In February 2025, the third article in the field of 3D printing technology was published in Additive Science. Dr. Shengduo Xu, a Chinese scholar from the Austrian Institute of Science and Technology, is the first author of the article titled “Interfacial bonding enhances thermoelectric cooling in 3D-printed materials.” The researchers successfully prepared a high-performance thermoelectric material using extrusion 3D printing technology combined with interfacial bonding optimization strategies, and assembled a cooling device capable of achieving a temperature difference of 50°C in air.

In February 2025, the third article in the field of 3D printing technology was published in Additive Science. Dr. Shengduo Xu, a Chinese scholar from the Austrian Institute of Science and Technology, is the first author of the article titled “Interfacial bonding enhances thermoelectric cooling in 3D-printed materials.” The researchers successfully prepared a high-performance thermoelectric material using extrusion 3D printing technology combined with interfacial bonding optimization strategies, and assembled a cooling device capable of achieving a temperature difference of 50°C in air. https://www.science.org/doi/10.1126/science.ads0426

https://www.science.org/doi/10.1126/science.ads0426

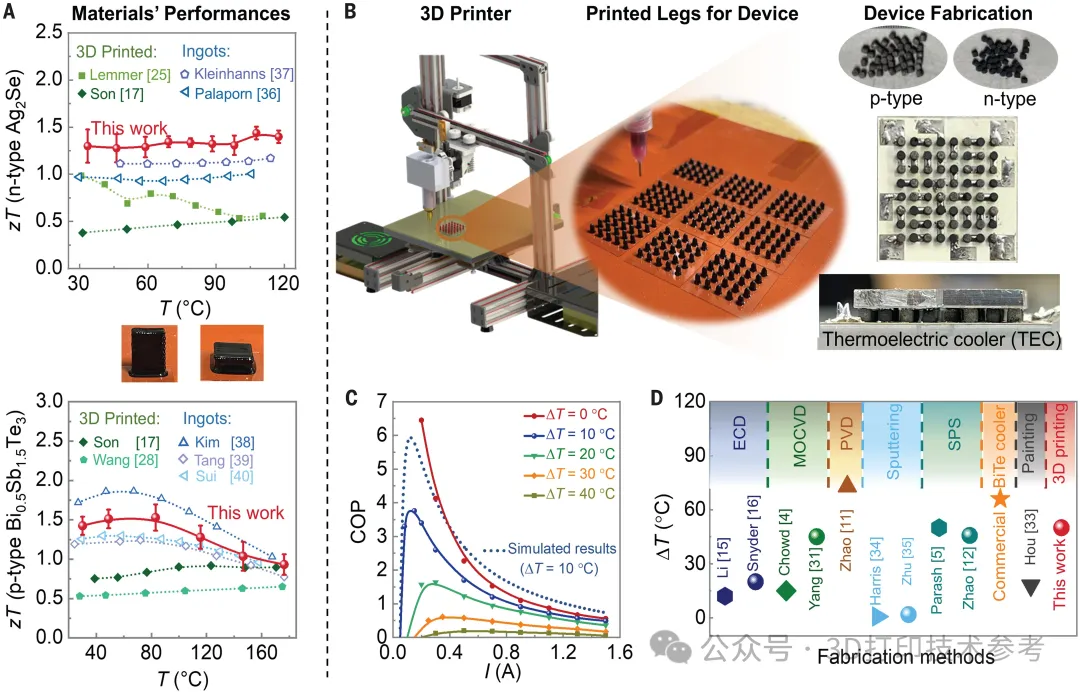

Currently, 3D printing technology can produce thermoelectric materials, but the performance of the products is still lower than that of ingots produced by traditional methods. This is mainly limited by factors such as poor internal grain connectivity of the materials and the complexity of optimizing high-performance materials in conjunction with efficient device engineering.

