In flexible electronics, biosensors, and new energy devices, screen printing technology is widely used due to its low cost and scalability. One of the key parameters determining the performance of these printed electrodes is a seemingly unfamiliar term: sheet resistance (方阻).

1.What is Sheet Resistance?

Sheet resistance, measured in Ω/□ (ohms per square), describes the electrical conductivity of a material in a two-dimensional plane. Its core characteristic is that regardless of whether the side length of the square is 1 millimeter or 1 meter, as long as the material is the same and the thickness is consistent, the sheet resistance value remains the same.

For example, if a carbon paste is used to print a square electrode with a side length of 1 centimeter and its resistance is measured at 100 Ω, then its sheet resistance is 100 Ω/□. Even if the square is enlarged to 10 centimeters, the resistance remains 100 Ω because the number of “squares” in the current path increases in sync with the side length, canceling each other out.

For screen-printed electrodes, the formula for calculating sheet resistance is:R□=t/ρ (where: ρ is the resistivity of the material (Ω·m), and t is the thickness of the conductive layer in meters). This means that to reduce sheet resistance, one must either choose a material with lower resistivity (such as silver instead of carbon) or increase the printing thickness.

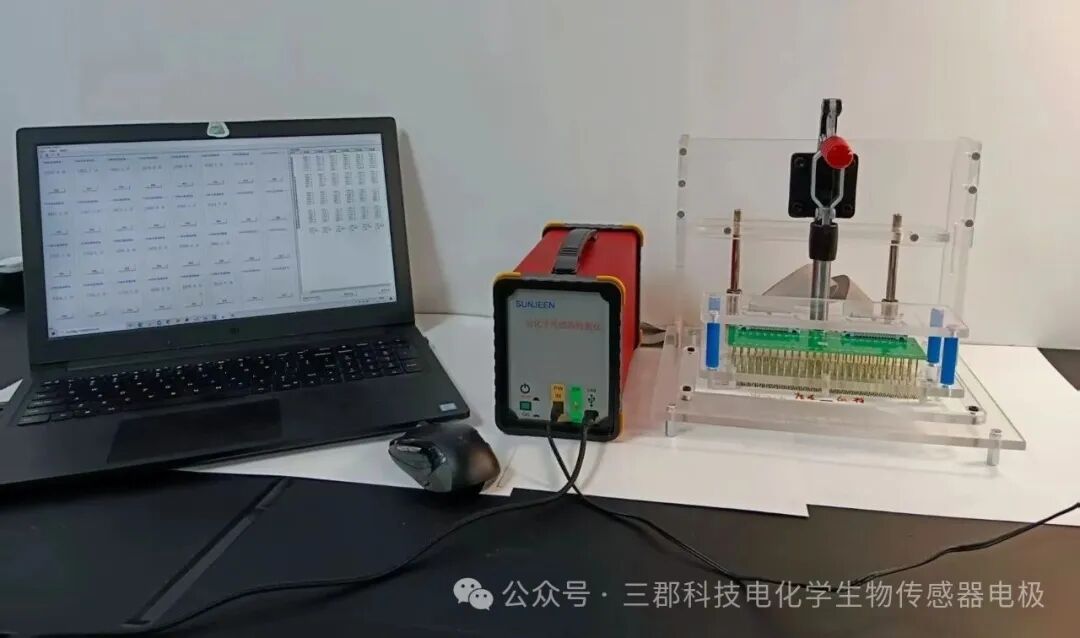

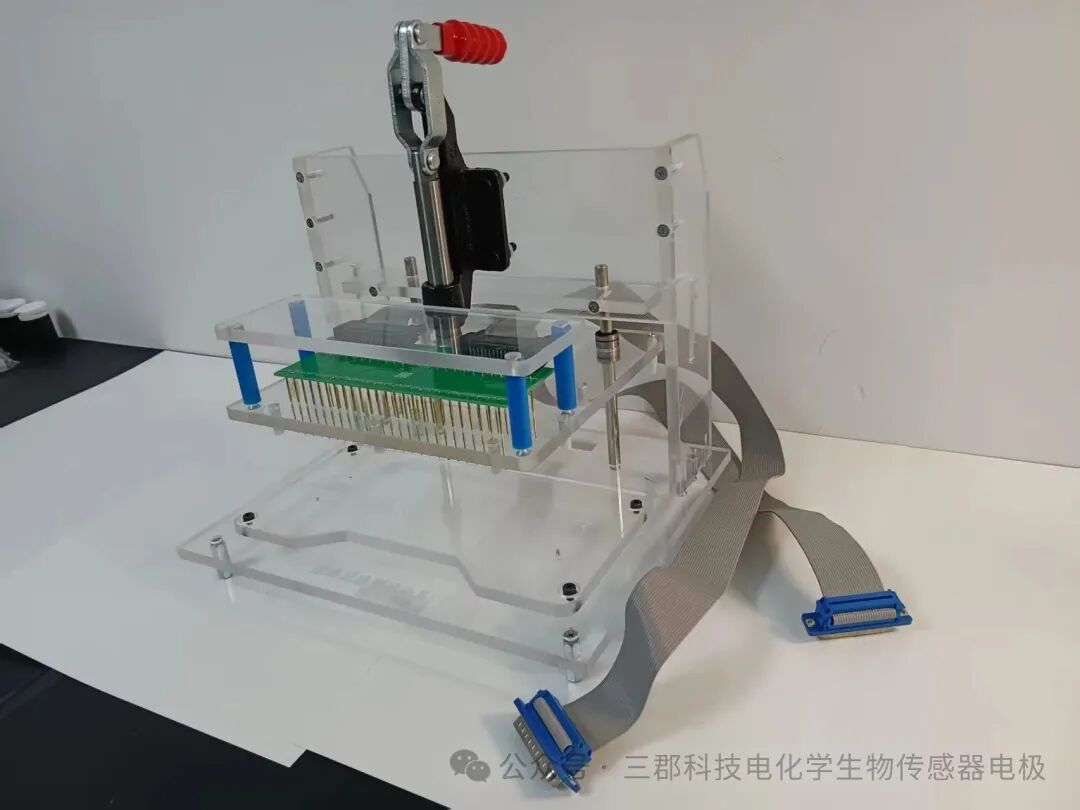

Sunjeen Technology’s electrochemical biosensor detection instrument (resistance detection)

Sunjeen Technology’s electrochemical biosensor detection instrument (resistance detection)

2. How Does Sheet Resistance Affect Practical Applications?

Electrochemical Sensors: Sensitivity Depends on Sheet Resistance Biosensors such as blood glucose test strips and heavy metal detectors rely on the conductivity of the electrodes. If the sheet resistance is too high (e.g., >500 Ω/□), weak current signals can be diminished, leading to detection errors. For instance, some low-cost carbon paste electrodes require the addition of silver particles to enhance performance due to high sheet resistance.

Flexible Electronics: Balancing Conductivity and Flexibility The flexible circuits in smart wristbands need electrodes to maintain low sheet resistance (e.g., <100 Ω/□) even when bent. Graphene ink can achieve a sheet resistance as low as 10Ω/□ and withstand over ten thousand bends, making it an ideal choice.

