Search on WeChat

Search on WeChat Electrical Engineering and Electrical Learning

Electrical Engineering and Electrical Learning

PLC program design generally adopts the intuitive method, which is based on the learning experience of the circuit designer, making it relatively subjective and direct.

It requires a period of trial and error, debugging the program until it meets the required functions or action requirements; therefore, the designed program varies from person to person. Apart from the original designer, users or maintenance personnel may find it difficult to understand the action flow, meaning the program’s readability is low.

However, there are some patterns to follow in program design, though few books on the market mention this part. Here, with a spirit of sharing, we will discuss the process of converting a “three-phase induction motor fault alarm control” circuit from a traditional electrical diagram to a ladder diagram, and we believe this will help you in related circuit conversions or program designs in the future.

01Traditional Electrical Diagram

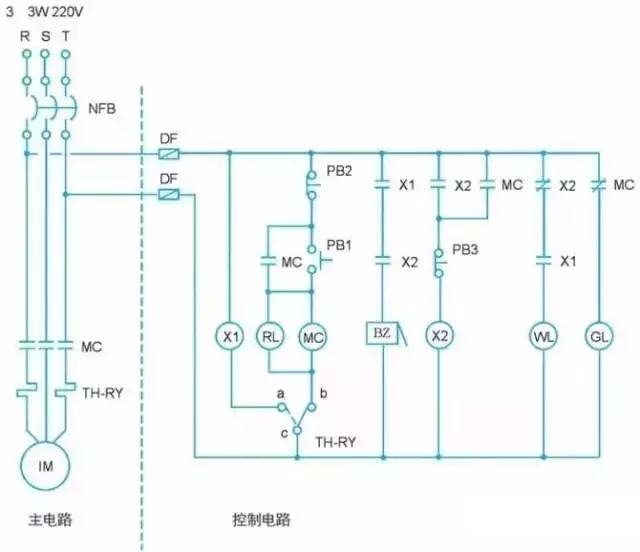

The known three-phase induction motor fault alarm control circuit, its traditional electrical diagram is shown in Figure 1:

Figure 1 Three-phase Induction Motor Fault Alarm Control Circuit Diagram

02Action Description

(1) When the power supply is normal, only the green light gl is on, and the motor does not operate.

(2) Pressing the start button pb1 activates the electromagnetic contactor mc, the motor immediately runs, the indicator light rl is on, and the green light gl goes off.

(3) Pressing the stop button pb2 cuts off the power to the electromagnetic contactor mc, the motor stops running, the indicator light rl goes off, and the green light gl is on.

(4) If the motor is running and due to overload or other faults, the thermal relay th-ry operates, causing the motor to stop, the buzzer bz sounds an alarm, the indicator light rl goes off, and the green light gl is on.

(5) Pressing the button switch pb3 stops the buzzer bz alarm, the white light wl is on, the green light gl is on, and the red light rl goes off.

(6) After troubleshooting, pressing the reset lever of the thermal relay th-ry will turn off the white light wl, turn on the green light gl, and turn off the red light rl, allowing the motor to be restarted.

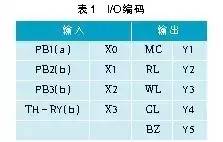

03I/O Coding

Using PLC means replacing hardware wiring with software programs. The main circuit in the traditional electrical diagram cannot be replaced by PLC; the part that PLC can replace is the control circuit. The first step in converting a traditional electrical diagram to a ladder diagram is I/O coding, which means determining the corresponding external input/output terminal numbers in the PLC for the input/output components in the traditional electrical diagram, as well as the wiring method for external input components using a/b contacts.

