With the rapid development of wearable electronic devices, thermoelectric technology has gained attention for its ability to convert low-grade thermal energy from the human body or the environment into electrical energy. Traditional electronic thermoelectric materials (such as inorganic semiconductors and conductive polymers) are limited by low thermoelectric potentials (usually below 10 µV K⁻¹) and rigid structures, making it difficult to meet the flexible and lightweight requirements of wearables. Ionic thermoelectric materials (i-TE) achieve efficient thermal-to-electric conversion through the Soret effect and redox effects via ionic migration, but their core electrolytes (such as hydrogels) face issues like dehydration and poor thermal stability, limiting long-term stability. Therefore, developing solid-state electrolytes with high environmental stability and excellent thermoelectric performance has become a key challenge.The team of Shen Guozhen and Li La from Beijing Institute of Technology proposed an ultra-thin wearable ionic thermoelectric patch (i-TE paster) based on a bionic structure inspired by “onion epidermal cells”. Its core is a fully solid-state organic ion gel electrolyte (PVDF-HFP-PEO gel), supported by a porous polymer framework, which, combined with the synergistic effects of thermal expansion and the Soret effect, significantly enhances thermoelectric performance. The thermoelectric figure of merit (ZT) of this electrolyte reaches 0.35, close to that of traditional inorganic semiconductor materials (0.4), and it exhibits high mechanical flexibility (breaking elongation of 251.3%) and thermal stability (negligible mass loss at 50°C). The patch uses polyaniline-modified carbonized PI electrodes (PANI-C@PI), which form a pyramidal conductive structure through laser sintering, increasing the electrode-electrolyte contact area, achieving a high Seebeck coefficient of 28 mV K⁻¹ and an energy conversion efficiency of 1.3%. The device thickness is only 0.197 mm, allowing it to closely adhere to the skin, successfully applied in thermal energy harvesting, material identification, contact/non-contact temperature detection, and photothermal conversion. The related literature titled “An Ultra-Thin Wearable Thermoelectric Paster Based on Structured Organic Ion Gel Electrolyte” was published in Nano-Micro Letters, with Dr. Du Zhijian as the first author.

