Industrial robots are multi-joint mechanical arms or multi-degree-of-freedom robots aimed at the industrial field.Industrial robots replace humans in production and are an important development trend in the future manufacturing industry, serving as the foundation for achieving intelligent manufacturing and ensuring future industrial automation, digitization, and intelligence.The harsh production and processing environment , the aging population leading to labor shortages , and high training costs for workers are driving the growth in demand for industrial robots.

Today

let’s learn about

The Basic Composition and Classification of Industrial Robots

It’s packed with useful information!

Basic Composition of Industrial Robots

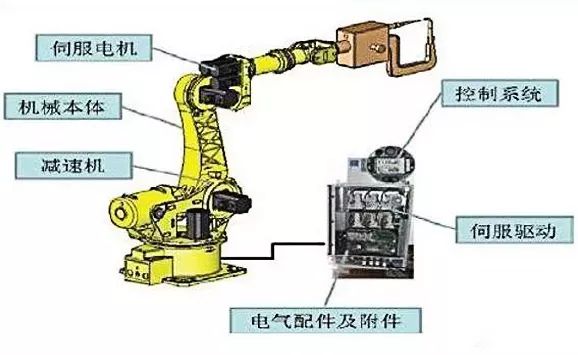

Industrial robots consist of main body, drive system, control system, three basic parts.

