Click on the ” Technical Training ” above, and select “Pin to Top“

150,000+ industrial control professionals follow this WeChat platform: technical sharing, learning exchanges, industrial control videos

As PLC and DCS have developed to this point, especially the line between large PLCs and DCS has become increasingly blurred, their concepts are becoming more and more ambiguous. If a PLC is miniaturized, it still follows traditional control methods. Large PLCs not only introduce DCS control functions based on their own control capabilities but are also increasingly完善.

Early PLCs developed from relay control circuits and did not have the capability to process analog signals; they primarily excelled at logical operations. DCS developed from the foundation of instrument panels, lacking the capability for logical operations and focusing on the control of analog instruments, with distributed control systems (DCS) managing centrally while controlling decentralized.

Due to long-standing perceptions, in smaller automated control environments, such as equipment, a small number of analog signals, and interlocks, there is still a tendency to prefer PLCs, whereas DCS is used for the opposite. Some people also tend to refer to control systems with more than 600 control points as DCS, but this is too absolute at present, as PLCs can also achieve this.

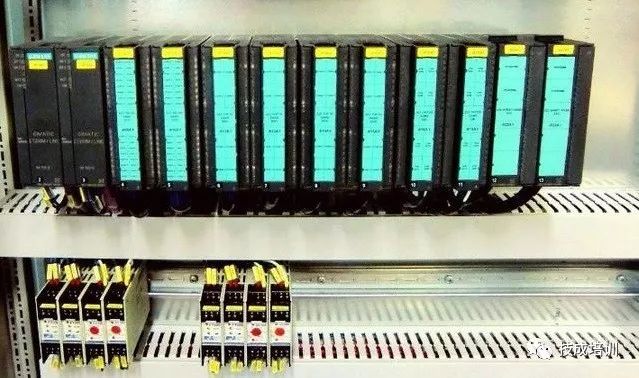

Currently, among large PLCs, significant models include Siemens S7-400, Yokogawa’s FA-MA3, Schneider’s Quantum, etc. They not only possess analog control capabilities but are also quite powerful. Conversely, DCS has also gained strong logical operation processing capabilities.

In conclusion, as of now, PLCs can be miniaturized or maximized, allowing for flexibility in industrial applications, while DCS has always been a large-scale product since its inception. Therefore, it can be said that in large automated control scenarios, its position remains difficult to shake. Since both currently possess each other’s functions and control methods, the choice of use depends on personal subjective preferences.

If there are any shortcomings in this article, feel free to leave a message to supplement. Let’s improve together!

If you like it, be sure to share

Click on Read the Original to learn about electrical engineering, PLC, frequency servo, CNC robots, and more.