(a) Wiring using a contact method

(b) Wiring using b contact method

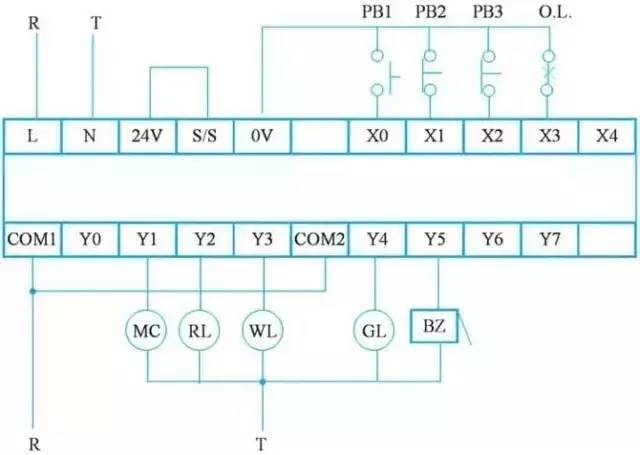

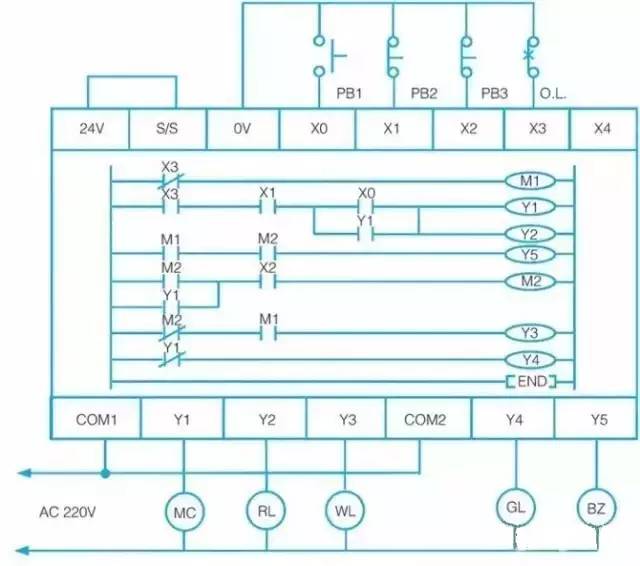

04PLC External Wiring Diagram

After I/O coding the input/output components and deciding on the a/b contact wiring method for external input components, the PLC external wiring diagram is shown in Figure 2. The PLC model shown is the Fengwei vigor-vb series, using NPN wiring, and can also connect the 24V terminal with the s/s terminal.

Figure 2 PLC External Wiring Diagram

05PLC Ladder Diagram

The steps for program design to convert a traditional electrical diagram to a ladder diagram are as follows:

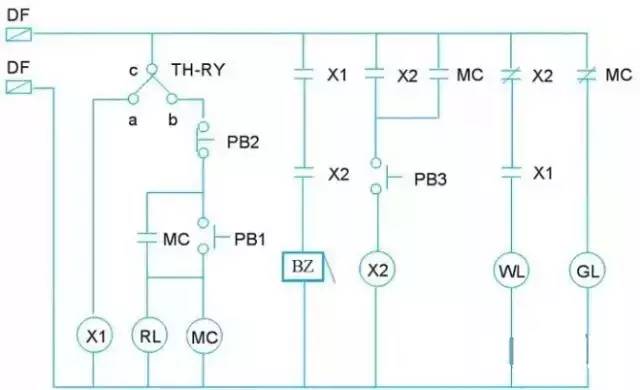

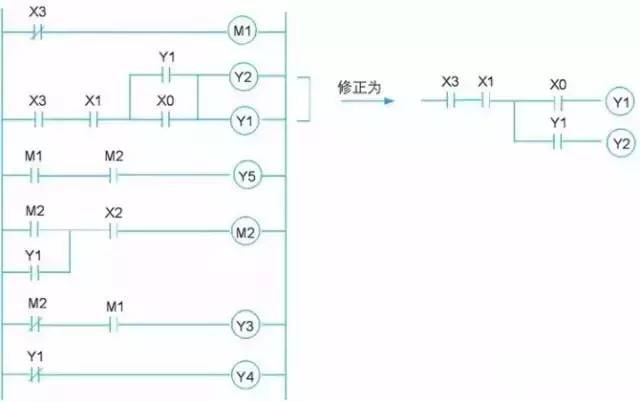

(1) Directly convert the control circuit in the electrical diagram to the corresponding ladder diagram. Since the PLC ladder diagram specifies that contacts must be at the front and output coils must be at the end of the circuit, the electrical diagram must be redrawn, adjusting the positions of contacts and output coils to meet the requirements of the PLC ladder diagram. The redrawn electrical diagram is shown in Figure 3.