-

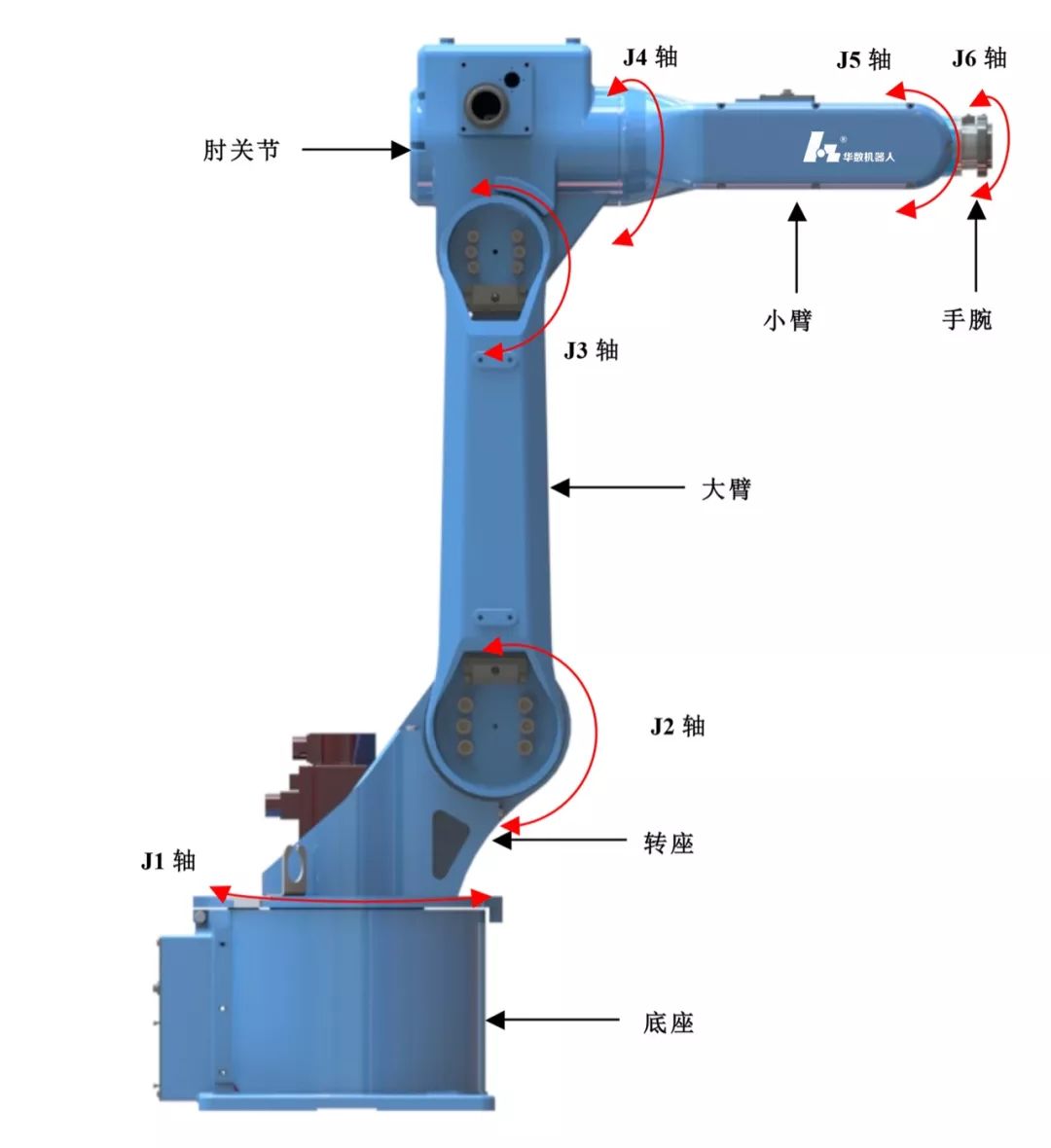

Main Body: This includes the base and the actuators, comprising the arm, wrist, and hand. Some robots also have a walking mechanism. The wrist part is also known as the end effector interface, where grippers, tools, sensors, etc., can be installed.

-

Drive System: This includes the power unit and transmission mechanism, used to make the actuators perform corresponding actions.

-

Control System: This sends command signals to the drive system and actuators according to the input program, controlling the industrial robot to act as required.

Classification of Industrial Robots

Classification by Joint Coordinate Form

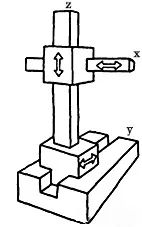

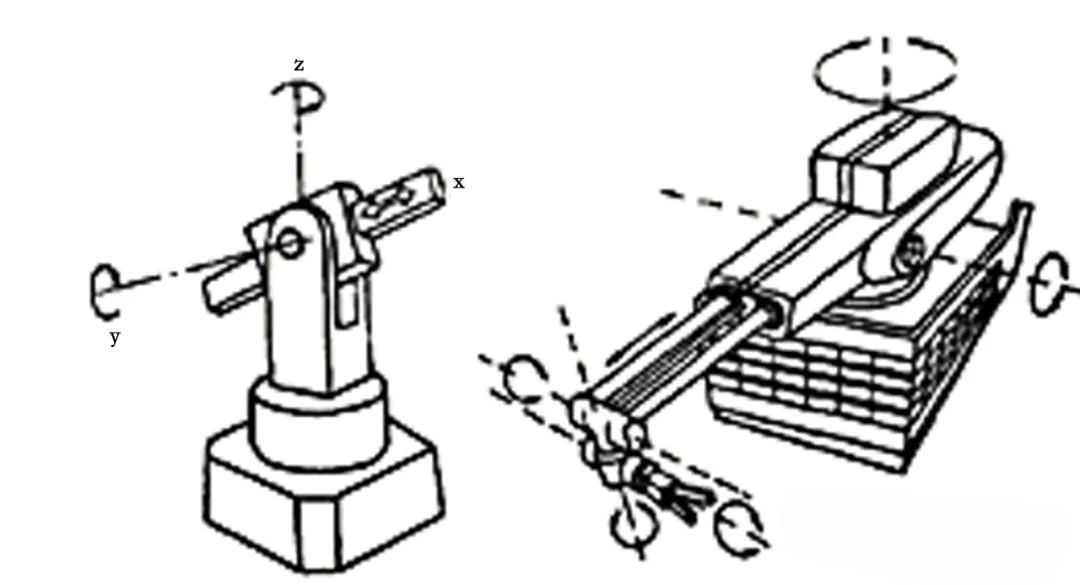

Cartesian Coordinate Robot (PPP)

The Cartesian coordinate robot, also known as a single-axis manipulator, changes the spatial position of its end effector (hand) by moving along three mutually perpendicular coordinates x, y, and z axes.