Figure Analysis

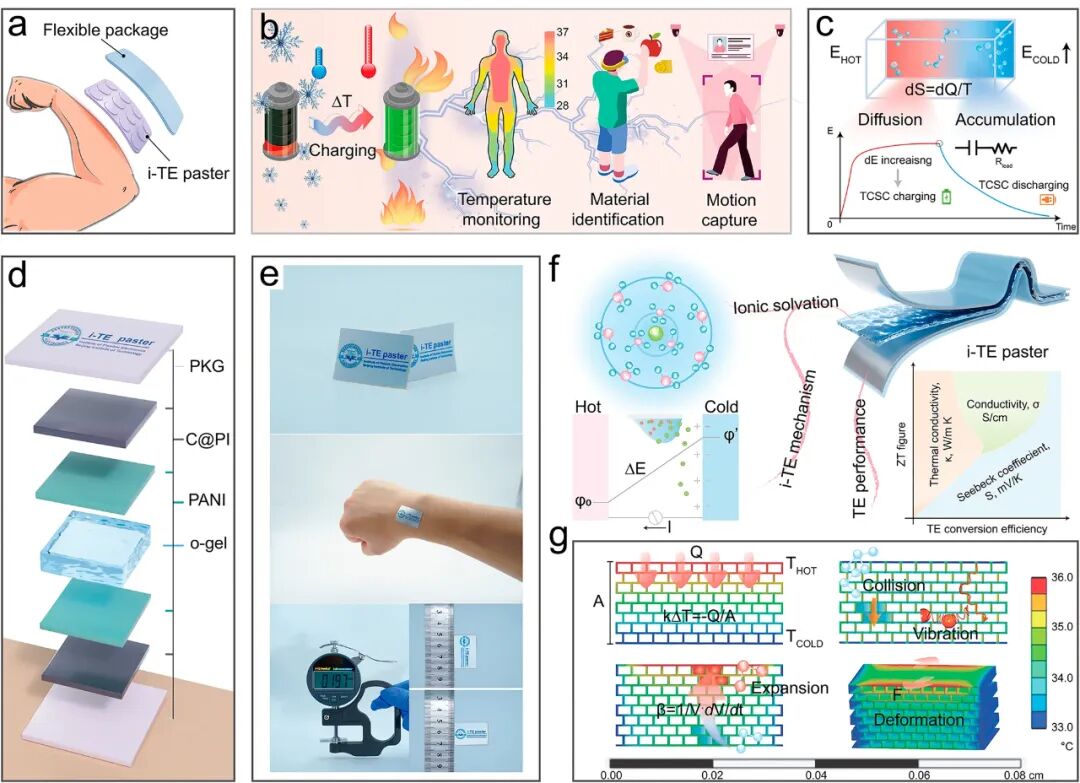

Figure 1 Design and Working Mechanism of the Wearable i-TE Patch

The patch adopts a symmetric “sandwich” structure (with the electrolyte layer sandwiched between two electrodes), with a thickness of only 0.197 mm, achieving efficient heat conduction and mechanical stability through a bionic porous framework. Animal experiments show that the patch has no inflammatory response, meeting medical standards. Finite element analysis (FEA) simulated thermal strain phenomena, verifying the rationality of the structural design.

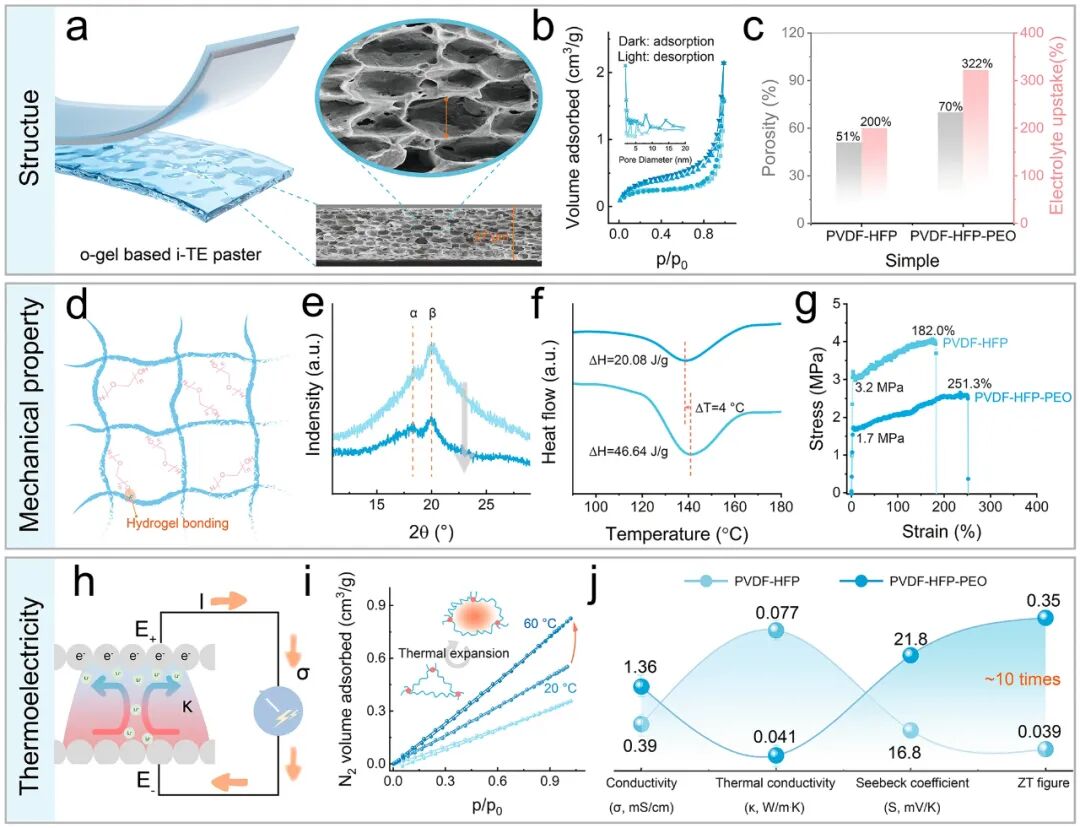

Figure 2 Comparison of Structure and Performance of PVDF-HFP-PEO Electrolyte

Characterization through SEM, XRD, and DSC revealed that the crystallinity of PVDF-HFP decreased and porosity increased (nitrogen adsorption increased by 50%) after copolymerization with PEO, with thermal conductivity reduced to 0.12 W m⁻¹ K⁻¹. The introduction of PEO increased the electrolyte’s conductivity to 1.8 S m⁻¹, with a Seebeck coefficient of 18 mV K⁻¹, and the ZT value improved nearly tenfold compared to pure PVDF-HFP gel.

