Siemens all-subject + TIA Portal + EPLAN electrical drawing video recordings are available for low-price packaging!

Chuangkong Education Siemens All-Subject Class Course Introduction

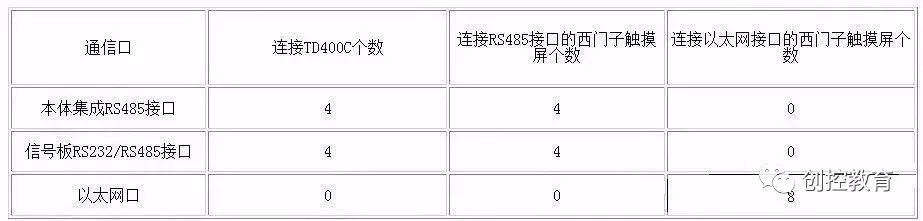

01 Connection Quantity

The S7-200 SMART CPU can connect to Siemens HMI devices that support the PPI protocol either through the integrated RS485 port or signal board, or through the integrated Ethernet port to connect to Siemens HMI devices that support the S7 protocol.

When the CPU’s three physical interfaces connect to Siemens HMI devices simultaneously (including the signal board), the maximum number of connection resources is 16.

Table 1. CPU Connection Capability

Smart Panels Supported PLC:

First generation product SmartLine (no Ethernet interface): S7-200, OMRON CP1 series, Mitsubishi FX series, Modbus RTU

Note: Only one communication connection can be established; otherwise, Smart Panels cannot start the project (white screen).

Second generation product SmartLine-IE:

Serial: S7-200, OMRON CP1 series, Mitsubishi FX series, Modbus RTU, Delta (DVP-SV/ES2 series)

Ethernet: S7-200 (CP243-1), Smart200, LOGO!

Smart Panels can only connect to one device via serial port and can connect to three devices via Ethernet, but serial and Ethernet cannot be used simultaneously (compilation will fail).

Note: Only one of the serial and Ethernet ports can be used; otherwise, compilation will fail.

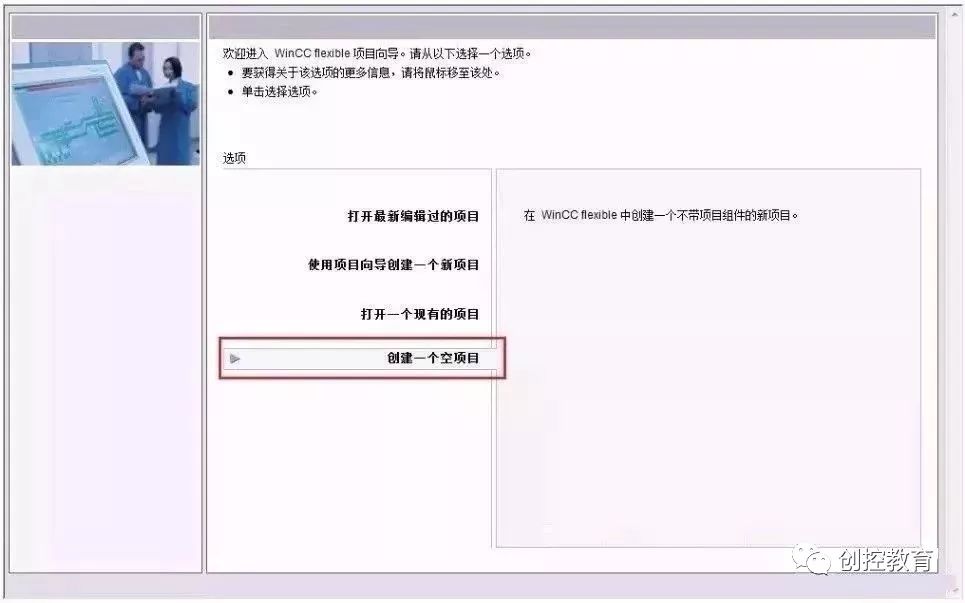

02Create Project

Users need to use WinCC Flexible 2008 SP2 China or above to configure the first generation product SmartLine. For the second generation product SmartLine IE, only WinCC Flexible 2008 SP4 China can be used for configuration.

Users can create projects directly in WinCC Flexible or use the wizard. The following mainly introduces how to create a project directly.