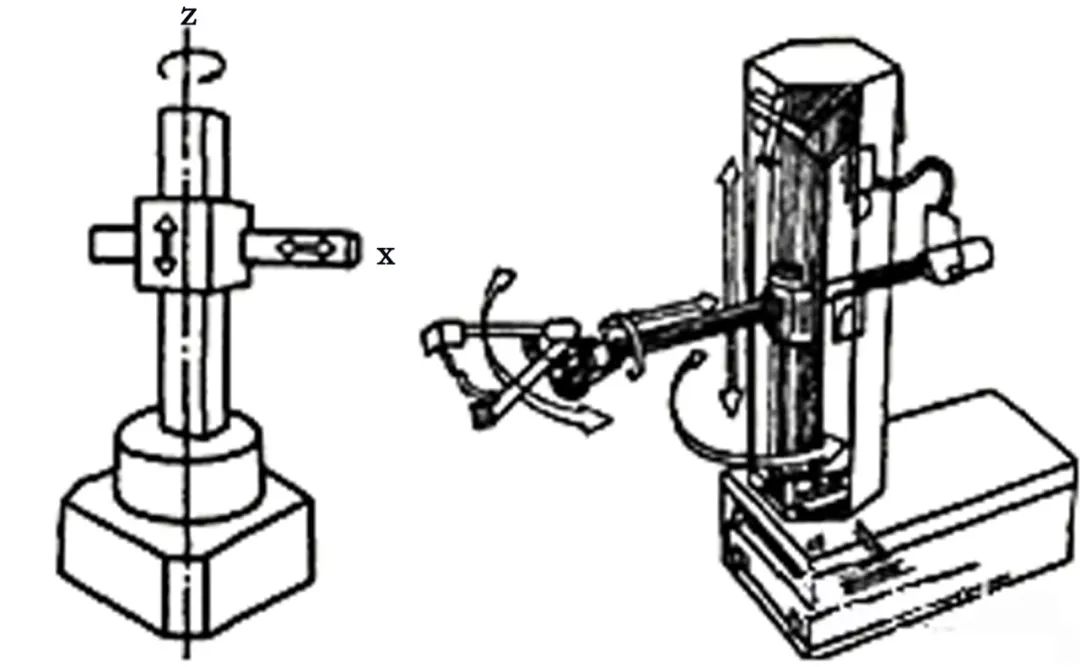

Cylindrical Coordinate Robot (RPP)

Spherical Coordinate Robot (RRP)

Joint Robot (RRR)

In addition, joint robots can also be classified according to their working nature, such as handling robots, palletizing robots, welding robots, painting robots, laser cutting robots, etc.