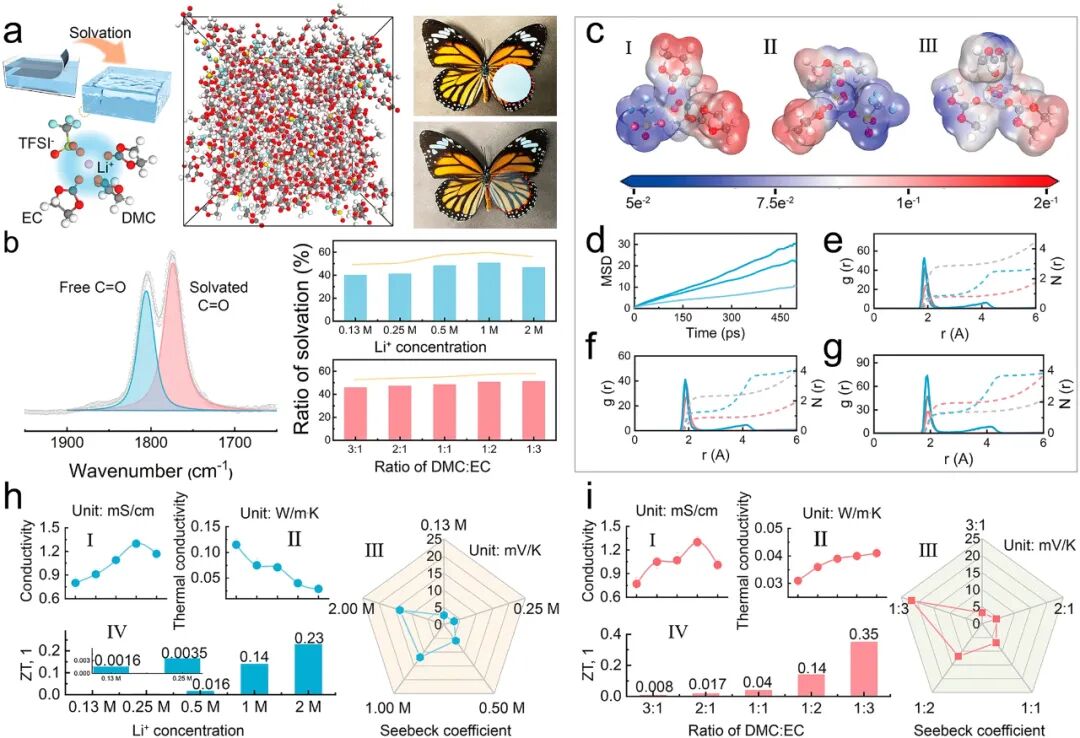

Figure 3 Impact of Electrolyte Composition on Thermoelectric Performance

Through FT-IR and molecular dynamics simulations, the effects of lithium salt concentration (LiTf) and solvent ratio (DMC:EC) on ionic solvation effects were analyzed. A 1 M LiTf mixed solvent system with DMC:EC=1:2 exhibited optimal ionic mobility (activation energy Eₐ=0.15 eV), with conductivity reaching 2.1 S m⁻¹ and ZT value increasing to 0.35.

