Understanding the Differences Between Profibus, Profinet, and Ethernet

Ethernet is a well-known network standard created by Xerox and developed in collaboration with Intel and DEC. It is the most widely used communication protocol standard for local area networks today, including standard Ethernet (10Mbit/s), Fast Ethernet (100Mbit/s), and 10G Ethernet (10Gbit/s).

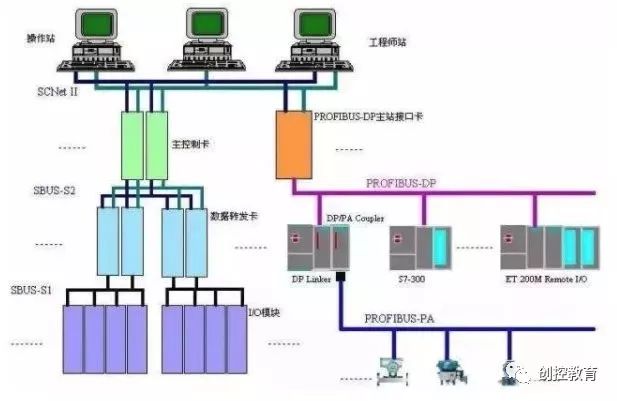

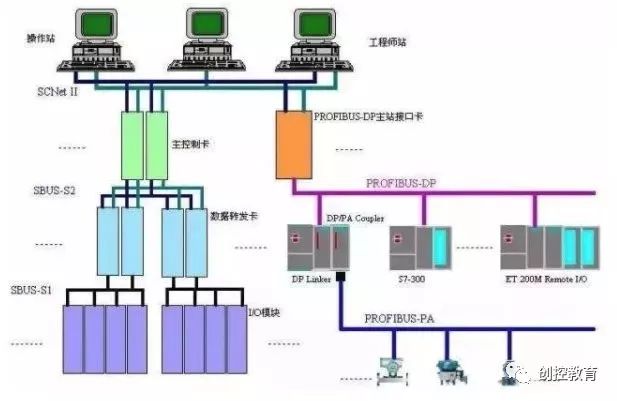

PROFIBUS is an international, open, fieldbus standard that does not depend on device manufacturers. The transmission speed of PROFIBUS can be selected within the range of 9.6kbaud to 12Mbaud, and all devices connected to the bus must be set to the same speed when the bus system starts. It is widely used in manufacturing automation, process automation, and other fields such as building and transportation automation. PROFIBUS is a fieldbus technology used for workshop-level monitoring and data communication and control at the field device layer. It enables decentralized digital control and field communication networks from the field device layer to workshop-level monitoring, providing a feasible solution for comprehensive factory automation and intelligent field devices.

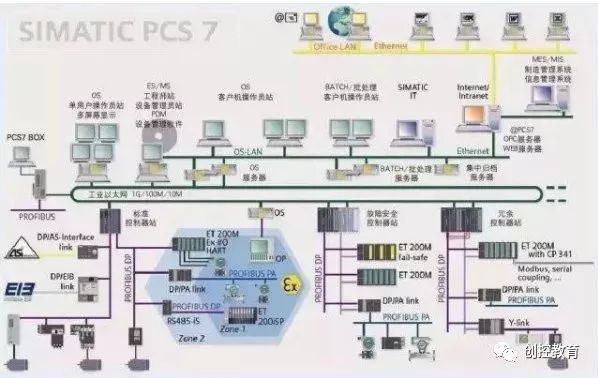

PROFINET = PROFIBUS + Ethernet, transplanting the master-slave structure of PROFIBUS onto Ethernet. Therefore, Profinet has Controllers and Devices, which can be simply corresponded to the Master and Slave of PROFIBUS. However, there are differences, but this correspondence can help with understanding. Additionally, since Profinet is based on Ethernet, it can have star, tree, and bus topologies, while PROFIBUS only has a bus topology. Thus, Profinet combines the master-slave structure of PROFIBUS with the topology of Ethernet. Other features, such as real-time capabilities that Siemens promotes, are also present in Ethernet, but Profinet can enhance the precision of real-time performance due to the presence of a Controller.

PROFINET is a new Ethernet communication system developed by Siemens and the Profibus User Association. PROFINET supports communication between multi-vendor products, automation, and engineering modes, and is optimized for distributed intelligent automation systems. The application results can significantly reduce configuration and debugging costs. The PROFINET system integrates Profibus-based systems, providing protection for existing system investments. It can also integrate other fieldbus systems.