Classification by Robot Axes

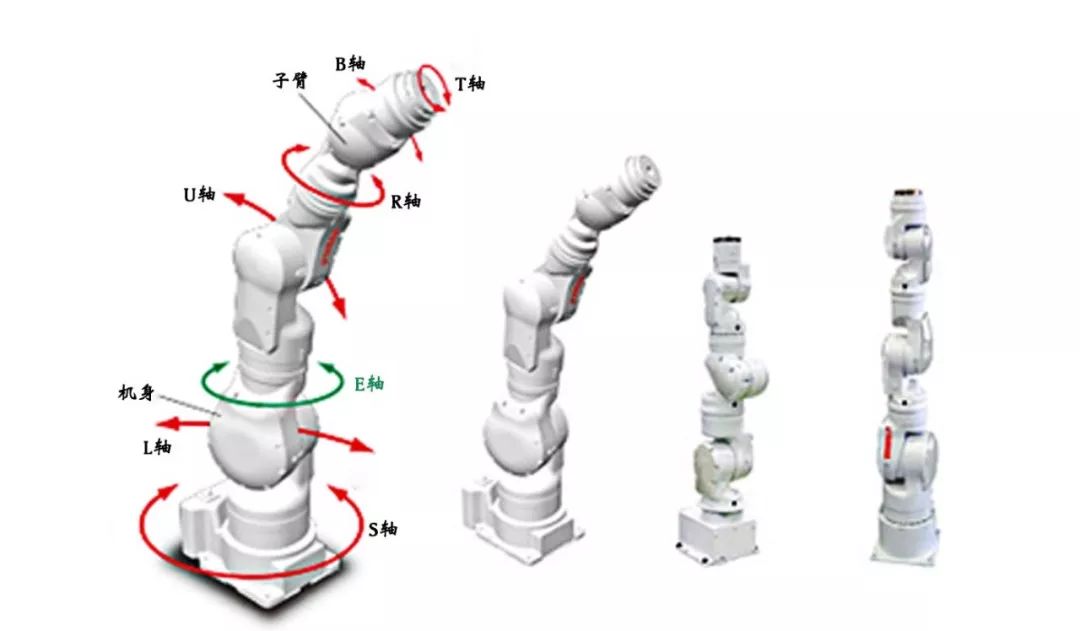

Traditional Six-Axis

Six-axis robots have 6 serially connected rotating joints, and traditional six-axis robots are divided into general-purpose six-axis robots and special-purpose six-axis robots.

Seven-Axis Robot

Also known as redundant robots. Compared to six-axis robots, the additional axis allows the robot to avoid certain specific targets, making it easier for the end effector to reach specific positions and adapt more flexibly to certain special working environments.

Collaborative Robot

Abbreviated as cobot or co-robot, it is a robot that can safely interact/contact directly with humans. Collaborative robots can combine the precision and repeatability of robots with the unique skills and abilities of humans, where humans excel at solving imprecise and ambiguous problems, while robots have advantages in precision, strength, and durability.

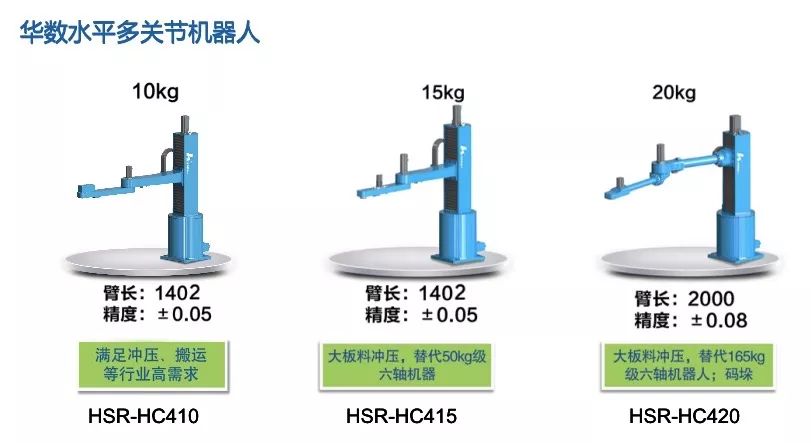

Four-Axis/SCARA Robot

Four-axis robots refer to “Selective Compliance Assembly Robot Arm”; the arm part of the four-axis robot can move freely in a geometric plane, i.e., it has translational freedom in the X, Y, Z directions and rotational freedom around the Z-axis.

Delta Parallel Robot

Delta robots are high-speed, lightweight parallel robots, generally capturing target objects through teaching programming or vision systems, determining the spatial position of the gripper center (TCP) with three parallel servo axes to achieve operations such as transporting and processing target objects.

Classification by Control System

Classification by Feedback

Divided into open-loop control and closed-loop control

Classification by Desired Control Quantity

Force control is divided into: direct force control, impedance control, and force-position mixed control

Position control is divided into: single-joint position control (position feedback, position speed feedback, position speed acceleration feedback), multi-joint position control (decomposed motion control, centralized control)

Classification by Intelligent Control

Divided into fuzzy control, adaptive control, optimal control, neural network control, fuzzy neural network control, expert control

In the current context of Industry 4.0 and Intelligent Manufacturing 2025, “machine replacing humans” has become an inevitable trend, and industrial robots are hailed as the “jewel on the crown of manufacturing”. Robotics engineers are increasingly becoming high-demand and high-paying professions. If you want to earn a high salary and enter a prestigious company, becoming a robot automation engineer is a great choice!