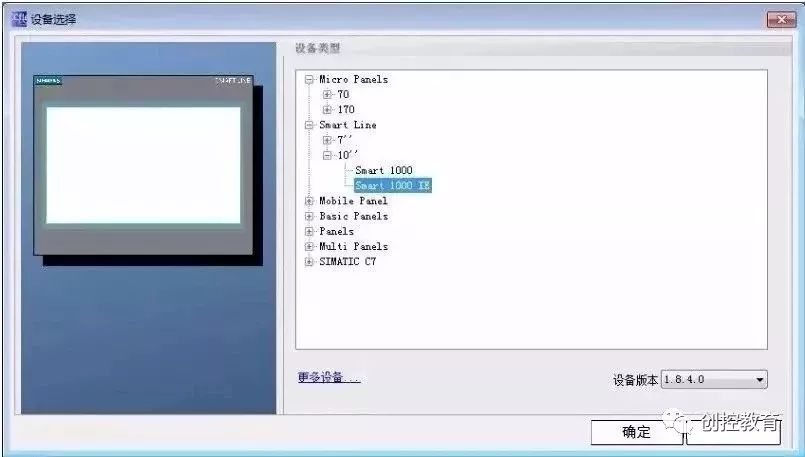

Double-click the SIMATIC WinCC flexible icon on the PC desktop to start WinCC flexible. In the startup screen, select “Create an empty project,” as shown in Figure 1. After left-clicking “Create an empty project,” the “Device Selection” interface as shown in Figure 2 will open. In this interface, select the device to be used, taking Smart 1000 IE as an example.

Figure 1. Directly Create Project

Figure 2. Device Selection

03Configure Communication Connection

Users can configure the PPI communication between Smart 1000 IE and S7-200 SMART CPU through the following steps.

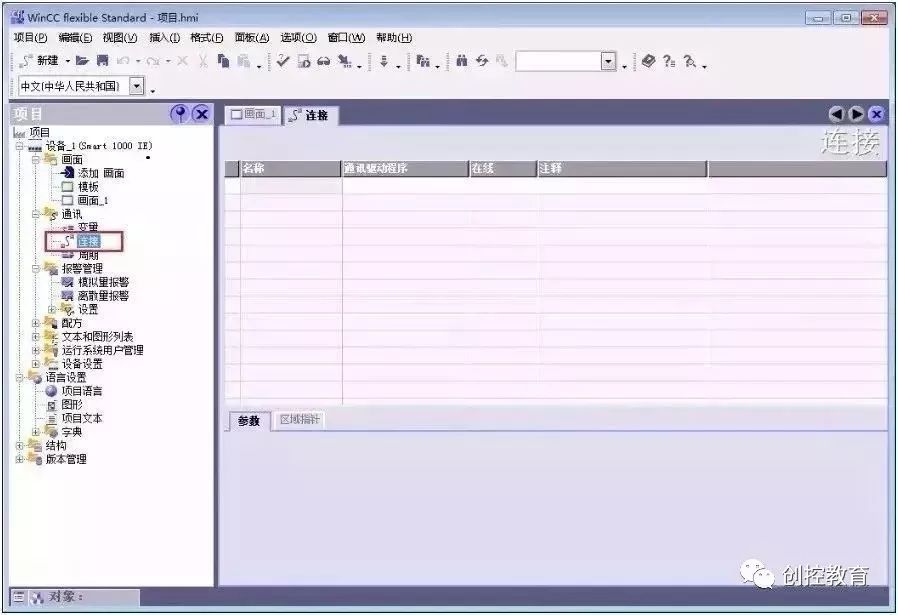

Step 1: In the main working window of WinCC flexible, expand the tree project structure on the left side, select “Project” > “Communication” > “Connection,” and double-click the “Connection” icon to open the “Connection Settings” properties window, as shown in Figure 3.

Figure 3. Open Connection Window

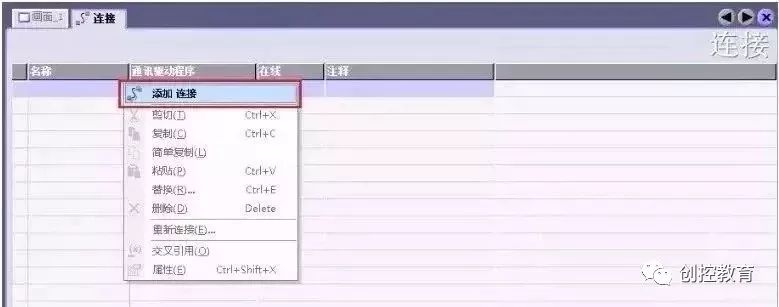

Step 2: In the “Connection” window, double-click the blank table below the name or right-click the mouse and select “Add Connection” from the shortcut menu to add a connection with the CPU, as shown in Figure 4.