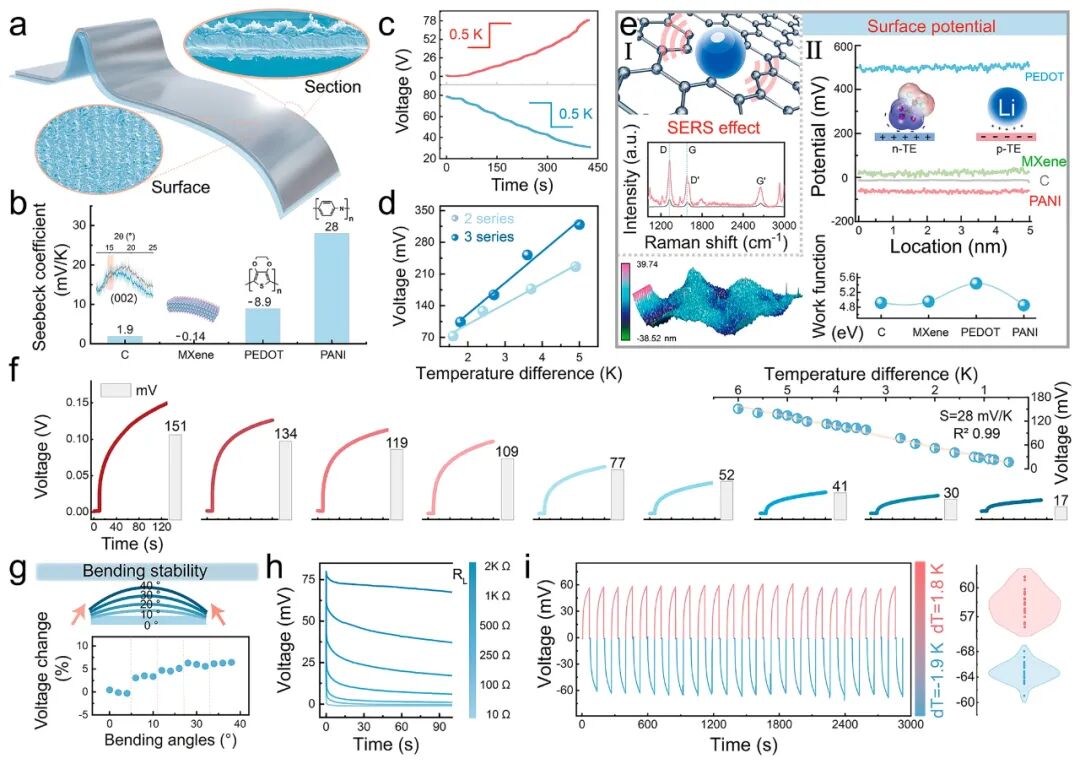

Figure 4 Optimization of PANI-C@PI Electrode and Device Output Performance

The carbonized PI electrode prepared by laser sintering has a pyramidal porous structure, and after PANI modification, the number of adsorption sites increased, with a significant negative shift in surface potential (-0.45 V). The device achieved a Seebeck coefficient of 28 mV K⁻¹, which increased to 71.2 mV K⁻¹ after connecting three components in series. Bending tests showed that output voltage fluctuations were less than 5%, with excellent charge-discharge cycle stability (fluctuation <3% after 20 cycles).