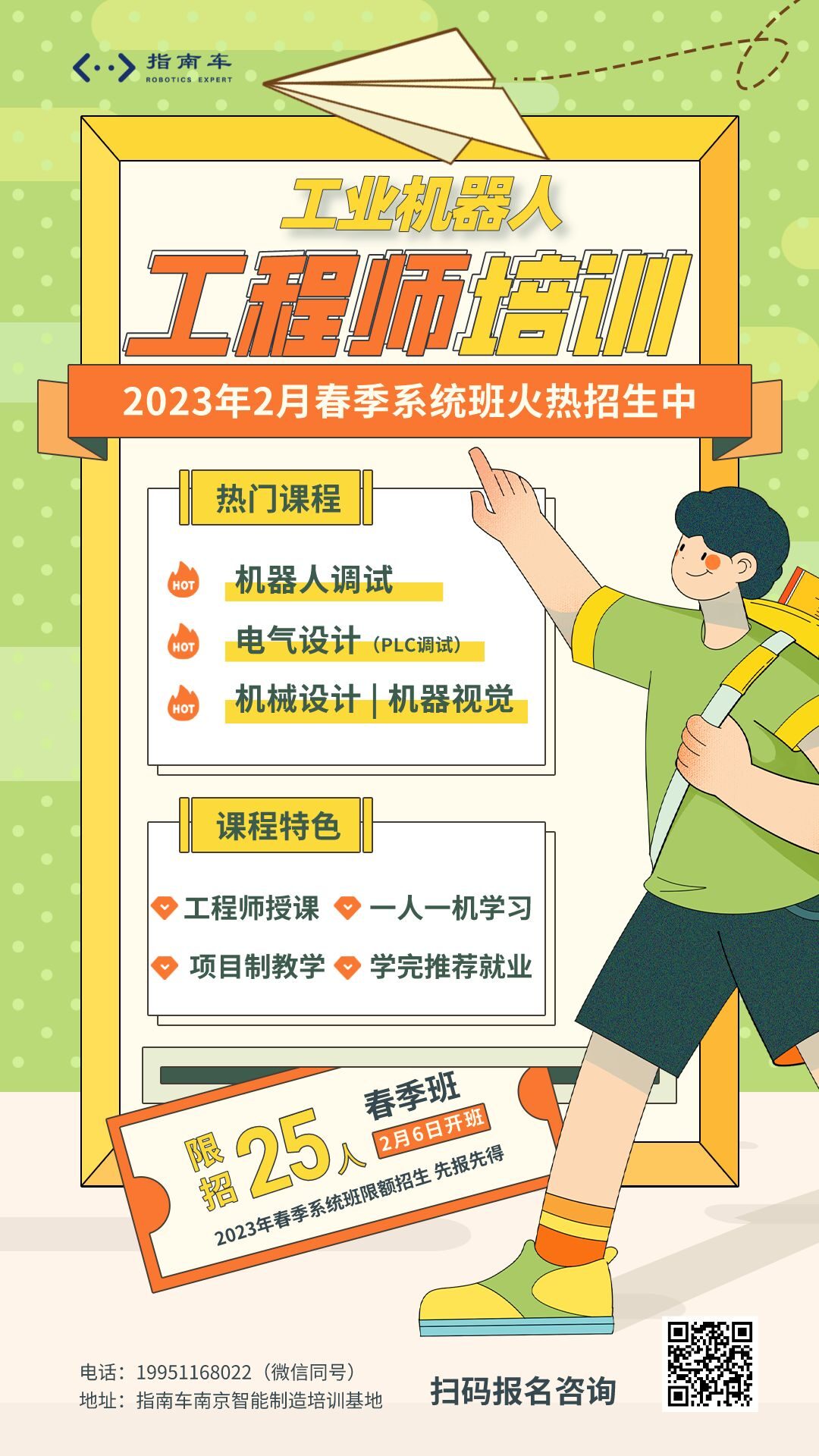

The Spring 2023 System Class at Guide Car is now enrolling…

↓ Click to read the original text to register and inquire about the robot course