Figure 3 Redrawn Electrical Diagram

(2) Replace the input/output components in the electrical diagram with the component numbers after I/O coding. It is important to note that the c-a and c-b contacts of th-ry should be separated and each become a control circuit, as shown in Figure 4.

Figure 4 Electrical Diagram After I/O Coding

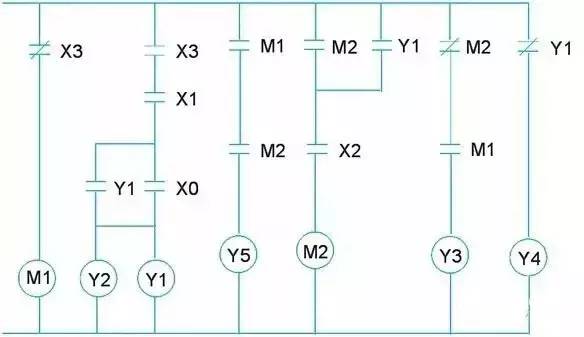

(3) Rotate the electrical diagram shown in Figure 4 to the left by 90°, then flip it vertically to become the PLC ladder diagram. However, since the y1, x0 contacts, and output coils y1 and y2 do not conform to the general programming software format, they need to be adjusted appropriately, as shown on the right side of Figure 5.

Figure 5 Adjusted and Corrected Ladder Diagram

※ If you use Visio to draw the electrical diagram, rotating it to the left by 90° and then flipping it vertically becomes very easy.

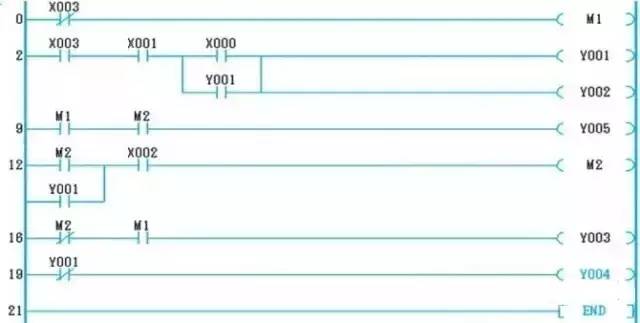

(4) The ladder diagram drawn using programming software, as shown in Figure 6, is exactly the same as the adjusted and corrected ladder diagram.

Figure 6 Ladder Diagram Drawn by Programming Software

06Instructions

The instructions for converting the ladder diagram are as follows:

07PLC Wiring and Ladder Diagram Conversion

The complete conversion of the traditional electrical diagram to PLC external input/output wiring and ladder diagram.

After replacing hardware wiring with software programs, the PLC external input/output wiring and ladder diagram are shown in Figure 7.

Figure 7 PLC After Replacing Hardware Wiring with Software Programs

08Conclusion

The purpose of PLC development is to replace relay-based sequential control, meaning using software programs to replace hardware wiring. Therefore, by changing the software program, the control sequence can be altered, easily achieving different control requirements.

Generally, PLCs are developed based on traditional relay control circuits, symbolizing the contacts and coils of relays. Once converted into a general ladder diagram or instructions, control can be achieved.

Disclaimer: This article is reprinted from the internet, and the copyright belongs to the original author. If there are any copyright issues, please contact us for deletion. Thank you!

Recommended Reading:The Secrets to Becoming a PLC Programming Expert, PLC Programming Steps, Techniques, and Practices, Click below “Read the Original

Recommended Reading:The Secrets to Becoming a PLC Programming Expert, PLC Programming Steps, Techniques, and Practices, Click below “Read the Original