In recent years

With the rise of global smart manufacturing, the Industrial Internet of Things (IIoT) has been developing rapidly in various fields as one of the paths to smart manufacturing. Service providers and integrators are emerging in droves, and various conferences and experts are constantly appearing, making it a feast for the eyes.

However, the actual implementation of the Industrial IoT is not commonly seen. What benefits can the Industrial IoT bring? What core products and technologies are required? Today, we will analyze a practical case of Industrial IoT application – Michelin’s IoT-based tire pressure monitoring system for transport vehicles, and see how it achieves IIoT.

Identifying the Need

This is an application case in Japan. In Japan, with the increasing aging population, the logistics industry faces a serious shortage of drivers, making it increasingly important to enhance transportation efficiency.

To address this, Michelin Tire Company and SoftBank Group collaborated to develop the Michelin Tire Pressure Monitoring System (TPMS) for fleet management and construction.

The system uses tire monitoring data to predict potential vehicle failure issues in advance, helping drivers avoid accidents and unsafe driving situations. With automatic tire monitoring, drivers can focus more on driving operations, and fleet operators can better manage vehicle maintenance, thereby improving road safety and operational efficiency.

Goals to Achieve

Reduce accidents: Prevent dangerous driving situations caused by improper tire inflation.

Minimize vehicle downtime: Avoid time loss due to tire leaks.

Solutions

• Michelin Tire Monitoring System:This system continuously monitors the tire pressure and temperature of vehicles, and if problems arise, it will alert fleet management personnel, Michelin tire suppliers, and the Michelin rescue network.

• Cloud Services:The TPMS checks for under-inflation, as under-inflation can cause tires to overheat, increasing the likelihood of tire damage and blowouts. Tire sensors send pressure and temperature data to Advantech’s gateway, which then transmits the data to SoftBank’s cloud service via SoftBank’s mobile network.

When the tire pressure or temperature exceeds its preset standard limits, the cloud service sends alert information, including vehicle number, location, and tire data, to fleet management personnel monitoring the tires via mobile phones, tablets, or personal computers, as well as call centers and roadside assistance teams.

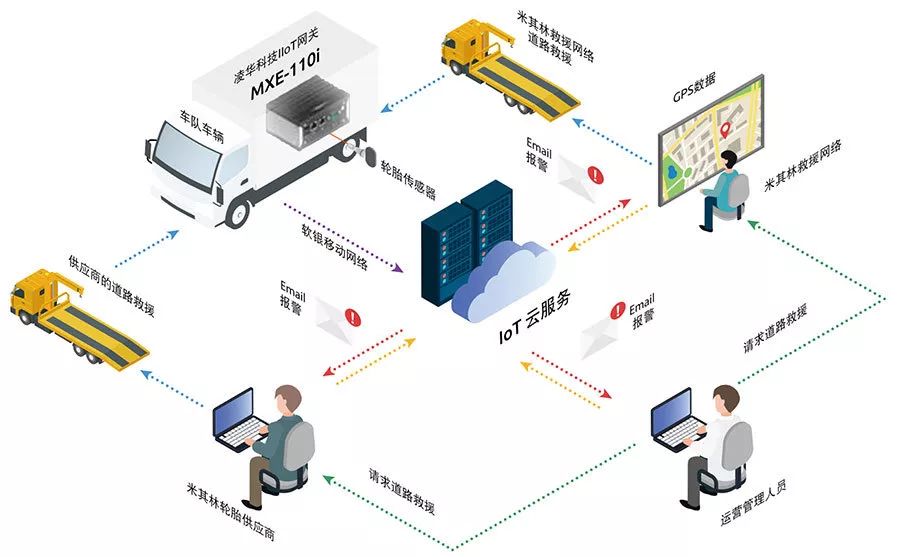

As shown in Figure 1, after receiving the alert, fleet management personnel will send a roadside assistance request to Michelin’s tire suppliers or Michelin’s rescue network. Urgent roadside assistance will be quickly dispatched to the vehicle’s location to address the relevant tire issues.

Figure 1. Communication Flowchart of Michelin Tire Monitoring System

• Industrial IoT Gateway:The gateway is installed on the vehicle to collect sensor data installed in the tires and transmit the data to Michelin’s tire detection system via SoftBank’s mobile network.

For this solution, Advantech’s MXE-110i Industrial IoT Gateway was selected. This gateway features a rugged fanless architecture that can withstand the harsh environments of commercial vehicle operation, such as higher vibrations and shocks, dust, electromagnetic interference (EMI), and extreme temperature ranges (-20°C to +70°C). The gateway also has low power consumption and a compact design, making it ideal for integration into trucks and other vehicles where power and space are limited.

For this IoT-related tire application, the gateway plays a role in data collection and remote monitoring, connecting to Michelin’s TPMS sensors via RS-232 interface and communicating via SoftBank’s 3G/4G cellular network. The MXE-110i is suitable for various Industrial IoT (IIoT) applications, such as smart cities, facility management, and industrial automation, and supports a rich set of I/O interfaces: 2x 10/100M GbE, 2x COM, 2x USB 2.0 host ports, 2 mini PCIe slots, and a micro-SIM slot for wireless connections (supporting Wi-Fi, Bluetooth, LoRa, and 3G/4G/LTE communications).

Figure 2. Advantech MXE-110i can connect to numerous sensors to collect data necessary for safe driving and improving operations

Business Value

Enhanced driving safety: This solution helps reduce the occurrence of accidents through proactive tire maintenance.

Higher production efficiency: Tire issues can be predicted in advance, avoiding long, costly, unplanned vehicle downtime, thereby enhancing the productivity of vehicles and drivers.

Benefits and Expansion of the Case

Currently, Michelin and SoftBank have begun offering the “Michelin Tire Pressure Monitoring System (TPMS) Cloud Service” in Japan.

With this remote tire control system based on Advantech’s MXE-110i Industrial IoT Gateway, Michelin aims to minimize vehicle downtime and improve efficiency in the logistics industry. Tire information can also be used to prevent low fuel consumption and excessive wear on traction systems and treads, all caused by under-inflation.

The system’s flexibility and versatility allow it to handle various mobile assets and vehicles, including campers, light trucks, heavy vehicles, trailers, and buses. SoftBank is also expected to launch similar IoT solutions for shared vehicles and autonomous cars.

– end –

Point

For more information about this case, click “Read the original text” to apply for downloading the case white paper!