Figure 4. Add Connection

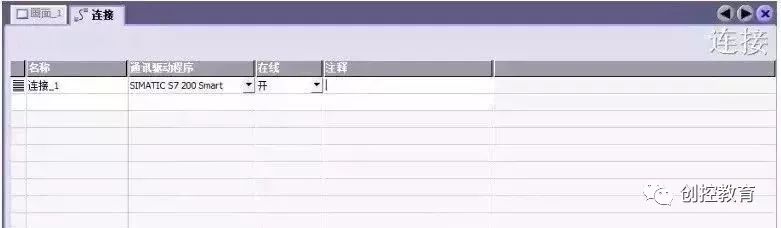

Step 3: After adding the connection, users can modify the default connection name “Connection_x” according to project requirements and select the “Communication Driver” and whether to go online. Since the connected device is the S7-200 SMART CPU, select “SIAMTIC S7 200 SMART” as the communication driver from the dropdown menu under “Communication Driver,” and activate the online connection, as shown in Figure 5.

Figure 5. Configure Connection

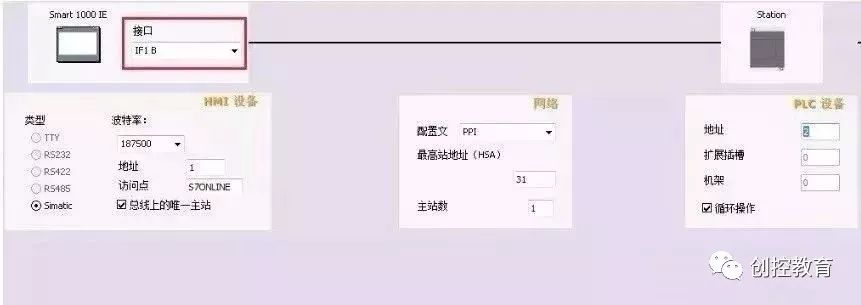

Step 4: Set connection parameters. First, select the interface of Smart 1000 IE as “IF1 B”, which is the RS422/485 physical interface of the touch screen. After selecting this interface, the parameter settings window for this interface will automatically display below. Set the communication baud rate of the touch screen to 187500 and the station address to 1.

Then, in the “Network” window, select “PPI” as the communication protocol for both parties.

Finally, in the “PLC Device” window, set the station address of the CPU; here the station address of the CPU is set to 2, as shown in Figure 5.

Figure 6. Connection Parameter Settings

Note: The address of the CPU must be different from that of the HMI device; the two cannot be the same.

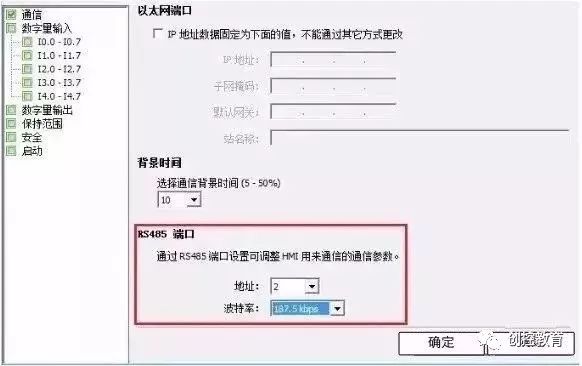

Step 5: Set the baud rate and station address of the S7-200 SMART CPU. In the project tree of STEP 7 Micro/WIN SMART software, select “System Block” and press the “Enter” key to open the “System Block” window as shown in Figure 7. The station address and baud rate set for the CPU’s RS485 port must be consistent with the configuration in Figure 6; the CPU’s station address is 2, and the communication baud rate is 187.5 kbps.

Figure 7. S7-200 SMART Communication Port Settings

At this point, the PPI communication between Smart 1000 IE and S7-200 SMART CPU has been configured.

04Start Operation Screen

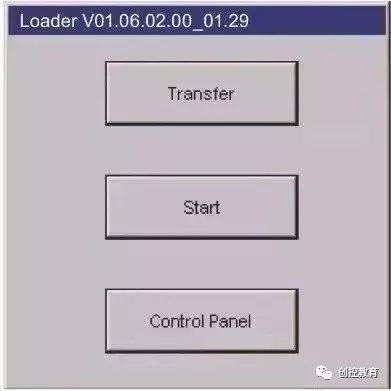

When powering on the Smart 1000 IE device, the screen will briefly display the startup screen, as shown in Figure 8. The three buttons in the figure represent the following meanings.