PROFINET is an advanced communication system that supports distributed automation. In addition to communication functions, PROFINET includes specifications for the distributed automation concept, which is based on manufacturer-independent objects and connection editors and XML device description language. Ethernet TCP/IP is used for communication between intelligent devices that do not require strict timing. All time-critical real-time data is transmitted through standard Profibus DP technology, allowing data from the Profibus DP network to be integrated into the PROFINET system via a proxy. PROFINET is the only bus that uses existing IT standards without defining its own dedicated industrial application protocol. Its object model is based on Microsoft’s Component Object Model (COM) technology. The interaction between all distributed objects on the network uses Microsoft’s DCOM protocol and standard TCP and UDP protocols.

In the PROFINET concept, devices and factories are divided into technical modules, each module includes mechanical, electronic, and application software. The application software of these components can be developed using dedicated programming tools and downloaded to the relevant controllers. These dedicated software must implement the PROFINET component software interface and be able to export the PROFINET object definitions as XML language. The XML file is used to input manufacturer-independent PROFINET connection editors to generate PROFINET components. The connection editor defines the exchange operations between PROFINET components on the network. Finally, the connection information is downloaded to the PROFINET devices via Ethernet TCP-IP.

PROFINET (Real-Time Ethernet) is based on industrial Ethernet, has excellent real-time performance, can directly connect to field devices (using PROFINET IO), and supports distributed automation control methods (PROFINET CBA, akin to communication between master stations).

After Ethernet is applied to industrial control scenarios and improved for use in industrial environments, it becomes Industrial Ethernet. If you have ever used Siemens network cards CP343-1 or CP443-1 for communication, you may have used protocols such as ISO or TCP connections. The TCP and ISO used here are protocols applied in Industrial Ethernet.

PROFINET is also a protocol in Siemens SIMATIC NET, specifically a collection of many protocols, including PROFINET IO RT, CBA RT, IO IRT, and other real-time protocols. Therefore, PROFINET cannot be compared with Industrial Ethernet; it can only be said that PROFINET is a real-time protocol running on Industrial Ethernet. However, some networks are often referred to as PROFINET networks because they have implemented the PROFINET protocol.

PROFINET is based on Industrial Ethernet, while PROFIBUS is based on RS485 serial bus. The protocols of the two are completely different due to the different media and have no relation. Both have excellent real-time performance due to their use of a streamlined stack structure. Any development based on standard Ethernet can be directly applied to PROFINET networks, and there are far more developers of Ethernet-based solutions in the world than PROFIBUS developers, resulting in more available resources for technological innovation.

For PROFIBUS, the maximum data transmission bandwidth is 12Mbps, while for PROFINET, it is 100Mbps.

For PROFIBUS, the data transmission mode is half-duplex, while for PROFINET, it is full-duplex.

For PROFIBUS, the maximum consistent data is 32bytes, while for PROFINET, it is 254bytes.

For PROFIBUS, the maximum user data is 244bytes, while for PROFINET, it is 1400bytes.

For PROFIBUS, the maximum bus length at 12Mbps is 100m, while for PROFINET, the bus length between devices is also 100m.

For PROFIBUS, configuration and diagnostics require specialized interface templates, such as CP5512, while for PROFINET, standard Ethernet network cards can be used.

For PROFIBUS, special tools are required for network diagnostics, while for PROFINET, IT-related tools are sufficient.

For PROFIBUS, the main sources of faults on the bus come from mismatched bus terminal resistors or poor grounding, while for PROFINET, no terminal resistors are needed.

(Content sourced from the internet, copyright belongs to the original author)

Disclaimer: If there are copyright issues, please contact for removal! No individual or organization bears related legal responsibilities.

Recommended Reading:

Last week’s public class video replay [Siemens S7-200SMART and V20 Inverter USS Communication Explanation]

Why is it difficult for engineers to find girlfriends? See if you fall into this category.

Latest industrial control programming software download (real-time updates)

Junior industrial control personnel vs. senior industrial control personnel

What is it like to date an electrical engineer?

Public class video on Siemens S7-300/400 STL language indirect addressing (16-bit pointer, 32-bit pointer)

How is working in industrial control? Is it easy? Does it make money? Unified answer!