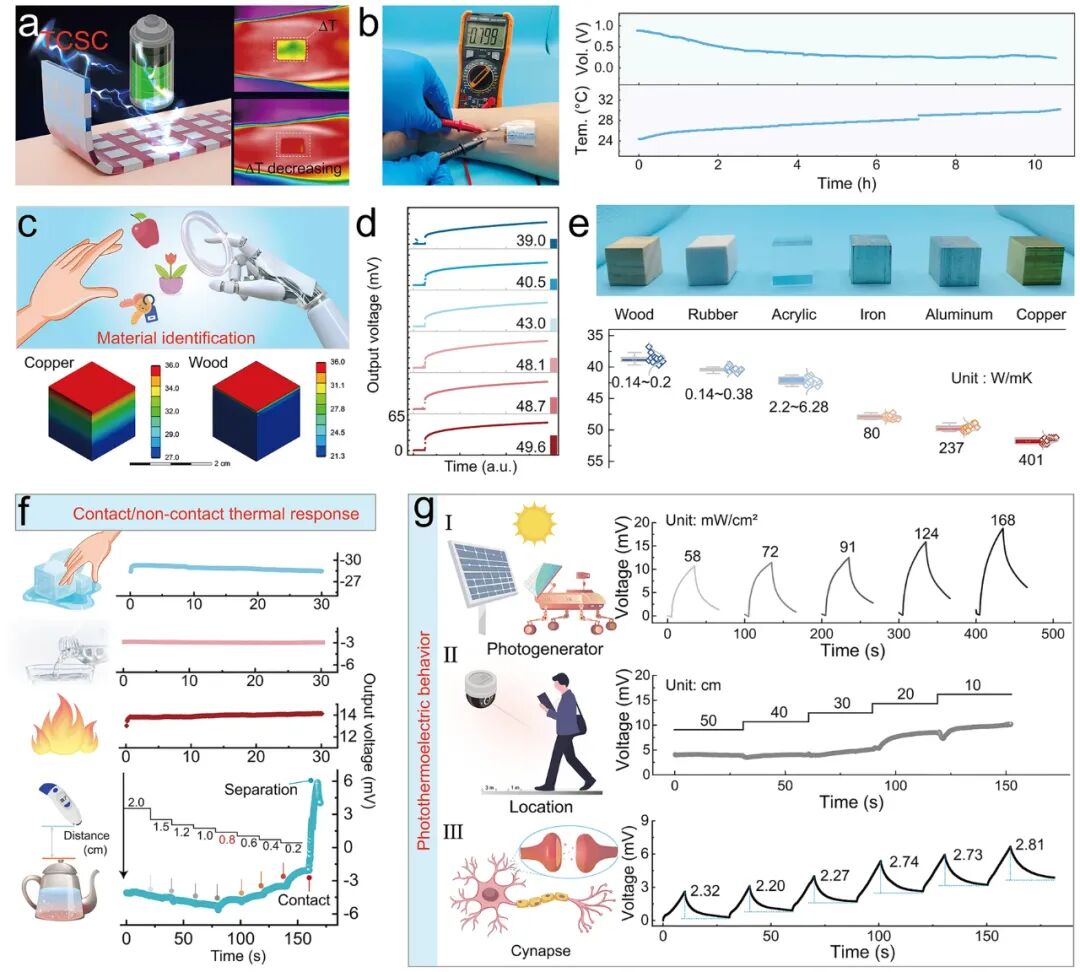

Figure 5 Validation of Multi-Scenario Applications of i-TE Patch

The patch, as a thermal charging supercapacitor (TCSC), can collect thermal energy from human skin (output -0.35 V at ΔT=3 K) and achieve material identification (voltage difference of 4.5 mV between copper and wood). In non-contact temperature detection, an 80°C heat source triggered an alarm within 0.8 cm distance, and photothermal response (925 nm red light) supports distance perception and synaptic simulation.

Summary and Outlook

This study developed an ultra-thin wearable ionic thermoelectric patch based on PVDF-HFP-PEO gel through a bionic “onion epidermal cell” structure design, addressing the issues of poor thermal stability and interface contact in traditional hydrogels. The synergistic effect of the porous polymer framework and PEO significantly enhanced ionic mobility and thermal expansion effects, achieving a ZT value of 0.35, comparable to inorganic thermoelectric materials. The PANI-modified carbonized PI electrode optimized through surface defects and adsorption sites achieved a high Seebeck coefficient of 28 mV K⁻¹ and excellent mechanical stability (performance fluctuation <5% at a bending angle of 40°). The device thickness is only 0.197 mm, with both biocompatibility and environmental tolerance, successfully applied in thermal energy harvesting, smart material identification, non-contact temperature detection, and photothermal conversion, providing an innovative solution for self-powered wearable electronics. Its core innovation lies in combining bionic structural design with ionic solvation effects, breaking through the performance bottleneck of ionic thermoelectric materials in flexible devices, showcasing broad application prospects.

Original link:

https://doi.org/10.1007/s40820-025-01721-4

Gel Labgazing at original articles. Personal forwarding and sharing are welcome. For reprints by publications or media, please contact via email:[email protected]

Research scholars are welcome to submit manuscripts (papers, project introductions, new technologies, academic exchanges, unit news, conference information, recruitment, etc.) to[email protected], and please indicate detailed contact information.

Disclaimer: The information is sourced from the internet, and the purpose of reprinting is to convey more information and share. It only provides a communication platform and is not responsible for copyright. If there is any infringement, please contact us for timely modification or deletion. Original articles are welcome for personal forwarding and sharing; for reprints by publications or media, please contact us.