Transfer: HMI device is set to “Transfer” mode.

Start: Start the project loaded on the HMI device.

Control Panel: Click this button to enter the control panel of the HMI device, where users can select transfer mode, add passwords, etc.

Figure 8. Startup Screen

05Download Project File

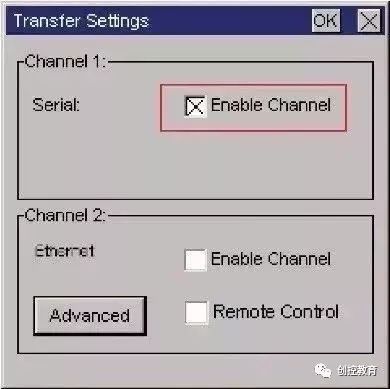

To download the configured project to the Smart 1000 IE device, first ensure that the communication port of the HMI device is activated, which can be set through the HMI device’s “Control Panel” > “Transfer,” as shown in Figure 9. If the project is downloaded via serial port, first check the “Enable Channel” next to “Serial.”

Figure 9. Enable Communication Port

Secondly, use Siemens original PPI programming cable to download the project; both RS-232/PPI cable (Order No. 6ES7 901-3CB30-0XA0) and USB/PPI cable (Order No. 6ES7 901-3DB30-0XA0) can be used. When using the USB/PPI cable, its E-STAND version must be 05 or higher.

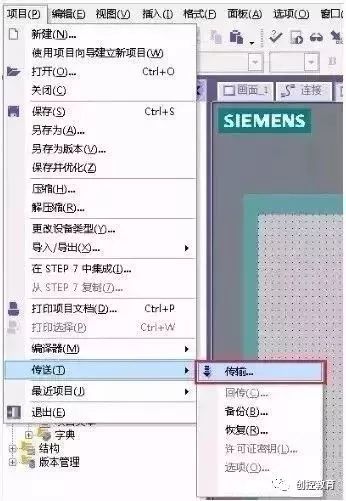

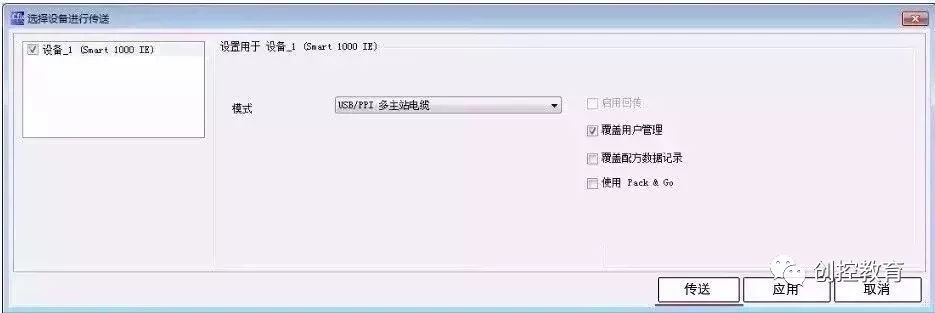

Then, in the menu bar of WinCC flexible software, select “Project” > “Transfer” > “Transfer,” as shown in Figure 10. Click “Transfer” to open the “Select Device for Transfer” window, as shown in Figure 11. In the “Select Device for Transfer” window, users can choose the transfer mode as “Serial” or “Serial (via USB-PPI cable)”; here select the latter for transfer.

Figure 10. Open Transfer Settings

Figure 11. Transfer Settings

After cutting off power to the Smart 1000 IE device and powering it back on, the HMI device will display the startup screen. Click the Transfer button to set the HMI device to “Transfer” mode.

Then, in the WinCC flexible software, select “Project” > “Transfer” > “Transfer,” click the “Transfer” button in Figure 11, and wait for the transfer status in the HMI device to display as “Transfer Complete”; at this point, the project has been successfully transferred to the HMI device via serial mode.

-

(Content sourced from the internet, copyright belongs to the original author) Disclaimer:If copyright issues arise, please contact for deletion!No person or organization bears related legal responsibility.

-

Siemens all-subject + TIA Portal + EPLAN electrical drawing video recordings are available for low-price packaging!

Chuangkong Education Siemens All-Subject Class Course Introduction