The 2025 government work report clearly lists embodied intelligence as a direction for future industrial cultivation, proposing the establishment of a “future industrial investment growth mechanism”, emphasizing the promotion of new productive forces through technological breakthroughs and scenario applications to enhance the autonomous controllability of the industrial chain and shape new advantages in global technological competition. On April 19, the world’s first humanoid robot half marathon was held in Beijing Yizhuang. Through this competition, the technical shortcomings that need to be addressed in the development of the robotics industry have become clearer. For example, issues such as joint overheating leading to performance degradation or falls, insufficient dynamic balance capability, the need for multiple battery replacements, and the robot’s posture and motion control capabilities have been highlighted, pointing the way for future industrial development. Joint overheating? Insufficient endurance? Unstable posture control? These reveal new challenges in motor and power system control technologies.

China Science (Shenzhen) Wireless Semiconductor Co., Ltd. released the world’s first AI ASIC embodied intelligent power system chip in February 2025. The chip integrates FPGA + (AI ASIC) and an array GaN driver, supporting a high-frequency neural reflex of 250Hz, with a perception-decision-execution link delay of less than 5ms, close to human neural reflex speed (30-100ms). By using an “edge physical model” to fuse multimodal sensor data (such as IMU and vision) in real-time, it can control over 100 simulated muscles and servo motors, achieving 32 degrees of freedom for a single posture movement, which is crucial for humanoid robots to achieve fast and precise motion control. High-frequency neural reflexes ensure that robots can respond quickly in complex environments, while low latency guarantees the smoothness and coherence of movements..

The company’s research team has been deeply engaged in the field of embodied intelligent AI ASIC chips and motion control models for many years. This chip and motion control model technology has obtained multiple invention patents and has won second and third prizes at the ICCV International Artificial Intelligence Competition in the past two years, and the championship at the International Artificial Intelligence Vision Tactile CVPR in 2024..

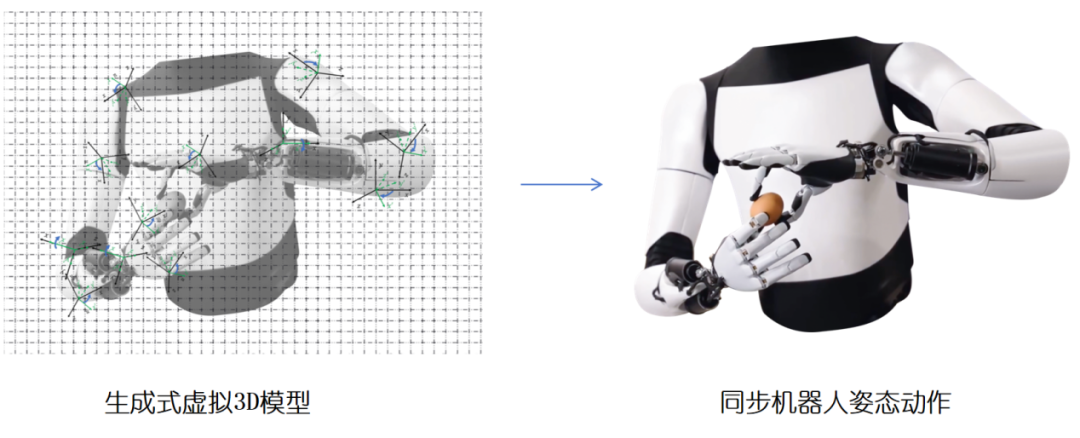

Through the chip’s built-in “physical motion control model” (which refers to the integration of physical laws, energy conservation, sensors, and vision into neural networks through data-driven methods), combined with the multimodal data fusion of inertial measurement units (IMU) and visual sensors, the output array control signals and posture coordinates can simultaneously control dozens of robotic joint modules within 5ms, maintaining the stability of the robot during high-speed motion and significantly shortening the robot’s development training time. This technological breakthrough will undoubtedly accelerate the standardization and generalization of the “robot AI physical motion control model”.

Recently, China Science Alpha Technology Co., Ltd. released a GaN-driven robotic joint module (model: ZK-RI 0–PRO-B) based on the family of China Science Semiconductor AI ASIC embodied intelligent power system chip joint series, utilizing GaN high electron mobility power chips. It features high energy conversion efficiency and low temperature rise, (improving by 40% compared to traditional Si-based MOSFET solutions, with a temperature rise ΔT≤25K@full load), especially excelling in energy efficiency and heat dissipation, allowing humanoid robots to maintain low energy consumption and stable temperatures during prolonged operation, thereby enhancing the robot’s endurance and stability..

By utilizing an innovative Manchester coding instant communication interface, it achieves multi-channel parallel communication, realizing a 5ms full-link delay and 250Hz high-frequency neural reflex. Compared to traditional CAN communication serial methods, the queuing message sending can lead to insufficient MCU computing resources, and combined with joint overheating causing MCU restarts and halting operations, results in instability and falls during the robot’s walking process when a joint loses its electromotive force.

The mass production of this robotic joint module marks a leap from “technology following” to “independent innovation” in the field of robotic AI physical models and core components in our country. It not only overcomes the bottlenecks of motion stability and endurance but also collaborates with domestic supply chains and ecosystems. It provides low-cost, low-latency, low-power, and high-performance solutions for the global robotics industry, promoting the healthy development of our country’s embodied intelligence industry chain.

Click the left bottom corner of the article to “read the original text” for more exciting content.

Source丨CT-Unite China Science Wireless Semiconductor Official Website Editor丨Qiu Jiangyong Design丨Maria Supervisor丨Zhao Chen

Tap “Looking” to stay connected

Tap “Looking” to stay connected