruptive method for a new factory or base.

So I believe that any method is merely a means; the key is what objectives we want to achieve. However, one thing I think is that regardless of the method used, digital transformation is a continuous improvement process with no endpoint. Therefore, we need to continuously refine it, improve it, break through it, and enhance it for digital transformation to be successful.

Host: You mentioned that digital transformation is a gradual process, and there will definitely be some new products emerging in this process. Regarding the current hot topic of AI intelligence, what are your thoughts?

Guo Rongwei:We have been tracking AI for quite some time and are continuously learning. For the company, we began experimenting and exploring AI in 2020. Why? Because from 2016 to 2017, after we started digital transformation, a lot of data was generated by 2020. We thought about how to utilize this data, so we started to leverage AI and other methods to discover its uses, gradually launching applications in quality inspection AI and big data prediction, achieving some results.

Recently, we have seen that AI is indeed a hot topic and a very vibrant direction. Personally, I believe it will undergo significant changes and developments and is not yet in its final form.Currently, we see two main directions for AI:One is human-computer interaction like Chat GPT, and the other is Huawei’s recently proposed Pangu model tailored for different industries.In my view, AI is somewhat like the automation machines that emerged when transitioning from an agricultural society to an industrial society.At that time, when automation machines appeared, people wondered if machines would replace humans, leading to mass unemployment. The reality is that some people did lose jobs, but not all jobs were replaced by automation machines; there were still many tasks that could not be replaced by manual labor.

So, I believe AI is similar; it will certainly replace many intellectual jobs, but it will not replace all jobs. On the other hand, it will also create many other new job positions. A typical example is video shooting; previously, professional personnel and equipment were required for video shooting, making production difficult. However, now we have progressed, and we can use smartphone apps for shooting videos, and there are AI beautification features. As a result, while the number of professional photographers may decrease, they may become more niche and specialized. On the other hand, a large number of ordinary people can now use their phones to shoot videos, leading to platforms like Douyin and various video content emerging. This has actually created many new positions, even roles like live streamers that didn’t exist before. Therefore, we view AI from an open perspective; it will certainly impact our work and may even pose information security challenges. However, this is a good thing for humanity; the key for individuals is how to utilize it well and not to position themselves poorly in the AI wave. That is my reflection.

Host: Please share a few words for all digital transformation practitioners.

Guo Rongwei:Digital transformation is never-ending; it is always in progress and never completed. What is needed is to combine this with the concept of continuous improvement, constantly enhancing and progressing.

Source: Compiled from the video account of the Dongguan Chief Information Officer Association. Copyright belongs to the original author. The purpose of reprinting is to share more information and does not represent the position of this account. If there are copyright issues, please contact the backend, and we will handle it promptly.

For more PCB industry news, scan the QR code below to view.

▲“Printed Circuit News” Electronic Journal▲