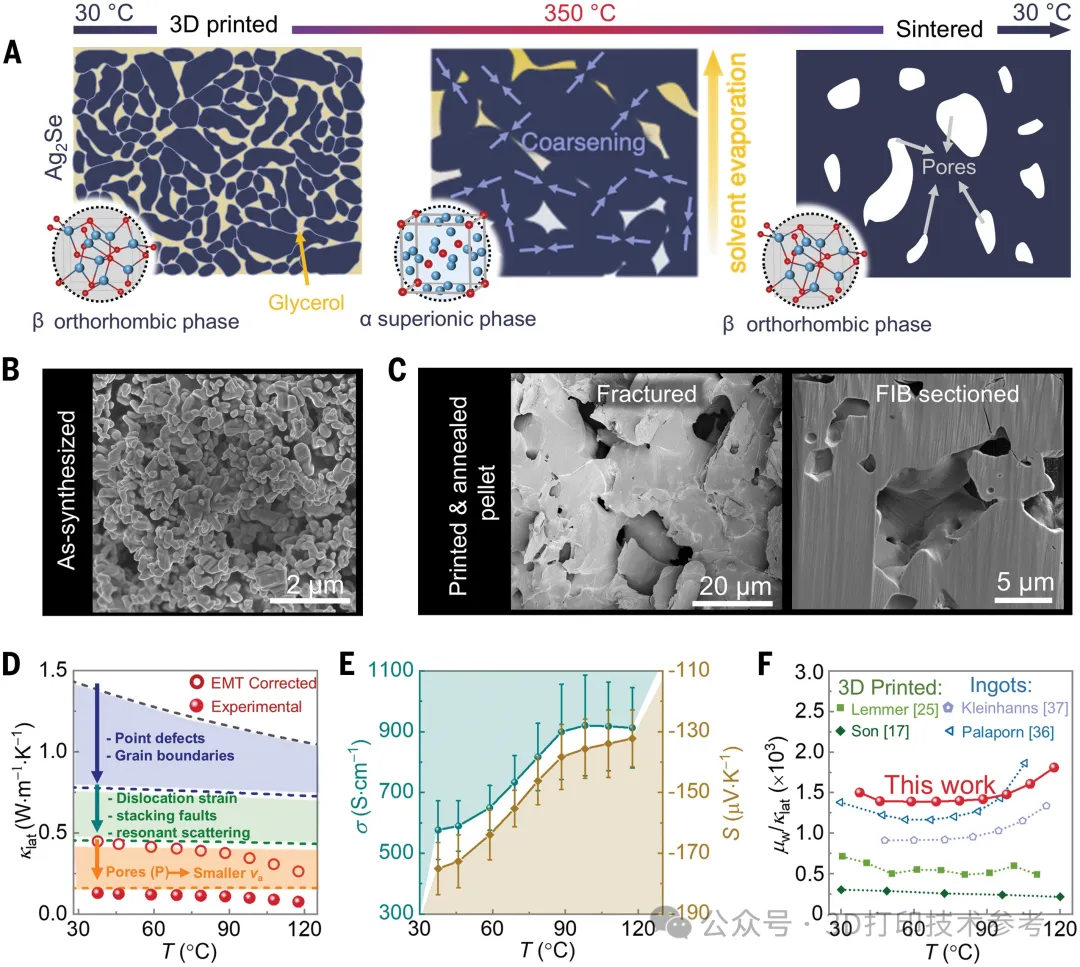

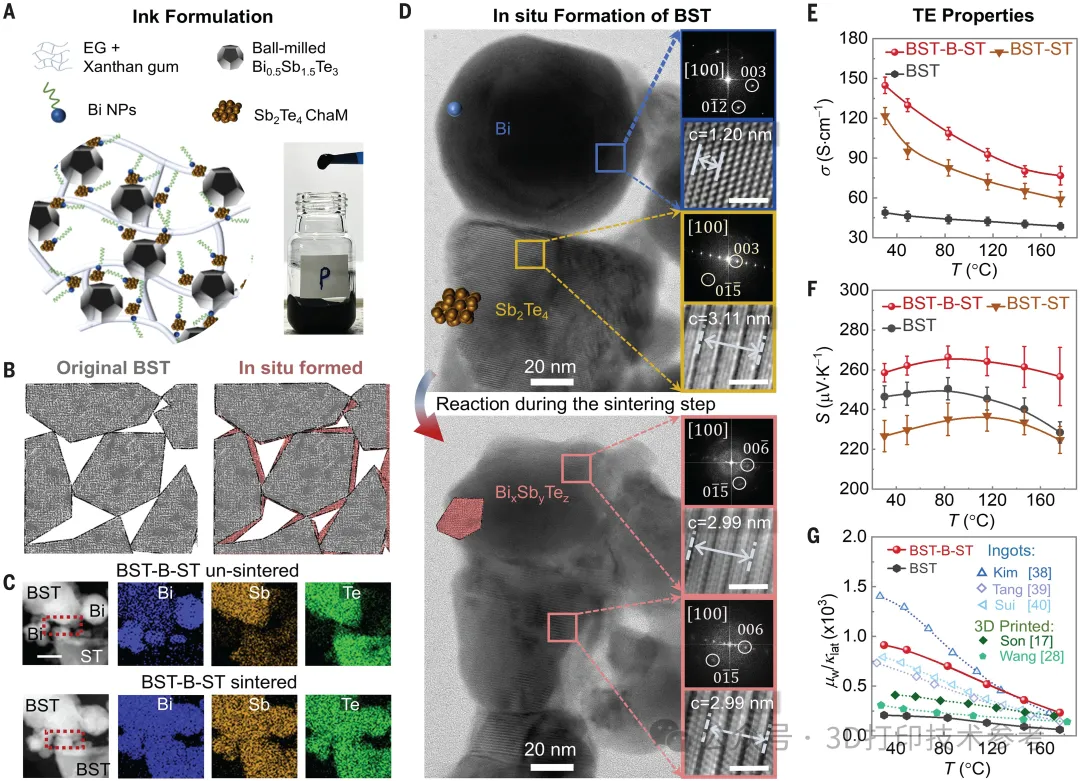

The purpose of this research is to construct thermoelectric cooling devices based on high-performance thermoelectric materials to achieve efficient and stable cooling effects. The researchers selected (Bi,Sb)2Te3-based thermoelectric materials and Ag2Se thermoelectric materials as research subjects, both of which are ideal materials for manufacturing thermoelectric cooling devices. By designing and optimizing ink formulations, and using extrusion 3D printing technology, it is possible to directly print high-performance thermoelectric materials and improve the interfacial bonding effects between particles during the post-sintering process.

Synthesis process and performance

3D printing preparation process

3D printing preparation process

Porous microstructure and thermoelectric performance of 3D printed Ag₂Se

Improving the thermoelectric performance of BST-B-ST by forming interfacial bonding between grains

Applicable for Manufacturing Cooling Systems for Wearable Devices

Applicable in medical fields such as burn care and muscle strains

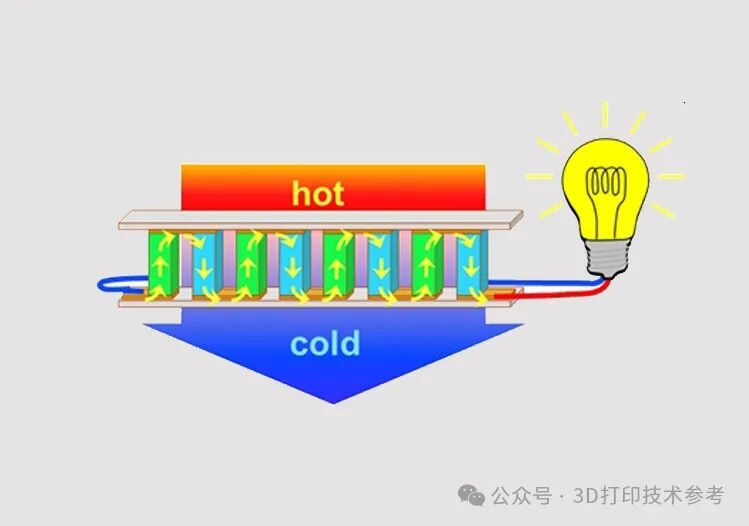

Applicable in medical fields such as burn care and muscle strains This technology can be used to manufacture thermoelectric power generation components.News commentary points out that the breakthroughs brought by this research can significantly reduce the production costs of thermoelectric materials, and the products manufactured with this technology have reached commercial-grade performance levels. In terms of applications, 3D printing technology references note that the results of this research can play a role in the cooling systems of electronic products and wearable devices, and can also be used in medical fields such as burn care and muscle strains; additionally, it can be used to manufacture thermoelectric generators with