Sheet resistance is not simply a case of “the lower, the better.”

In applications, it is necessary to find a balance between electrode materials, detection scenarios, and process limitations, considering conductivity, noise suppression, and practicality.Common reference data includes:

-

Low sheet resistance (<50 Ω/sq): High current or high-frequency applications (e.g., energy storage, transparent electrodes).

-

Medium sheet resistance (50–200 Ω/sq): Biosensors, flexible electronics.

-

High sheet resistance (>200 Ω/sq): Environmental sensors with high surface modification requirements.

3. How to Optimize Sheet Resistance?Material Upgrades

Silver paste has a sheet resistance (0.1–1 Ω/□) that is far lower than that of carbon paste (10–1000 Ω/□), but it is more expensive. Emerging materials such as carbon nanotubes and MXene can achieve a balance between cost and performance.

Process Improvements

Sintering Temperature: The sheet resistance of carbon paste can be reduced by 30% after sintering at 300°C. Number of Printing Layers: Double-layer printing increases thickness compared to single-layer printing, halving the sheet resistance.

Structural Design Using a grid pattern instead of a solid coating can reduce sheet resistance while saving material.

4.Future Outlook

As nanomaterials (such as graphene and conductive polymers) mature, the sheet resistance of screen-printed electrodes will further decrease, driving more innovative applications:

Wearable Medical Devices: Ultra-low sheet resistance electrodes can achieve more accurate physiological signal monitoring.

IoT Sensors: Low-cost printed circuits make disposable environmental monitoring tags possible.

Conclusion: Although sheet resistance is a microscopic parameter, it directly affects the performance and reliability of electronic devices. From household blood glucose meters to flexible circuits in space satellites, precise control of sheet resistance is essential. In the future, with advancements in materials science, screen printing technology may become the foundational manufacturing process of the “Internet of Everything” era, with sheet resistance serving as the “invisible guardian” in this process.