higher efficiency, maximizing the conversion of industrial waste heat into electricity. Therefore, this research has not only strong academic value but also great potential for rapid practical application.Note:This article is created by 3D Printing Technology Reference and is not authorized for reproduction without contact..Welcome to share

This technology can be used to manufacture thermoelectric power generation components.News commentary points out that the breakthroughs brought by this research can significantly reduce the production costs of thermoelectric materials, and the products manufactured with this technology have reached commercial-grade performance levels. In terms of applications, 3D printing technology references note that the results of this research can play a role in the cooling systems of electronic products and wearable devices, and can also be used in medical fields such as burn care and muscle strains; additionally, it can be used to manufacture thermoelectric generators with higher efficiency, maximizing the conversion of industrial waste heat into electricity. Therefore, this research has not only strong academic value but also great potential for rapid practical application.Note:This article is created by 3D Printing Technology Reference and is not authorized for reproduction without contact..Welcome to share

Industry expert communication groupQ group:248112776

Further reading:

1. Dr. Li Fangzheng: Five Major Characteristics of China’s Additive Manufacturing Industry Development

2. In the first quarter of 2025, China’s 3D printing equipment exports surged! 965,000 units and 2.35 billion yuan! Both increased by over 20%!

3. Investing 300 million, the Xi’an Jiaotong University team builds a precision medical biological 3D printing base!

4. From anti-static to flame-retardant: Fuzhi Technology launches four new 3D printing materials to meet multi-scenario needs